Green tea drying system

A drying system, green tea technology, applied in the field of green tea drying system, can solve the problems of total reduction, monomer ratio change, affecting tea quality and health care effect, etc., to improve quality, reduce oxidation degree, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

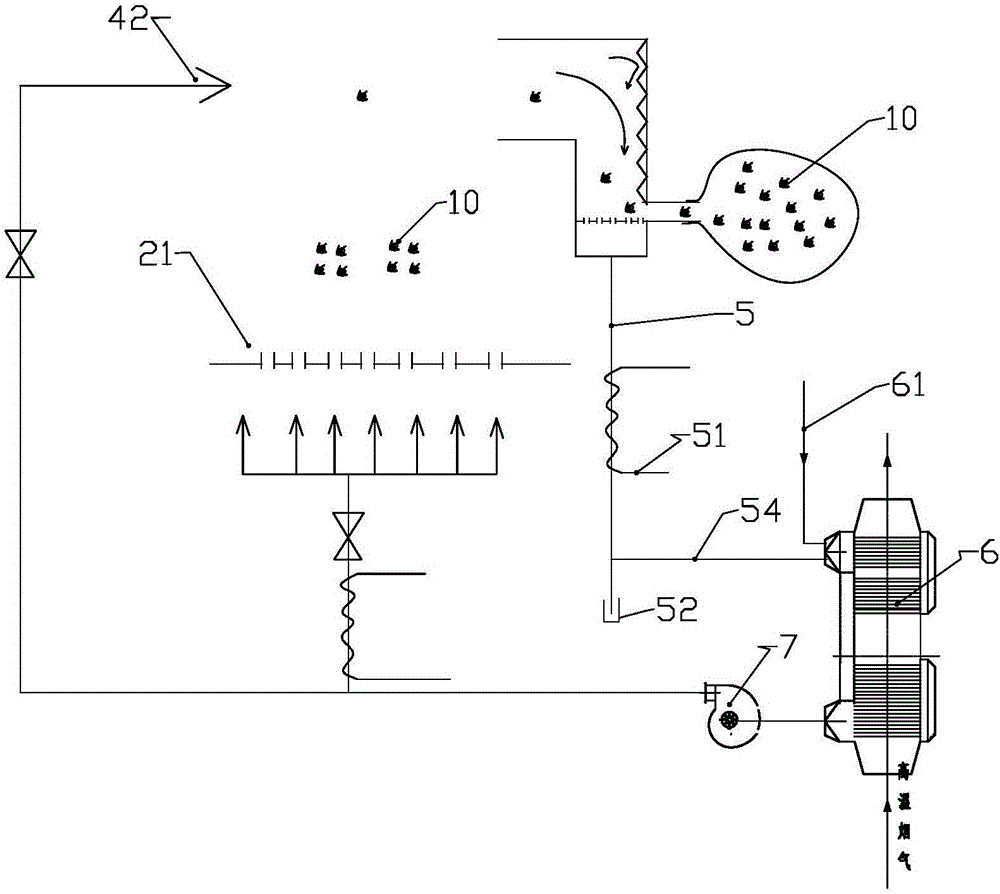

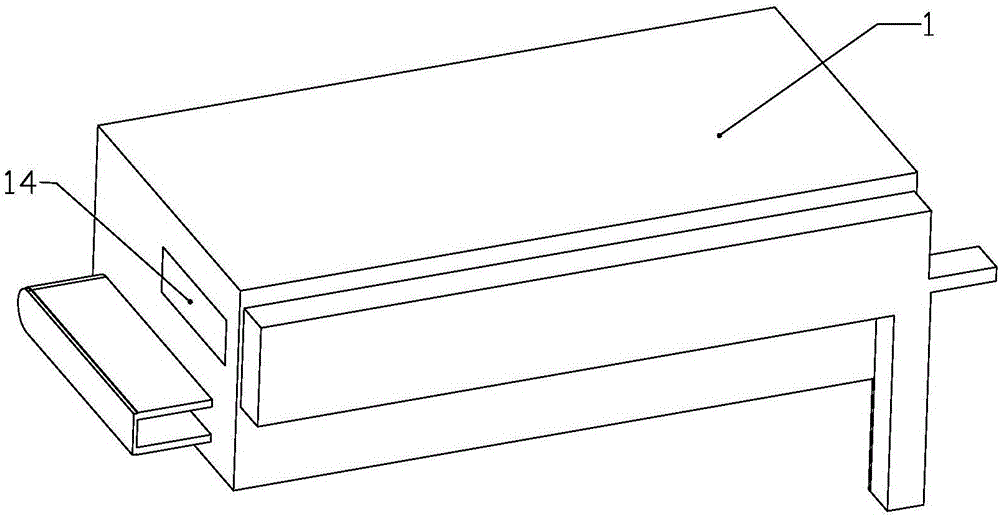

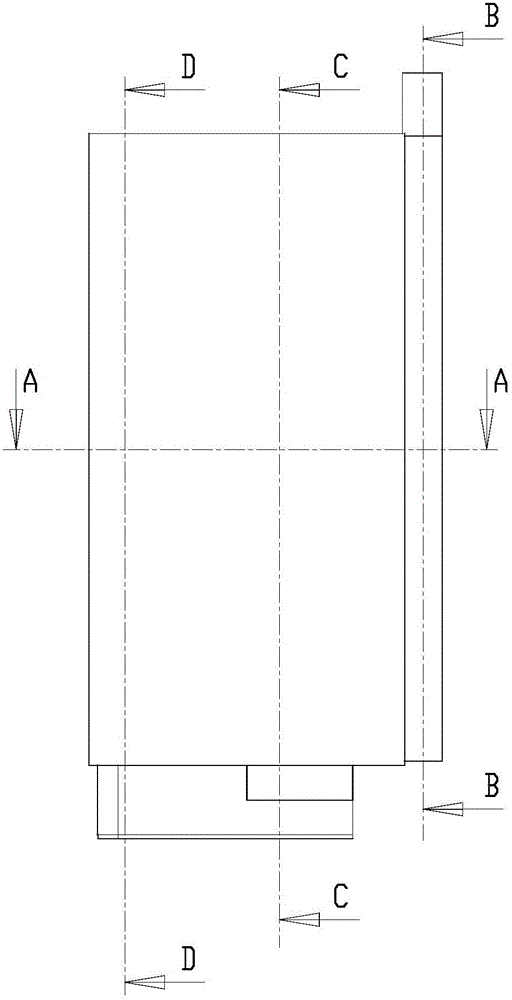

[0048] Such as Figure 1 to Figure 14 as shown,

[0049] Existing drying equipment adopts high temperature drying. The so-called high temperature refers to forming a temperature of about 100 degrees Celsius. Among them, in this process, the purpose is to dry the tea leaves quickly, and high temperature is only a condition for drying them. . But too high temperature can cause unfavorable influence to the quality of green tea, for existing defect, protection subject of the present invention is as follows:

[0050] The development is a kind of drying equipment, which comprehensively utilizes the principles of photoelectricity, heat and boiling for drying treatment. At the same time, the dried green tea is taken out in time by airflow sorting to avoid over-drying. During the drying process, the airflow speed should be increased as much as possible. , increase the nitrogen content, reduce the temperature of the airflow, and control the temperature at about 60 degrees Celsius, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com