Patents

Literature

41results about How to "Improve bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

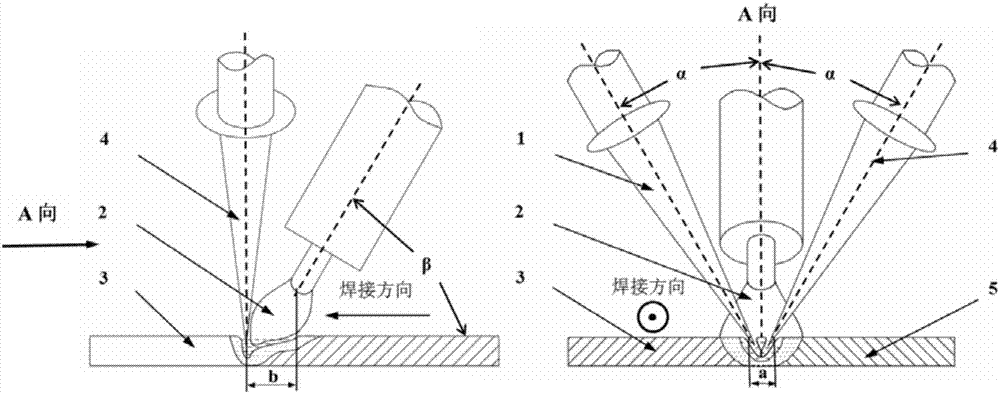

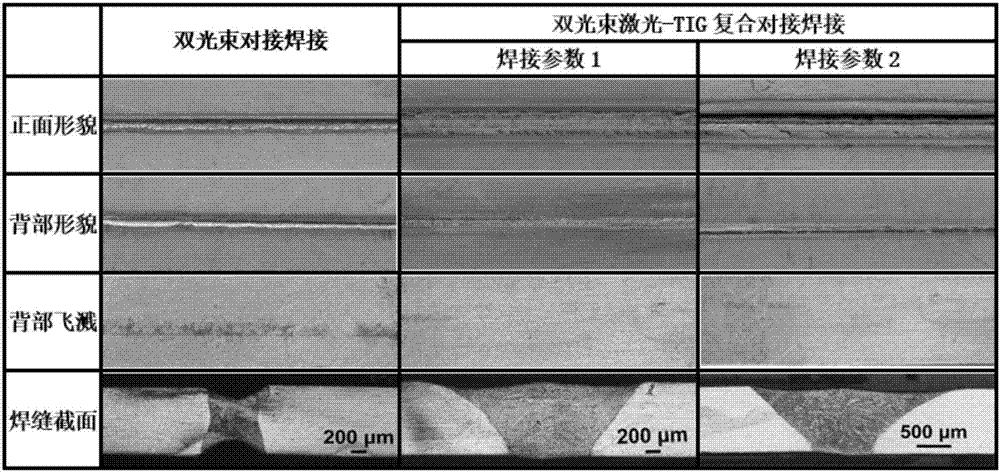

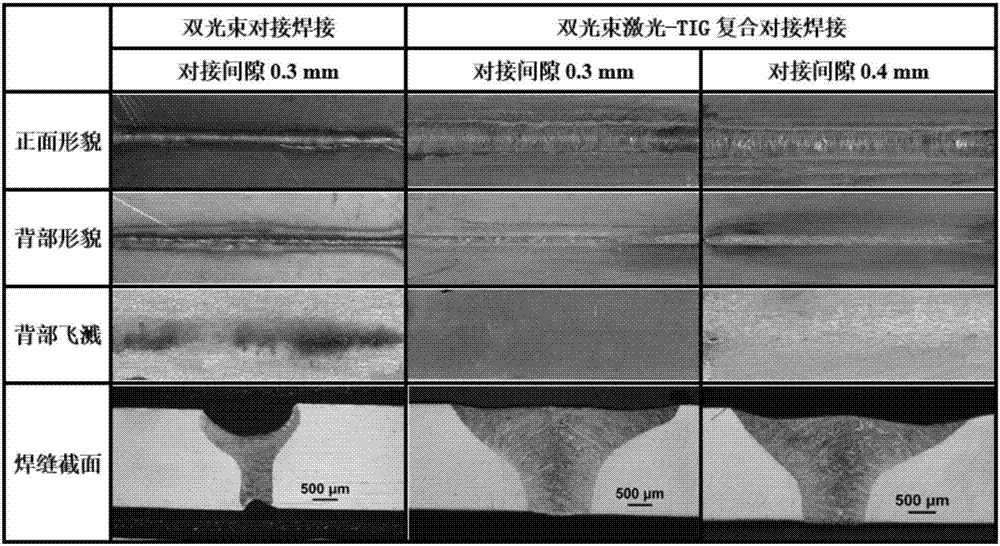

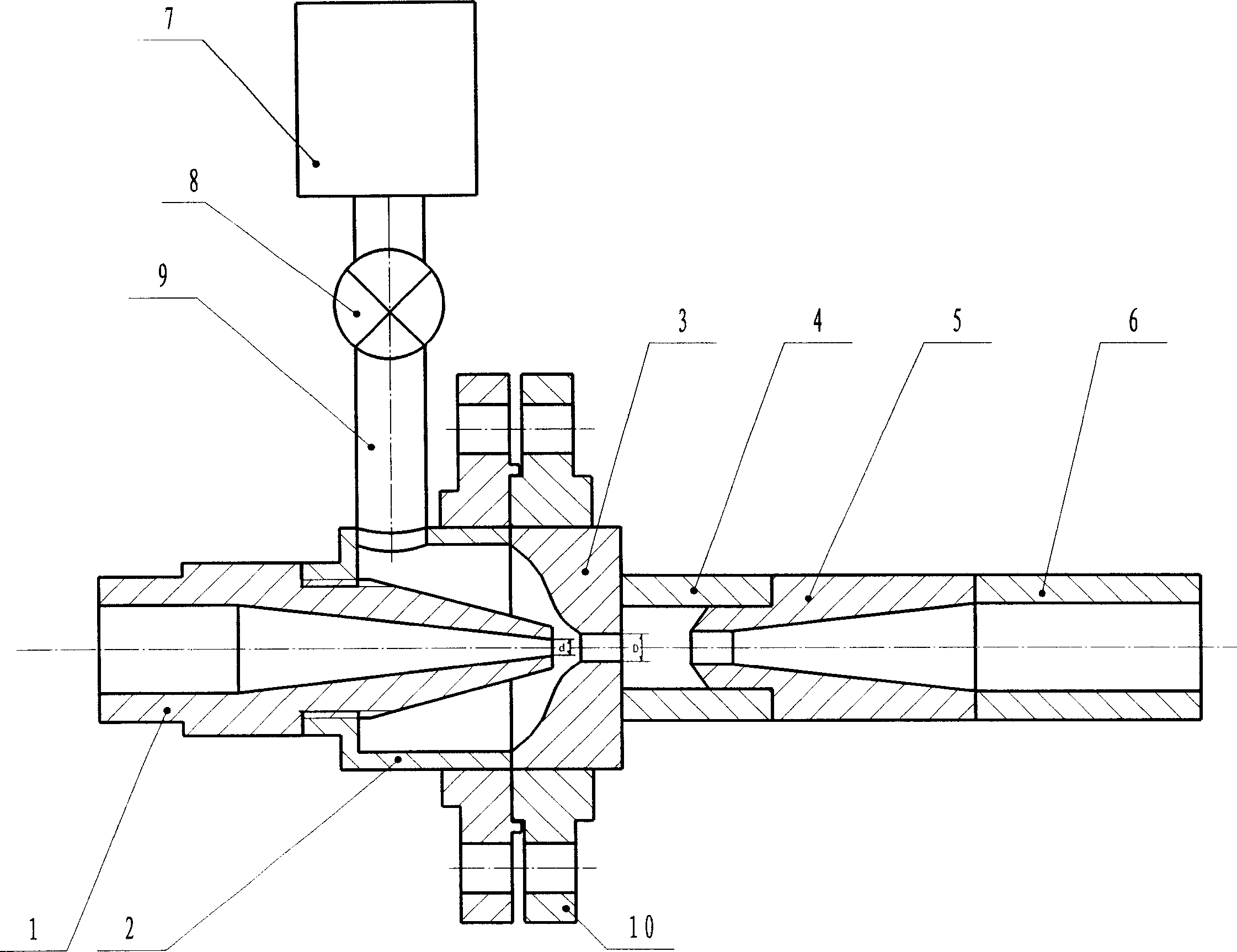

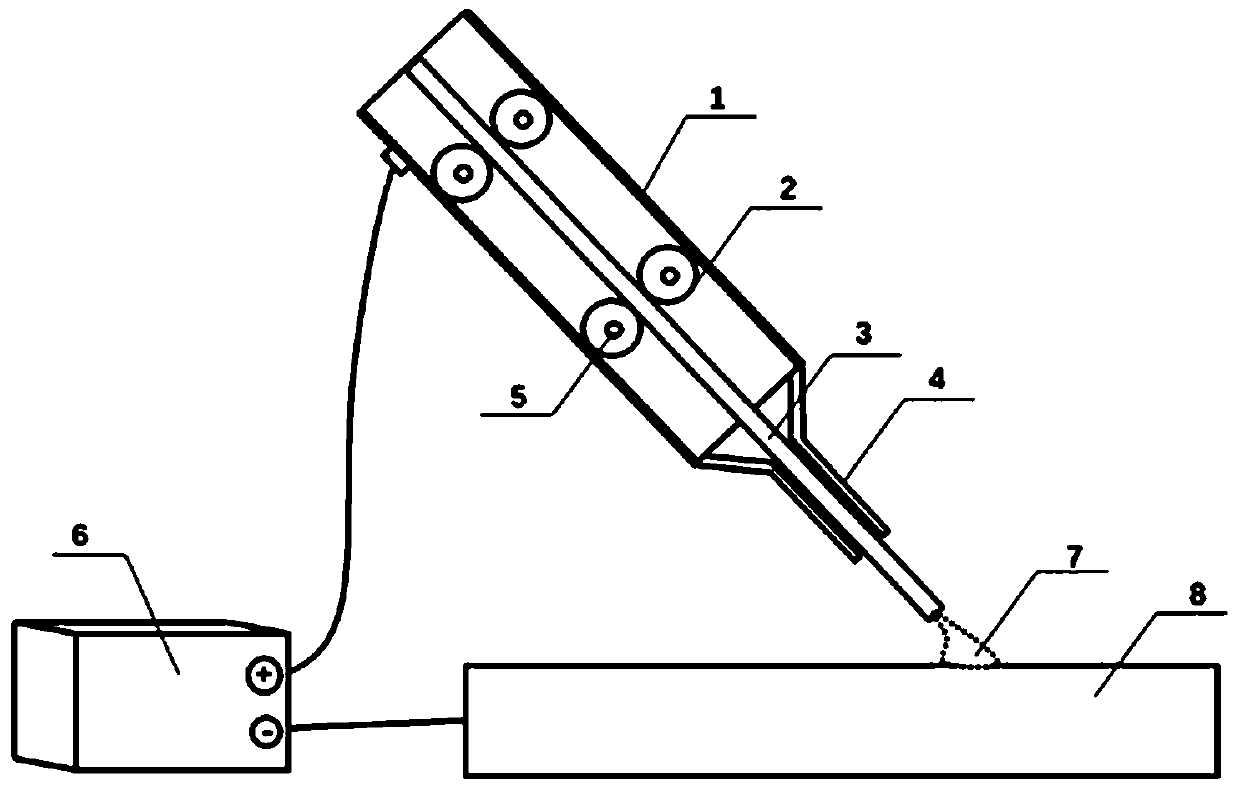

Double-beam laser TIG composite welding process for thin plate butt welding net forming

InactiveCN106944756AImprove bridgingImprove adaptabilityWelding/soldering/cutting articlesMetal working apparatusButt weldingButt joint

The invention discloses a double-beam laser TIG composite welding process for thin plate butt welding net forming, and the double-beam laser TIG composite welding process is suitable for butt welding of a thin plate. A provided welding method is suitable for realizing butt welding net forming of the thin plate under a butt joint clearance condition, and defects such as the sinking, the undercut, the back protrusion and splash which are prone to appear in a butt welding process are overcame. The process is characterized in that a butt welding seam serves as a center, incidence of double laser beams is conducted obliquely, and focuses of the double laser beams are symmetrically distributed on mental base materials at the two sides of the butt clearance; and a centre line of a TIG electric arc is in the same plane as a centre line of the butt welding seam and has a certain angle with a plate face; during the welding, the TIG electric arc is located at the rear side of the perpendicular bisector of the connection line of the focuses of the double laser beams. Compared with the traditional laser butt welding method, the clearance adaptability of the double-beam laser TIG composite welding process for thin plate butt welding net forming is greatly improved in the thin plate butt welding process, the weld width of a welding seam is obviously increased, surface forming and back forming of the welding seam are significantly improved, and the defects of back splash, protrusions and the like are effectively suppressed.

