Distributed natural gas hydrogen production reactor

A hydrogen production reactor and natural gas technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restarting the time interval, reducing the reaction coil temperature, reducing the service life of the device, etc., to achieve energy utilization Maximization, improved reaction efficiency, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

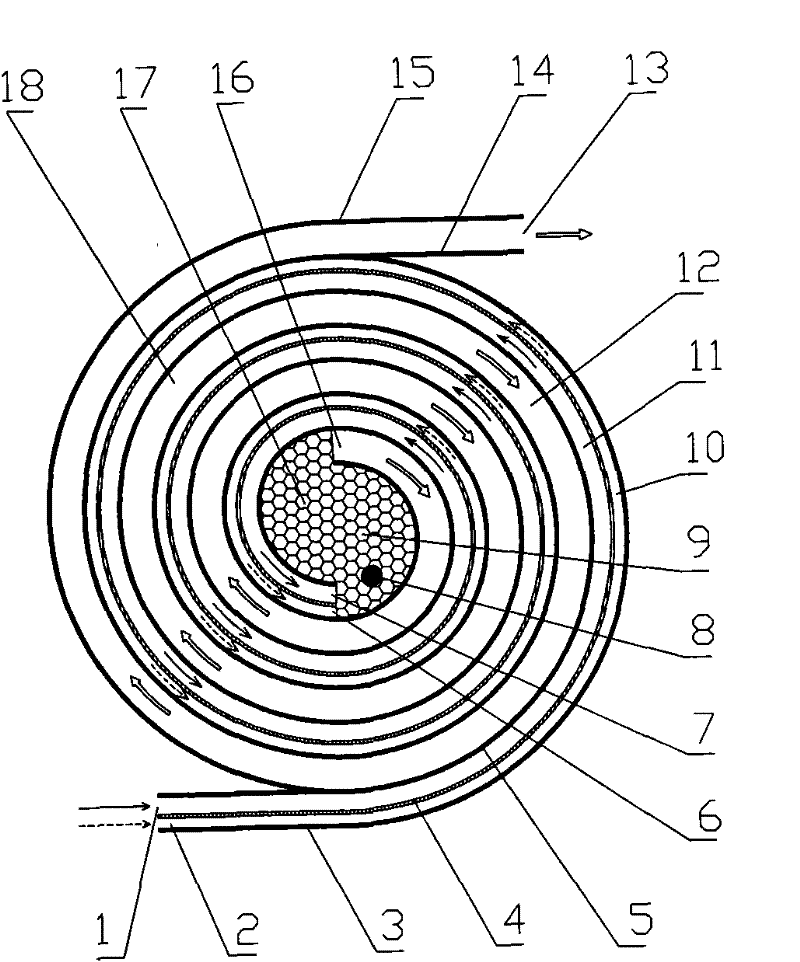

[0024] figure 1 A structural schematic diagram of this embodiment is given when the multiple counterflow heat exchanger 18 has a spiral ring shape, the number of turns of the intake passage and the exhaust passage 12 are 3, and the central reaction zone 17 is not divided.

[0025] The distributed natural gas hydrogen production reactor includes: an air inlet channel outer wall thin plate 3 and an air inlet channel inner wall thin plate 5, and an exhaust channel outer wall thin plate 15 and an exhaust channel inner wall thin plate 14 to form a bidirectional countercurrent annular inlet The channel and the exhaust channel 12, the porous medium 9 placed in the central reaction zone 17 in the multiple counterflow heat exchangers 18, and the ignition rod 8 placed in the porous medium 9.

[0026] In specific implementation, the number of turns of the annular intake passage and the annular exhaust passage 12 may be 3-20, and the shape may be a spiral ring shape or a spiral square ring shap...

