Radiant Tube Heating

A technology of tubular heating and radiant tubes, which is applied in the direction of lighting and heating equipment, burners, combustion types, etc., can solve the problems of thermal efficiency improvement limitations, environmental hazards, etc., and achieve the effect of suppressing local rise and suppressing generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Next, modes for carrying out the present invention will be described.

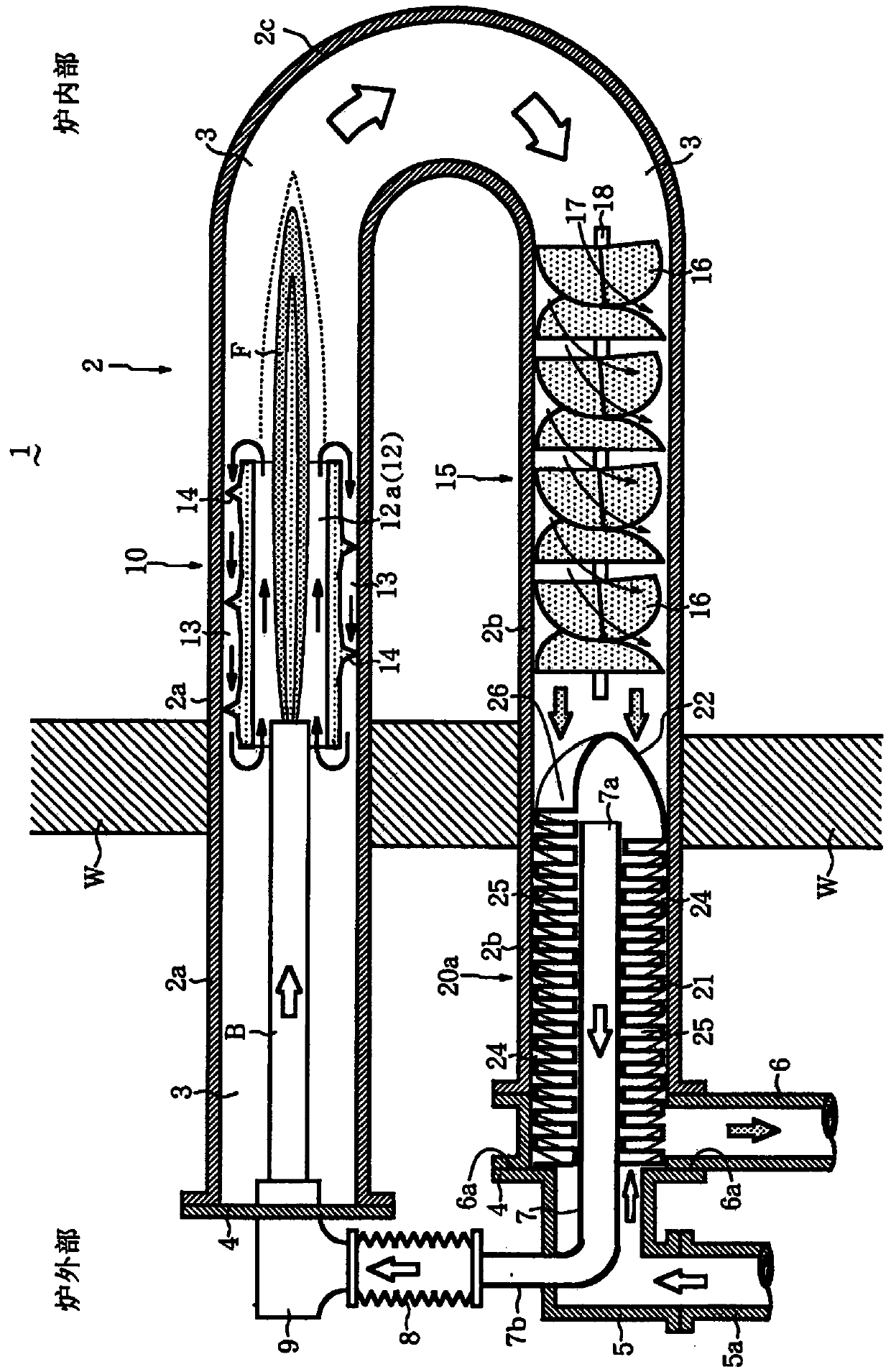

[0067] figure 1 is a vertical sectional view showing the radiant tube heating device 1 according to the embodiment of the present invention. The radiant tube heating device 1 corresponds to the third radiant tube heating device described above.