Owner:BEIJING UNIV OF TECH

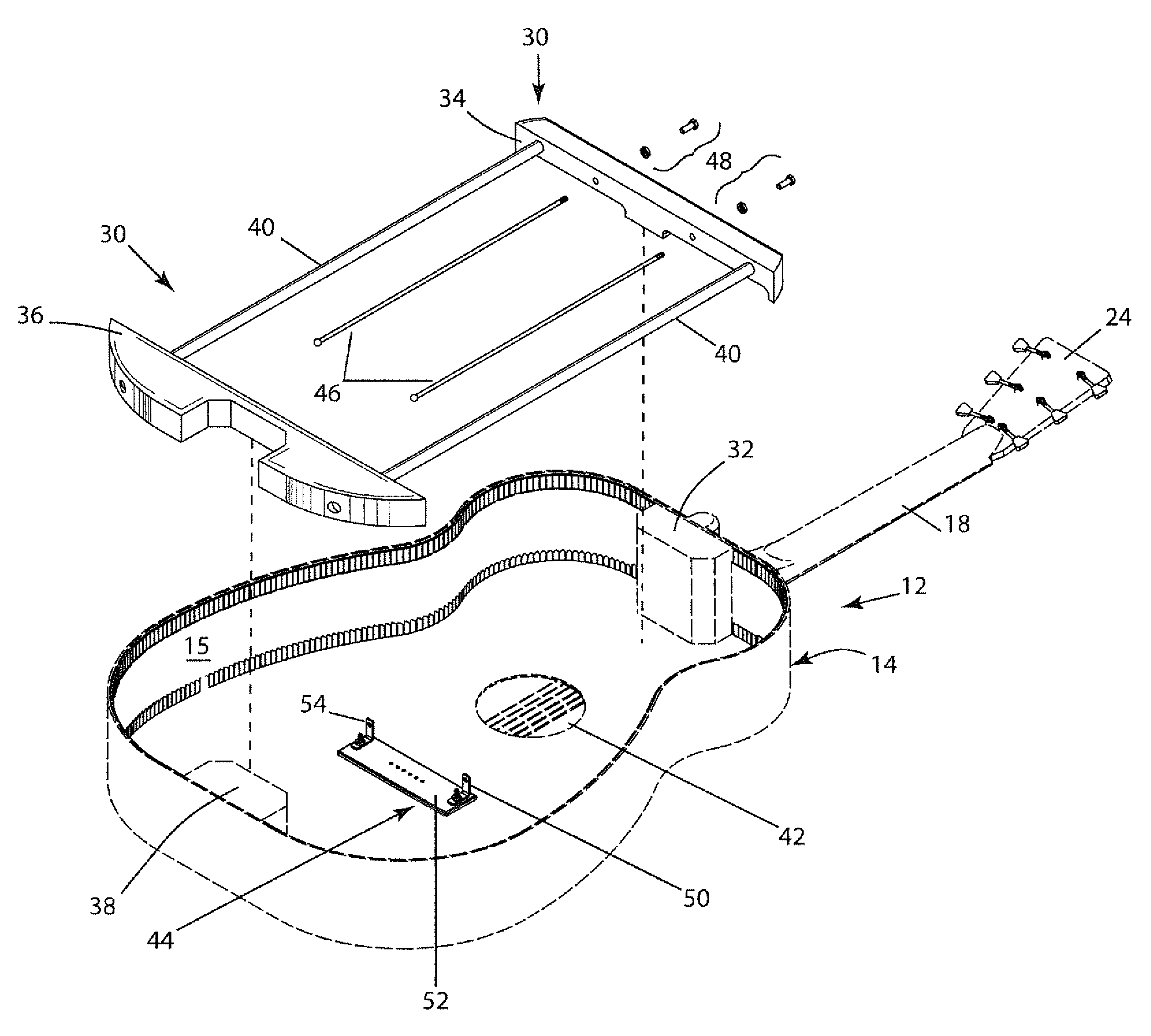

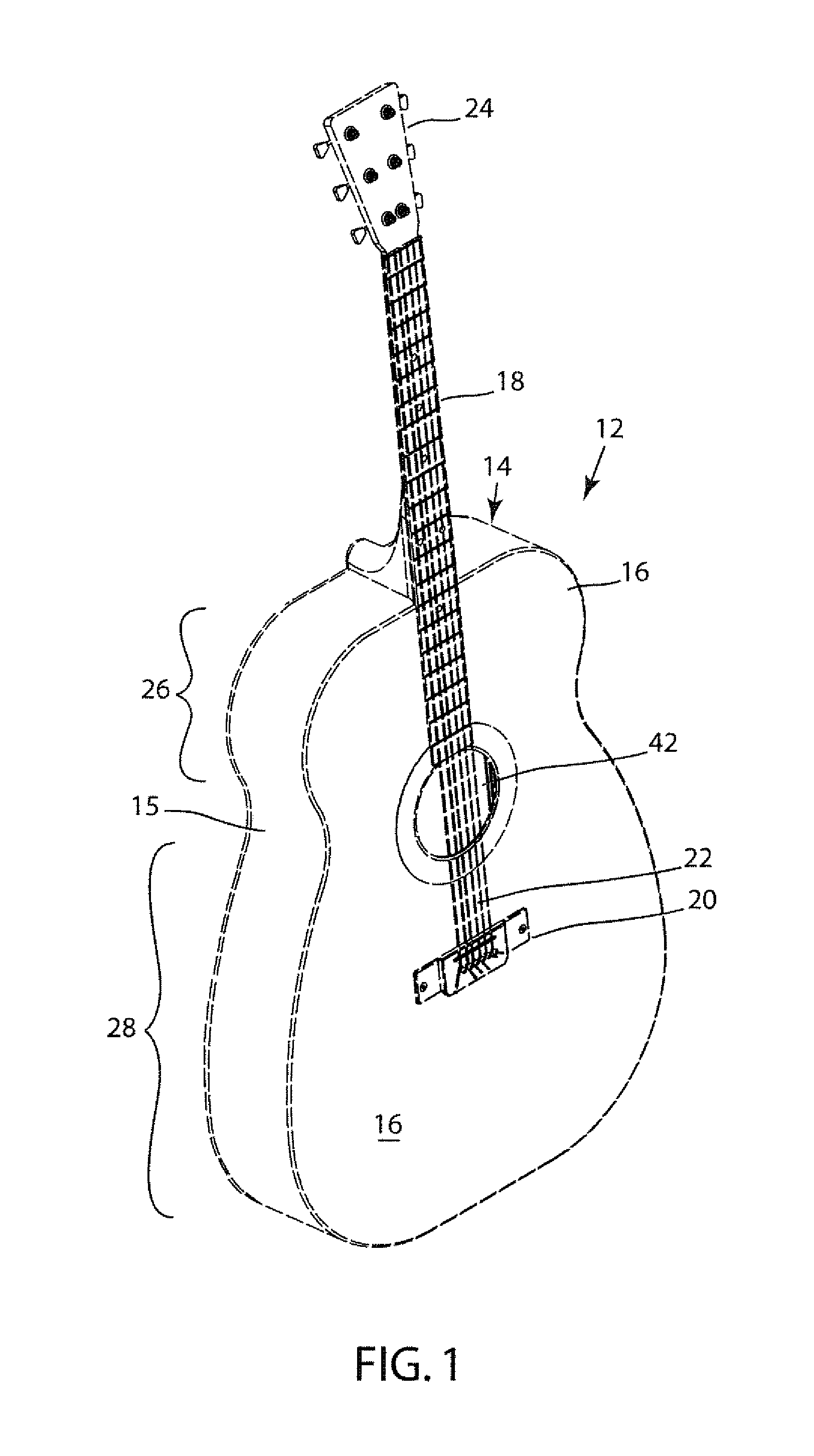

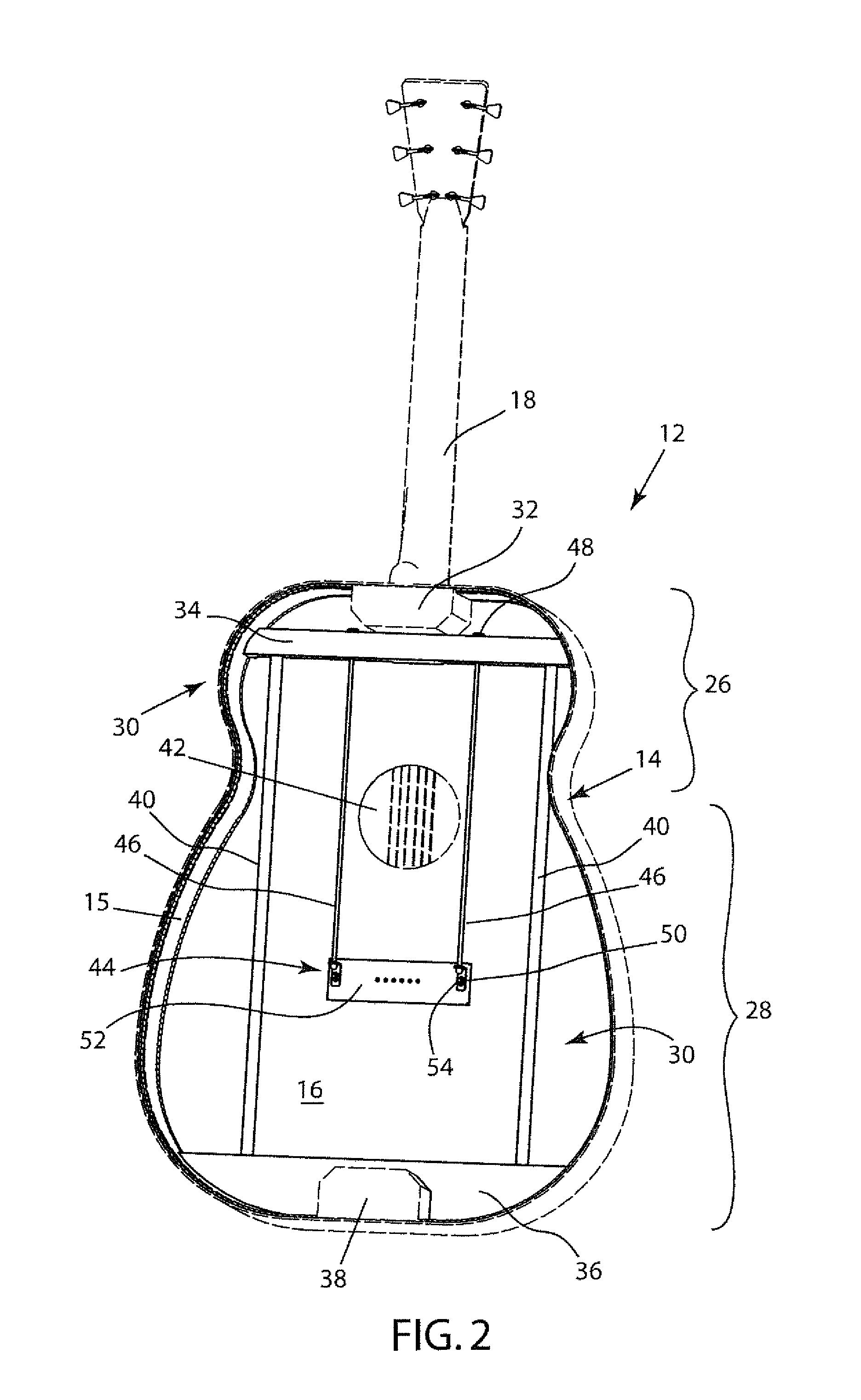

Brace for stringed instrument

A new and improved body and bridge bracing system for stringed musical instruments includes an bracing system that consists of an upper brace located in the upper body of the instrument's body and a lower brace located in the lower body. Two or more longitudinal braces connect to each of the lateral braces and provide the instrument's neck, body, and soundboard support against the constant stress of the strings. A bridge reinforcing means is also included and consists of two or more truss rods. The rods connect the upper body lateral brace to the bridge area and further counteract the tension of the strings thereby preventing damage to the bridge and soundboard.

Owner:KEMP CHRISTOPHER CLAYTON

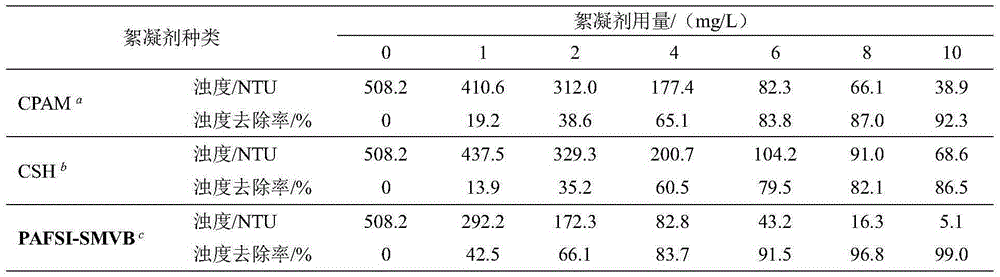

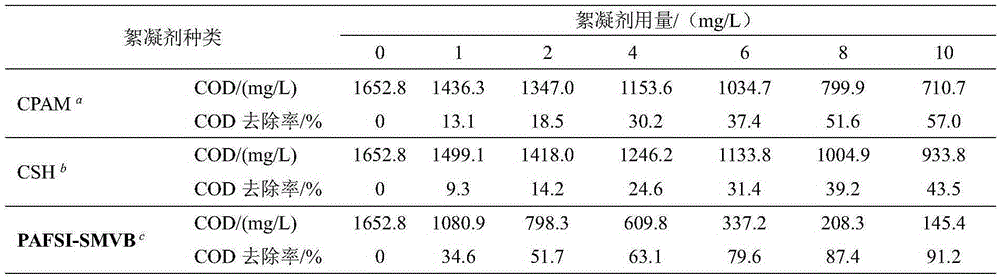

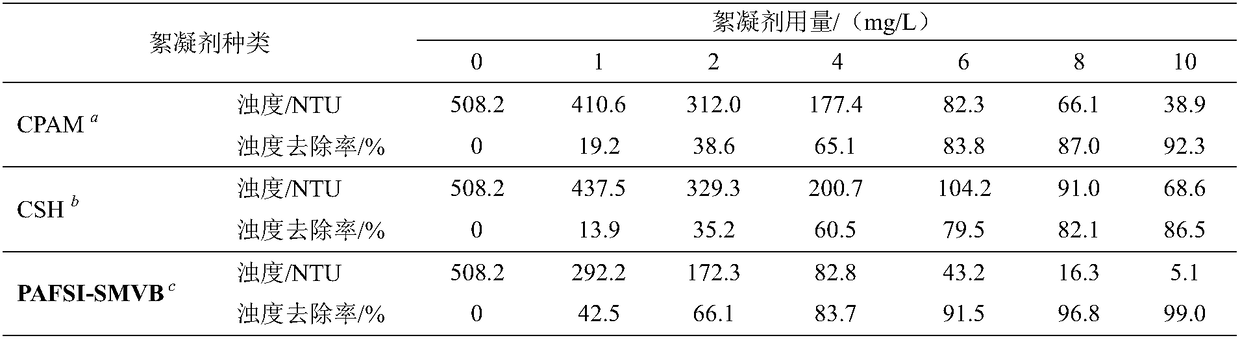

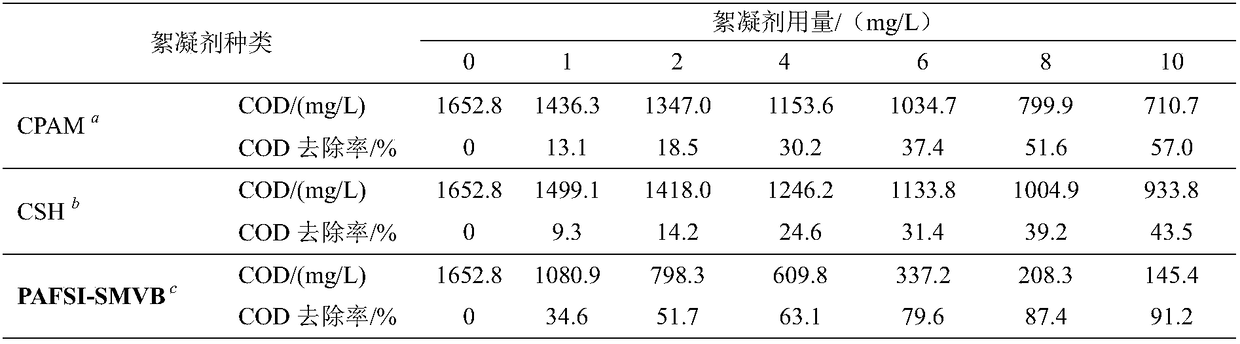

Preparation method of namometer PAFSI (polyaluminum ferric silicate)-graft modified starch hybrid flocculent

InactiveCN105417655AImprove solubilityGood electrical neutralizationWater/sewage treatment by flocculation/precipitationIonAluminum silicate

The invention discloses a preparation method of a namometer PAFSI-graft modified starch hybrid flocculent. The preparation method is characterized by comprises the steps that 20 parts of Na2SiO3 and 350 parts of deionized water are added to a reaction bottle, the pH value ranges from 2 to 5, the room temperature reaction is performed for 2-3 h, and activated silicic acid is prepared; a certain amount of AlCl3 and FeCl3 ethylene glycol solution is added slowly in 20 parts of activated silicic acid for reaction, 1-5 parts of CTAC (cetanecyl trimethyl ammonium chloride) is added after cooling, curing is performed, and namometer PAFSI is prepared; 20 parts of starch and 20-400 parts of deionized water are added to the reaction bottle, N2 is fed, the starch is cooled to 30 DEG C after gelatinized for 0.5-1 h under stirring and at the temperature of 65 DEG C to 90 DEG C, 0.5-6.0 parts of CTAC is added, 2-10 parts of nanometer PAFSI is added, the pH value ranges from 5 to 7, 0.05-0.5 part of potassium persulfate and 0.02-0.3 part of sodium sulphite are added at the temperature of 30 DEG C to 55 DEG C, 3-10 parts of cationic monomers and 2-10 parts of macromonomers are added slowly, N2 is fed, the reaction is performed for 4-8 h, and the namometer PAFSI-graft modified starch hybrid flocculent is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

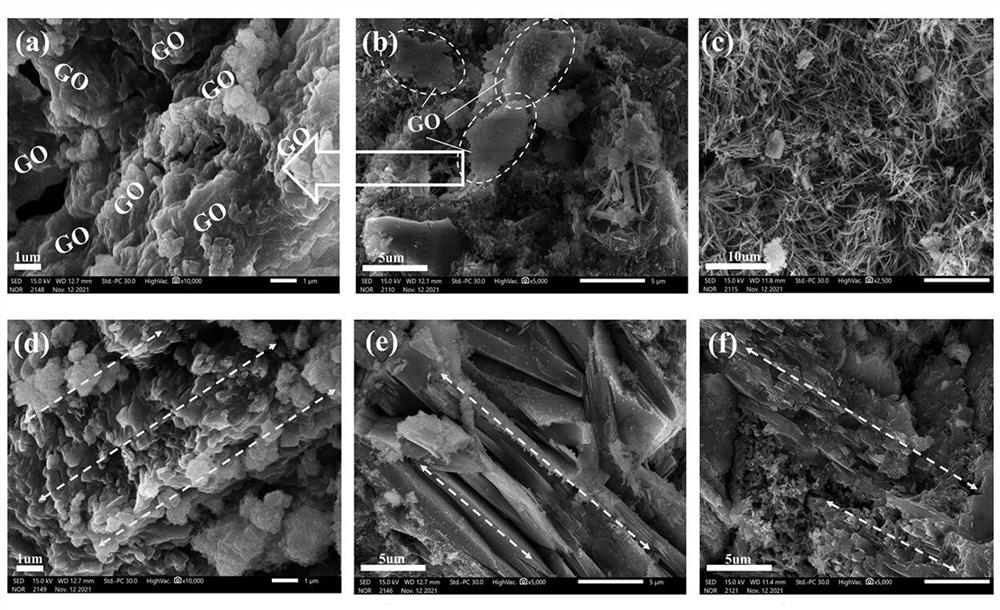

Preparation method of high-toughness biomimetic structured graphene-based ceramic composite material

The invention discloses a preparation method of a high-toughness biomimetic structured graphene-based ceramic composite material. The preparation method comprises the following steps: preparing layered porous ceramic blank body by adopting an electrostatic field freeze-drying method, treating by a vacuum infiltration process to make graphene to be completely impregnated into pores of the prefabricated blank, carrying out microwave sintering in the inert gas protection, crystallizing graphene and coating the ceramic crystal surface with graphene crystal to form the microscopic continuously distributed layered shell-like graphene-based ceramic composite material. Compared with traditional ceramic materials, the composite ceramic material has high density and fracture toughness; with excellent performance of graphene, the thermal and electrical properties of the material are significantly improved. The preparation method has huge application value in the fields of transportation, architecture, aerospace, military and the like.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

