Removable dotting feeding assembly of PCB dotting device

A PCB circuit board and circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of automatic solder feeding, non-detachable structure, and poor printing effect, so as to improve heat utilization rate, convenient printing, connection and Take-and-place convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

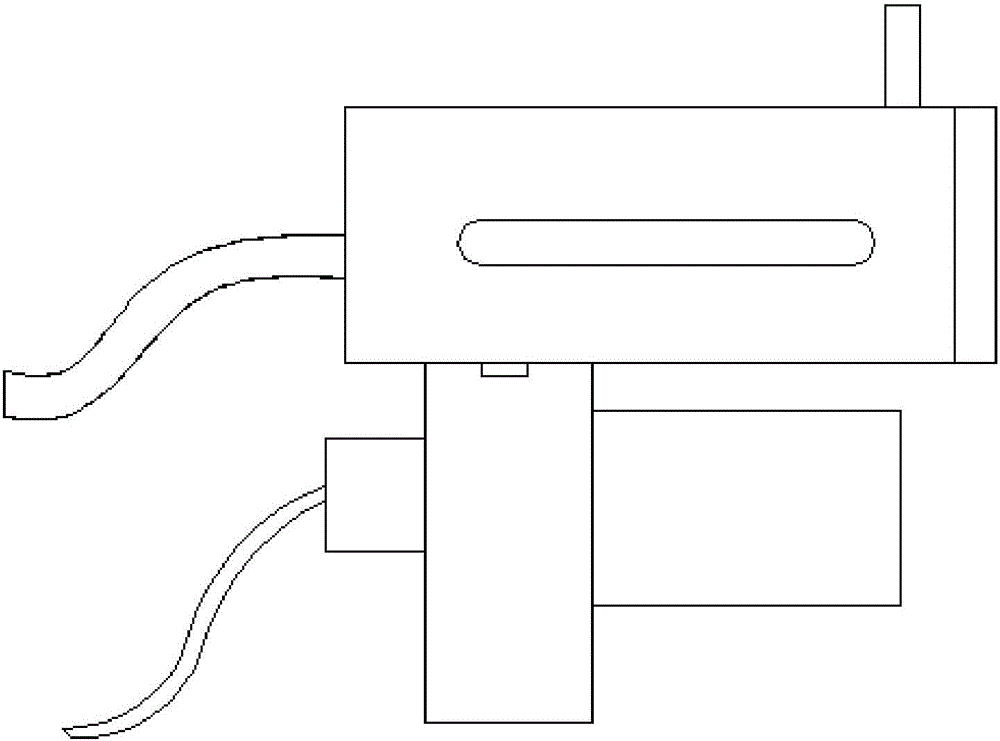

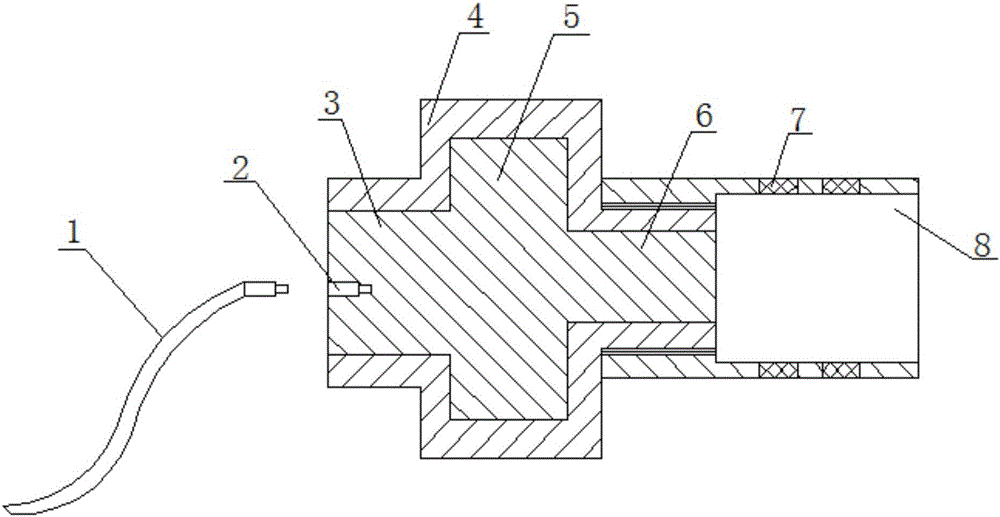

[0028] Such as Figure 1-Figure 5 As shown, the detachable dotting feeding assembly of the PCB circuit board dotting device includes a dotting joint and a solder feeding device that is clamped on the dotting joint;

[0029] in,

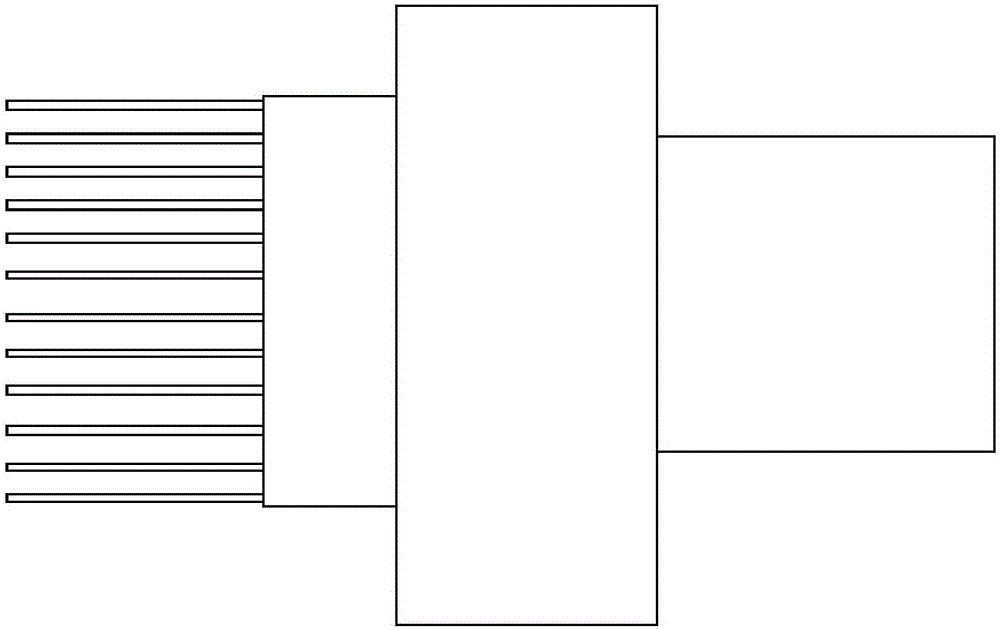

[0030] The dotting joint includes a metal heat-conducting block 5, and the two sides of the metal heat-conducting block 5 protrude outward to form a connecting head 3 and a positioning head 6 respectively. A plurality of metal heat conduction sheets 1 are plugged in. The cross section of the metal heat conduction sheets 1 is an S-shaped curve structure and its end section is a sharp angle. Inlaid with a plurality of permanent magnets 7.

[0031] The solder feeding device includes a heat-conducting metal solder cylinder 10 for filling solder, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com