Heat exchanging chamber and coke oven

A heat exchange chamber and coke oven technology, applied in the coking field, can solve the problems of complex coke oven structure, excessive nitrogen oxides, and high air temperature, and achieve the effects of simplifying the process and coke oven system, reducing emissions, and reducing combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

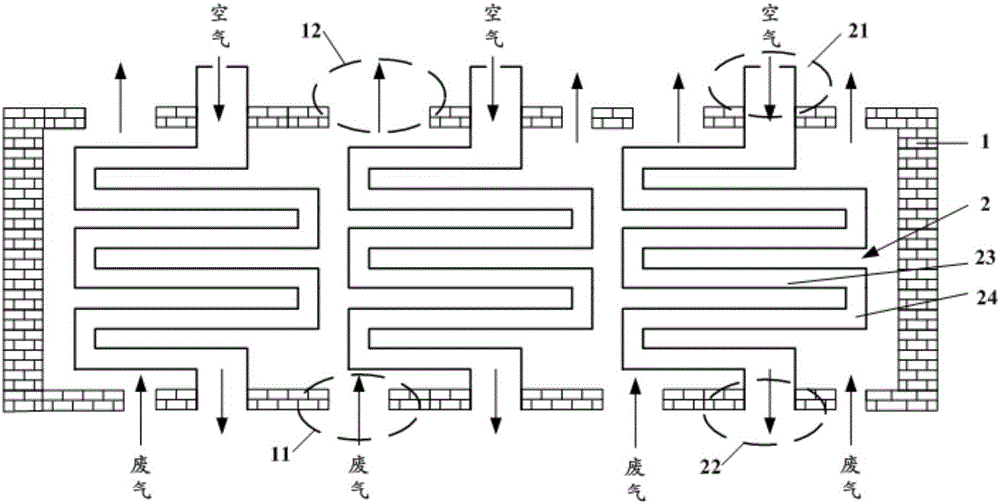

[0025] like figure 1 and 2 As shown, this embodiment provides a heat exchange chamber for a coke oven, which includes a chamber body 1 and a heat exchange tube 2 . The heat exchange tube 2 is arranged in the chamber body 1; the chamber body 1 is provided with an exhaust gas inlet 11 and an exhaust gas outlet 12; the two ends of the heat exchange tube 2 are an air inlet 21 and an air outlet 22 respectively.

[0026] Specifically, as figure 1 As shown, the heat exchange chamber includes a chamber body 1 and a heat exchange tube 2, wherein the chamber body 1 refers to the main chamber of the heat exchange tube 2, which is provided with an exhaust gas inlet 11 and an exhaust gas outlet 12; the heat exchange tube 2 is arranged in In the chamber body 1, its two ends are respectively an air inlet 21 and an air outlet 22. Wherein, the air inlet 21 and the air outlet 22 are located on the wall of the chamber body 1 or outside the chamber body 1). However, there is a gap between the...

Embodiment 2

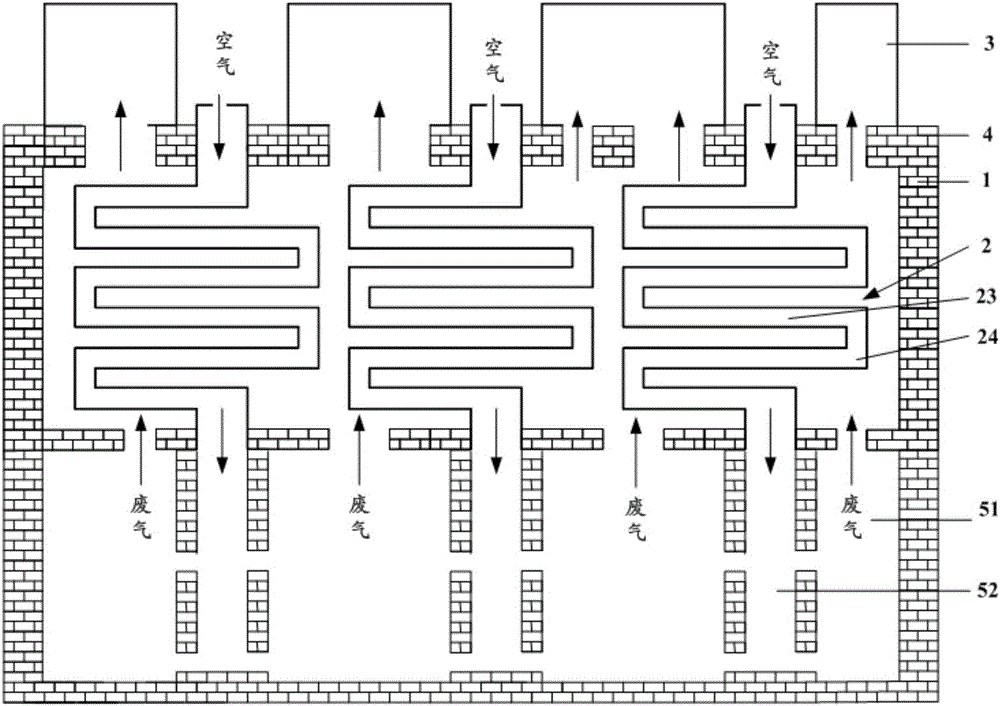

[0045] like figure 1 and 2 As shown, this embodiment provides a coke oven, including the heat exchange chamber provided in Embodiment 1.

[0046] The coke oven in this embodiment utilizes the waste heat of the exhaust gas through the heat exchange chamber. For a detailed description of the structure of the heat exchange chamber, see Embodiment 1, which will not be repeated here.

[0047]The difference from the traditional coke oven is that the traditional coke oven utilizes the waste heat of the coke oven exhaust gas through the regenerator, while the coke oven of this embodiment utilizes the waste heat of the exhaust gas by setting up a heat exchange chamber, and the waste gas is preheated. During heat utilization, there is no need for heat storage lattice bricks, reducing the reversing device, simplifying the waste heat utilization process and coke oven system. At the same time, the air temperature preheated by the coke oven in this embodiment is lower than the air tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com