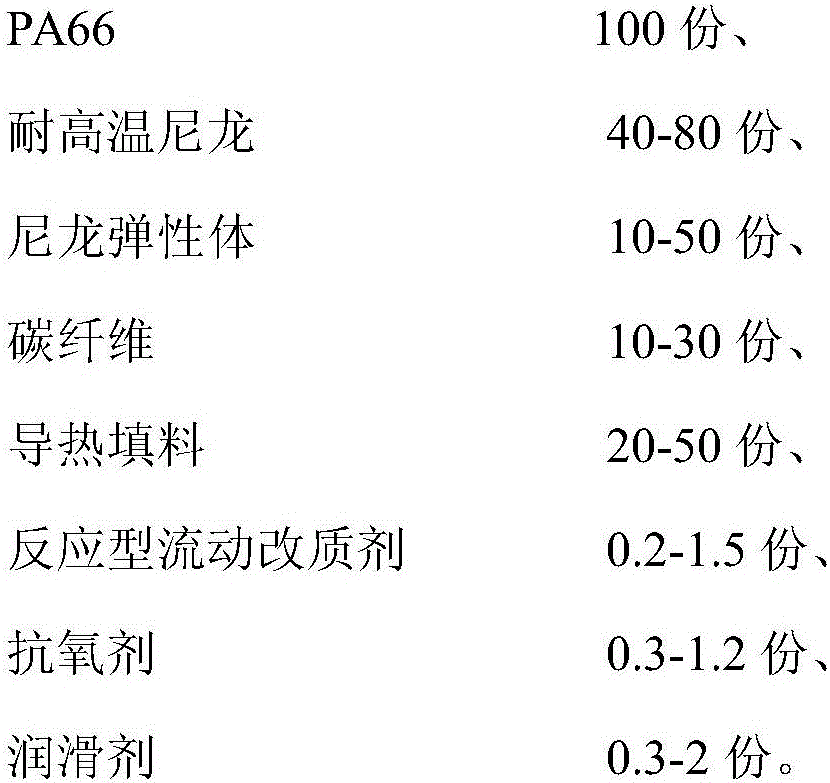

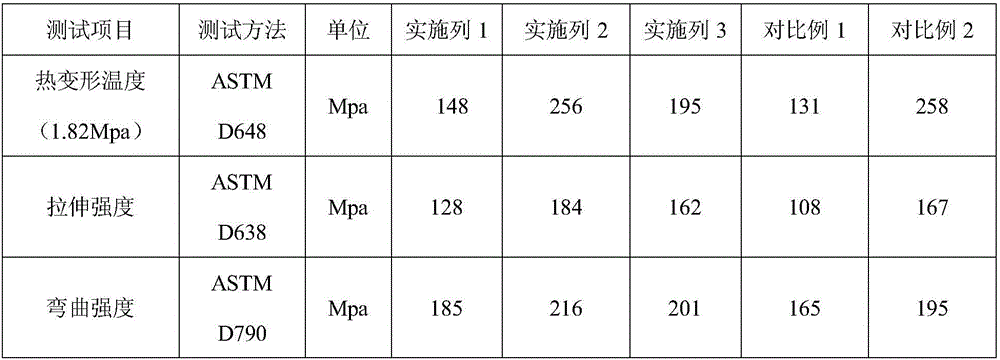

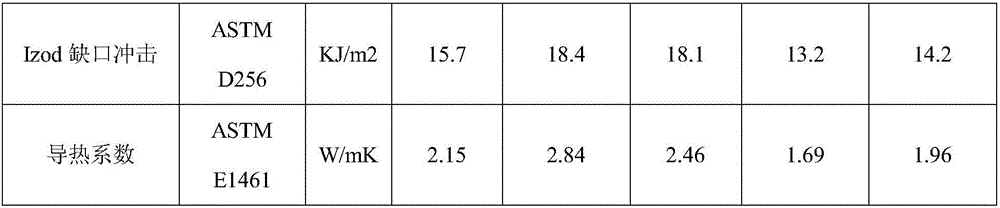

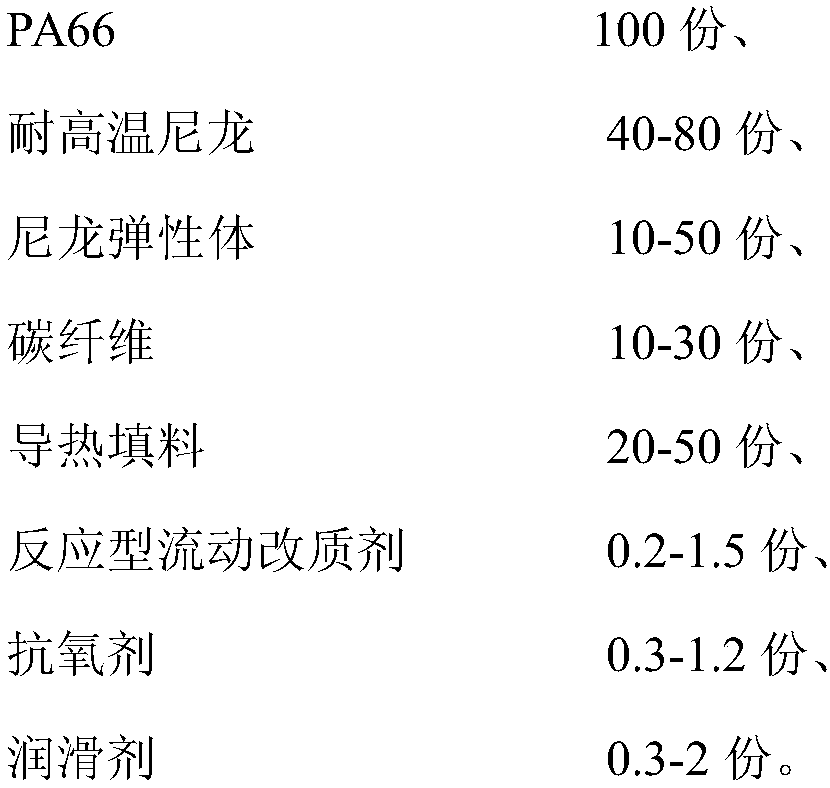

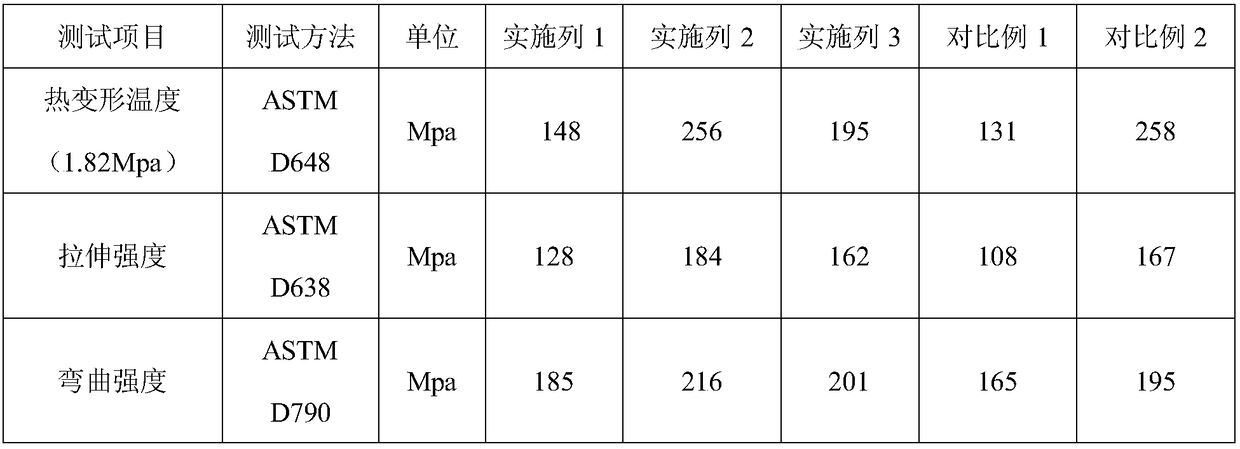

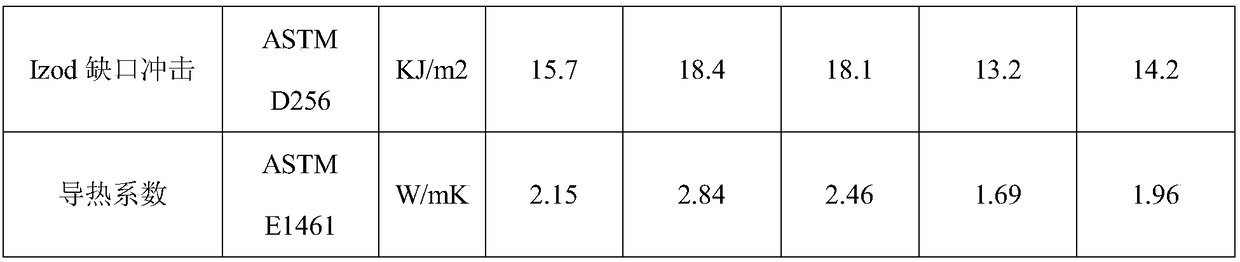

High-temperature-resistant and heat-conductive nylon composite material and preparation method thereof

ActiveCN106147224ATake advantage of ease of processingTake full advantage of high temperature resistanceElastomerGlass fiber

The invention relates to a high-temperature-resistant and heat-conductive nylon composite material and a preparation method thereof. The high-temperature-resistant and heat-conductive nylon composite comprises the following components in parts by weight: 100 parts of PA66, 40-80 parts of high temperature-resistant nylon, 10-50 parts of a nylon elastomer, 10-30 parts of carbon fibers, 20-50 parts of a heat-conductive filler, 0.2-1.5 parts of a reactive flow modifier, 0.3-1.2 parts of an antioxidant and 0.3-2 parts of a lubricating agent. The preparation method comprises the following steps: uniformly pre-mixing the PA66, the high-temperature-resistant nylon, the nylon elastomer, the heat-conductive filler, the reactive flow modifier, the antioxidant and the lubricating agent, adding from a main feeding port of a double-screw extruder, adding the carbon fibers from a glass fiber mouth, controlling the rotating speed to be 800-1200 revolutions / min and the temperature to be 250-285 DEG C and performing extrusion granulation to obtain the high-temperature-resistant and heat-conductive nylon composite material. The material has excellent high temperature resistance and heat conduction and simultaneously has the characteristics of being good in mechanical property and easy to process.

Owner:上海日之升科技有限公司

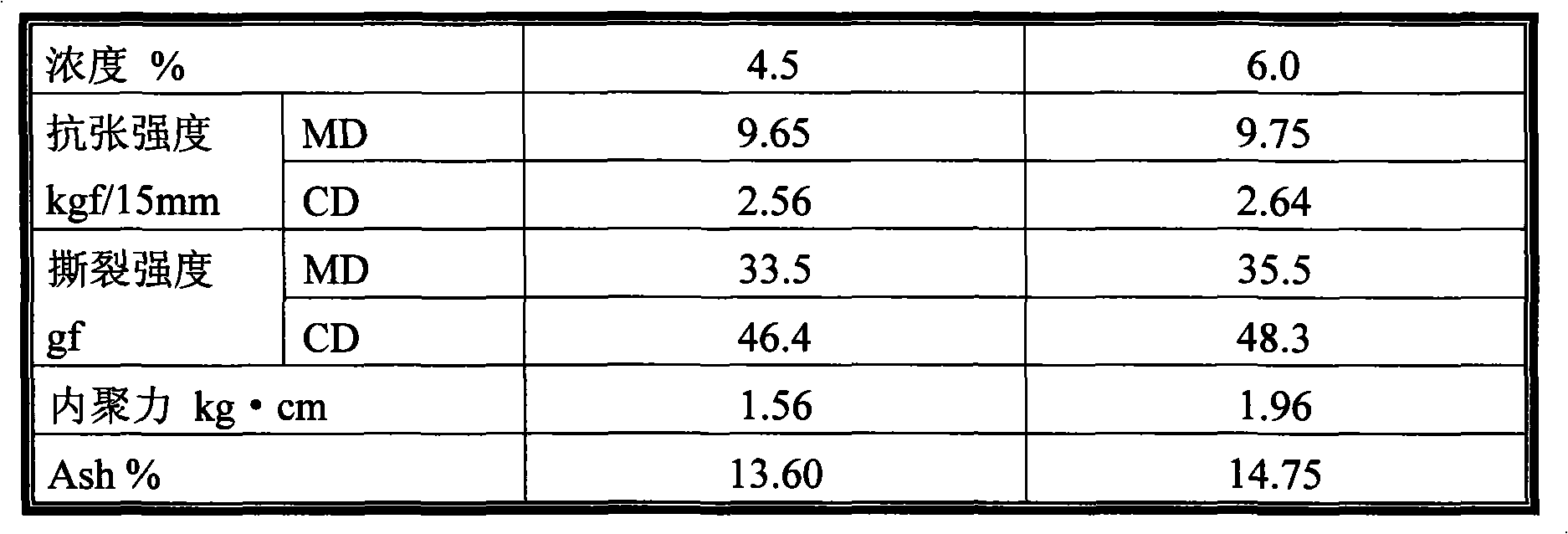

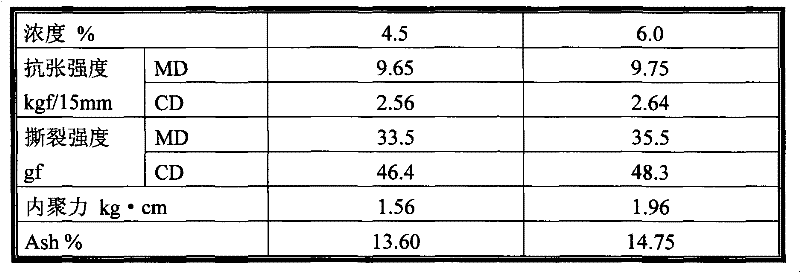

Method for realizing mid-consistency grinding in low-consistency device

InactiveCN101654884AConcentrated Refining RealizationHigh strengthPaper/cardboardChemical/chemomechanical pulpMetallurgySlurry

The invention discloses a method for realizing mid-consistency grinding in a low-consistency grinding device. In a slurry preparing stage, a slurry flowage modifier is added so that the slurry flowability is unchanged after increasing the grinding consistency to realize mid-consistency grinding in the low-consistency grinding device. The method comprises the specific steps as follows: placing paper pulp into a pulper for pulping, and adding a slurry flowage modifier inthe pulping process, wherein the use amount of the flowage modifier is 0.005-5 percent of that of oven dry stock; and grindingthe mid-consistency slurry of 6-8 percent after adding the slurry flowage modifier in the low-consistency grinding device for grinding. The method is simple and safe, and realizes mid-consistency grinding in the low-consistency grinding device without equipment investment; in addition, the manufactured slurry can be applied as ordinary slurry for improving the quality of paper.

Owner:GOLD EAST PAPER JIANGSU

Frustule asphalt modifier, frustules asphalt modifier modified composite asphalt, and preparation method of frustule asphalt modifier

InactiveCN108342090ASmall particle sizeSmaller and more uniform particle sizeBuilding insulationsCrack resistanceWaste rubber

The invention relates to a frustule asphalt modifier, a frustules asphalt modifier modified composite asphalt, and a preparation method of the frustules asphalt modifier. The frustules asphalt modifier is prepared from, by weight, 5 to 20 parts of frustule, 10 to 25 parts of waste rubber powder, 0 to 5 parts of petroleum resin or low grade asphalt, and 0 to 3 parts of a stabilizing agent. The invention also discloses a frustules composite modified asphalt, and a preparation method thereof. The frustule asphalt modifier is capable of improving the high temperature performance, the low temperature performance, the fatigue resistance, and the water stability of asphalt mixtures; the obtained frustules composite modified asphalt possesses excellent heat storage stability, and low temperature crack resistance, and is capable of prolonging the service life of road. A part of expensive SBS is replaced by cheap frustule, compared with the pavement performance of modified asphalt prepared via using of only SBS, the pavement performance is improved, and modified asphalt cost is reduced.

