Multi-tube external-heat fume reverse extraction rotary carbide furnace

A carbonization furnace, external heating technology, applied in the field of multi-tube external heating type flue gas extraction rotary carbonization furnace, can solve the problems of long carbonization cycle, difficult to control, uneven carbonization, etc., to reduce slag stacking and reduce environmental pollution , The clean effect of the operation workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

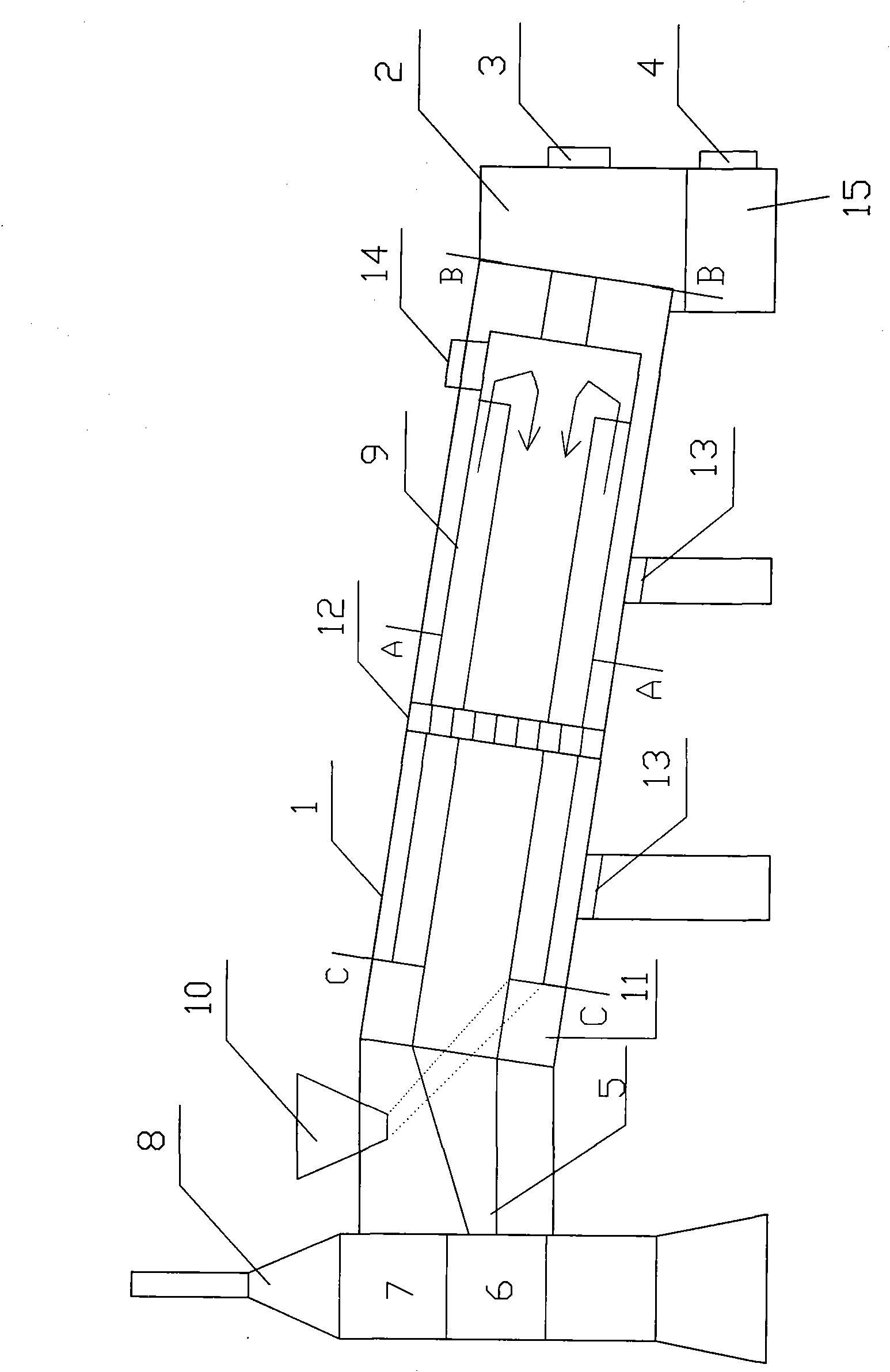

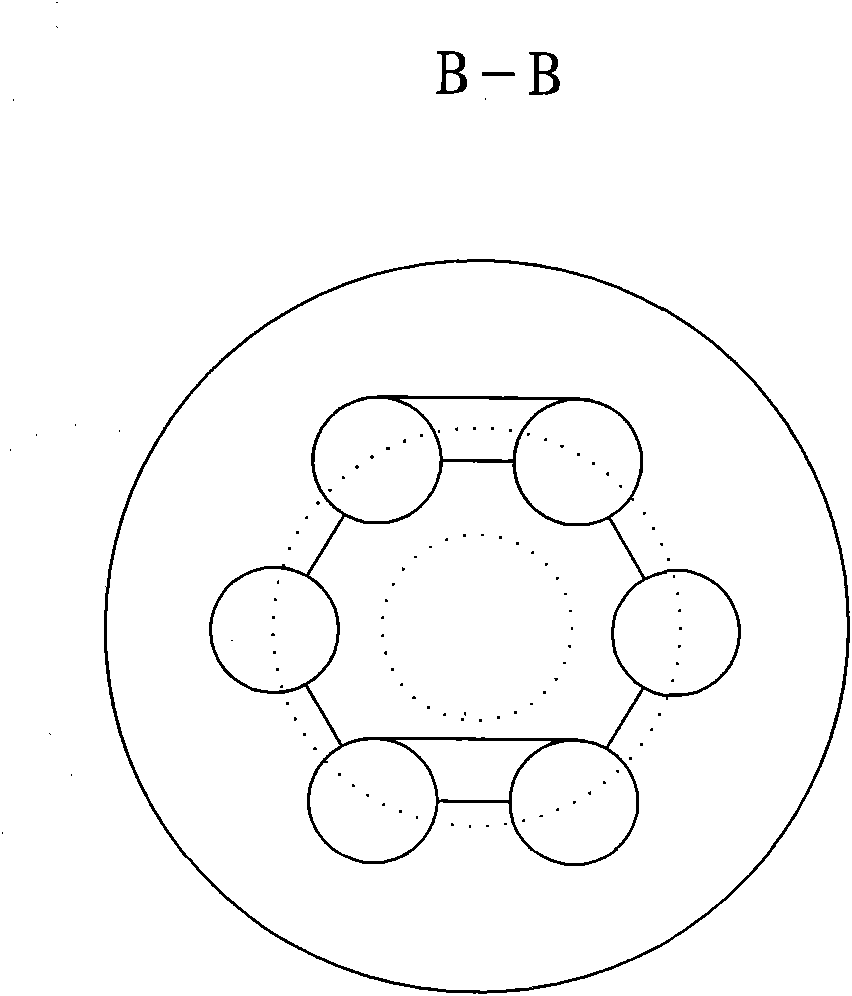

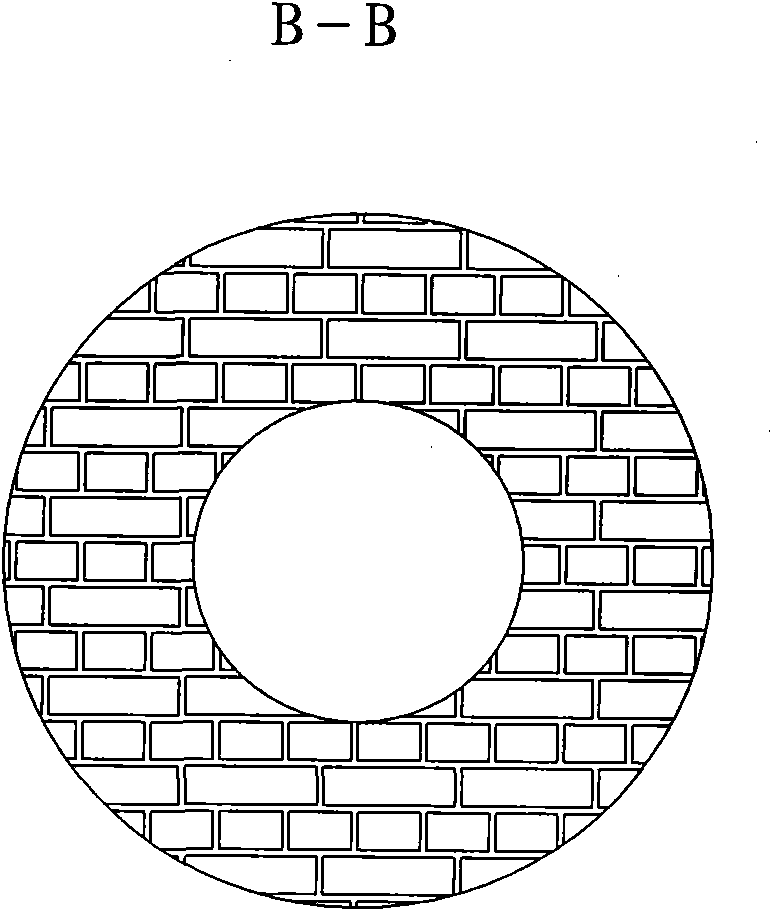

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0020] The main body of the present invention is an oblique horizontal rotary furnace body (1). The high-end side of the furnace body is equipped with a feed hopper (10) and a flue gas secondary utilization device, and the low-end side has a discharge port (14) and a combustion chamber. chamber (2), the furnace body has tube bundles (9) distributed circularly along the cross-section. During carbonization, the carbonized material enters the feed port distributor (11) from the feed hopper (10), goes through the tube pass, and passes through the discharge port (14 ) is discharged, the heated flue gas goes to the shell side, the carbonized material and the flue gas pass through the tube bundle separately, and the flue gas enters the incinerator (6) in the flue gas secondary utilization device through the flue (5) for secondary combustion, and the remaining heat can be It is used to heat the waste heat boile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com