Carbonization furnace for producing biomass charcoal

A technology for biomass charcoal and carbonization furnace, which is applied to rotary carbonization furnaces, biofuels, coke ovens, etc., can solve the problems of inability to continuously produce carbon, complex production processes, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

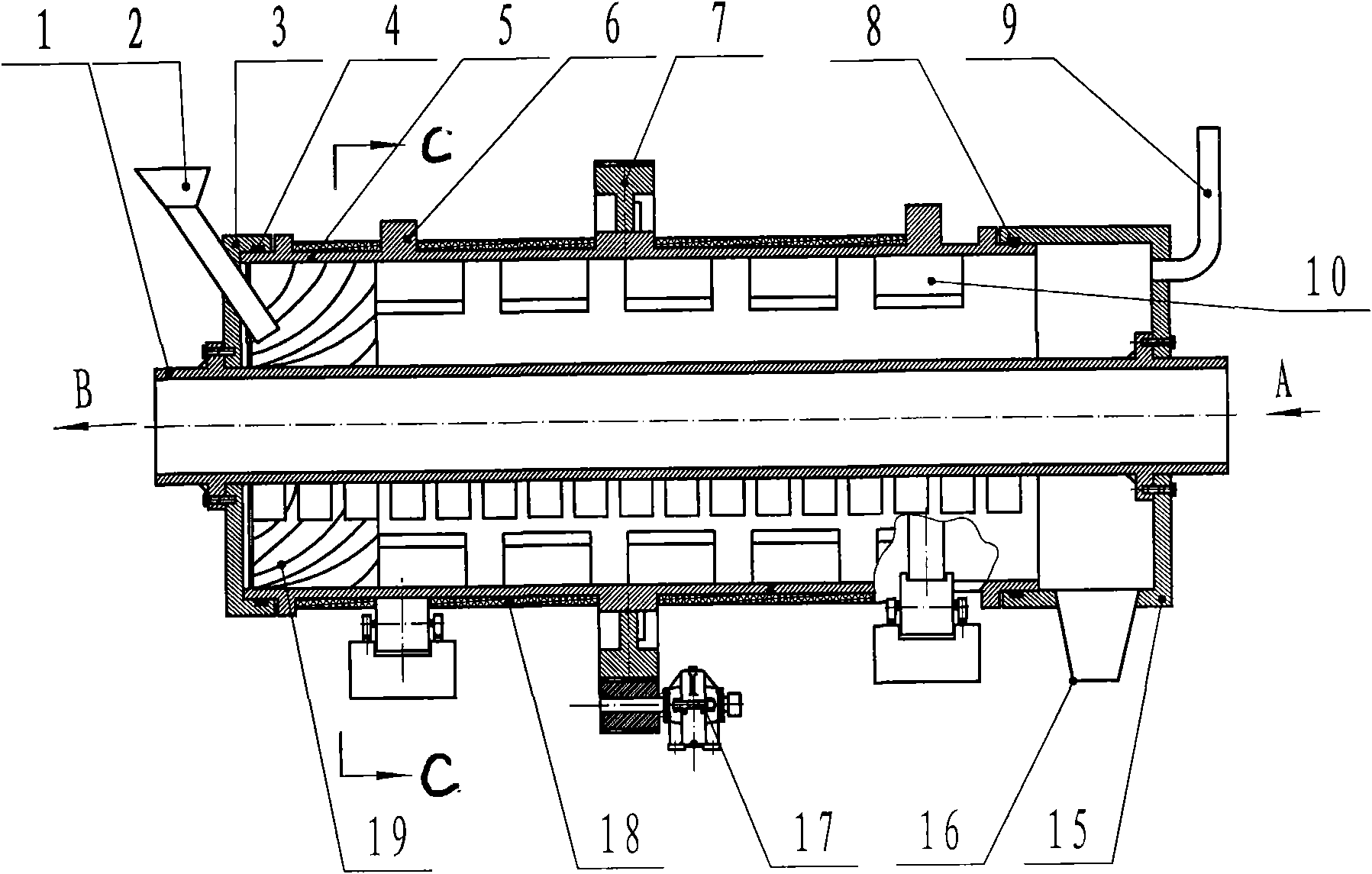

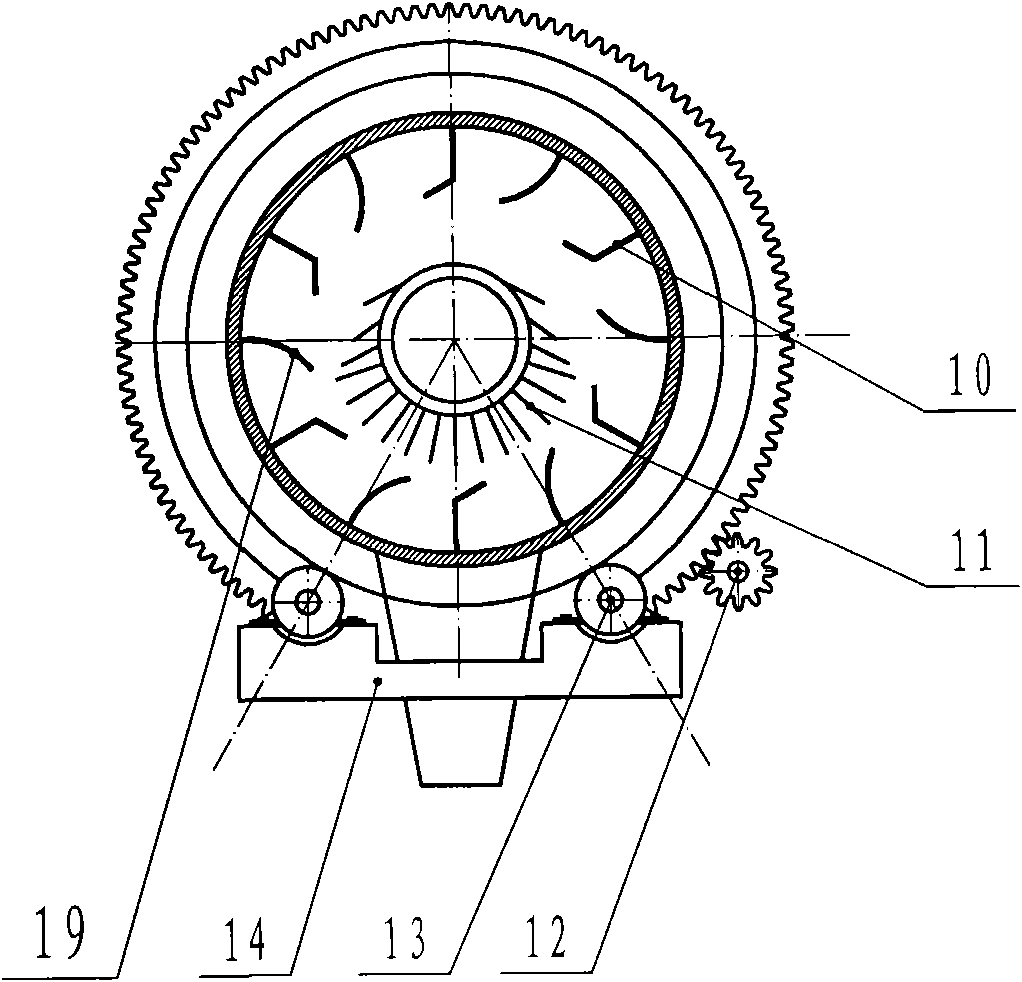

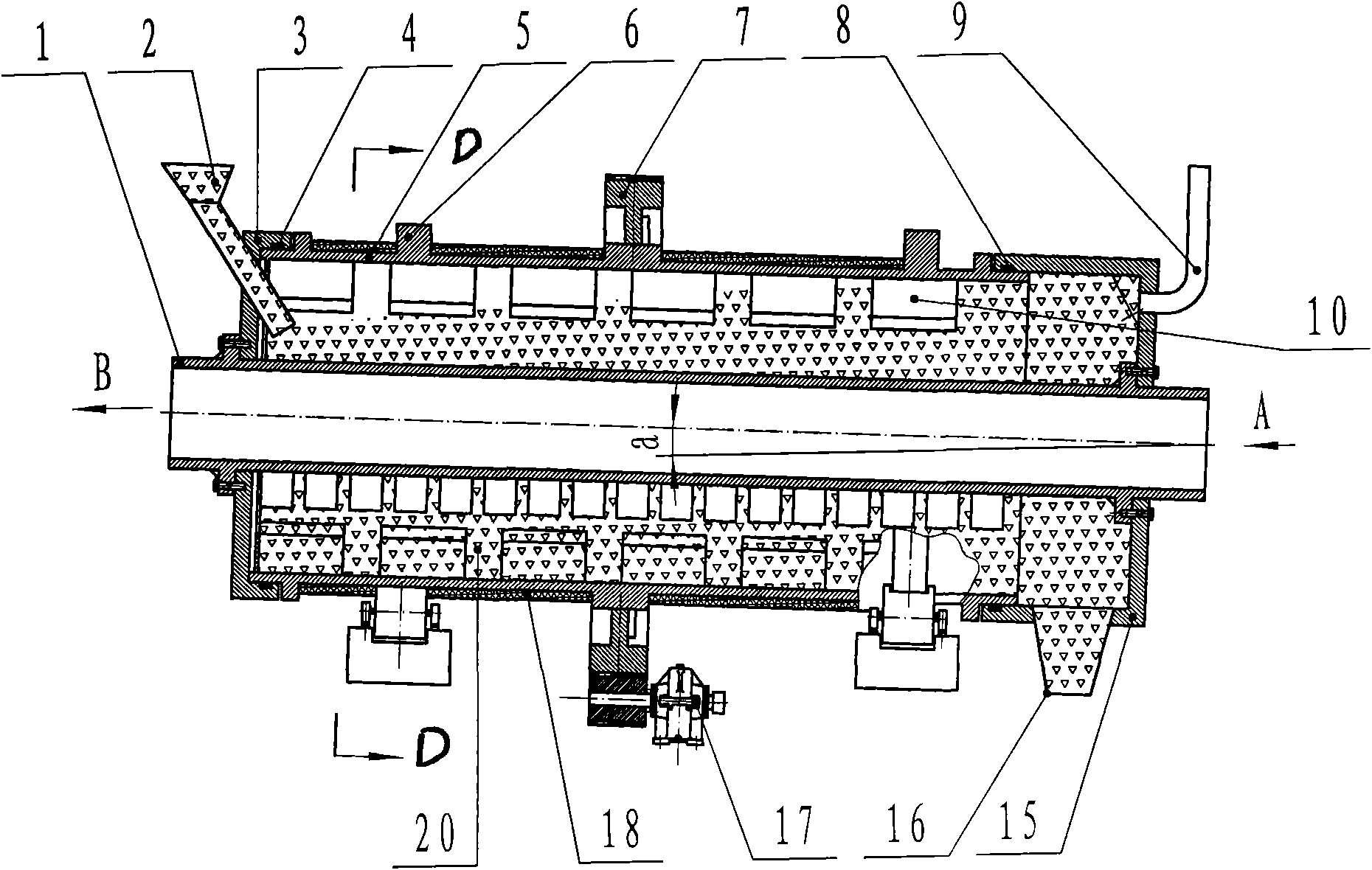

[0012] Reference attached figure 1 ——attached Figure 4 , the carbonization furnace consists of a chimney 1, a feed hopper 2, a front cover 3, a front sealing ring 4, a rotating furnace body 5, a support wheel 6, a large gear 7, a rear sealing ring 8, an oil and gas discharge pipe 9, a lifting plate 10, a heat dissipation Sheet 11, pinion 12, rotating supporting wheel 13 supporting wheel seat 14, rear end cover 15, discharge hopper 16, motor reducer system 17, insulation layer 18, spiral blade 19 and biomass raw material 20, etc.

[0013] It includes a chimney, a rotary furnace body, a feed hopper, a discharge hopper, and an oil and gas discharge pipe. The rotary furnace body is supported by a rotating supporting wheel, and the feed hopper, discharge hopper, and oil and gas discharge pipe are installed on the rotary furnace body. In the rotary furnace body, the chimney is coaxial with the rotary furnace body, and the inner wall of the rotary furnace body is provided with spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com