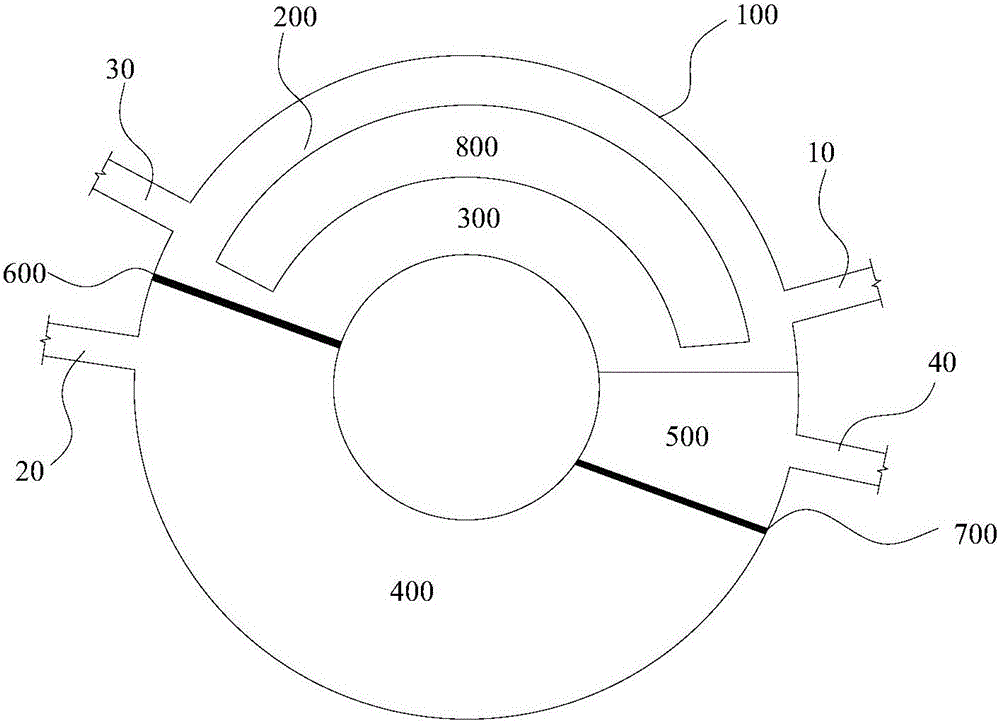

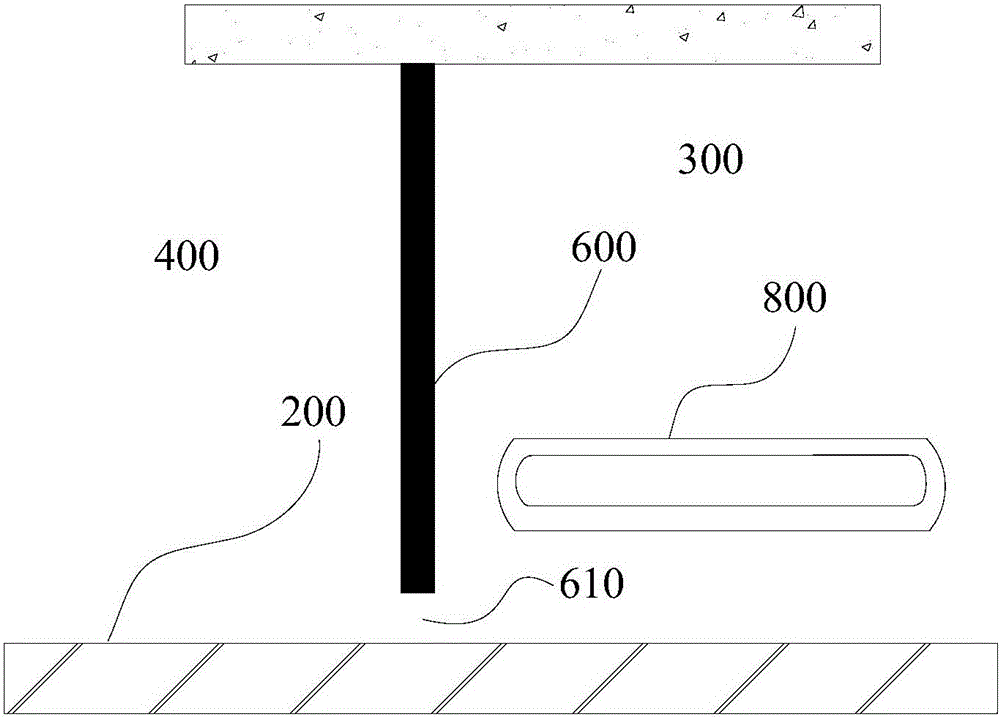

Rotary hearth furnace and method for treating low-rank coal and iron-containing materials

