Microwave multi-spiral pyrolyzation equipment

A multi-screw and microwave technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of feeder number and area limitation, inability to handle materials, low production capacity, etc., to improve heating safety and structural design Reasonable, rapid pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

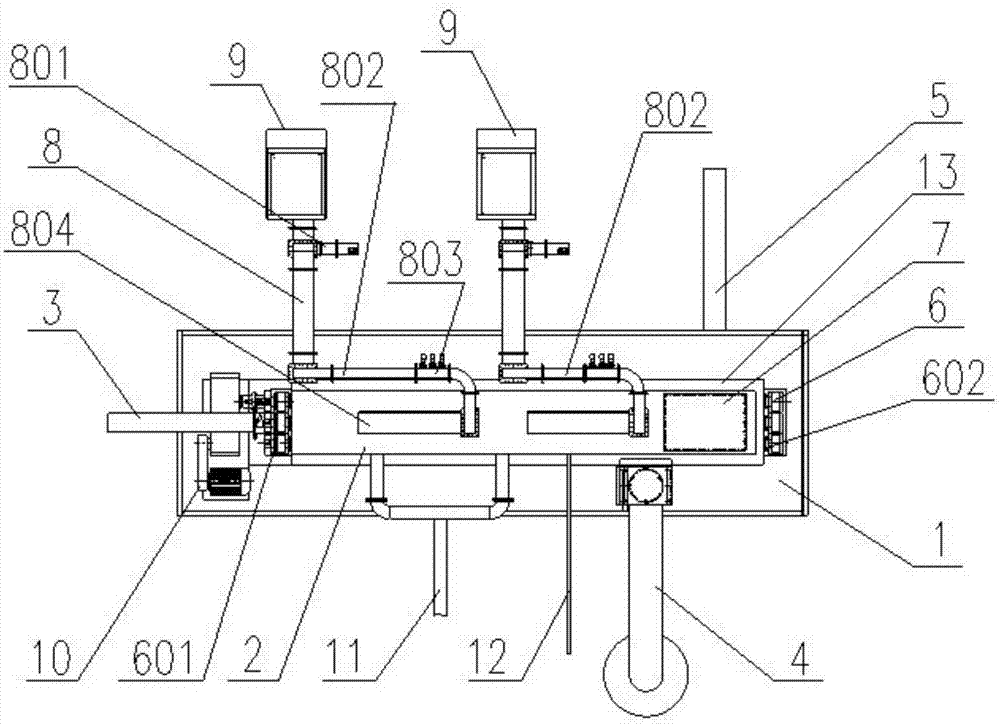

[0033] Such as figure 1 Shown, a kind of microwave multi-helical pyrolysis equipment, it comprises frame 1, the microwave pyrolysis chamber 2 that is installed on the frame 1, feed pipeline 3 that links to each other with microwave pyrolysis chamber 2, explosion venting system 4, outlet Material pipeline 5, exhaust pipeline 11 and nitrogen flushing pipeline 12; Furnace door 7 is installed on described microwave pyrolysis chamber 2, and microwave pyrolysis chamber 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com