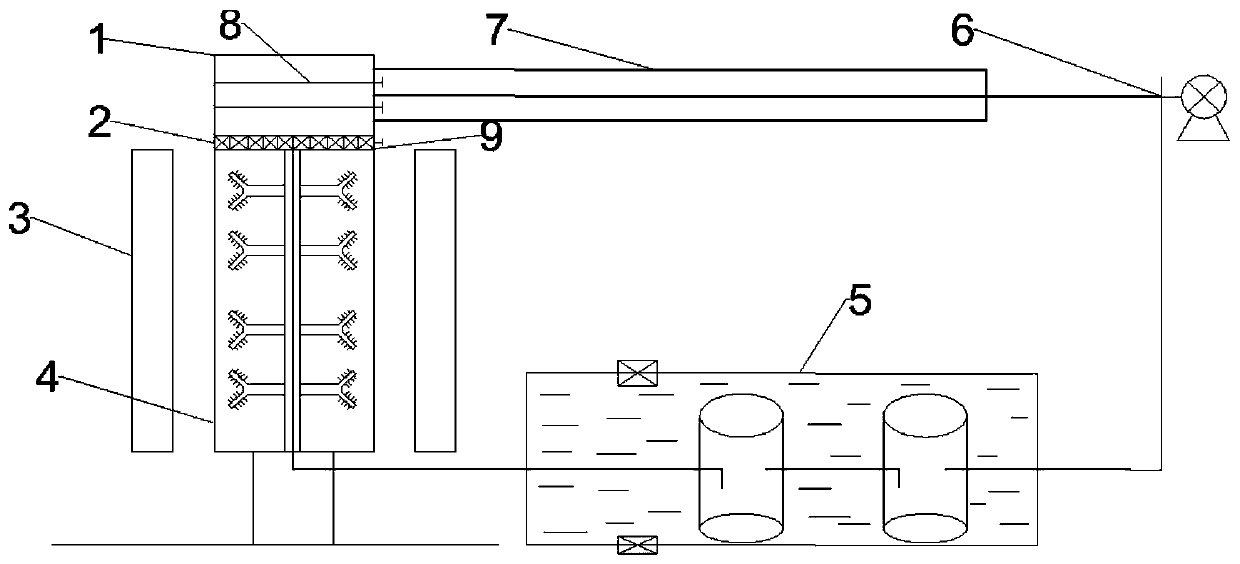

An oil producing device integrating biomass drying, crushing and pyrolysis

A biomass and drying technology, used in the preparation of liquid hydrocarbon mixtures, petroleum industry, grain processing, etc., can solve the problems of trivial pretreatment process, incomplete pyrolysis, and high energy loss, achieve complete pyrolysis, and eliminate the need for machinery. energy, reducing the effect of the preprocessing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

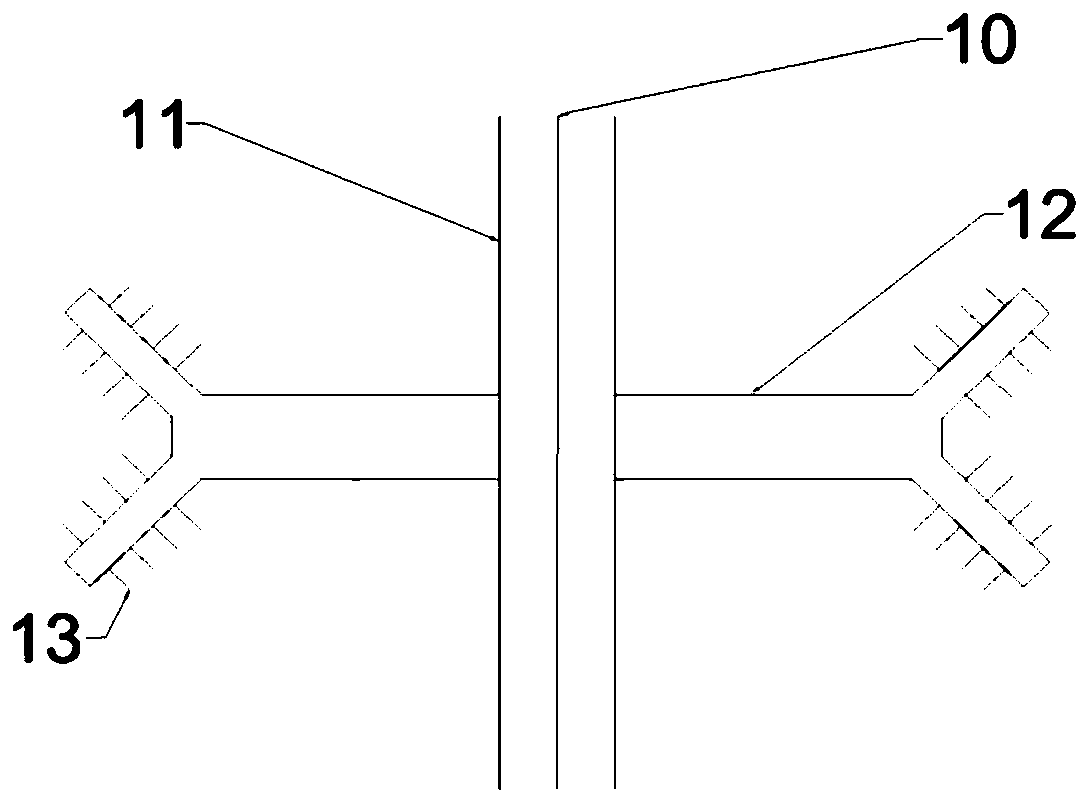

[0035]Put the prepared biomass on an electronic balance to weigh and record the value, weigh three parts and put them into the third layer, the second layer, and the first layer of the feeding storage device 1 in sequence. Connect the instrument and equipment to the nitrogen cylinder, connect the instrument plug, turn on the main power of the pyrolysis device, blow nitrogen gas (flow rate 150ml / min) through the pipeline, check the air tightness of the device, ensure that no other gas enters, and continue to purge the nitrogen gas 5min, remove the oxygen in the pyrolysis chamber, create a nitrogen environment pyrolysis chamber 4, make the pyrolysis chamber 4 reach an oxygen-free or anoxic environment, set the fixed bed pyrolysis reaction temperature to 450°C, turn on the power of the instrument, and use the thermoelectric With the heating of the couple, the temperature in the pyrolysis chamber 4 increases gradually. When the temperature rises to the preset pyrolysis chamber 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com