Drying furnace or pyrolyzing furnace with rotary beds

A technology of rotating material bed and pyrolysis furnace, which is applied to furnaces, coke ovens, furnace types, etc., can solve the problems of back-mixing and tandem of materials, deterioration of heat transfer uniformity, and deterioration of uniformity of pyrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

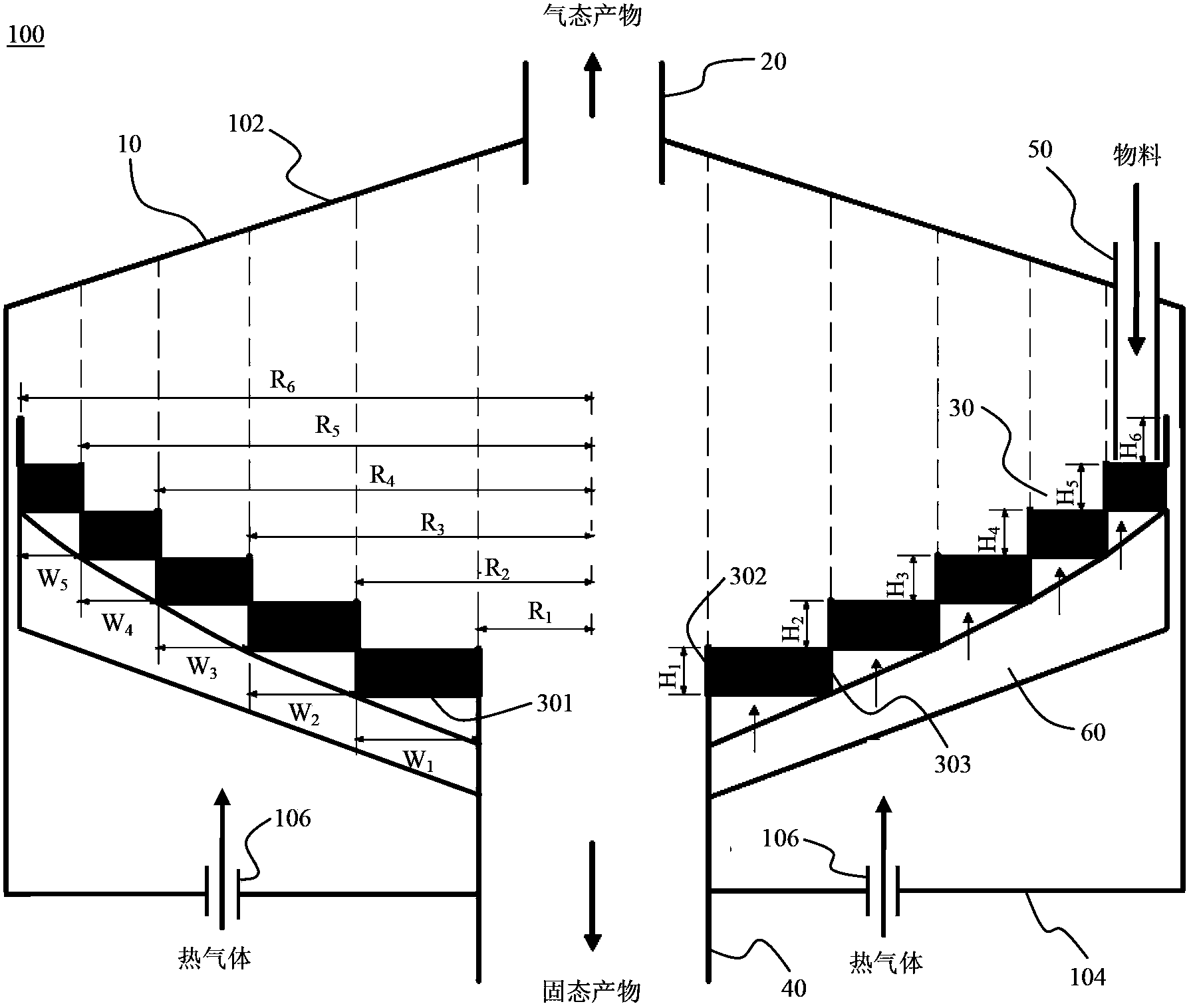

[0034] As an exemplary embodiment of the present invention, the closed case 10 may include an upper case 102 with a conical top and a lower case 104 connected to the upper case 102, wherein the upper case 102 and the lower case 104 A water seal is provided between them, and the pressure in the housing 10 can be maintained at atmospheric pressure or slightly positive pressure. The inner space formed by the upper casing 102 and the lower casing 104 accommodates N rotating material beds 30, and the central rotating shaft (discharging pipe) 40 is arranged along the center line of the casing 10, and extends downward through the lower casing 104 and bearings. (not shown) and transmission (not shown).