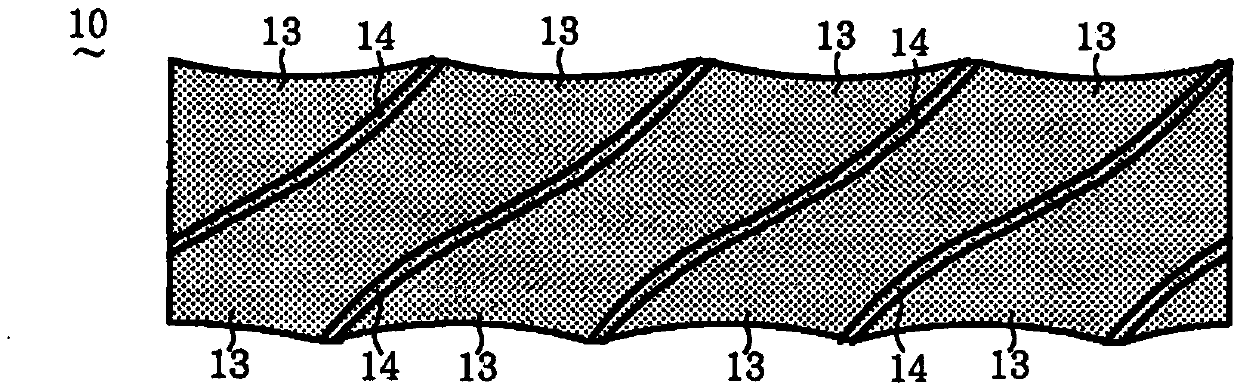

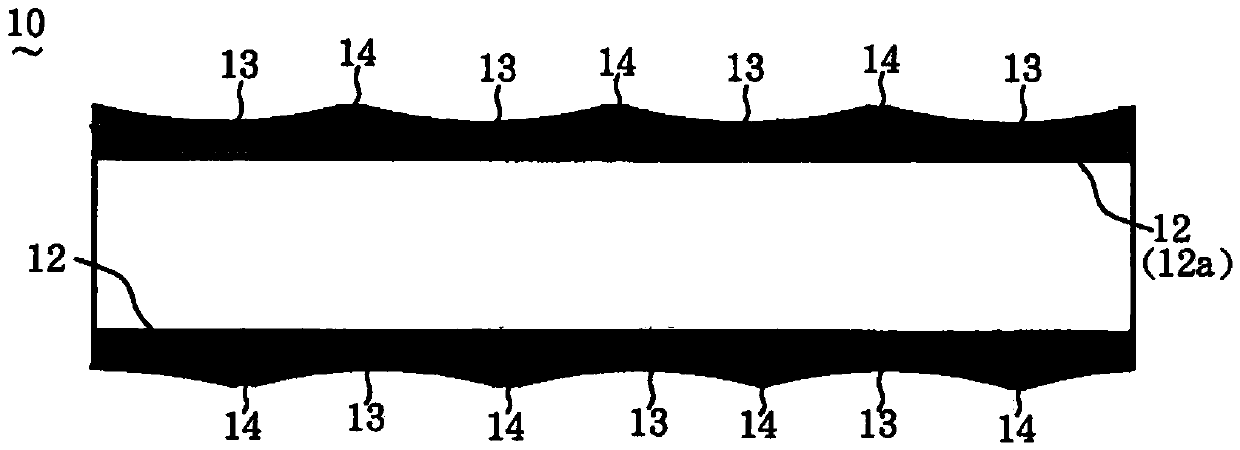

[0068] Such as figure 1 As shown, the radiant tube heating device 1 includes: a tubular radiant tube 2, which passes through the furnace wall (furnace body) W horizontally along the inner and outer directions; a burner B, which is coaxially arranged on one end side of the radiant tube 2 In the central portion of the hollow portion 3 of the radiant tube 2; the temperature rise suppressing member 10 arranged in the hollow portion 3 at a position surrounding the opening portion on the tip side of the burner B; and the heat radiation member 15 and the heat exchanger 20a , which are successively arranged in the hollow portion 3 on the other end side of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com