Owner:深圳市海绵城市科学研究院

Method for improving formed coke consolidation strength

ActiveCN102634398AEnhance carbonization and consolidationLoose structureSolid fuelsMicrometerCarbonization

The invention discloses a method for improving formed coke consolidation strength. Superfine grinding fillers (the superfine grinding fillers are coke powder or anthracite, and the average particle size of the fillers is less than 30.0 micrometers) are mixed with pitch, and then evenly mixed with the coke powder to obtain a mixture, the obtained mixture is added with water for wetting and then fully and evenly mixed again, and is subjected to pressing and forming process as well as volatilization and carbonization treatment at normal temperature to obtain carbonized formed coke, wherein the compression strength can be up to above 19.0 MPa. According to the method disclosed by the invention, the superfine grinding fillers are added into the pitch, enables the superfine grinding fillers to be embedded in a skeleton structure formed by carbonized pitch so as to fill pores created in coal tar pitch heat treatment, enrich the carbonized skeleton and enhance a bridge chain effect among coke powder particles and further improve the formed coke strength. According to the method, only a procedure of superfine grinding filler preparation needs to be added in the method, so that the effect of obvious improvement of the formed coke strength can be reached by performing the process in the conventional formed coke production process.

Owner:CENT SOUTH UNIV

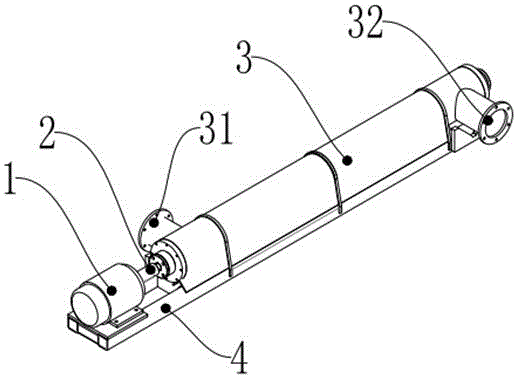

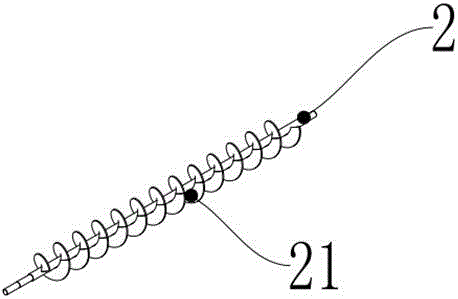

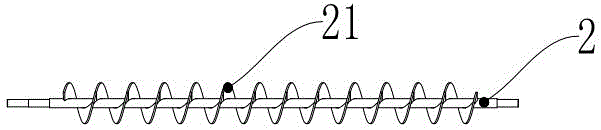

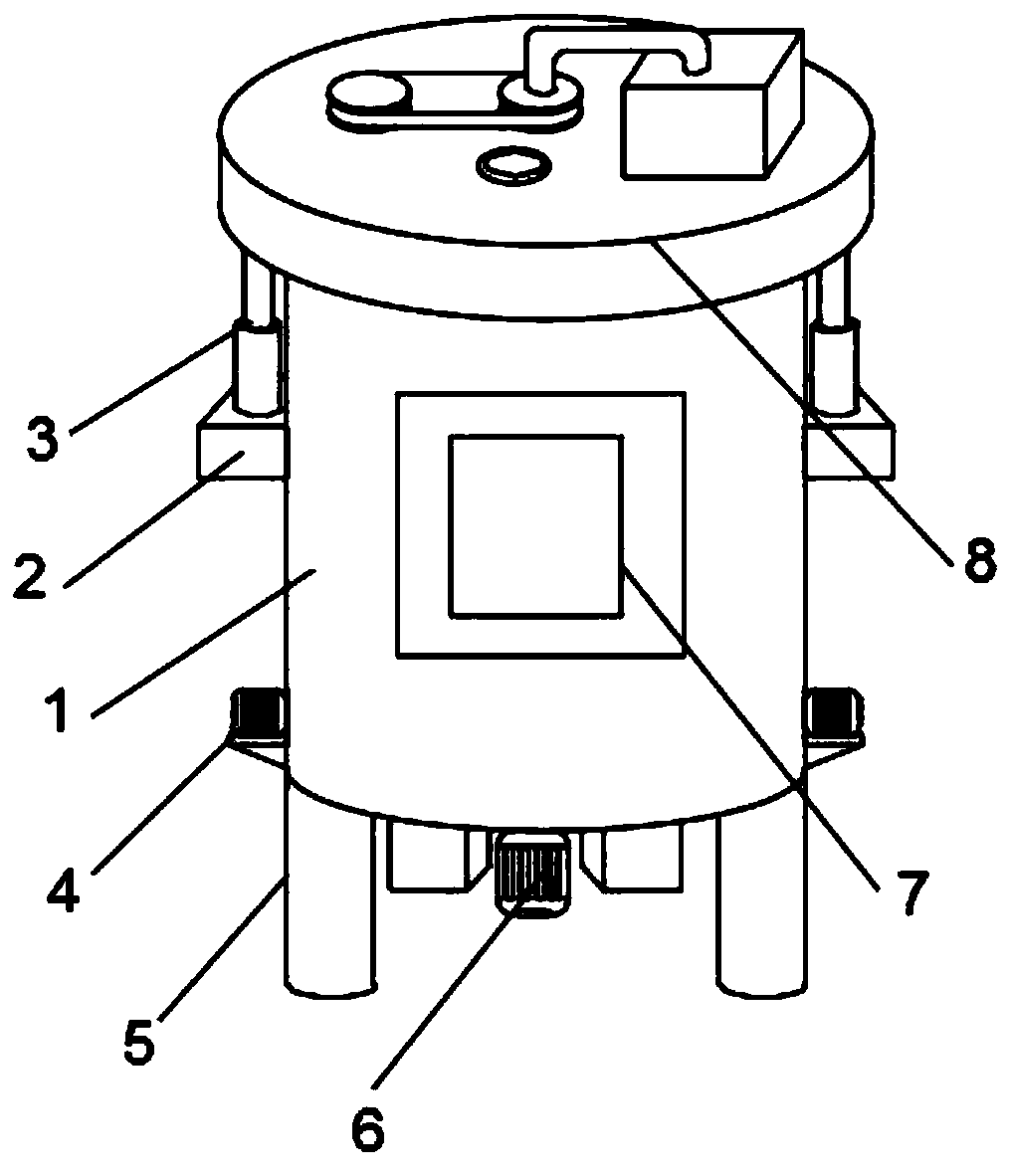

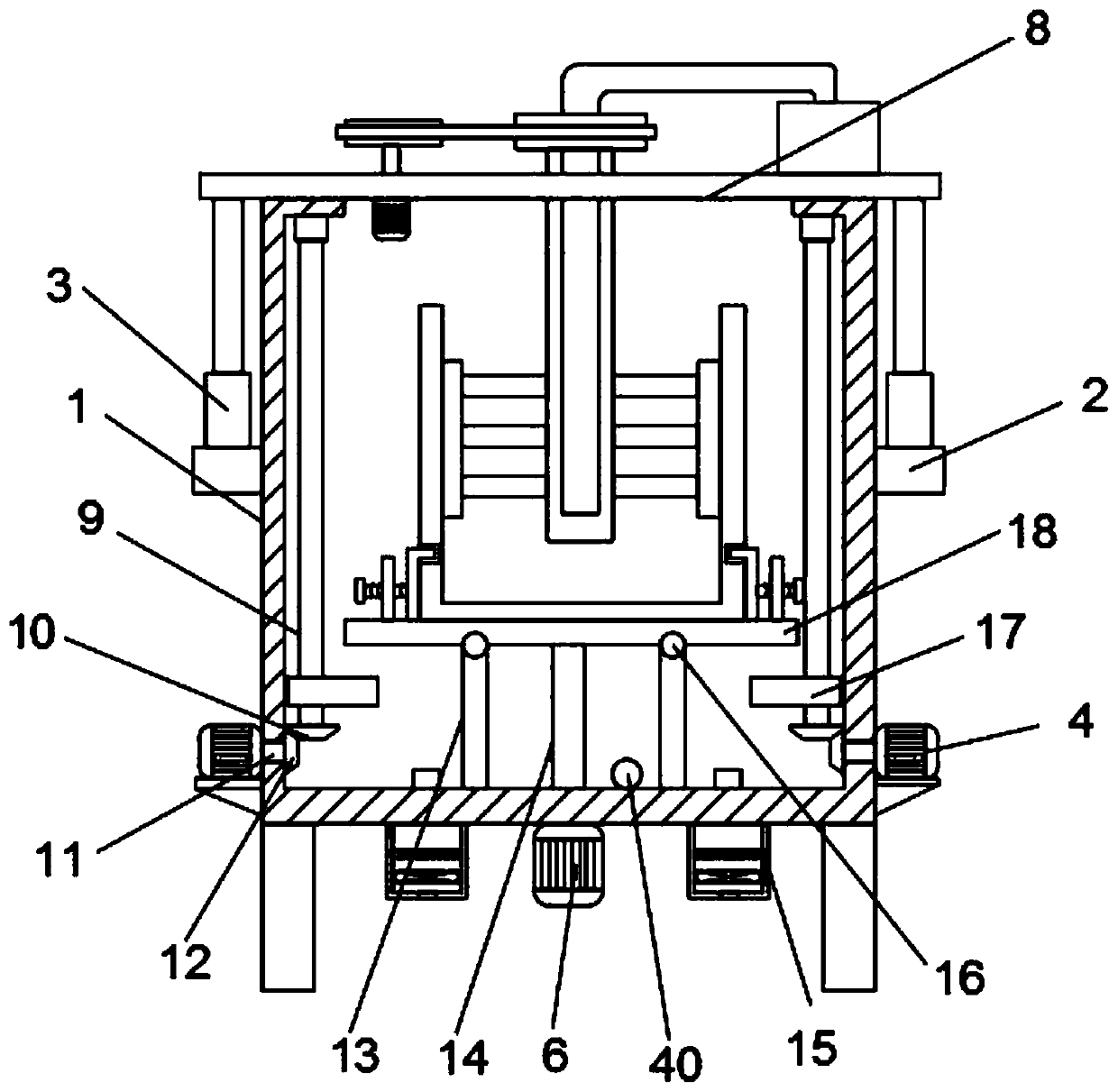

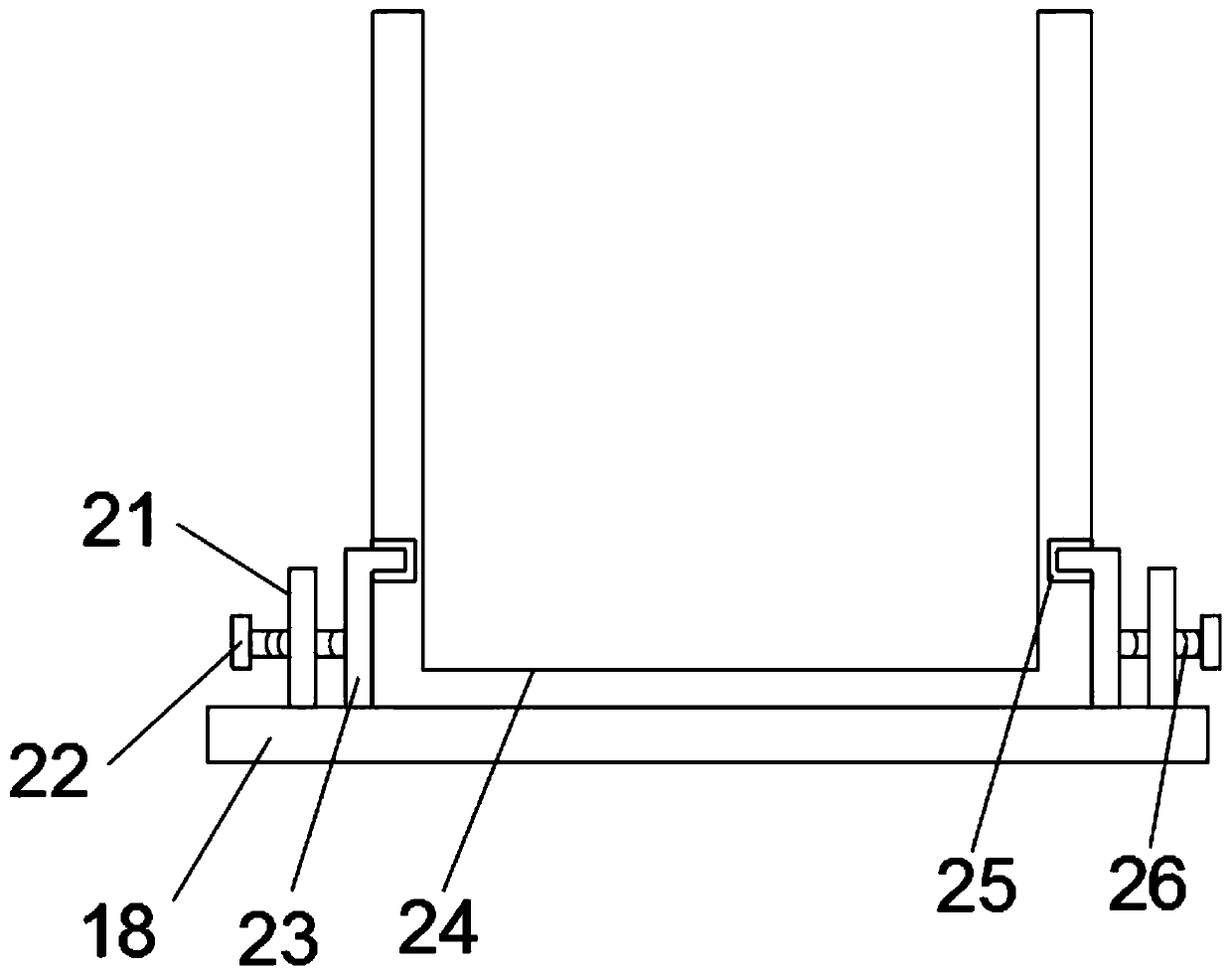

Sludge treatment chemical adding pipeline mixer

InactiveCN106621901AIngenious structural designImprove bridgingSludge treatment by de-watering/drying/thickeningRotary stirring mixersFlocculationMotor drive

The invention discloses a sludge treatment chemical adding pipeline mixer which comprises a motor, a spindle, a mixed pipe and an installing frame. The mixed pipe and the motor are arranged on the installing frame, the spindle penetrates the mixed pipe, the output end of the motor is connected with the spindle, and the motor drives the spindle to rotate, and the motor is a rotary motor. The spindle is provided with an integrally formed spiral blade, the surface of the spiral blade is a bent surface, and the inner side of the spiral blade is provided with a supporting frame. The two ends of the mixed pipe are provided with a feeding pipe and a discharging pipe respectively, and the feeding pipe and the discharging pipe are perpendicular to the mixed pipe respectively. According to the sludge treatment chemical adding pipeline mixer, the rotary motor is adopted to provide power, a mixing degree is increased, the spiral blade is arranged in the mixed pipe, a flocculant in the mixer can continuously and evenly contact with sludge particles, effects of bridging and adsorption of colloidal particles by flocculant particles are effectively increased, and mixing and flocculation effects are better.

Owner:广东绿建环保科技有限公司 +1

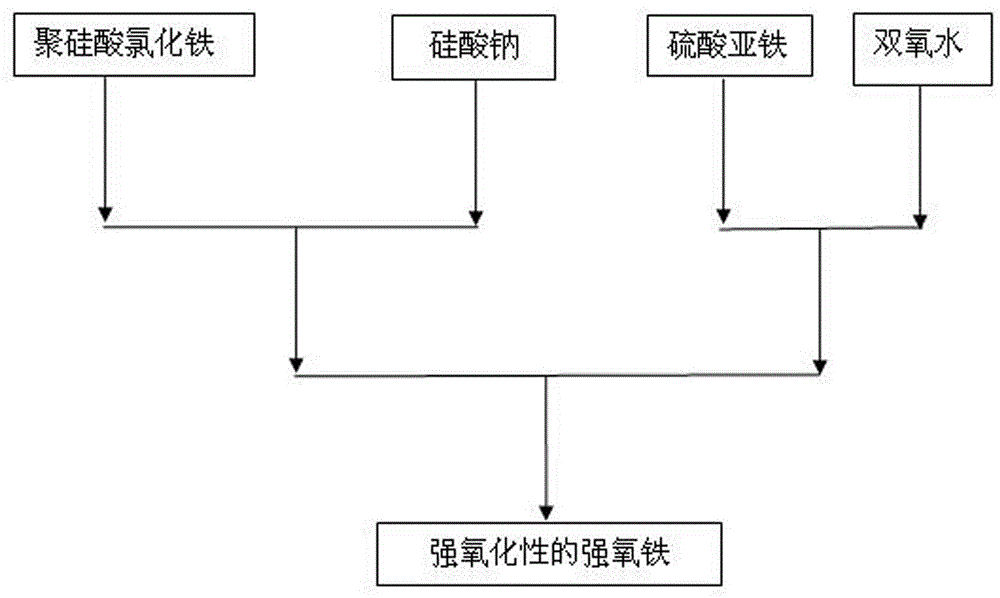

Treatment agent of wastewater rich in arsenic ions and heavy metal ions and preparation method

InactiveCN105948204AHigh removal rateEasy to prepareWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationSilicic acidPrecipitation

The invention relates to a treatment agent of wastewater rich in arsenic ions and heavy metal ions and a preparation method. The agent is a polymeric ferric salt which is formed by mixing, by mass, 90-110 parts of polysilicate ferric chloride, 0.5-1.5 parts of sodium silicate, 3-8 parts of ferrous sulfate and 0.2-0.8 part of hydrogen peroxide and has a strong oxidizing property. The treatment agent is rich in hydroxyl free radical which is very high in oxidability, the agent itself has very high oxidability, As ions in wastewater can be effectively oxidized, the As ions are changed from trivalent arsenic to pentavalent arsenic which is easy to precipitate, and formed precipitate is more stable; the agent is rich in a large amount of trivalent arsenic and contains a large amount of silicic acid, silicic acid has a very good adsorption bridging function, the bridging and net capturing functions of ferric ions are greatly strengthened, flocculability is high, heavy metal can be effectively captured, the removal rate of arsenic is greatly increased, formed alumen ustum is big and dense, precipitation is rapid, and the precipitate is high in stability.

