Method for preparing aluminum nitride ceramic substrate by clinker slicing

A technology of aluminum nitride ceramics and slicing method, which is applied in the field of ceramic substrates, can solve problems such as complex process routes, low production efficiency, and low qualified rate of finished products, and achieve reduced investment and operating costs, improved slicing efficiency, and uniform sintering. transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

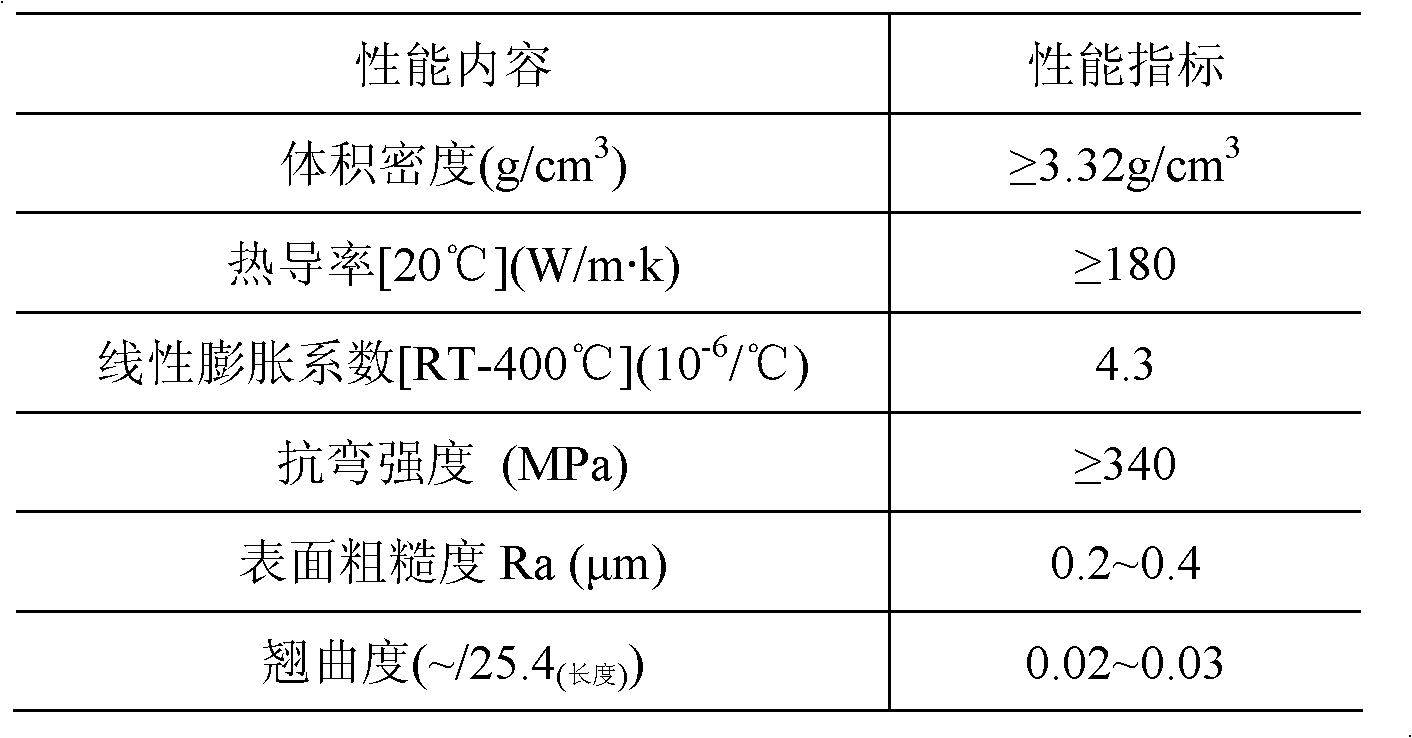

Examples

Embodiment 1

[0025] 1) Select high-purity (oxygen content2 o 3 Powder, proportioned according to the following mass percentage: AlN powder 95%, Y 2 o 3 The powder is 5%, and mixed evenly by dry ball milling to obtain a mixed powder.

[0026] 2) Using a molding machine to mold the mixed powder to obtain a mixed powder base; the shape of the mixed powder base may be a cubic mixed powder base with a cross-section of 50mm×50mm or more.

[0027] 3) Sintering the mixed powder body; said sintering the mixed powder body, the mixed powder body can be put into a graphite sintering mold and sintered by hot pressing in a graphite sintering furnace. 2 Protection, the pressure is 25MPa, the temperature is raised to 1550-1650°C, kept for 4-5 hours, and cooled with the furnace.

[0028] 4) Slicing the sintered mixed powder billet, and then grinding and polishing to obtain an aluminum nitride ceramic substrate. For the slicing, a multi-wire slicing machine can be used to cut the sintered mixed powder b...

Embodiment 2

[0030] Similar to Example 1, the difference is that AlN powder and Y 2 o 3 The powder is proportioned according to the following mass percentages: AlN powder 96%, Y 2 o 3 Powder 4%. The temperature of hot-press sintering is 1700-1750°C, and the time of hot-press sintering is 5-6 hours.

Embodiment 3

[0032] Similar to Example 1, the difference is that AlN powder and Y 2 o 3 The powder is proportioned according to the following mass percentage: AlN powder 93%, Y 2 o 3 Powder 7%. The shape of the mixed powder blank may be a cylindrical mixed powder blank with a diameter of 50 mm or more. When the mixed powder blank is sintered, put the mixed powder blank into a sintering mold made of AIN material and sinter under pressure; the sintering can be sintered by microwave in a microwave sintering furnace, and the temperature of the microwave sintering can be 1500-1550°C. The time is 10 ~ 15min. When slicing, a circular cutting machine can be used to cut the sintered mixed powder billet into thick slices with smooth surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com