Buffer device of bulk material conveyor belt end point

A buffer device and bulk material technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of material quality impact, operating environment pollution, etc., to achieve the effect of reducing impact, reducing initial speed, and reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

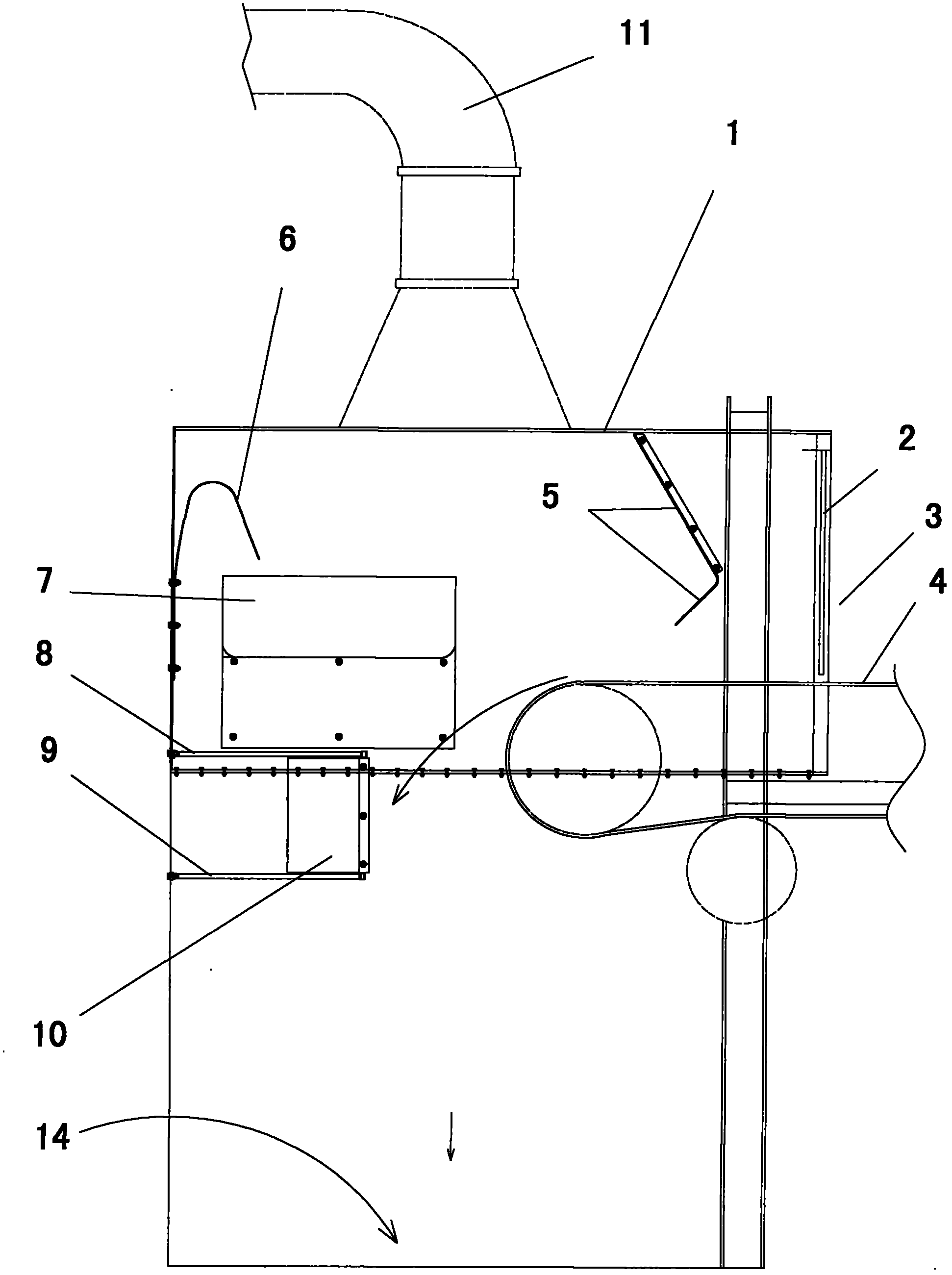

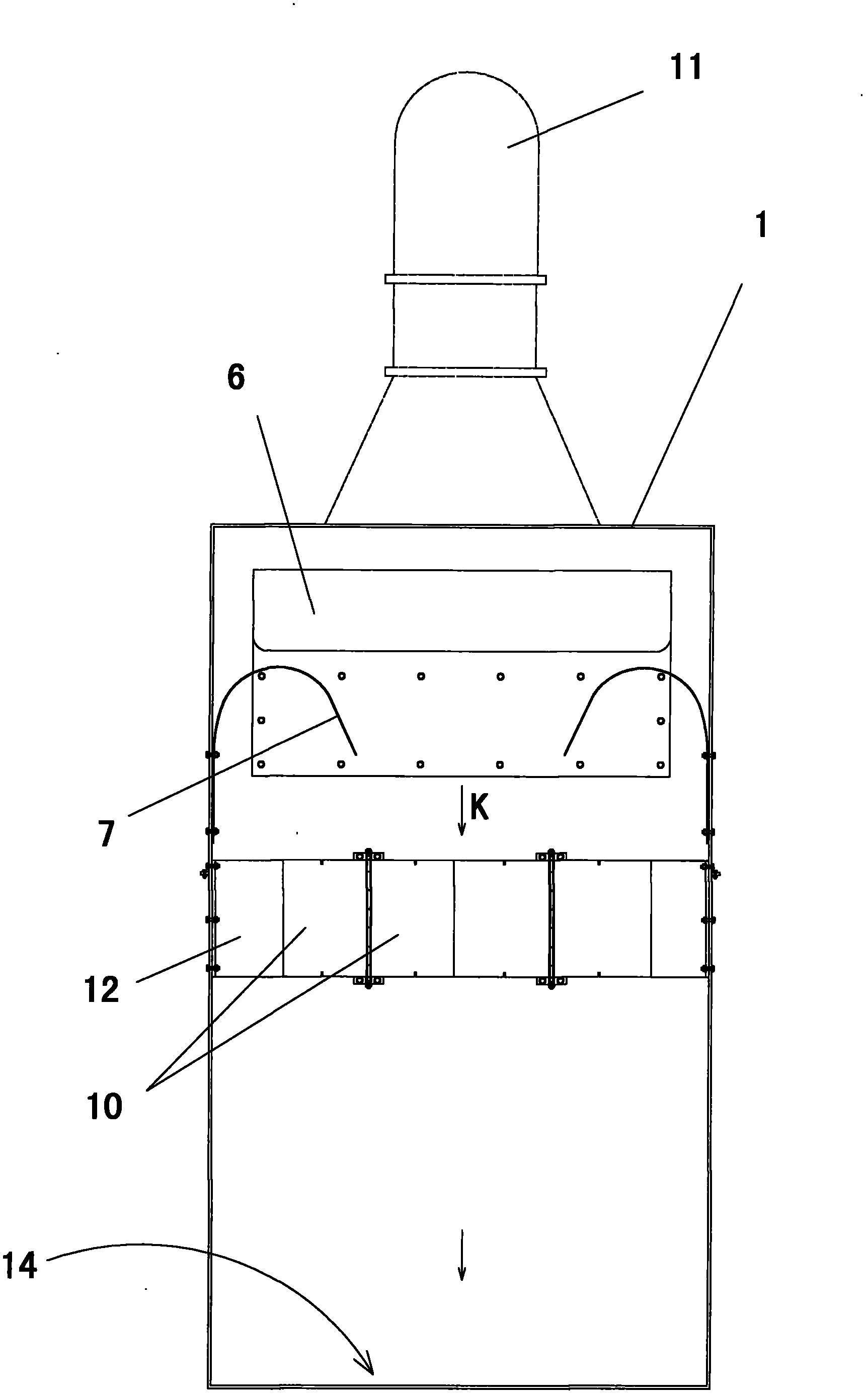

[0012] Such as figure 1 , 2 , Shown in 3, 4: 1 is the case cover of rectangular parallelepiped shape, adopts sheet metal to make, and outlet is arranged on the top and joins with draft pipe 11. Below is the blanking port 14.

