Discharging control device and method of disk filter

A disc filter and control device technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve the problems of poor air permeability, great influence on processing capacity, production capacity attenuation, etc., so as to reduce wear and achieve stable operation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

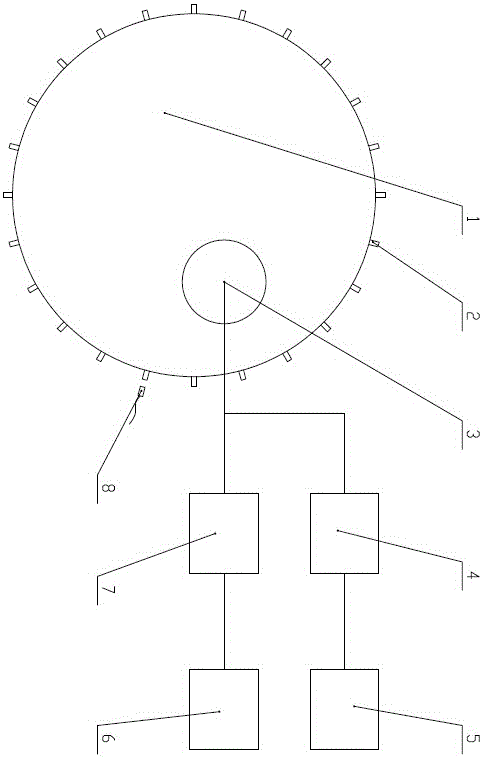

[0028] Such as figure 1 As shown, a discharge control device for a disc filter includes: a signal transmitter 2, a signal receiver 8, a control processor, an actuator, a blowing system, a vacuum system, and the signal transmitting end of the control processor is connected to the disc The signal transmitter 2 evenly distributed on each fan-shaped plate on the circumference of the disc filter main shaft 1 is connected, and the signal receiving end of the control processor is connected with the signal receiver 8 corresponding to the fan-shaped plate on the circumference of the disc filter main shaft 1, and the control processor outputs The ends are respectively connected with the blowing system and the vacuum system through the actuator.

[0029] Described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com