A technology of low metamorphic coal and rotary hearth furnace, which is applied in the fields of metallurgy and chemical industry, which can solve the problems that the product cannot be directly used, the economic benefit of the product is poor, and the production cost is high, so as to improve the efficiency and effect, prevent insufficient pyrolysis, and prolong the residence time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

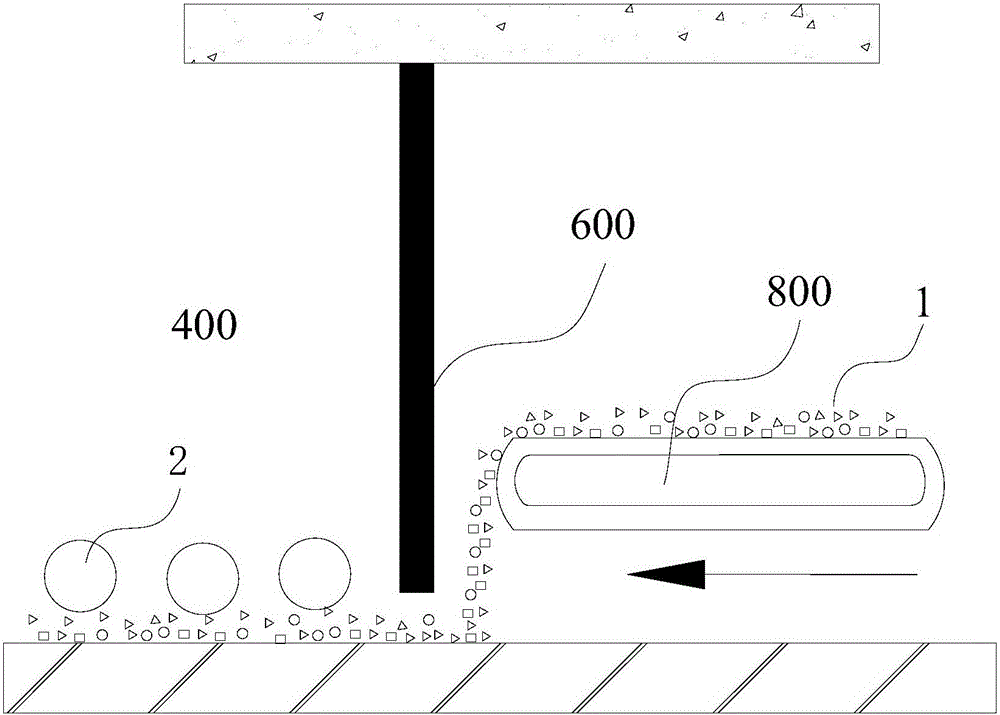

Embodiment 1

[0052] Using lignite and iron concentrate as raw materials, the lignite composition is as follows (mass percentage): moisture 10.19%, ash 1.94%, volatile matter 46.53%, and fixed carbon content 41.34%. The TFe grade of the iron concentrate is 72wt%. The lignite is prepared by drying to a particle size of 8-12 mm, and the iron concentrate is made into pellets with a particle size of 6-8 mm. Firstly, the lignite block is placed on the chain plate of the pyrolysis zone through the inlet of low metamorphic coal, and the distance between the chain plate device and the bottom refractory material is 10cm. The temperature in the pyrolysis zone is 500°C, and the time is 20 minutes. The oil and gas produced by pyrolysis are recovered through the collection and separation device, the yield of tar is 6.51%, the yield of gas is 20.49%, and the calorific value of gas can reach 5476.53Kcal / Nm 3 . The pyrolyzed semi-coke falls from the chain plate at the first retaining wall (18mm from the...

Embodiment 2

[0054] Using long-flame coal and iron ore as raw materials, the coal composition is as follows (mass percentage): moisture 12.03%, ash 2.21%, volatile matter 46.31%, fixed carbon content 39.45%, iron ore TFe grade 48wt%. The long-flame coal is dried to a particle size of 10-14 mm, and the iron ore is made into pellets with a particle size of 8-10 mm. Firstly, the long-flame coal is distributed into the chain plate of the pyrolysis zone through the low metamorphic coal inlet, and the chain plate device is 15cm away from the bottom refractory material. The temperature in the pyrolysis zone is 700°C, and the time is 16 minutes. The oil and gas produced by pyrolysis are recovered through the collection and separation device, the yield of tar is 5.69%, the yield of gas is 31.28%, and the calorific value of gas can reach 5697.82Kcal / Nm 3 . The pyrolyzed semi-coke falls from the chain plate at the first retaining wall (26mm from the bottom) and enters the reduction zone at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com