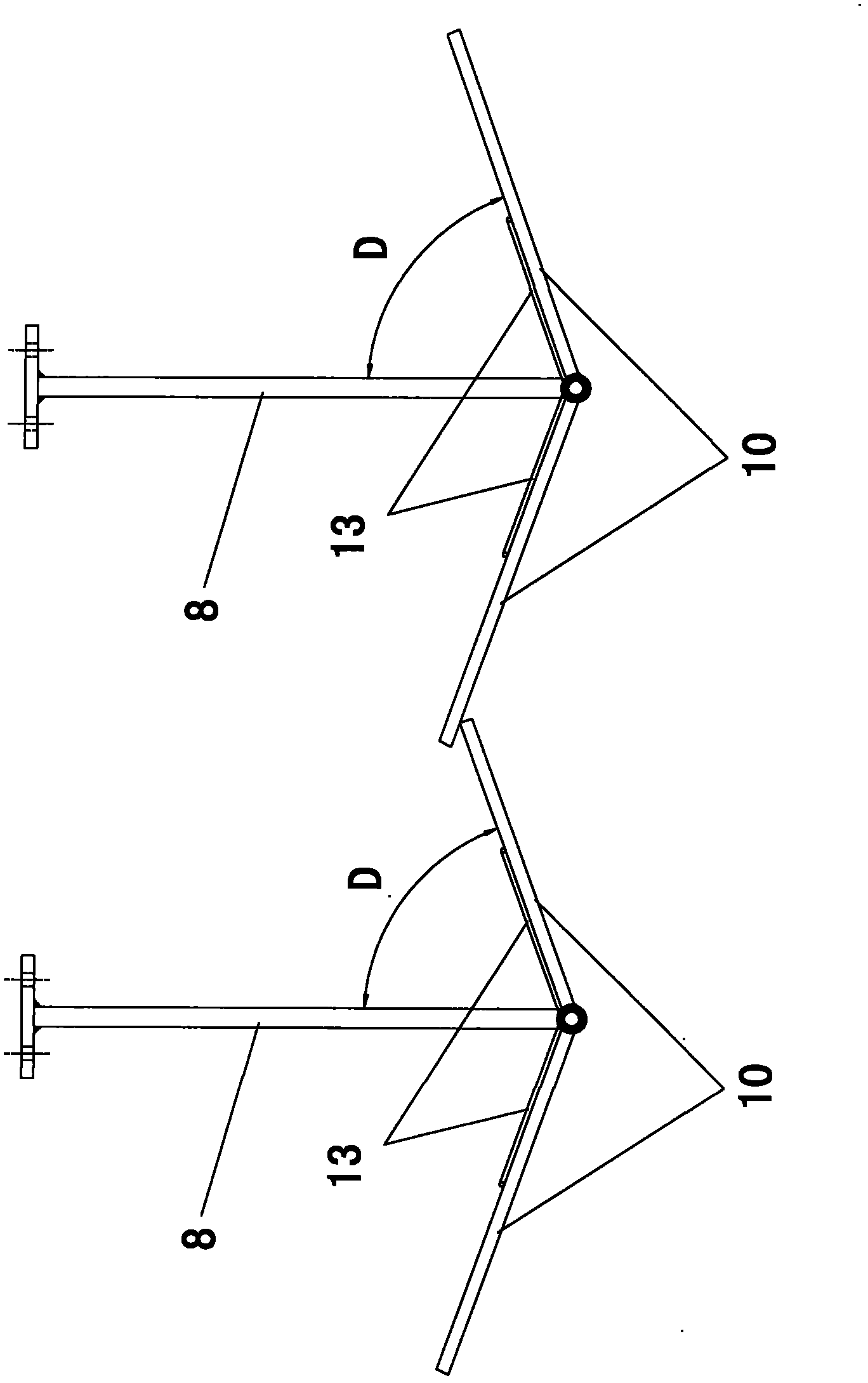

[0013] The upper side of the box cover 1 is provided with a feed door 3 matched with the conveyor belt 4, and the conveyor belt 4 sends materials into the box cover 1 from the feed door 3 during operation. A plurality of rotating buffer plates are arranged below the opposite side of the charging door 3 in the inner side of the case cover 1, and a reset torsion spring 13 is provided at the rotating shaft of the buffer plates. Wherein the buffer board includes a middle buffer board 10 and a side buffer board 12 . Every two buffer plates 10 in the middle form a group, and the sides of the two buffer plates in each group are rotatably connected to each other, that is, a rotating shaft or a hinge are arranged between them to connect. Rotating shaft or hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com