Owner:JIANGSU GUOSONG ENVIRONMENT SCI & TECH DEV CO LTD +1

Preparation method of composite polyferric sulfate flocculating agent for industrial wastewater

InactiveCN110563109AGood dispersionStrong sinking effectWater/sewage treatment by flocculation/precipitationFerricChemistry

The invention discloses a preparation method of a composite polymeric ferric sulfate flocculant for industrial wastewater. The preparation method of the composite polymeric ferric sulfate flocculant comprises the following steps: dissolving 10-16 g of ferrous sulfate heptahydrate in 30-100 mL of water to prepare a ferrous sulfate solution; and then adjusting the content of SO4<2-> of the solutionby using 0.40-1.20 mL of concentrated sulfuric acid so as to allow a molor ratio of SO4<2-> to Fe<2+> to be 1.2-1.4. According to the invention, since the rotating directions of a second rotating motor and a first rotating motor are opposite, raw materials can be stirred, air flowing is accelerated and drying efficiency is improved under the action of the second rotating motor and the first rotating motor; and through the arrangement of a movable plate, a screw rod and an inserting groove, a containing barrel is convenient to mount and dismount and easy to maintain and replace, and fetching and discharging of a material are facilitated.

Owner:马鞍山健鼎化工有限公司

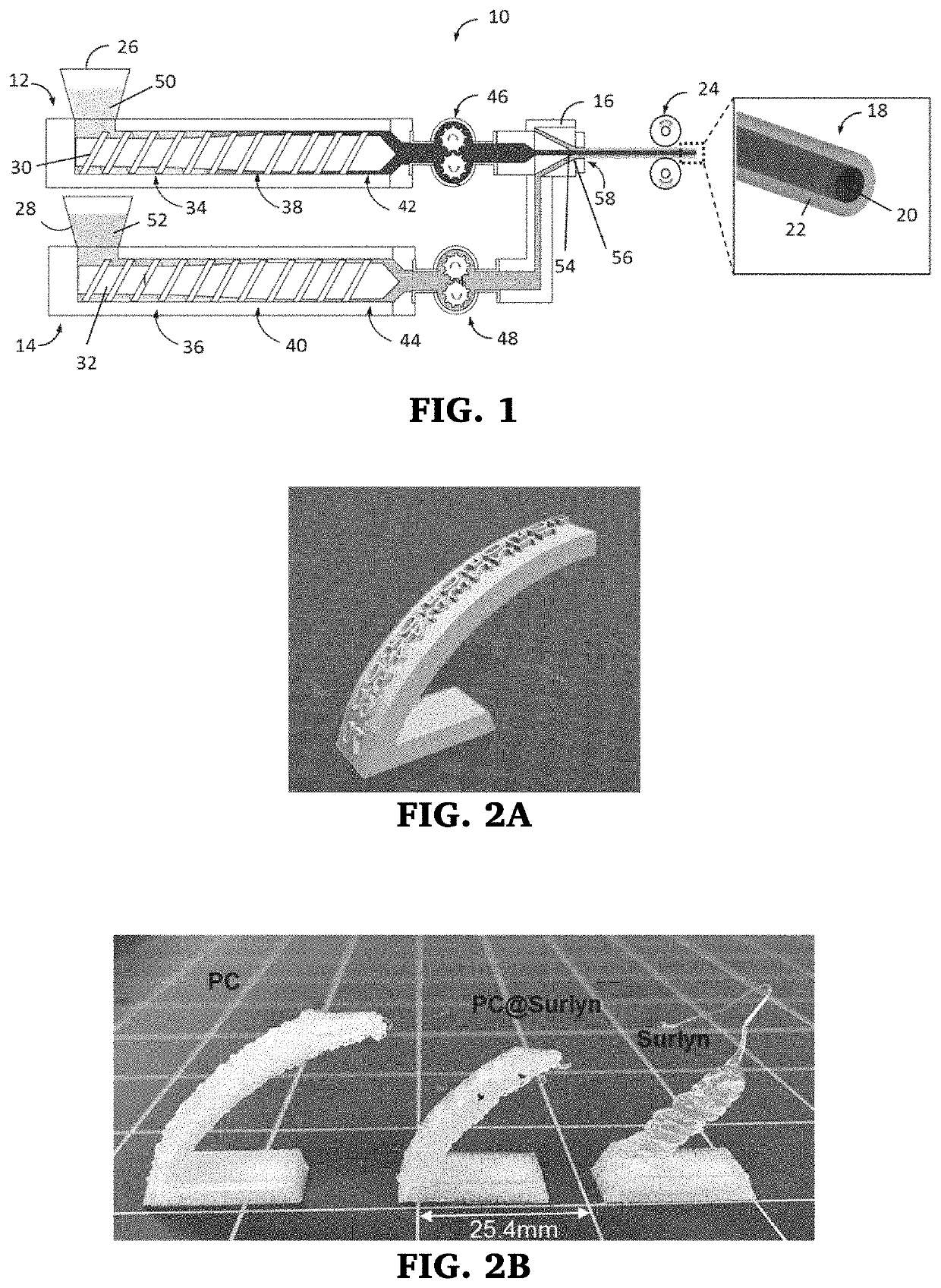

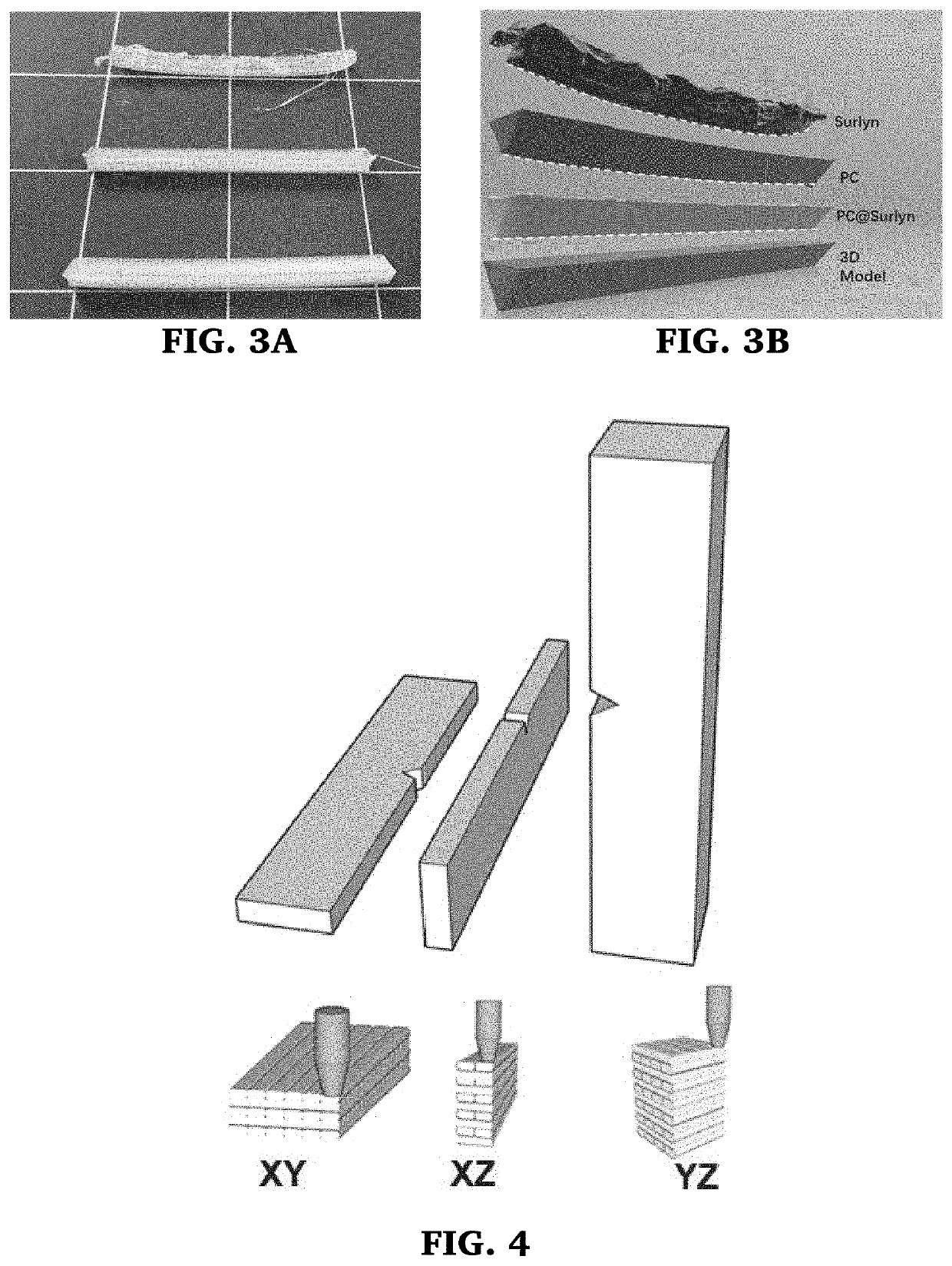

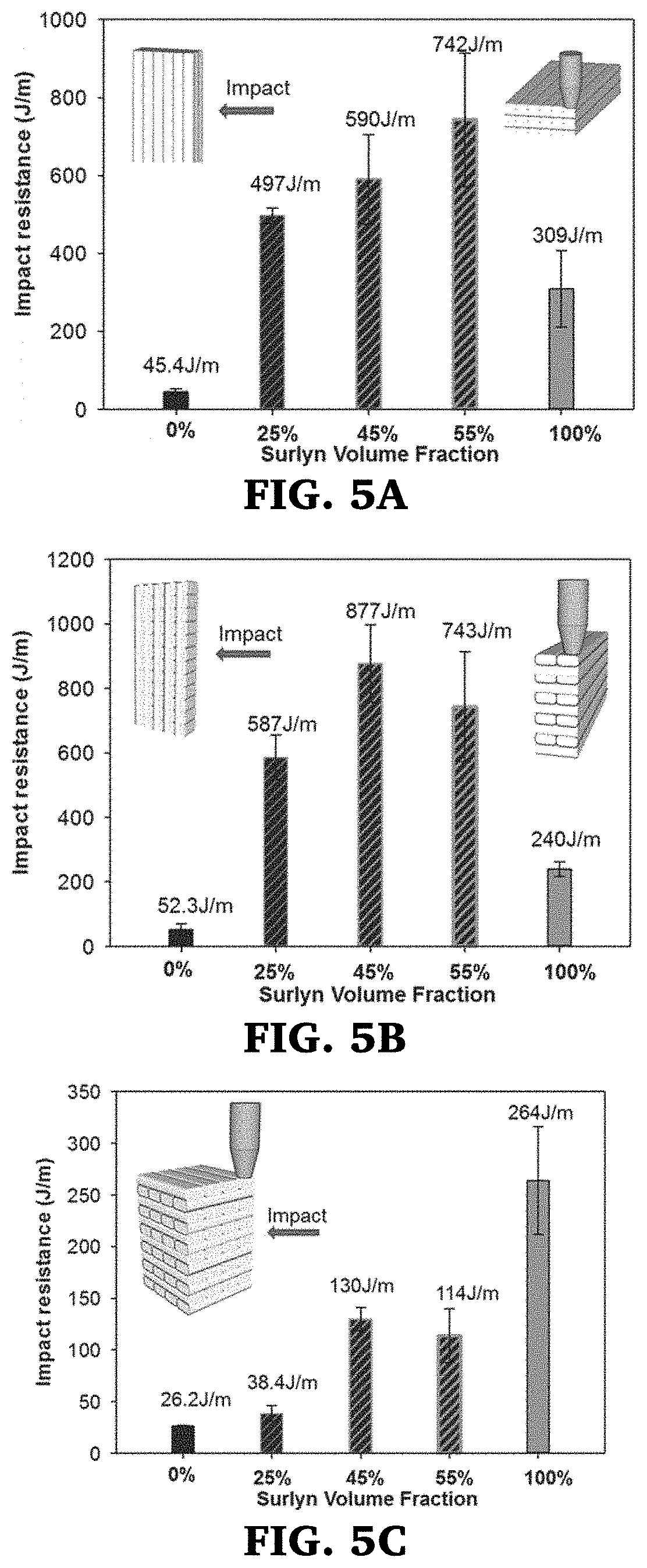

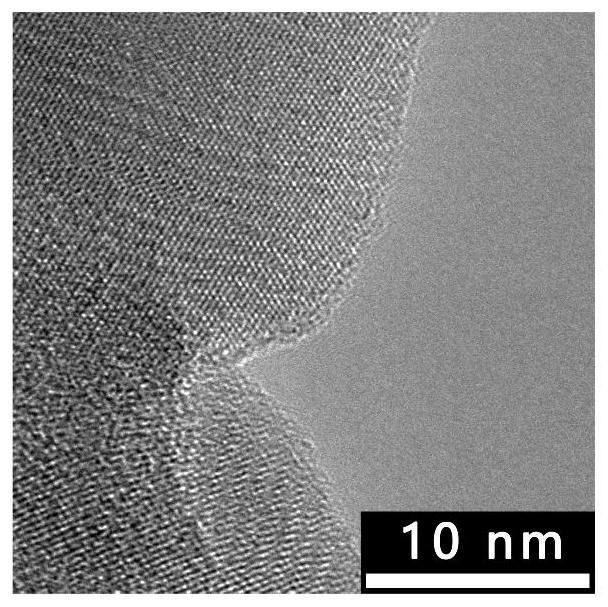

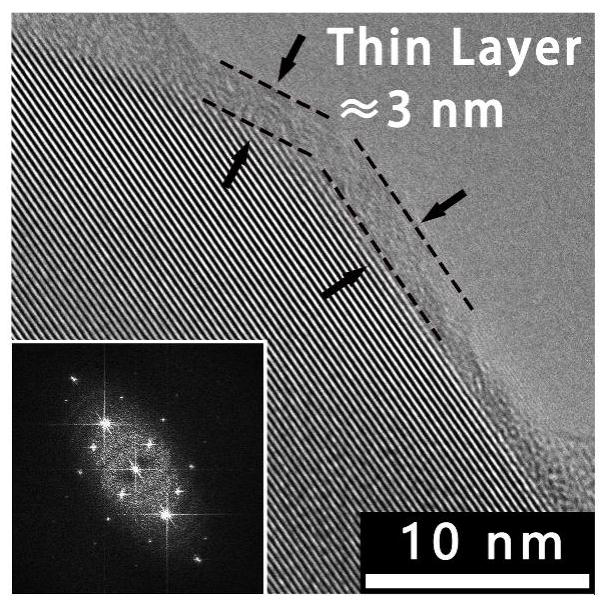

Tough, high impact resistant 3D printed objects from structured filaments

InactiveUS20200080237A1Reinforce printed shapeLow Tg shellAdditive manufacturing apparatus3D object support structuresFused filament fabricationPolymer science

In various embodiments the invention is directed to a structured filament for use in fused filament fabrication comprising an inner core comprising an first polymer or polymer blend; and an outer shell surrounding said inner core comprising a second polymer or polymer blend having ionic or crystalline functionality; wherein said first polymer or polymer blend has a higher solidification temperature than said second polymer or polymer blend. The ionic or crystalline functionality of the outer shell material strengthen the interface between the printed layers. This structured filament leads to printed 3D structures having improved dimensional fidelity and impact resistance in comparison to the individual components. The impact resistance of structures printed from these is greatly increased as energy is dissipated by delamination of the shell from the core near the crack tip, while the core remains intact to provide stability to the part after impact.