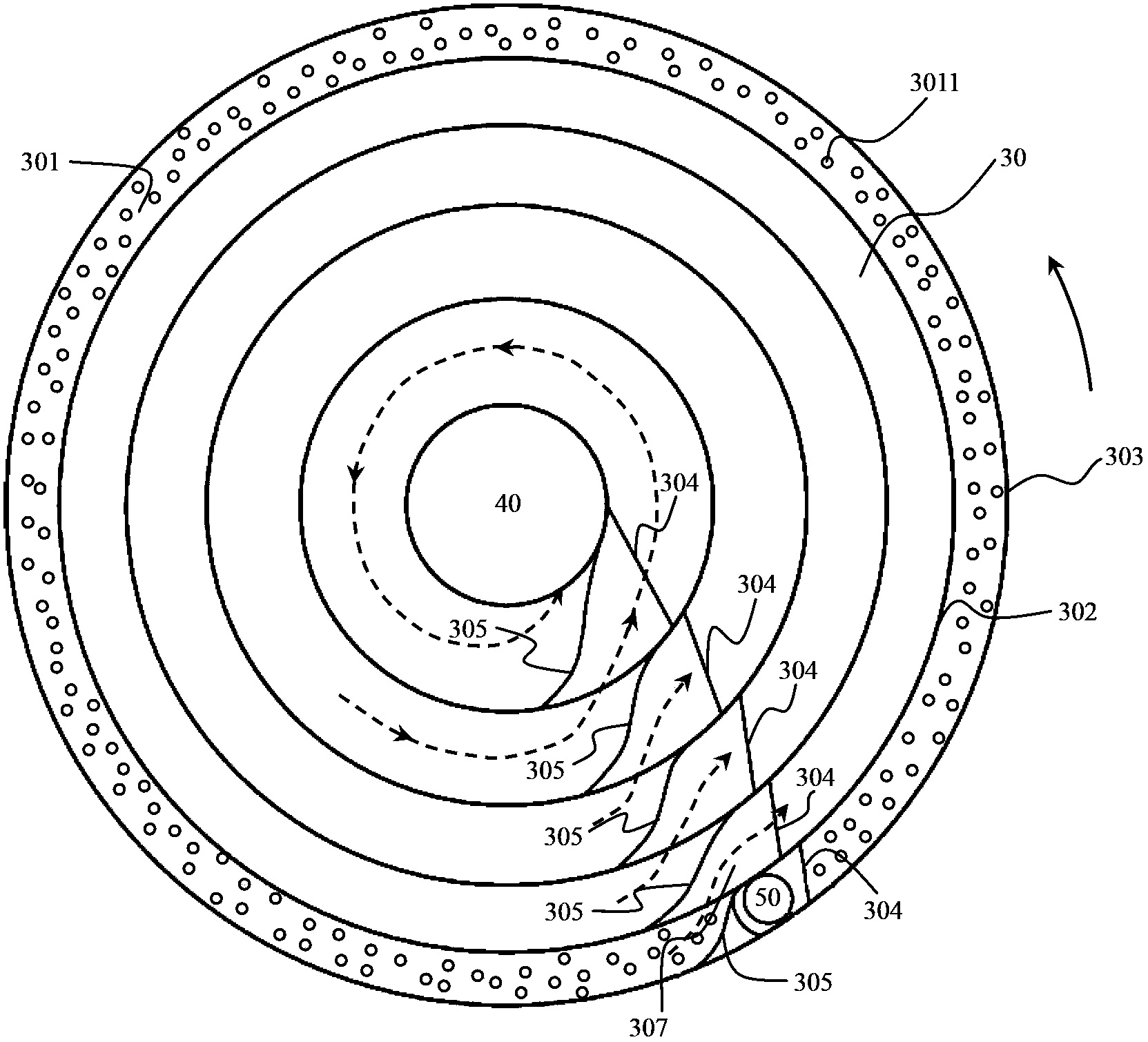

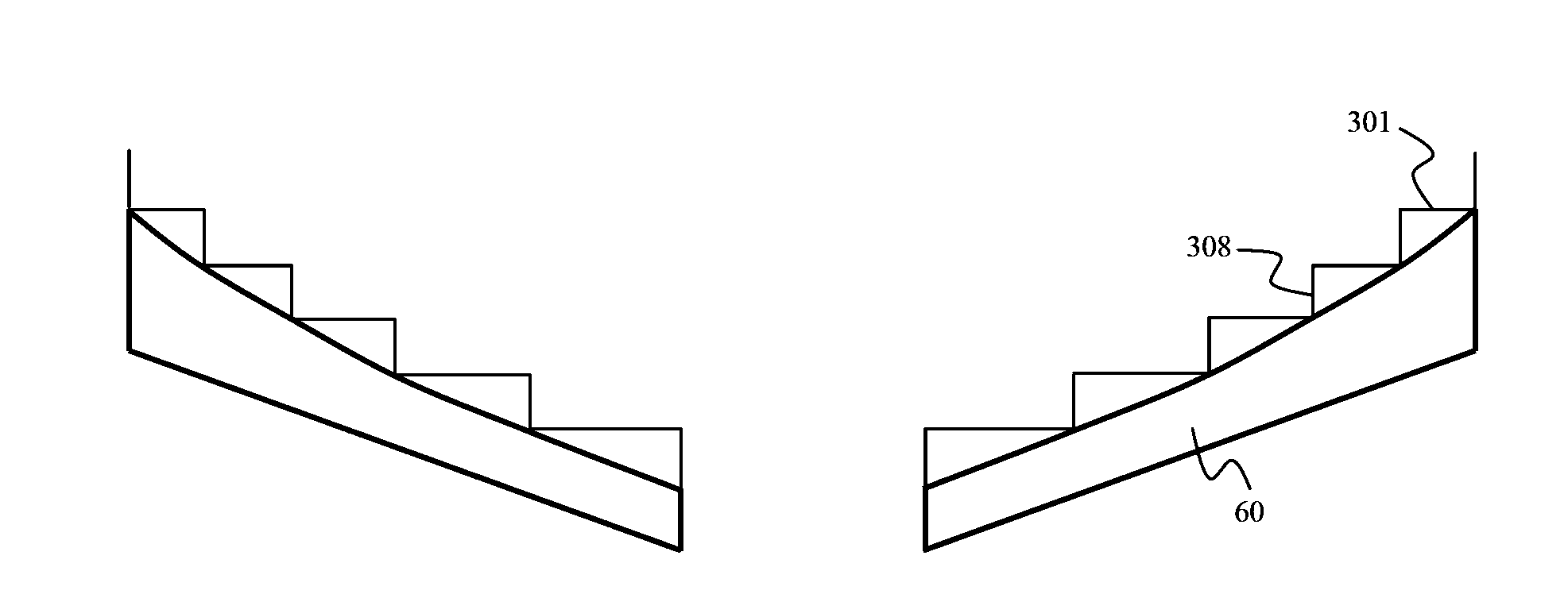

[0035] In one embodiment of the present invention, N rotating material beds 30 define N moving trajectories of materials. Each rotating material bed 30 includes a rotatable annular planar bed bottom 301 and an inner wall 302 and an outer wall 303 that are stationary relative to the b...

Embodiment 1

[0061] use Figure 1-Figure 5 The shown drying furnace or pyrolysis furnace of the present invention carries out low-temperature pyrolysis of Hulunbeier lignite in the following Table 1 and Table 2 for its industrial analysis and elemental analysis respectively. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0062] Table 1

[0063]

[0064] Table 2

[0065]

[0066] The Hulunbeier lignite with a particle size of 15-50 mm obtained through crushing and screening is continuously sent into the above-mentioned drying furnace or pyrolysis furnace 100 on an industrial scale, and a furnace with an oxygen content of 0.8% and a temperature of 700 ° C is introduced into it. Oxygen-deficient hot gas is subjected to low-temperature pyrolysis with the following process parameters and operating conditions.

[0067] The structural parameters of the pyrolysis furna...

Embodiment 2

[0080] The Hulunbeier lignite with a particle size of 15-30 mm obtained through crushing and screening is continuously sent into the above-mentioned drying furnace or pyrolysis furnace 100 on an industrial scale, and an anaerobic furnace with an oxygen content of 0.8% and a temperature of 850 °C is passed through. The hot gas is subjected to low-temperature pyrolysis with the following process parameters and operating conditions.

[0081] The structural parameters of the pyrolysis furnace 100:

[0082] Daily processing capacity: 5000 tons / day;

[0083] Feed density 705kg / m 3 ;

[0084] The overall height of the rotating material bed: 2.5m, the minimum inner diameter: 5m,

[0085] The outer diameter of the pyrolysis furnace: 20m;

[0086] The pyrolysis furnace includes 5 gradually rising rotating material beds, the width of which is: W 1 = 2.5m, W 2 =1.6m, W 3 =1.3m; W 4 =1.1m, W 5 =0.99m;

[0087] The material flow thickness in the rotating material bed is 500mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com