Destructive distillation device of biomass horizontal rotary drum

A biomass and rotary drum technology, applied in the fields of biofuels, special forms of dry distillation, indirect heating dry distillation, etc., can solve the problem that intermittent calcining furnace equipment cannot achieve continuous industrial operation, toxic dry distillation gas leakage is safe and environmentally friendly, and cannot be effective. Control the emission of nitrogen oxides and other problems to achieve the effect of continuous and automatic feeding and discharging operations, simple structure and large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

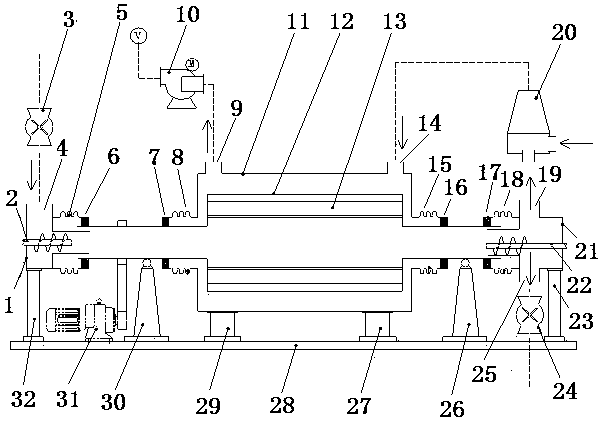

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] see figure 1 . A biomass horizontal drum retort device, comprising a feed mechanism, a drive mechanism 31, a drum mechanism, a discharge mechanism, a common chassis 28, a retort gas combustion furnace 20, an induced draft fan 10 and auxiliary components. The feeding mechanism includes a feeding shell 1 and a feeding screw 2 inside thereof, and the feeding shell 1 is provided with a feeding port 4 . Auxiliary components include rotating supports and fixed supports. The rotating support includes a first rotating bracket 30 and a second rotating bracket 26 , both of which are fixed on a common chassis 28 . The rotating cylinder mechanism includes an outer cylinder 11 and an inner cylinder 12 arranged horizontally. The outer cylinder 11 is provided with a smoke inlet 14 and a smoke outlet 9. The inner cylinder 12 is driven by the driving mechanism 31 around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com