Conveying device, rubberizing device and conveying method

A technology of feeding device and driving device, which is applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of uncontrollable unloading tension, easy breakage of the material belt, complicated structure, etc. feeding and ensuring the effect of feeding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

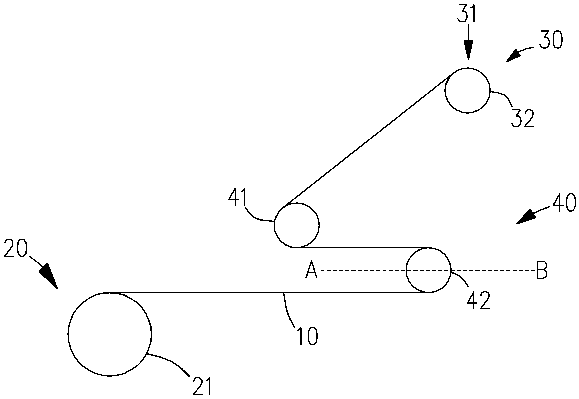

[0028] Please refer to figure 1 , in the first embodiment, the feeding device of the present invention mainly includes a discharge mechanism 20 for providing the material tape 10 provided on a frame not shown in the figure, and is used for carrying out the material tape 10 at the first preset position 31. An operating mechanism 30 for operations (such as but not limited to cutting, attaching materials, sucking materials, etc.), and a conveying mechanism 40 for transferring the material tape 10 from the discharging mechanism 20 to the first preset position 31 .

[0029] In this embodiment, the unwinding mechanism 20 includes an unwinding wheel 21 driven by the driving mechanism, and the strip 10 is long and wound on the unwinding wheel 21 . Driven by the drive mechanism, the unwinding wheel 21 rotates at a constant speed for unwinding.

[0030] The conveying mechanism 40 includes a temporary storage mechanism for temporarily storing at least a part of the material tape release...

Embodiment 2

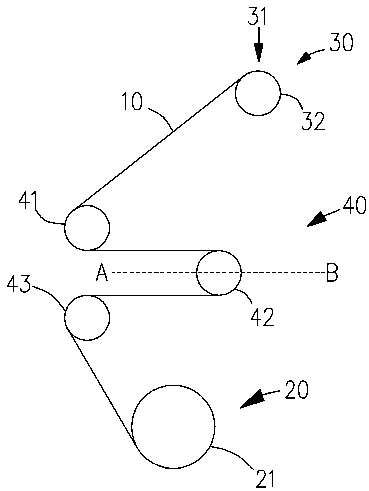

[0036] Please refer to figure 2 The main difference between the second embodiment and the first embodiment is that there is a third transmission member 43 between the second transmission member 42 and the discharge mechanism 20 . The third transmission member 43 is similar in structure to the first transmission member 41, and is a rotatable wheel or shaft, on which is formed a slot for position limitation, and the material strip 10 is located in the slot. The second transmission member 42 moves between two end points A (second preset position) and end point B (third preset position) of the dotted line segment AB. The end point A, that is, the second preset position is close to the first transmission member 41 and the third transmission member 43 , and the end point B, that is, the third preset position is away from the first transmission member 41 and the third transmission member 43 . The third transmission member 43 is disposed at the same distance from the end point A and...

Embodiment 3

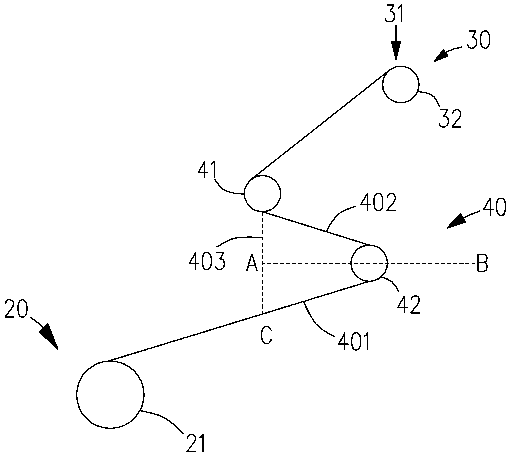

[0041] Please refer to image 3 The main difference between the third embodiment and the first embodiment is that the material belt 10 between the first transmission member 41 and the second transmission member 42 is not parallel to the material belt between the second transmission member 42 and the discharge mechanism 20 . The first transmission member 41 as the output end of the temporary storage mechanism is located on the side of the end point A of the dotted line segment BA (the intersection point of the perpendicular line from the central axis of the first transmission member 41 to the line segment AB and the straight line AB is the end point A), as the input end The unwinding wheel 21 is located on one side of the extended line of the dotted line segment BA. In this way, the output speed of the temporary storage mechanism when the second transmission member 42 moves between AB can be calculated according to the plane geometric relationship between the first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com