Circulation type fluidized-bed furnace, treating system equipped with circulation type fluidized-bed furnace, and method of operating circulation type fluidized-bed furnace

A circulating fluidized bed and operating method technology, applied in fluidized bed combustion equipment, chemical instruments and methods, incinerators, etc., can solve the problems of cumbersome operation and increased cost, and achieve increased reaction area, reduced cost, reduced Effect of Small Blower Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail in conjunction with the accompanying drawings. The scope of the present invention is not limited unless the dimensions, materials, shapes, relative arrangements, etc. of the components described in the present embodiment are specifically described, and they are merely illustrative examples.

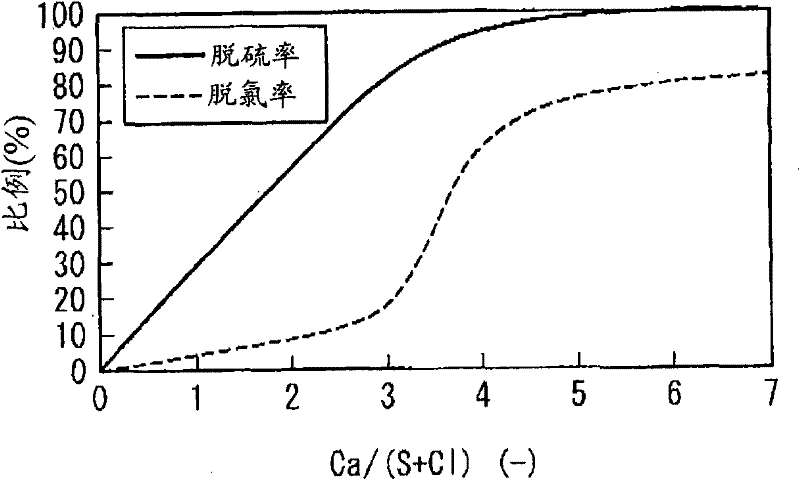

[0043] The treatment objects in the circulating fluidized bed boiler of this embodiment are chlorine-containing wastes, for example, sewage sludge, urban waste, industrial waste, etc., and the circulating fluidized bed boiler of this embodiment is especially suitable for sewage sewage Mud treatment. While the circulating fluidized bed boiler burns these wastes, it also desulfurizes the furnace by putting in desulfurization materials, so as to achieve desulfurization and dechlorination.