Owner:THE UNIVERSITY OF AKRON

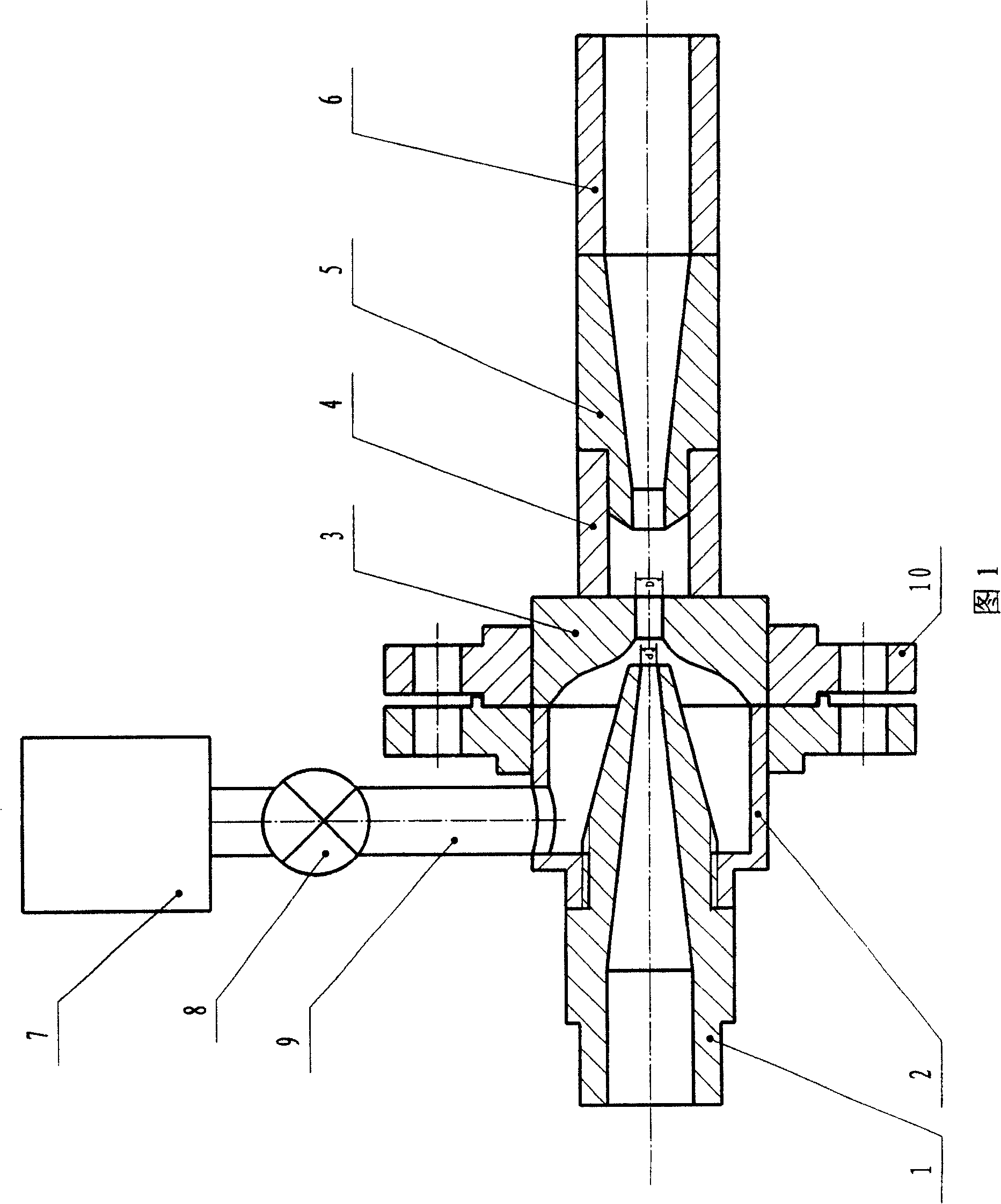

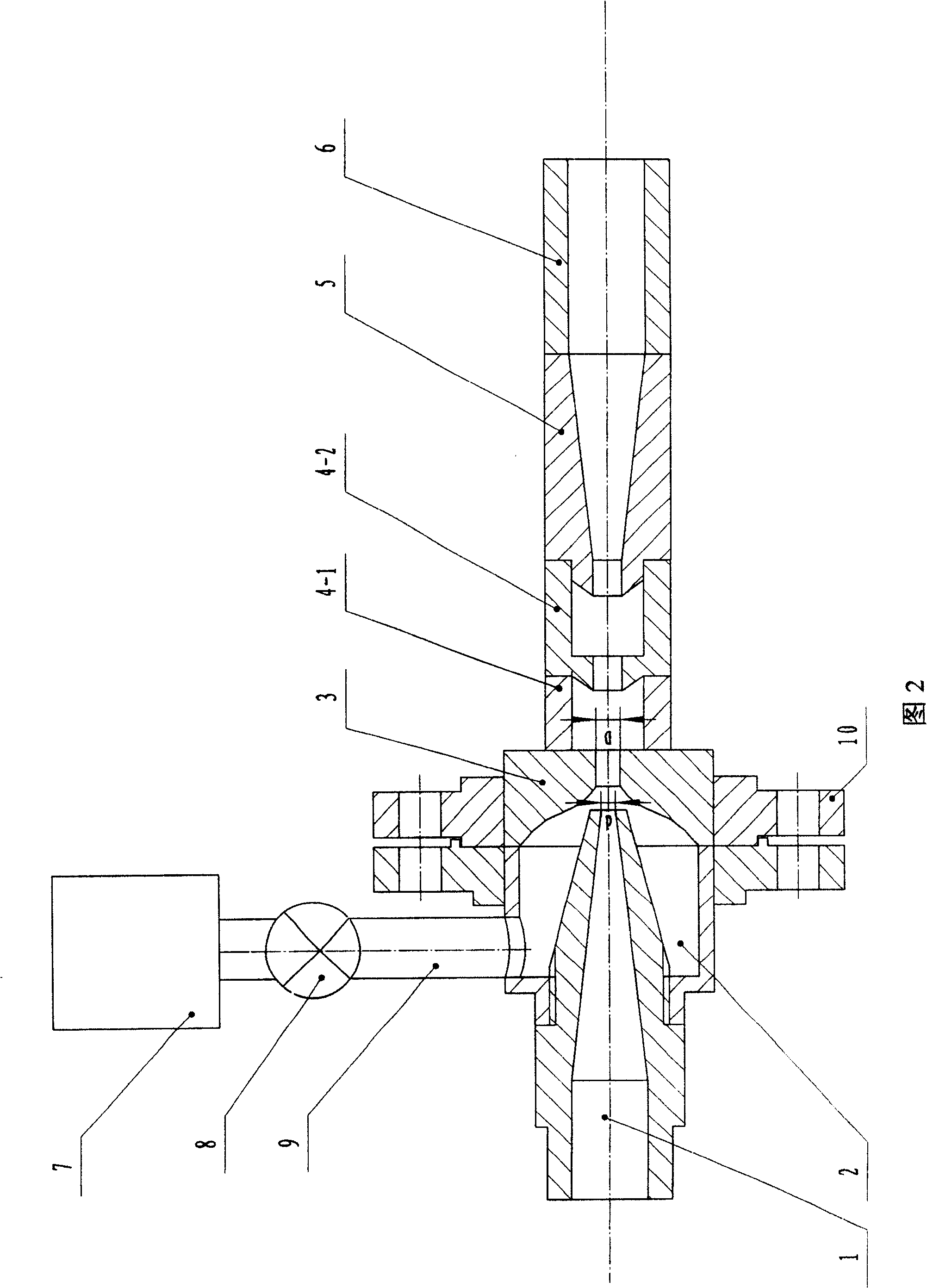

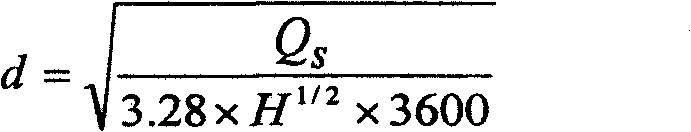

Self exciting oscillation pipeline type flocculating device

InactiveCN1821113AImprove mixing conditionsEnhanced turbulenceWater/sewage treatment by flocculation/precipitationPulse flowSewage

The self exciting oscillation pipeline type flocculator is for water supply, industrial waste water and domestic sewage treating engineering and possesses flocculation, deposition, floating and other functions. The flocculator includes water nozzle, mixing cavity, upper nozzle, self exciting cavity and lower nozzle connected successively through pipeline; as well as chemical adding tank, flow rate regulating valve and flocculant conveying pipe with outlet to the mixing cavity connected together. The present invention has raised colloid particle bridging and adsorbing effect and thus raised flocculating efficiency. The flocculator has the pulse flow with pressure amplitude 15-30 úÑ higher than that of inflow.

Owner:CHONGQING UNIV

Low-temperature carbonization method of directly heating formed coke

ActiveCN102757806ACompact structureReduce the number of poresCoking carbonaceous materialsMetallurgyNitrogen

The invention discloses a low-temperature carbonization method of directly heating formed coke. The low-temperature carbonization method comprises the steps of: performing advanced co-grinding treatment on asphalt and a certain amount of powder material (the powder material is coke powder or pulverized coal); then adding the mixture into the coke powder to be mixed uniformly; then adding a certain amount of water and a dimethylbenzene activator in the uniformly mixed material; performing normal-temperature briquetting forming and volatilization treatment; and finally directly heating the formed coke to realize low-temperature carbonization of the formed coke, thereby obtaining the carbonized formed coke. Through the measures, the low-temperature carbonization and solidification of the formed coke is realized through direct heating on the premise that the quality of the formed coke is guaranteed. Only by pre-treating the raw materials, can the formed coke be carbonized at low temperature by direct heating under an air, nitrogen or carbon dioxide atmosphere; therefore, the low-temperature carbonization method of directly heating the formed coke, disclosed by the invention, has the advantages of simplifying the subsequent process flow, reducing the production cost and breaking the limitation that the formed coke in the traditional formed coke process must be indirectly heated to a high temperature for the carbonization under a sealing condition.

Owner:CENT SOUTH UNIV

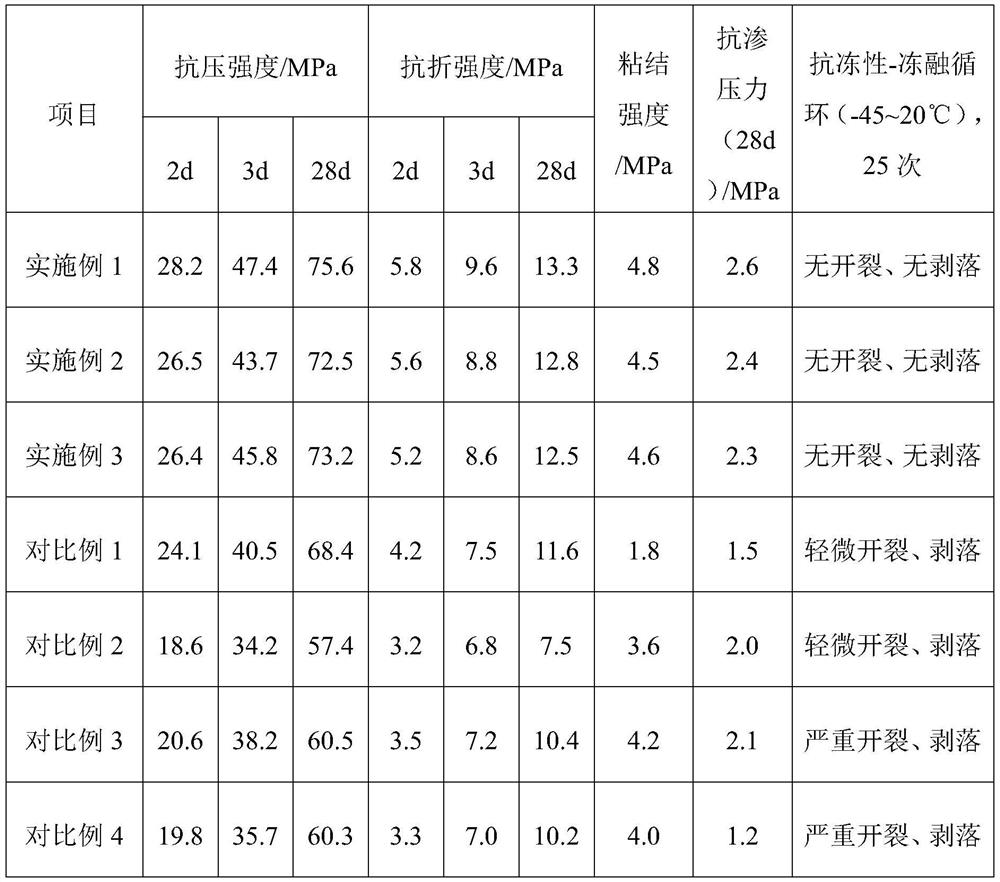

Concrete crack repairing material based on nano material and preparation method thereof

ActiveCN114751706AImprove corrosion resistanceImprove impermeabilitySolid waste managementPolyesterFiber

The invention discloses a concrete crack repairing material based on a nano material and a preparation method of the concrete crack repairing material, and belongs to the technical field of building materials. The concrete crack repairing material is prepared from the following raw materials: seaweed, sulphoaluminate cement, natural sand, nano silicon powder, calcium formate, fly ash, anhydrous calcium sulphoaluminate, polyester fibers, a water reducing agent, a corrosion inhibitor and water. The invention also provides a preparation method of the concrete crack repairing material, the raw materials of the repairing agent are reasonably selected and proportioned, and all the raw materials synergistically play a role, so that the prepared concrete repairing material has good compressive strength, breaking strength and bonding strength, and is excellent in anti-permeability and anti-freezing performance; the method can be used for repairing concrete cracks in a marine environment, and has very important application value.

Owner:浙大宁波理工学院 +1

High-salt-tolerance super absorbent resin and preparation process thereof

The invention belongs to the technical field of resins, and particularly relates to a high-salt-resistance super absorbent resin and a preparation process thereof. The high-salt-tolerance super absorbent resin is prepared from the following raw materials in parts by mass: 5 to 10 parts of sodium alginate, 80 to 100 parts of acrylic acid, 50 to 60 parts of acrylamide, 20 to 30 parts of chitosan, 10to 20 parts of diatomite, 10 to 20 parts of humic acid, 0.05 to 2.5 parts of an initiator, 0.3 to 5 parts of a cross-linking agent and 0.05 to 3 parts of an antioxidant. According to the preparationprocess disclosed by the invention, chitosan is directly dissolved in an acrylic acid solution for reaction to provide a neutralization effect on acrylic acid, so that the acrylic acid does not need to be neutralized before reaction, the process steps are reduced, and the production cost is reduced; sodium alginate is utilized to enhance the degradability of the resin so as to achieve an environment protection effect; and the porous structure of diatomite plays a role in bearing other raw materials and improving the water absorption of the resin, and the flocculation performance of the diatomite is improved through the reaction of the diatomite and the sodium alginate.

