Continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment

A biomass pyrolysis and rotary carbonization furnace technology, which is used in rotary carbonization furnaces, biofuels, combustion using block fuels and gaseous fuels, etc., can solve the problems of incomplete combustion, poor gas permeability, and low thermal efficiency, etc. Achieve the effect of increasing residence time, increasing heating area and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

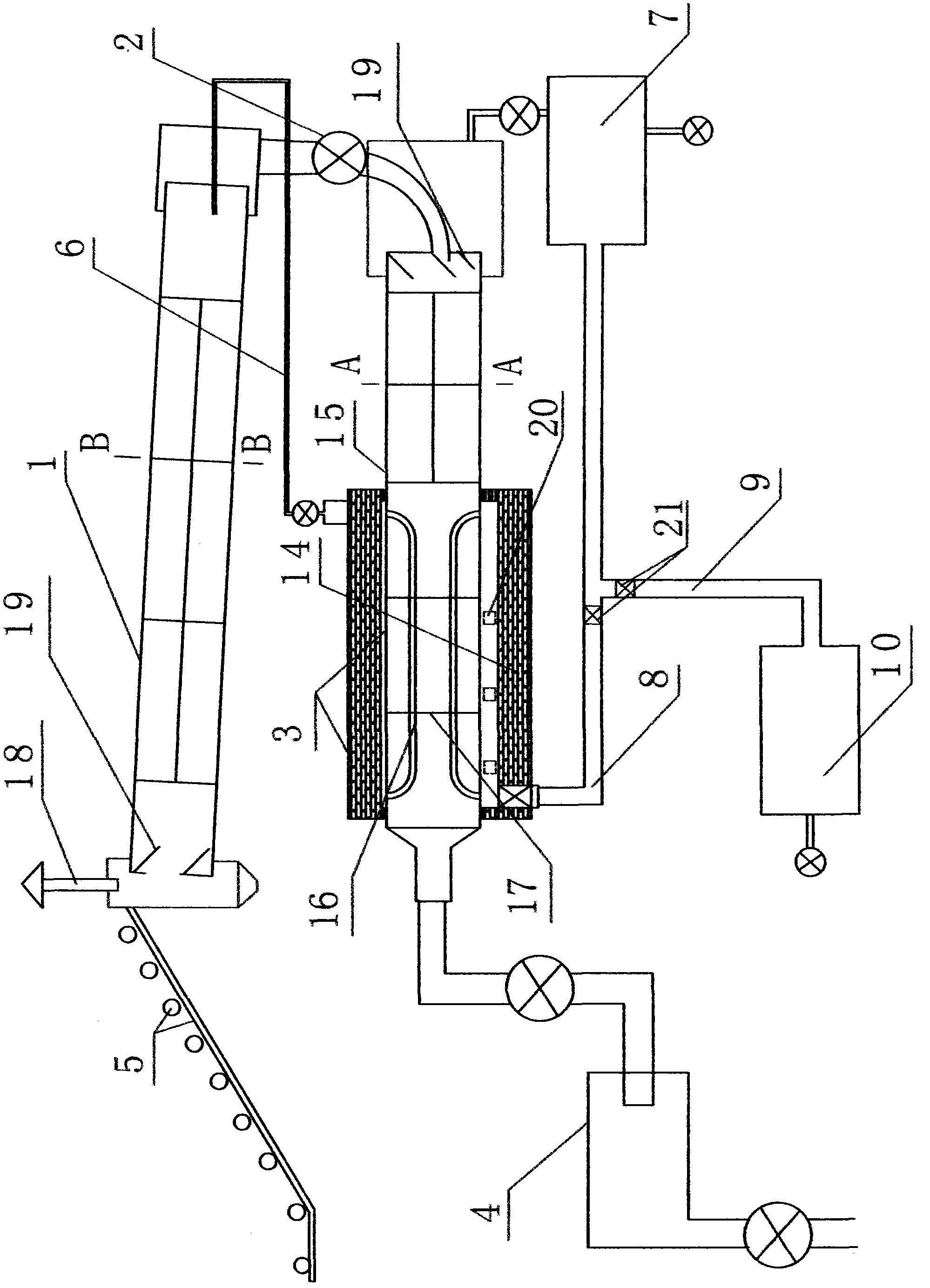

[0014] Below in conjunction with accompanying drawing and example, structure and working principle of the present invention are described in detail:

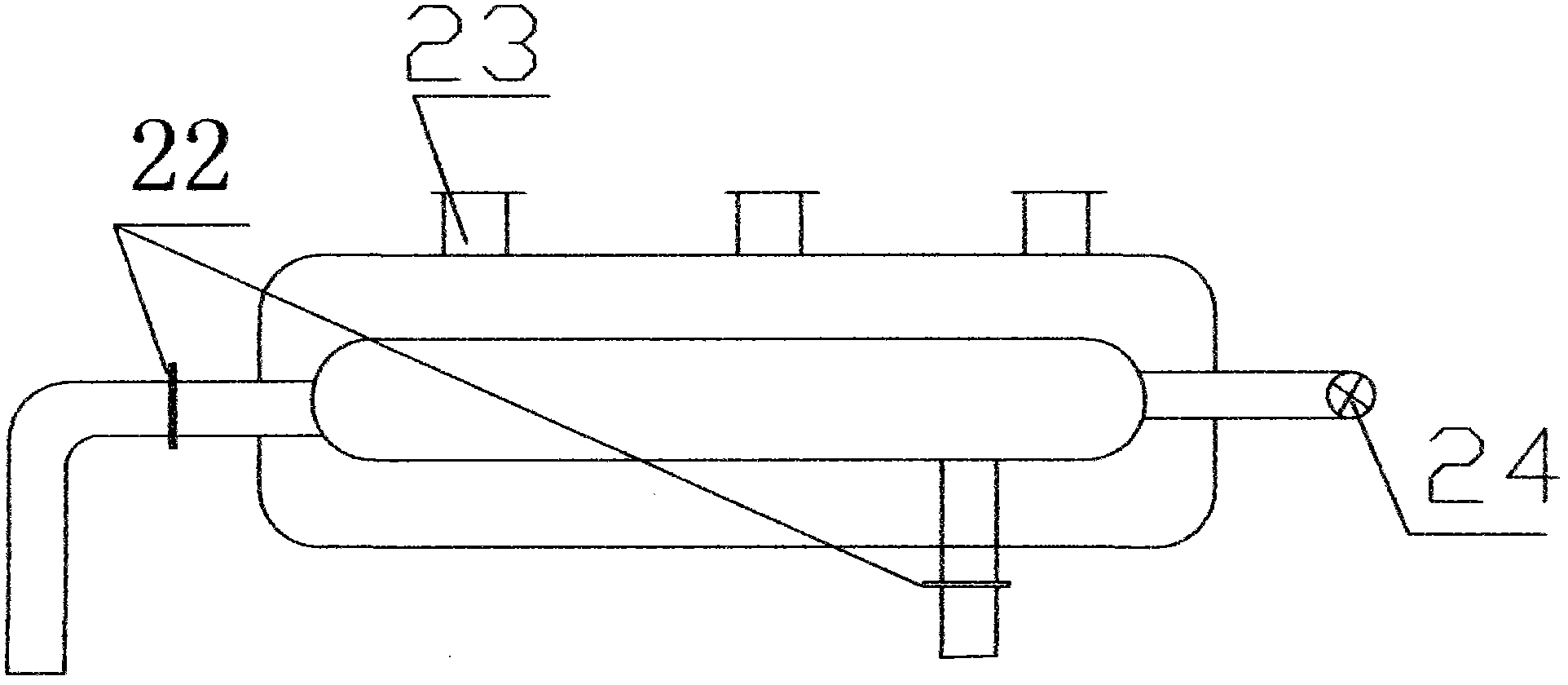

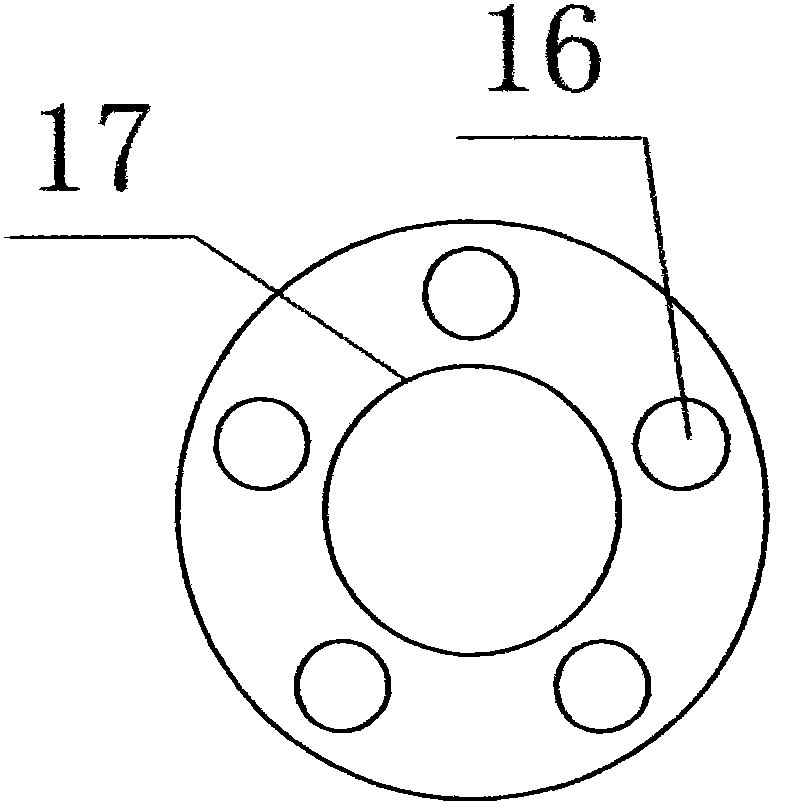

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the equipment for the integration of continuous rotary biomass pyrolysis carbonization and boiler heating in the present invention includes raw material conveying equipment 5, rotary drying furnace 1, star feeder 2 and rotary carbonization furnace 3, and Can include screw discharger 4, described raw material conveying equipment is prior art, comprises raw material conveyer belt and conveyer belt drive mechanism, and star feeder is prior art, and rotary discharger is prior art, as screw Extrusion discharge device or other discharge mechanism can be used. Its structural feature is that the raw material conveying equipment 5 is connected to the rotary drying furnace 1, and its function is to send raw materials such as sawdust or wood shavings int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com