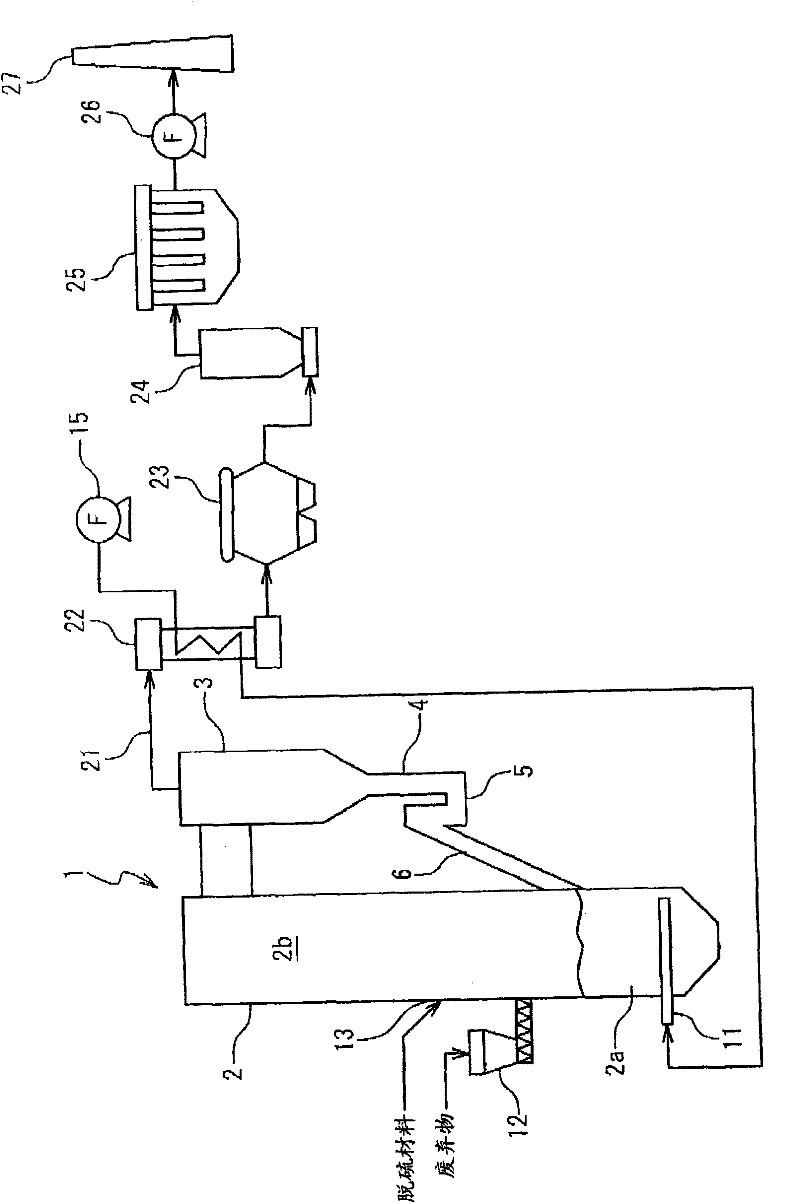

[0044] refer to figure 1 The circulating fluidized bed boiler and processing system of this embodiment will...

no. 2 Embodiment

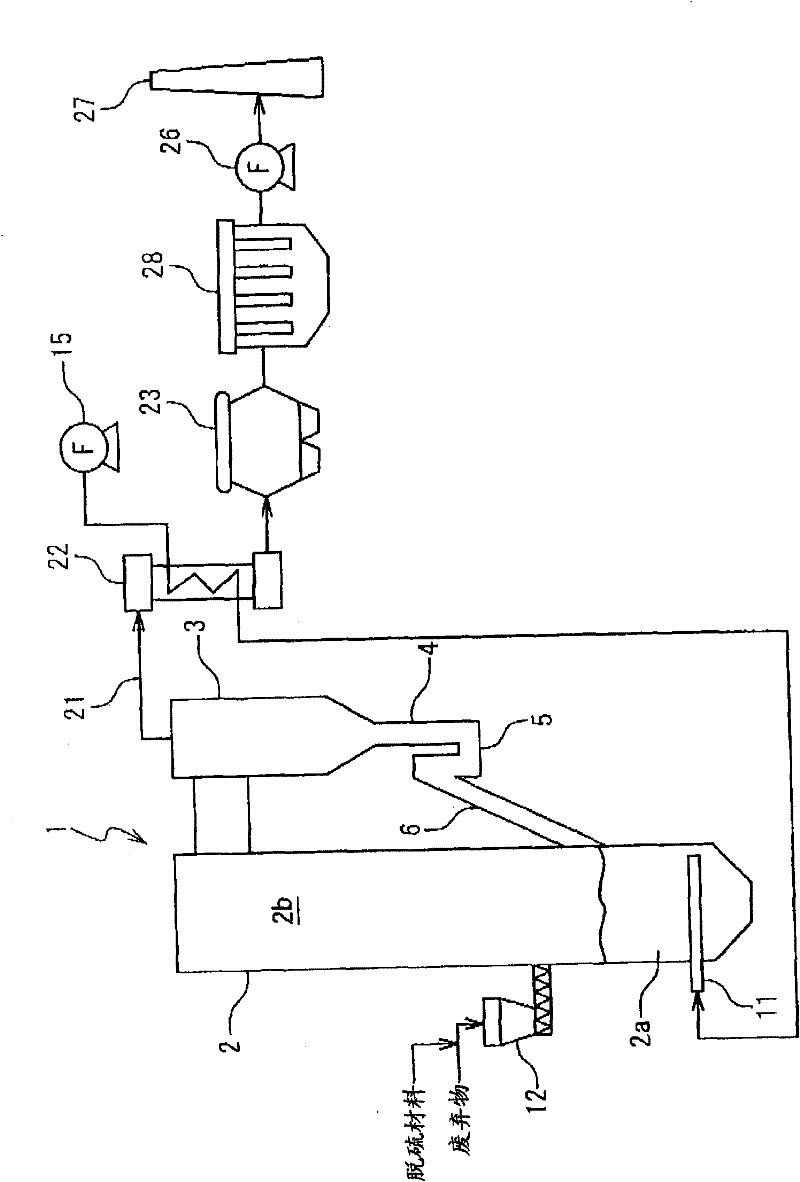

[0077] Hereinafter, a second embodiment of the present invention will be described.

[0078] According to the first embodiment, by using a material having an average particle diameter smaller than the limit particle diameter of the cyclone separator 3 as the desulfurization material, the dechlorination effect can be improved. However, nitrogen compounds may be contained in wastes fed to circulating fluidized bed boilers. For waste containing nitrogen compounds, the furnace exhaust gas will contain nitrogen compounds (NH 3 , HCN and N 2 O, etc.). For example, when sewage sludge is thrown in as waste, the content of nitrogen compounds tends to increase. In addition, the present inventors also found that when only the desulfurization material (hereinafter referred to as the first desulfurization material) whose average particle size is smaller than the limit particle size of the cyclone separator 3 is used, nitrogen compounds (NH 3 , HCH, N 2 O, etc.) concentration increases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com