A kind of slurry for extruding 3D printing fiber-reinforced metal matrix composite material and preparation method thereof

A fiber reinforced, composite material technology, applied in metal processing equipment, additive processing, process efficiency improvement, etc., can solve problems such as changing the direction of fiber arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

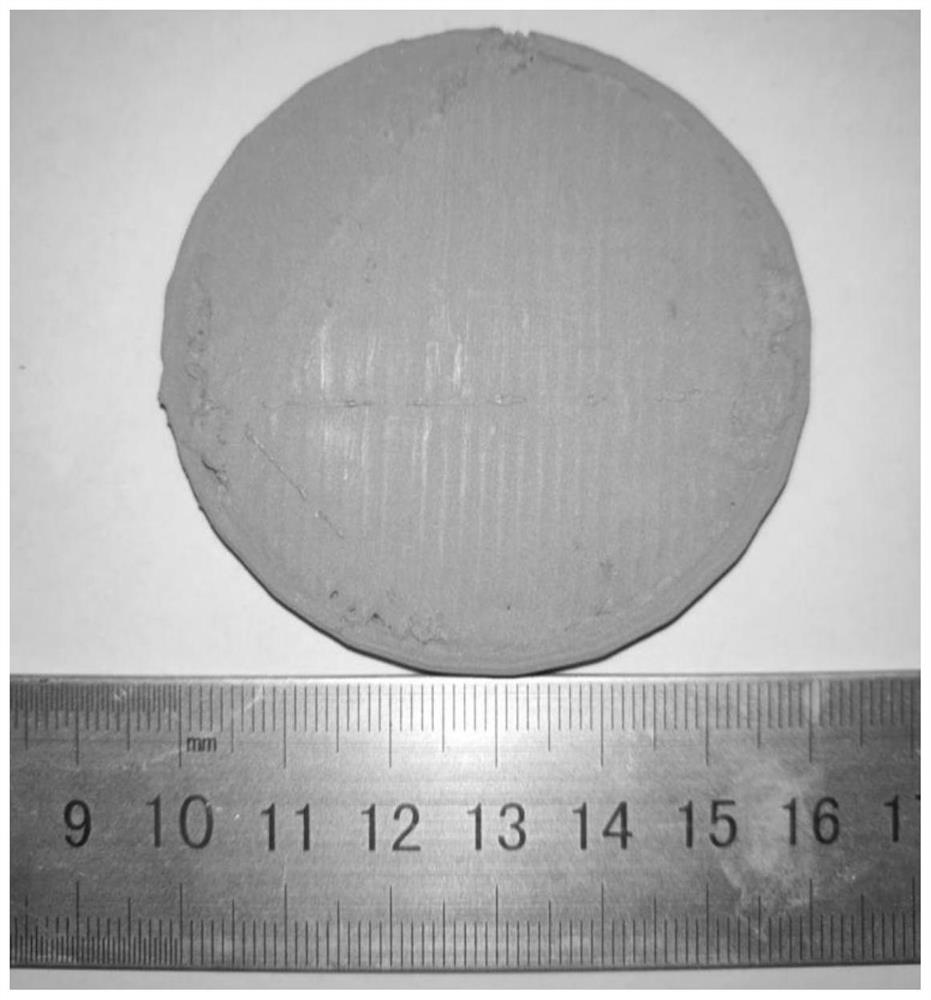

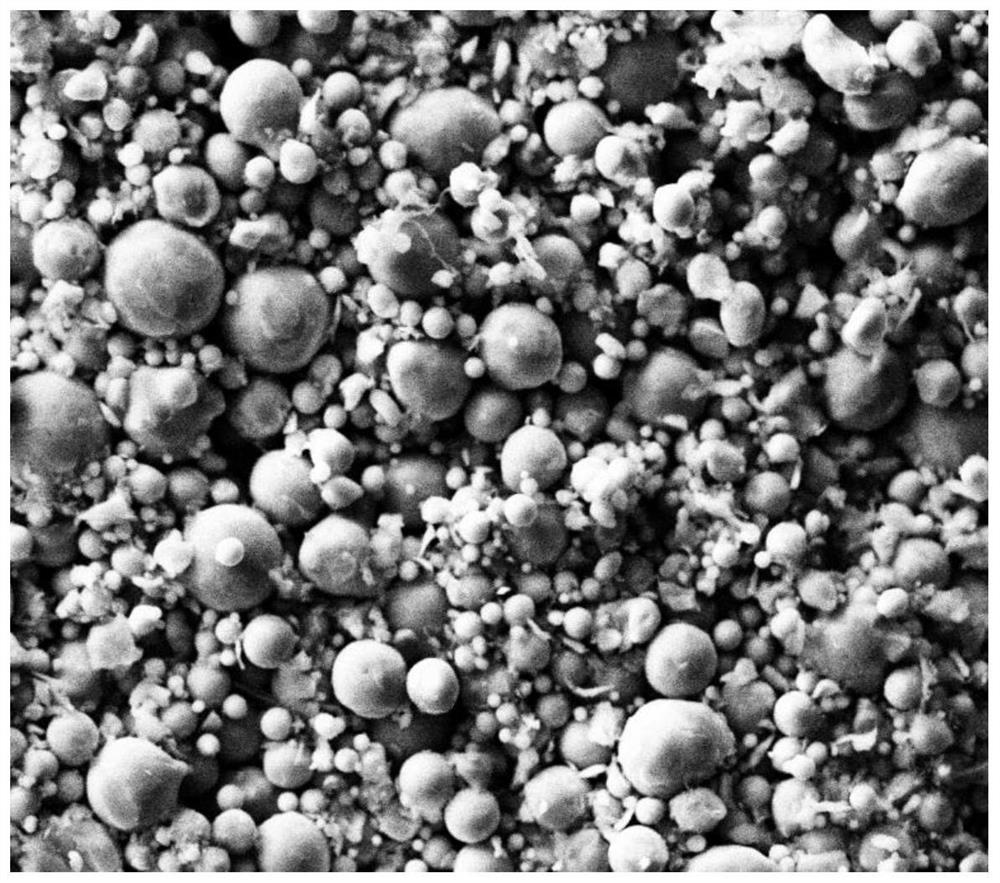

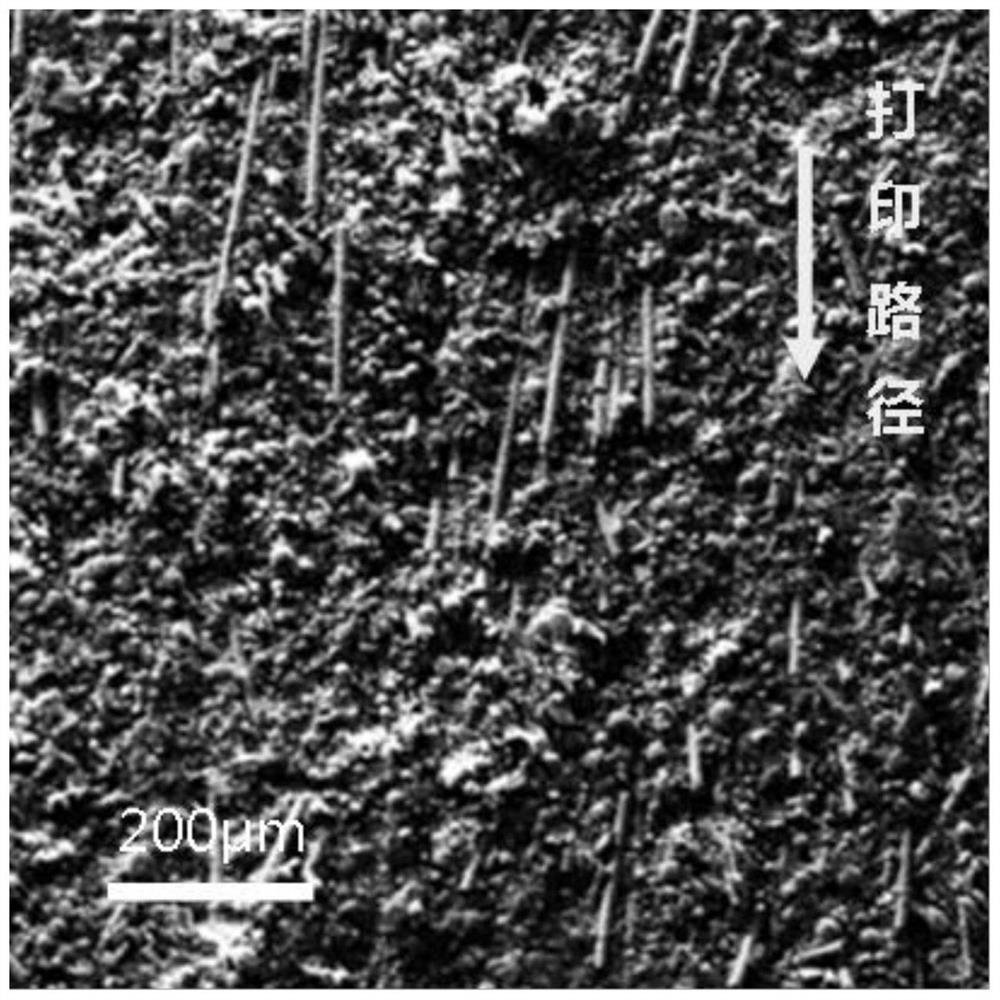

[0029] 1. Select 7075 aluminum alloy powder with an average length of 200 μm, a diameter of 7 μm, an average particle size of 15 μm, and D(90)<30 and polylactic acid of 4032D type.

[0030] 2. Preparation of a slurry for extruding a fiber-reinforced metal matrix composite material for 3D printing, using the above carbon fiber, aluminum alloy powder, polylactic acid and dichloromethane as raw materials, including the following steps:

[0031] A, first soak 2g polylactic acid in 8g methylene chloride for 24h, then, ultrasonically treat 30min to make polylactic acid fully dissolve in methylene chloride;

[0032] B. Mix 30g metal powder and 8g fiber evenly in proportion, divide into 5 parts, divide 10g methylene chloride prepared in advance into 5 parts, add metal powder and fiber mixed powder and methylene chloride to step A to obtain in turn Dissolve in polylactic acid in dichloromethane, stir well after each addition of powder and dichloromethane, then remove and seal.

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com