Low-temperature carbonization method of directly heating formed coke

A low-temperature carbonization and heating technology, which is used in the coking of carbon-containing materials, coke ovens, petroleum industry, etc., can solve the problems of increasing production costs and complicating the process flow of coke, so as to improve the coking value, shorten the carbonization and coking time, Effect of promoting thermal decomposition polycondensation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

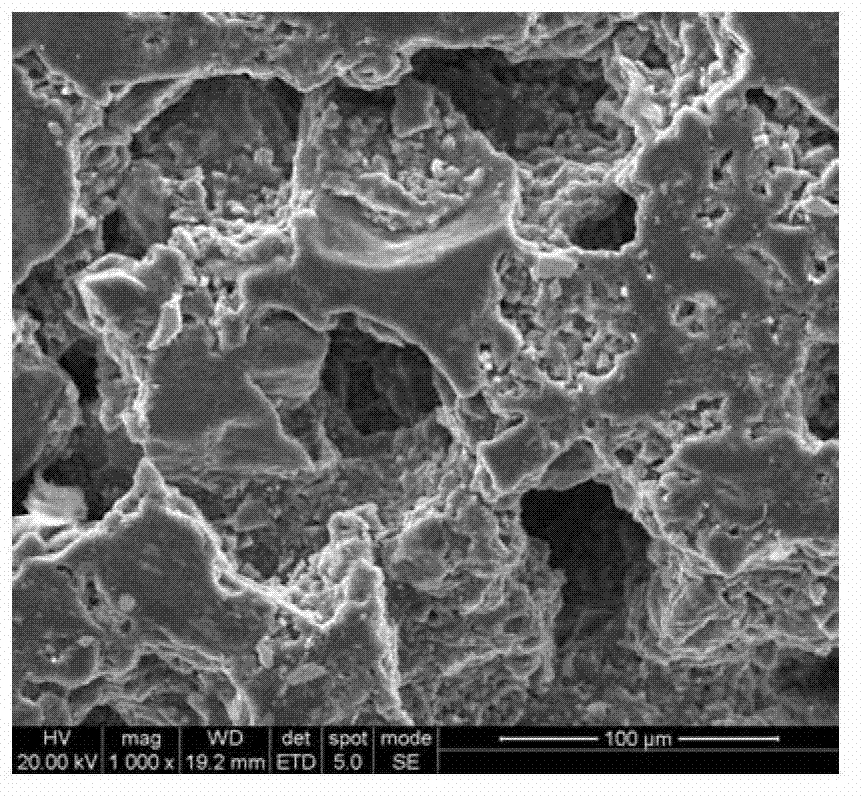

[0022] Example 1: 10% coal tar pitch with a mass ratio of 10% and fine coke powder with a mass ratio of 10% are pre-co-milled. After co-grinding, the volume average particle size of the powder is less than 30.0 μm, and the asphalt particle size is less than 0.15 mm. Then mix it with coke powder with a mass ratio of 80% and a particle size of -5mm, and then add water accounting for 10% of the total mass of the mixed material and xylene accounting for 20% of the asphalt mass, and mix again, and often warm and compact Forming and volatilization treatment at 370°C for 20 minutes to obtain volatile blocks, and finally put the volatile blocks in N 2 Formed coke was obtained by carbonizing at 600°C for 30 minutes in an ordinary electric resistance furnace under atmosphere. The compressive strength of the coke is 18.8Mpa.

Embodiment 2

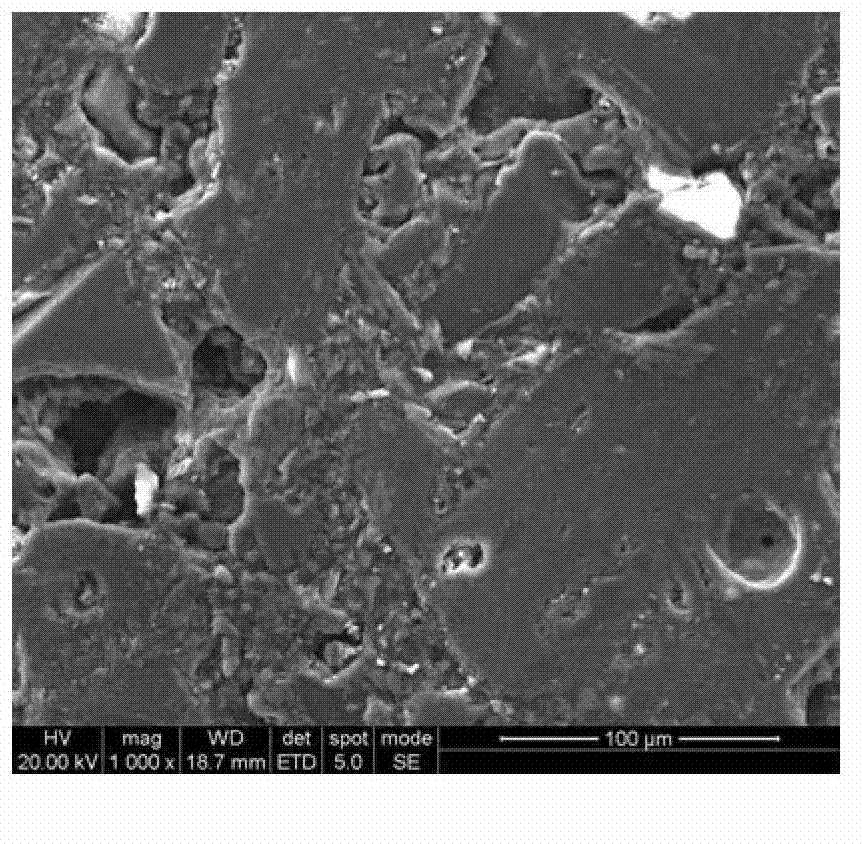

[0023] Embodiment 2: the volatilization block among the embodiment 1 is in CO 2 Formed coke was obtained by carbonizing at 600°C for 30 minutes in an ordinary electric resistance furnace under atmosphere. The compressive strength of the coke is 19.1Mpa.

Embodiment 3

[0024] Example 3: Take the volatile block in Example 1, and carbonize the volatile block in an ordinary electric resistance furnace at 600° C. for 30 minutes in an air atmosphere to obtain a carbonized block with a compressive strength of 18.1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com