Special method for industrial treatment on waste plastic in classified garbage

A waste plastic and garbage transfer station technology, applied in the treatment of hydrocarbon oil, petroleum industry, special forms of dry distillation, etc., can solve the problems of inability to industrialize production, low energy consumption, fast reaction speed, etc., and achieve fast reaction speed and low energy consumption. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

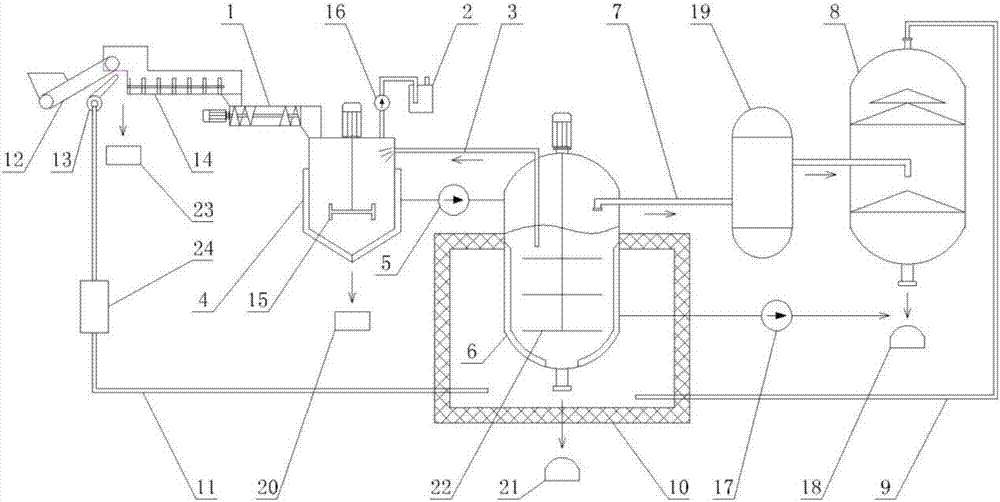

[0012] Firstly, the material is fed through the belt conveyor 12. While the belt conveyor 12 throws the material to the scraper machine 14, the fan 13 conveys hot air to the material. On the one hand, it plays the role of simple winnowing, and a part of impurities can be selected, and the impurities that fall into the bottom In the receiving bin 23; on the other hand, the hot air enters the scraper machine 14 to play the role of drying. The dried material is conveyed to the liquefaction kettle 4 through the screw feeder 1, and the high-temperature oil in the cracking kettle 6 is sprayed on the material in the liquefaction kettle through the spray pipe, and the agitator 15 in the liquefaction kettle is also working at the same time , The upper part of the liquefaction kettle 4 is equipped with an air extraction device 16, which mainly extracts the hydrogen chloride gas generated in the liquefaction kettle 4, and the hydrogen chloride gas enters the chemical treatment liquid 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com