Embodiment 2

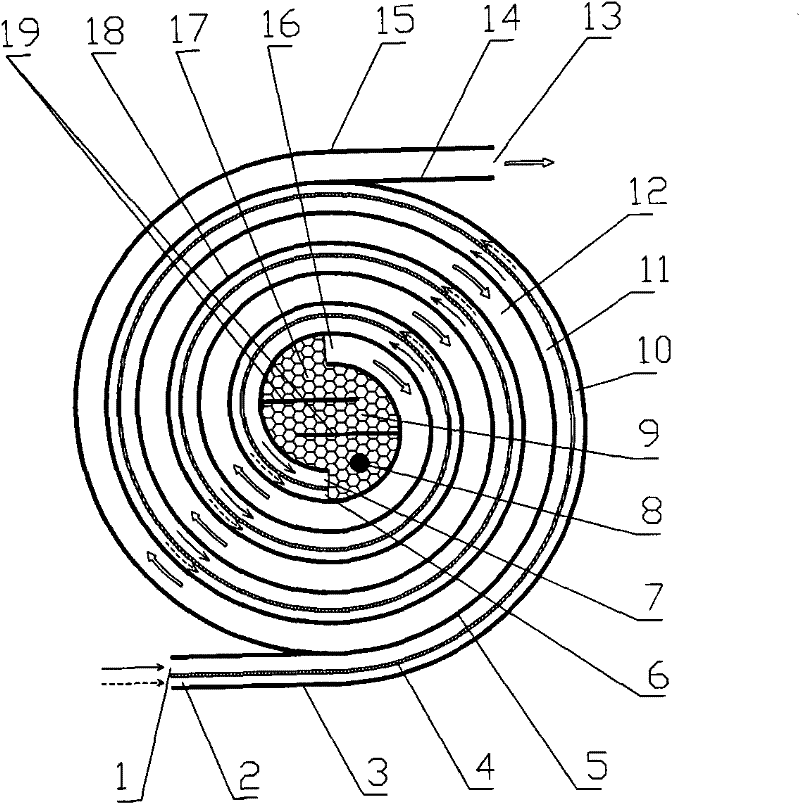

[0033] figure 2 The structure diagram of the embodiment in the case where the multi-strand counterflow heat exchanger 18 has a spiral ring shape, the number of turns of the intake passage and the exhaust passage 12 are three, and the central reaction zone 17 is arranged with two partitions 19 .

[0034] In this embodiment, two partitions 19 added to the central reaction zone 17 separate the central reaction zone 17 into a zigzag-shaped baffle channel. The rest of the structural features are the same as the first embodiment, and the operation method is also the same as the first embodiment.

Embodiment 3

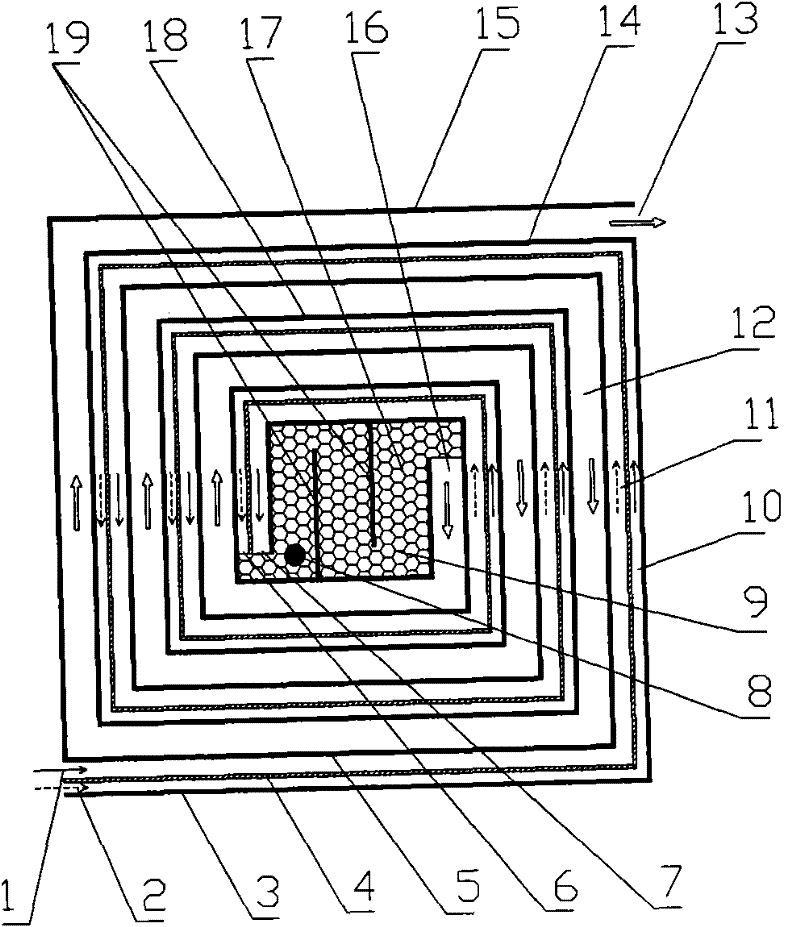

[0036] image 3 The embodiment structure in the case where the multiple counterflow heat exchanger 18 is a spiral square ring, the number of turns of the intake passage and the exhaust passage 12 are three, and the central reaction zone 17 is arranged with two partitions 19 Schematic.

[0037] The other structural forms in this embodiment are the same as those in the second embodiment, and the operating method is the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com