Owner:乐清市川嘉电气科技有限公司

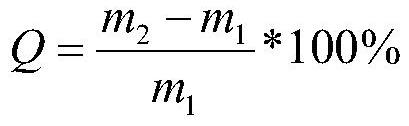

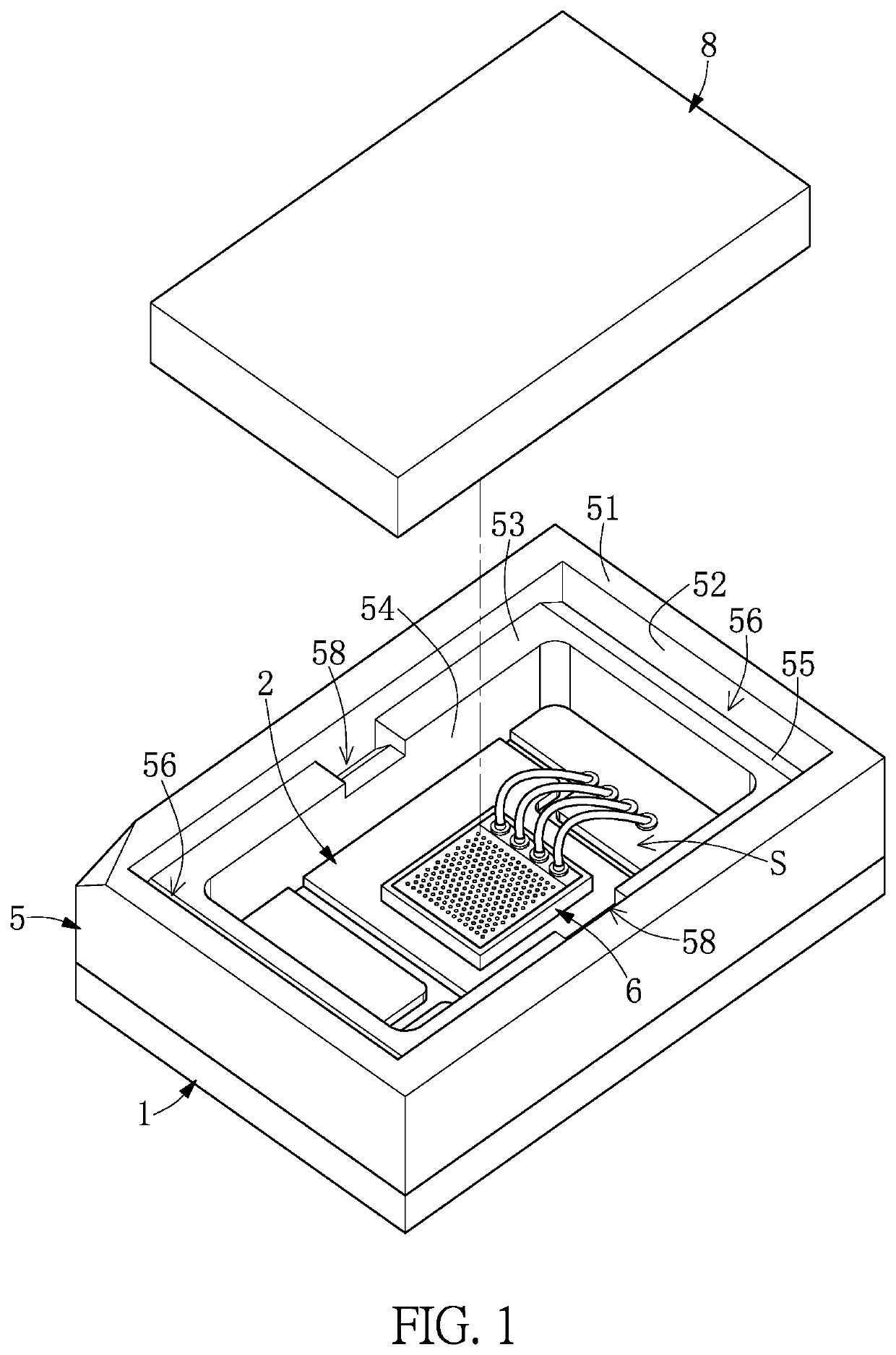

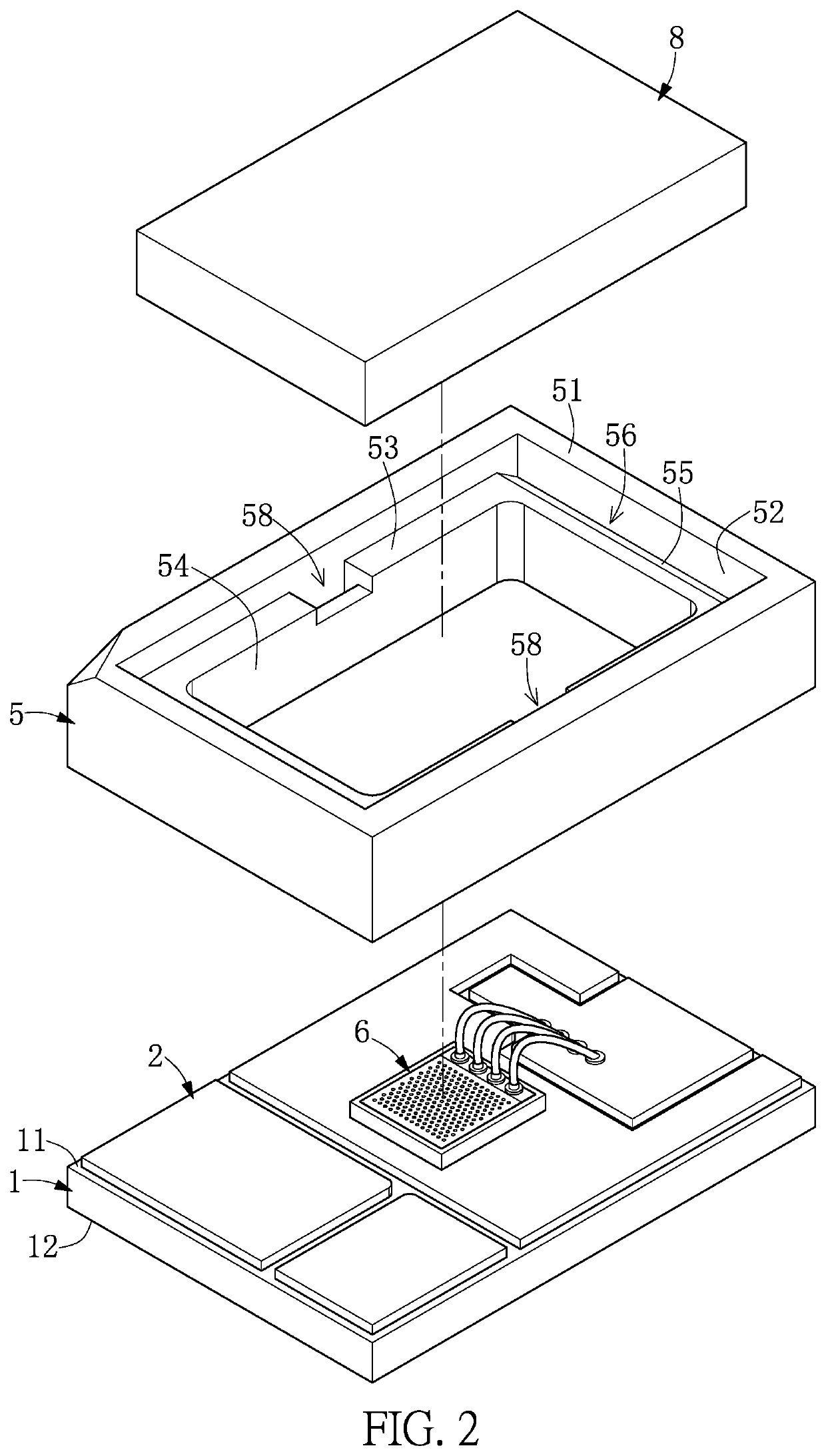

Light source package structure

ActiveUS10816176B1Effectively improve on the issuesReliable electrical connectionElectric circuit arrangementsSemiconductor devices for light sourcesHemt circuitsElectrically conductive adhesive

A light source package structure is provided. The light source package structure includes a substrate, an upper electrode layer and a lower electrode layer respectively disposed on two sides of the substrate, a light emitting unit mounted on the upper electrode layer, a surrounding wall disposed on the substrate and arranged to surround the light emitting unit, a conductive unit disposed on the surrounding wall and electrically connected to the lower electrode layer, a light permeable element disposed on the surrounding wall, a detection circuit formed on the light permeable element, and at least one conductive adhesive. The conductive adhesive includes a colloid and a plurality of fillers mixed with the colloid. The colloid and the fillers of the conductive adhesive are partially filled within the gap.

Owner:LITE ON OPTO TECH (CHANGZHOU) CO LTD +1

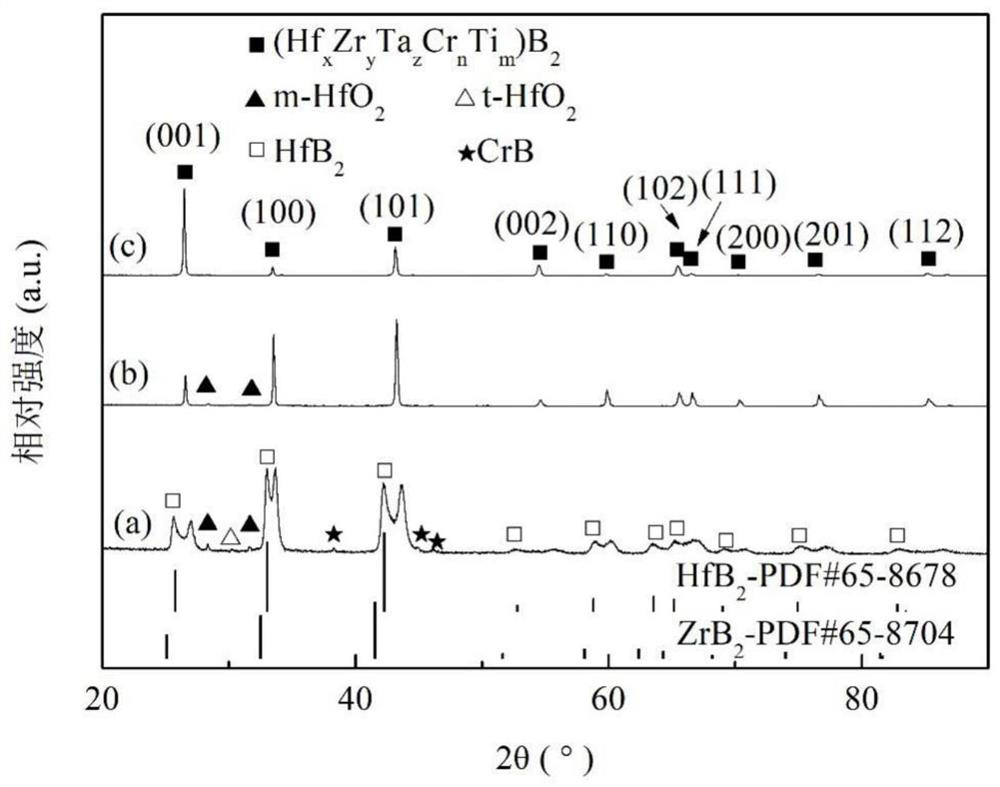

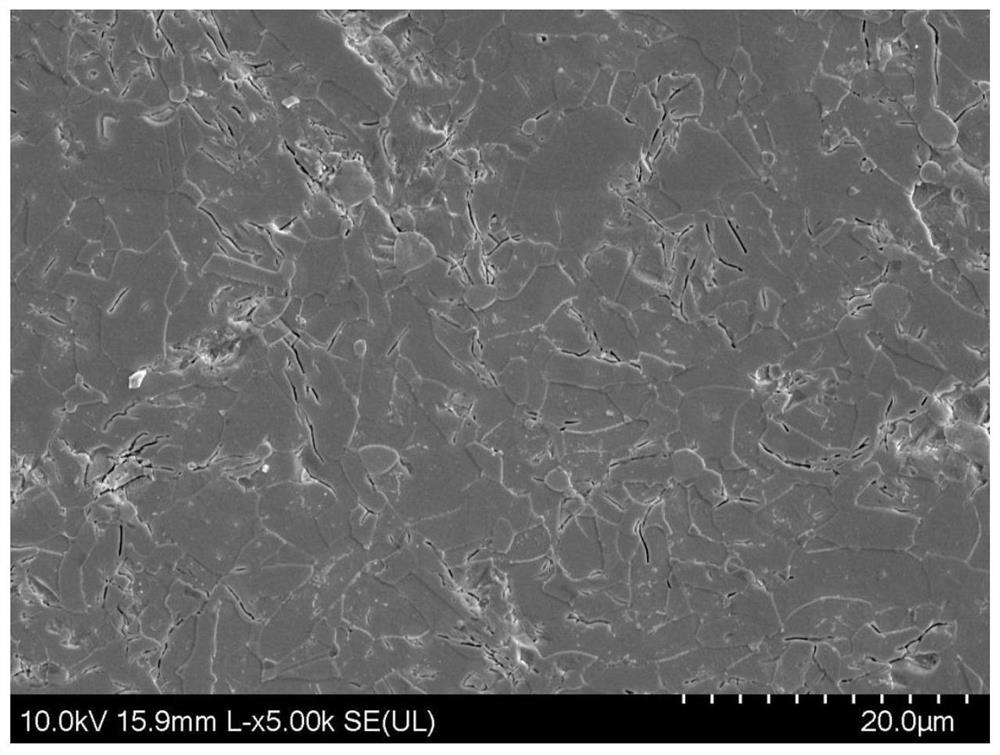

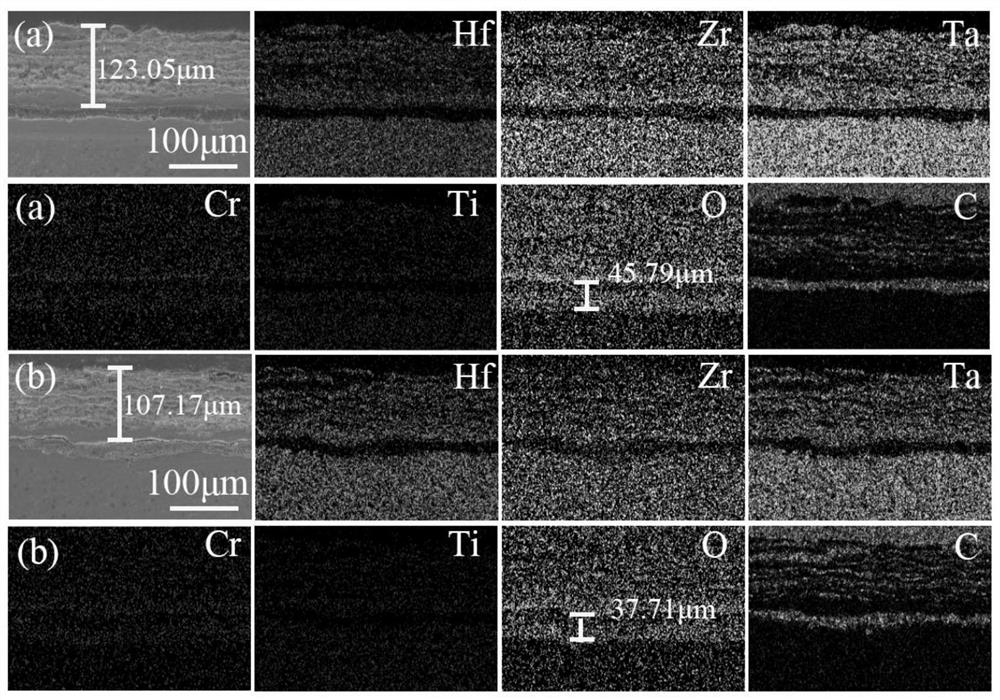

High-toughness oxidation-resistant textured high-entropy ceramic as well as preparation method and application thereof

ActiveCN111943682AImprove fracture toughnessPromotes directional growthMetal working apparatusHeat treatedGreen body

The invention belongs to the technical field of ceramic materials, and discloses high-toughness oxidation-resistant textured high-entropy ceramic as well as a preparation method and application thereof. The molecular formula of textured high-entropy ceramic is (HfxZryTazCrnTim)B2, 0.1 <= x <= 1, 0.1 <= y <= 1, 0.1 <= z <= 1, 0.1 <= n <= 1, 0.1 <= m <= 1, and x + y + z + n + m = 1. The ceramic is prepared by the following steps: carrying out mold pressing on mixed powder of metal oxides to prepare a green body, heating the green body to 1400-1600 DEG C under a vacuum condition, carrying out heat treatment, grinding and screening the green body to obtain (HfxZryTazCrnTim)B2 textured high-entropy ceramic powder, heating the powder to 1000-1400 DEG C by spark plasma sintering, introducing a protective atmosphere, heating the mixture to 1800-2200 DEG C, and calcining the product. The textured high-entropy ceramic has a uniform solid solution phase, high toughness and oxidation resistance, and has a textured morphology directionally growing along a c-axis. The ceramic product can be applied to the field of ultrahigh-temperature oxidation resistance or cutters.

