Anti-corrosion compact checker brick for upper part of coke oven regenerative chamber and preparation method thereof

A technology of compact checker bricks, applied in the field of coking, can solve the problems of high impurity content of semi-silica bricks, poor high temperature resistance, poor corrosion resistance, etc., achieve high softening temperature under load, reduce production costs, and high temperature pressure creep Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

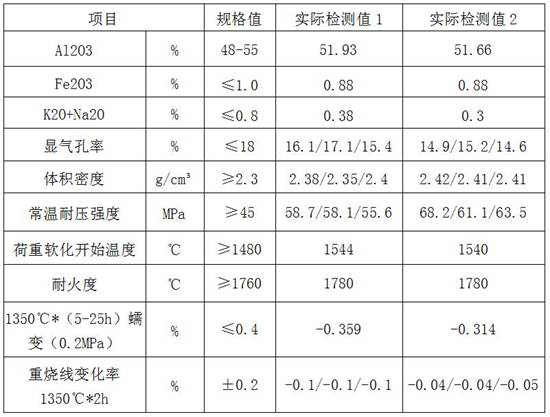

Image

Examples

Embodiment 1

[0026] An anti-alteration dense checker brick for the upper part of a coke oven regenerator, which is composed of the following raw materials in parts by weight:

[0027] 25 parts of low-alumina mullite particles with a particle size of 0.1mm, 15 parts of andalusite, 4 parts of high-temperature alumina micropowder with a particle size of 0.003mm, 10 parts of high-purity kaolin fine powder with a particle size of 0.074mm, and clay with a particle size of 0.045mm 10 parts, 5 parts of dextrin solution.

[0028] The preparation method of the anti-alteration dense checker brick, (1) first mix andalusite fine powder, alumina fine powder, kaolin fine powder and clay evenly to make a mixed powder; mix low-aluminum mullite particles and andalusite particles Evenly, then add the binder and mix for 2 minutes; finally add the mixed powder and mix for 5 minutes, and the effective mixing time is 10 minutes to obtain a uniformly mixed mud;

[0029] (2) Use an inclined high-speed mixer for m...

Embodiment 2

[0031] An anti-alteration dense checker brick for the upper part of a coke oven regenerator, which is composed of the following raw materials in parts by weight:

[0032] 60 parts of low-alumina mullite particles with a particle size of 3 mm, 25 parts of andalusite, 6 parts of high-temperature alumina micropowder with a particle size of 0.003 mm, 15 parts of high-purity kaolin fine powder with a particle size of 0.074 mm, and 15 parts of clay with a particle size of 0.045 mm Parts, 6 parts of dextrin solution.

[0033] The preparation method of the anti-alteration dense checker brick, (1) first mix andalusite fine powder, alumina fine powder, kaolin fine powder and clay evenly to make a mixed powder; mix low-alumina mullite particles, red Mix the pillar stone particles evenly, then add the binder, and mix for 3 minutes; finally add the mixed powder, mix for 7 minutes, and the effective mixing time is 10 minutes to obtain a uniformly mixed mud;

[0034] (2) Use an inclined hig...

Embodiment 3

[0036] An anti-alteration dense checker brick for the upper part of a coke oven regenerator, which is composed of the following raw materials in parts by weight:

[0037] 40 parts of low-alumina mullite particles with a particle size of 1 mm, 20 parts of andalusite, 5 parts of high-temperature alumina micropowder with a particle size of 0.003 mm, 12 parts of high-purity kaolin fine powder with a particle size of 0.074 mm, and 13 parts of clay with a particle size of 0.045 mm Parts, 5.5 parts of dextrin solution.

[0038] The preparation method of the anti-alteration dense checker brick, (1) first mix andalusite fine powder, alumina fine powder, kaolin fine powder and clay evenly to make a mixed powder; mix low-alumina mullite particles, red Mix the pillar stone particles evenly, then add the binder, and mix for 2.5 minutes; finally add the mixed powder, mix for 6 minutes, and the effective mixing time is 10 minutes to obtain a uniformly mixed mud;

[0039] (2) Use an inclined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com