Air-preheating-type heat recovery coke oven

An air preheating and air preheating technology, which is applied in the direction of preheating coke ovens, coke ovens, fixed carbonization furnaces, etc., can solve the problems of low production efficiency, promotion and development of coking technology in vertical heat recovery coke ovens, Problems such as long coking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

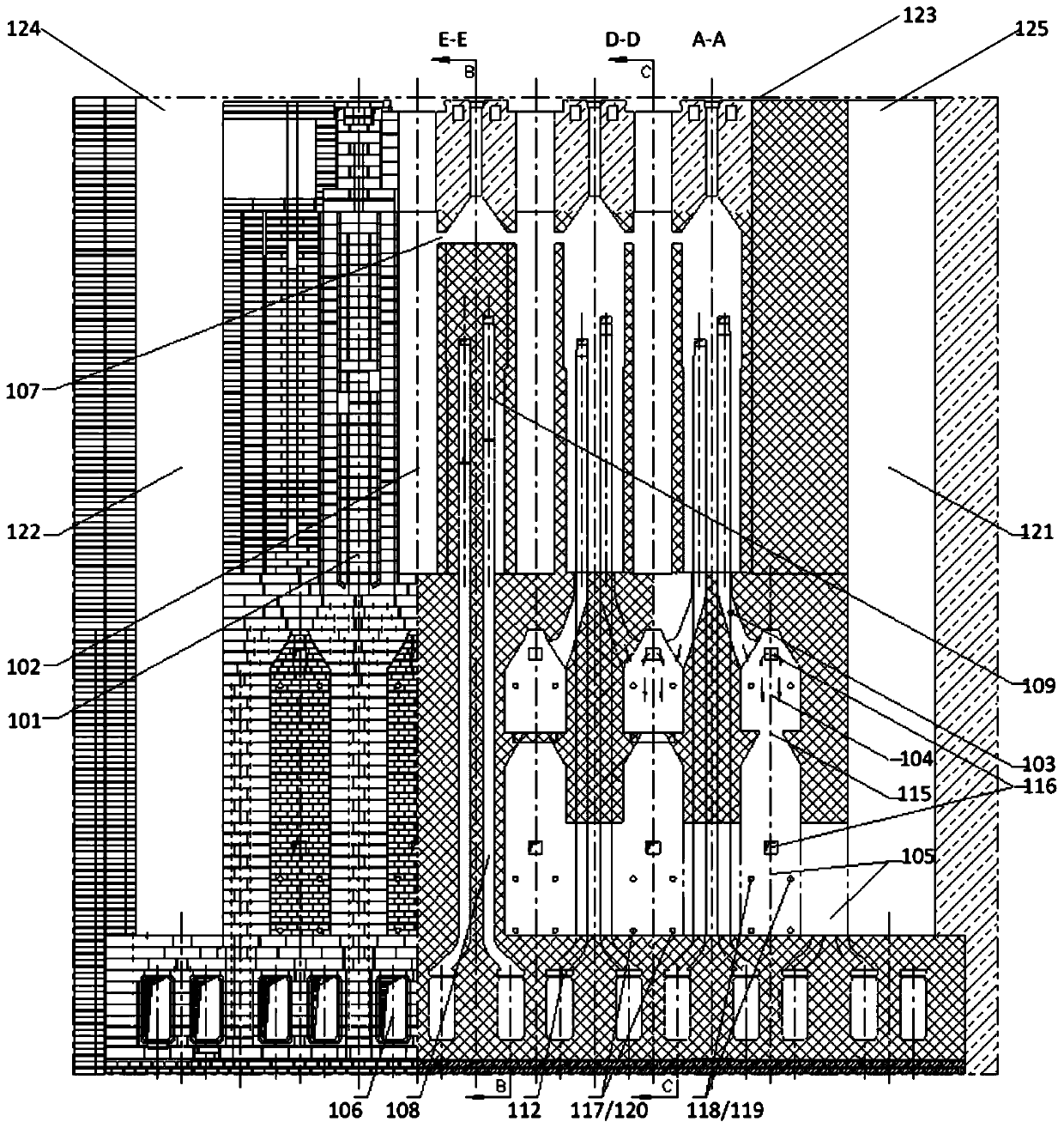

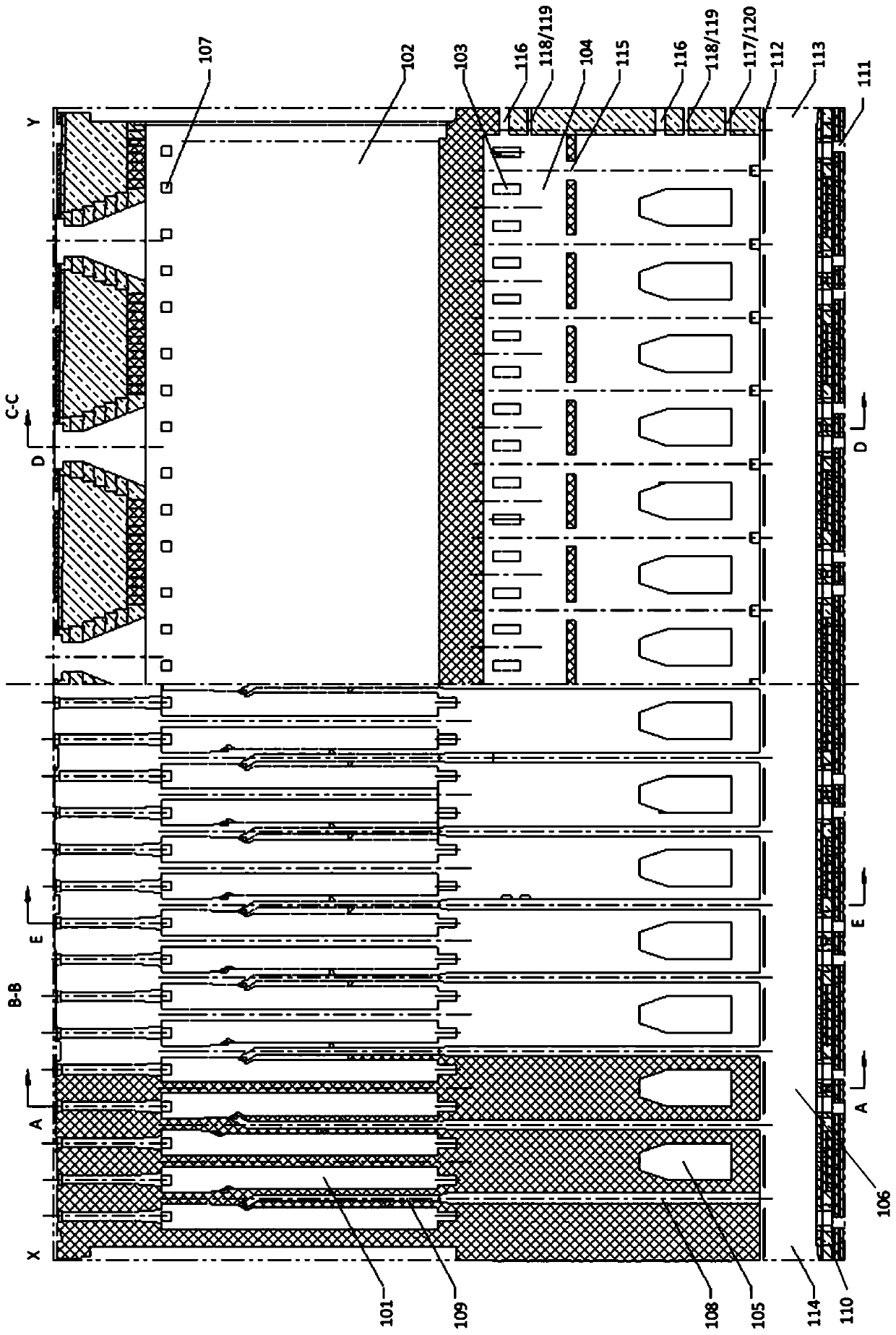

[0065] combined with figure 1 , 2 , this embodiment provides an air preheating heat recovery coke oven, including a combustion chamber 101, a carbonization chamber 102, a chute 103, a pressure balance chamber 104, a vertical and horizontal exhaust gas flue 105, and a combustion air distribution channel 106, wherein:

[0066] The combustion chamber 101 is composed of vertical fire passages, and fire passage partition walls are set up between the vertical fire passages;

[0067] The top of the carbonization chamber 102 and the top of the combustion chamber 101 are provided with a raw gas channel 107;

[0068] The chute 103 is connected between the combustion chamber 101 and the pressure balance chamber 104, and communicates the combustion chamber 101 and the pressure balance chamber 104; partition formation;

[0069] The vertical and horizontal exhaust gas flue 105 is arranged at the lower part of the pressure balance chamber 104 and communicates with the pressure balance cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com