A filter device that removes nitrous oxides and dioxins from discharge gas and filtrating method thereof

A filter equipment and nitrogen oxide technology, applied in chemical instruments and methods, nitrous oxide capture, separation methods, etc., can solve the problems of adsorbent damage, construction cost increase, corrosion, etc., to prevent oxidation/corrosion, guarantee Retention time, effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

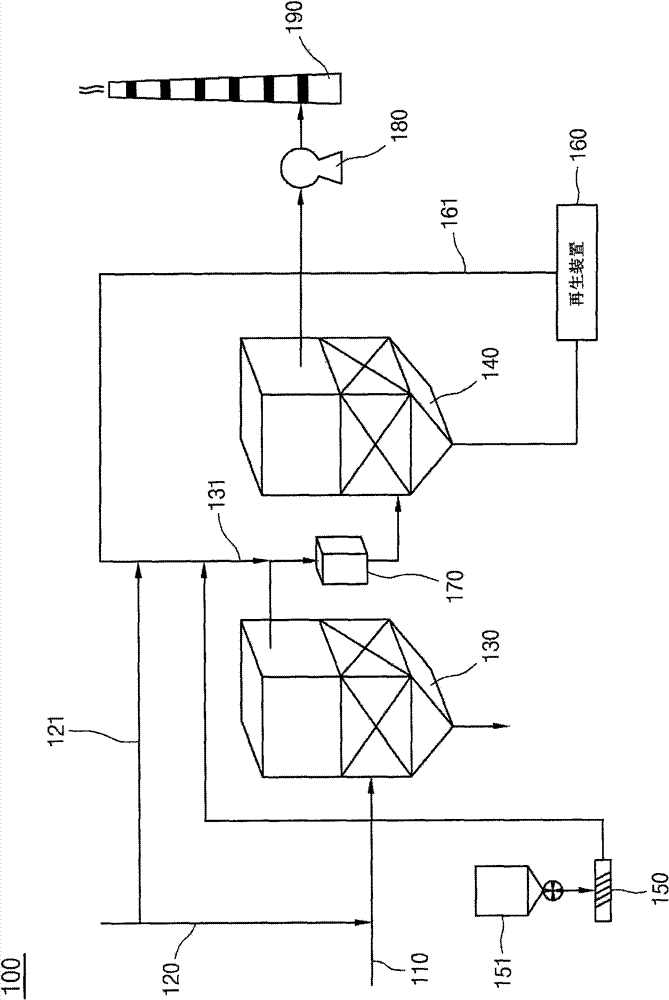

[0068] The purpose of this experimental example is to compare the NO filtration efficiencies when using the existing powder impregnated activated carbon (AC) and the catalyst of the present invention respectively.

[0069] The flow rate of this experimental example is 7780ml / min, the linear velocity is 0.8m / min, the temperature is 160°C, the amount of activated carbon added is 5g, and the residence time is 0.5s.

[0070] Figure 7 is to use the catalyst of the present invention respectively (V 2 o 5 / TiO 2 Department, MnO x System) and the comparison chart of NO filtration efficiency when the existing powder impregnated activated carbon. With the increase of catalyst injection amount, the NO filtration efficiency of each catalyst increased, however, the addition of MnO x When the catalyst is used, the maximum filtration efficiency reaches 64.39%, compared with TiO 2 The catalyst of the series has an advantage of about 20%, reflecting an excellent filtering effect.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com