Owner:GUANGDONG UNIV OF TECH

Preparation method of nano polyaluminum iron silicate-graft modified starch hybrid flocculant

InactiveCN105417655BImprove solubilityGood electrical neutralizationWater/sewage treatment by flocculation/precipitationPotassium persulfateSilicic acid

The invention discloses a preparation method of a namometer PAFSI-graft modified starch hybrid flocculent. The preparation method is characterized by comprises the steps that 20 parts of Na2SiO3 and 350 parts of deionized water are added to a reaction bottle, the pH value ranges from 2 to 5, the room temperature reaction is performed for 2-3 h, and activated silicic acid is prepared; a certain amount of AlCl3 and FeCl3 ethylene glycol solution is added slowly in 20 parts of activated silicic acid for reaction, 1-5 parts of CTAC (cetanecyl trimethyl ammonium chloride) is added after cooling, curing is performed, and namometer PAFSI is prepared; 20 parts of starch and 20-400 parts of deionized water are added to the reaction bottle, N2 is fed, the starch is cooled to 30 DEG C after gelatinized for 0.5-1 h under stirring and at the temperature of 65 DEG C to 90 DEG C, 0.5-6.0 parts of CTAC is added, 2-10 parts of nanometer PAFSI is added, the pH value ranges from 5 to 7, 0.05-0.5 part of potassium persulfate and 0.02-0.3 part of sodium sulphite are added at the temperature of 30 DEG C to 55 DEG C, 3-10 parts of cationic monomers and 2-10 parts of macromonomers are added slowly, N2 is fed, the reaction is performed for 4-8 h, and the namometer PAFSI-graft modified starch hybrid flocculent is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

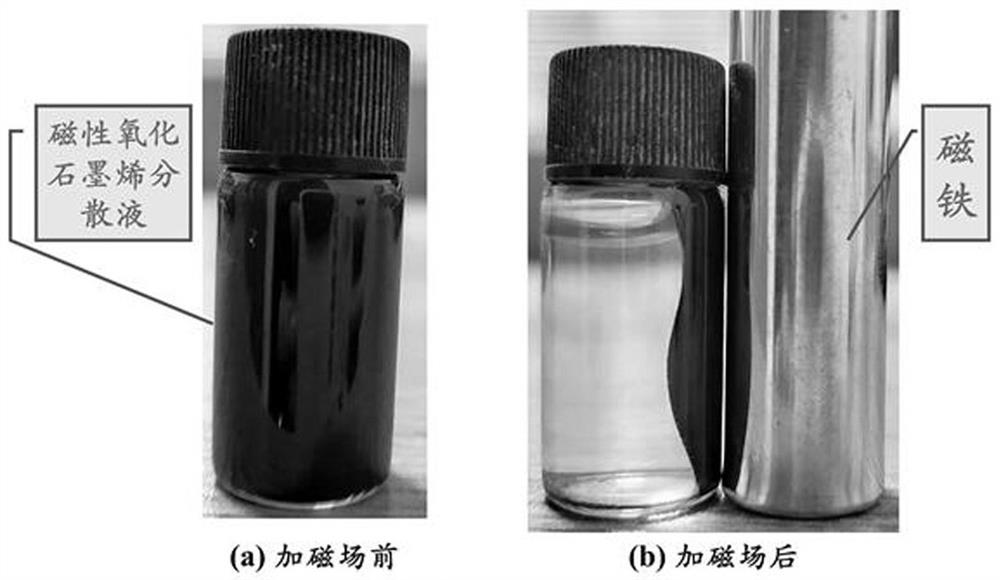

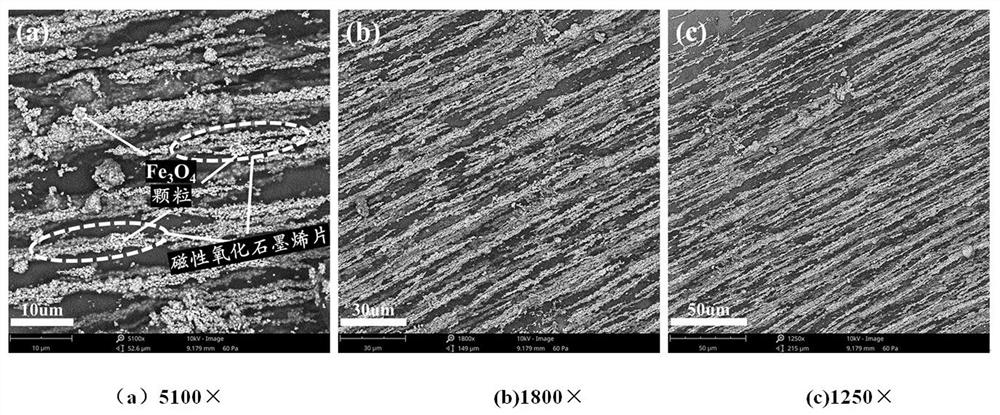

Graphene oxide magnetic orientation dispersion reinforced cement-based composite material and preparation method thereof

ActiveCN114573284BImprove magnetic propertiesAchieving controllable directional dispersionSolid waste managementFeeding arrangmentsMagnetite NanoparticlesWater reducer

The invention discloses a graphene oxide magnetically oriented dispersion reinforced cement-based composite material and a preparation method thereof; the composite material is prepared from the following raw materials: cement, graphene oxide, Fe 3 O 4 Magnetic nanoparticles, water reducing agent and water; among them, cement, graphene oxide, Fe 3 O 4 The mass ratio of magnetic nanoparticles and water reducing agent is 100: (0.02~0.08): (0.1~0.4): (0.08~0.16). The invention controls the orientation and spatial position of the graphene oxide nanosheets in the cement matrix by applying an external magnetic field, thereby realizing the controllable directional dispersion of the graphene oxide in the cement matrix to a certain extent, and the directionally arranged magnetic graphene oxide The improvement of the mechanical properties of cement-based composites plays a greater role, achieving the goal of using graphene oxide efficiently, reducing economic costs, and promoting the application of graphene oxide in actual construction projects.

Owner:TAIYUAN UNIV OF TECH

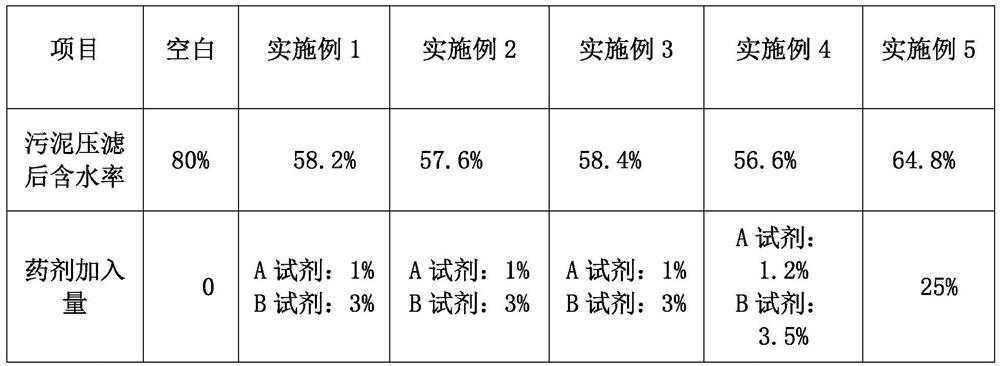

A kind of production method of environment-friendly composite sludge conditioner

The invention discloses a production method of an environment-friendly composite sludge conditioner, comprising the following steps: (1) Preparation of reagent A: at 40-60°C, polydimethyldiallylammonium chloride, polydiallyl chloride Ethyl ether tetramethylethylenediamine and epichlorohydrin-dimethylamine copolymer are dissolved in pure water, stirred for 1-2h, and cooled to become A reagent; (2) Preparation of B reagent: a certain amount of alginic acid Sodium and chitosan are respectively added to a certain amount of acetic acid solution, configured into sodium alginate solution and chitosan solution, and then sodium alginate and chitosan are compounded to obtain a composite agent of polymer and fly ash, which is B Reagent, the environmental protection composite sludge conditioner of the present invention changes the sludge characteristics through the synergistic conditioning effect of the two compounds, and greatly enhances the sludge dehydration; and each component in the conditioner is relatively environmentally friendly, non-toxic and harmless, and the preparation process is easy.

Owner:河南永泽环境科技有限公司

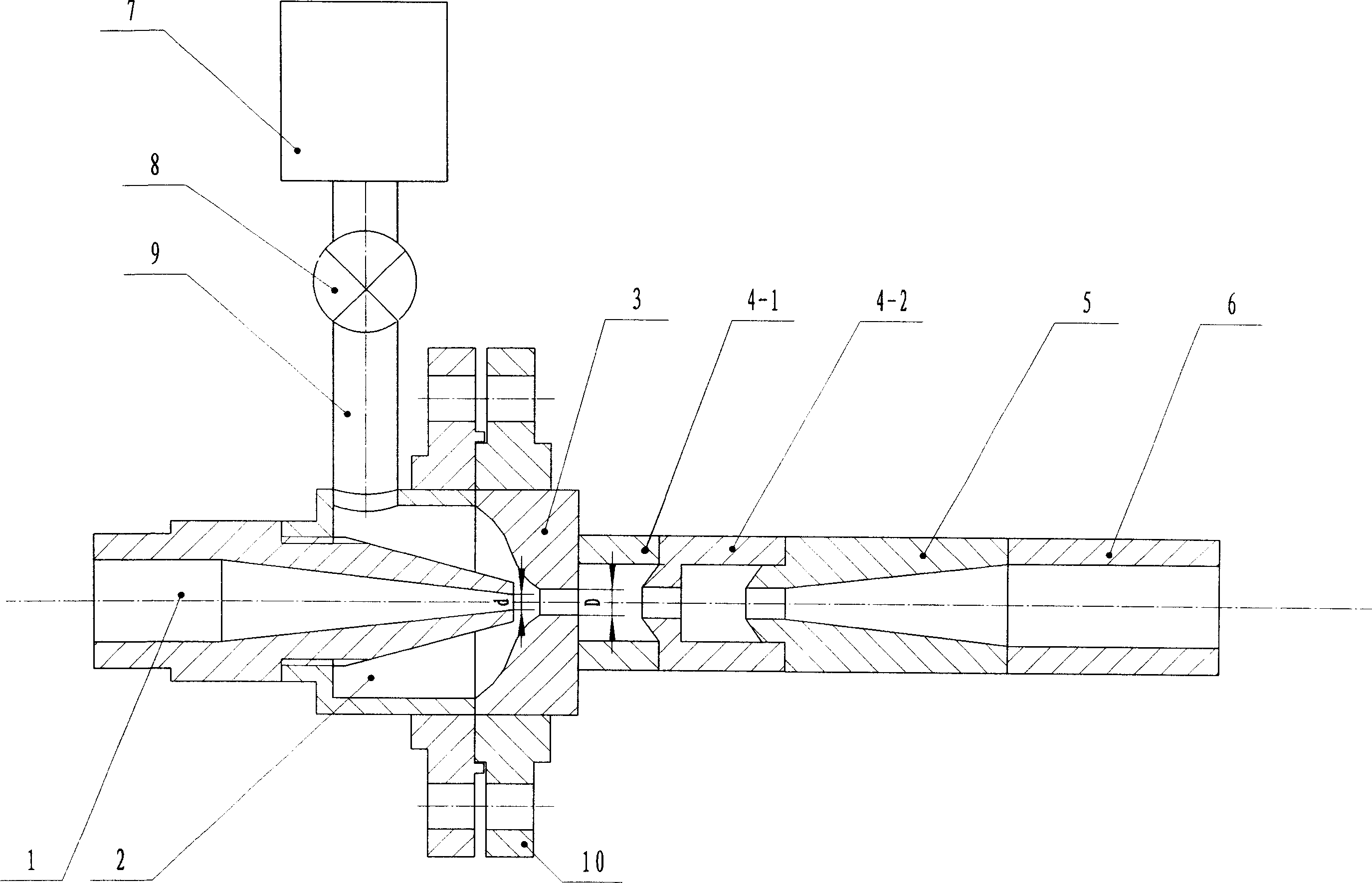

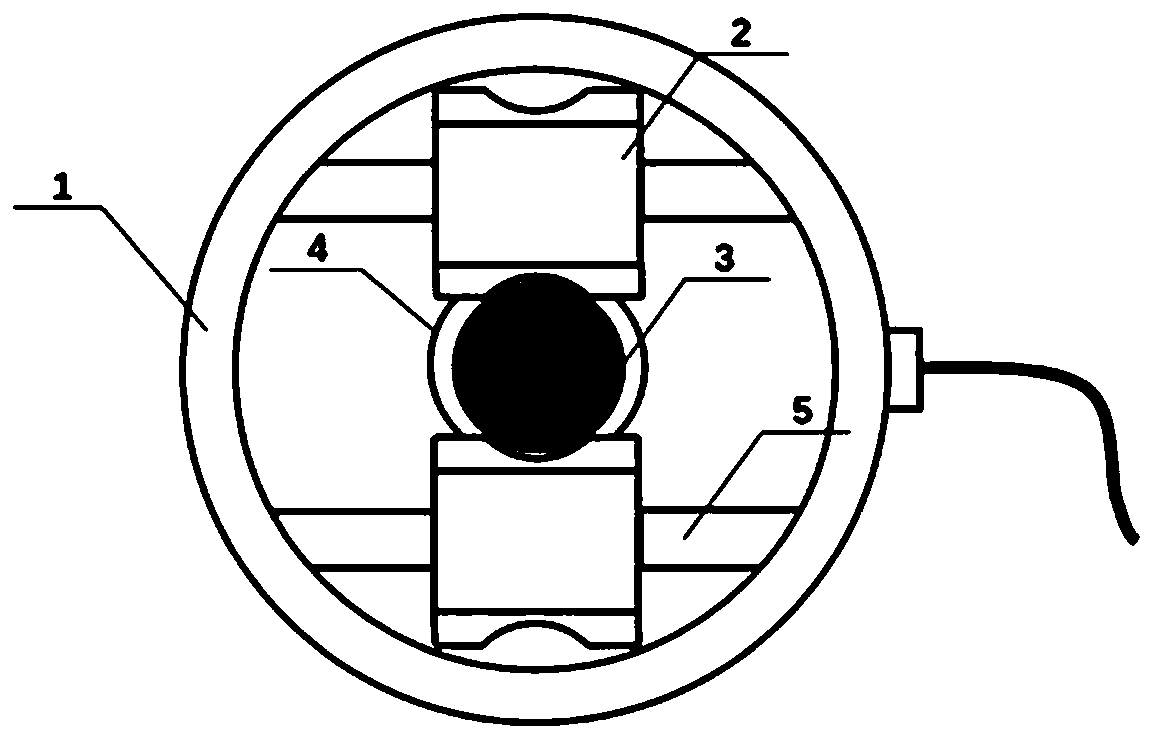

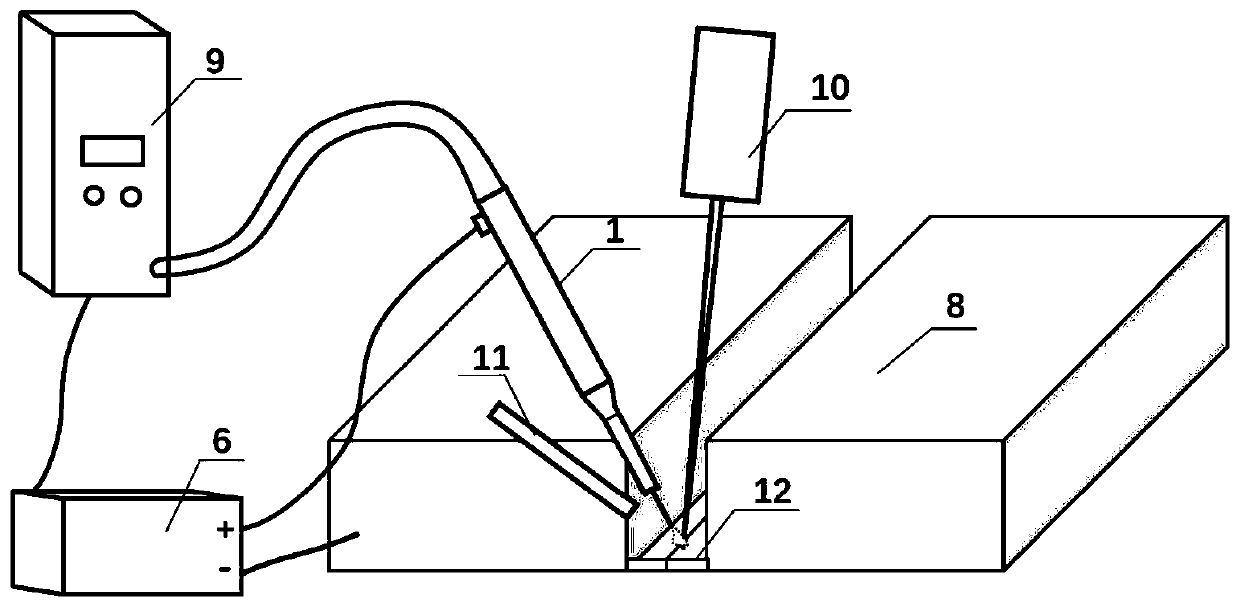

Welding Method of Laser-Low Current Welding Wire Spontaneously Induced Arc Hybrid Welding System

ActiveCN110625260BImprove laser absorption rateSuppression of Welding DefectsLaser beam welding apparatusElectrically conductiveElectric arc

A laser-low current welding wire autonomous induction electric arc composite welding system comprises a laser head, a wire feeding mechanism, a welding wire, a shielding gas device, a constant-voltagecharacteristic power source and an electric arc control center. The wire feeding mechanism comprises an annular electrode suitable for a narrow gap, an electric conduction wire feeding wheel and a wire feeding mouth. In the welding process, the constant-voltage characteristic power source outputs a low current, the wire feeding mechanism feeds in a wiring wire, the welding wire autonomously induces an electric arc on the surface of a to-be-welded workpiece, the electric arc and a laser beam generated by the laser head are recombined, and welding is conducted. The electric arc control center monitors the magnitude of an electric current of an electric circuit in the welding process in real time through the constant-voltage characteristic power source, and the welding wire feeding action ofthe wire feeding mechanism and an output current of the constant-voltage characteristic power source are adjusted according to the magnitude of the electric current so as to maintain electric arc stability. According to the welding system, the electric arc can be introduced into a highly constrained space of the welding process of large thick plate and an ultra-narrow gap, the electric arc and alaser generate a synergetic enhancement effect, and advantages of laser electric arc composite welding and laser filler wire welding are combined.

Owner:SOUTHWEST JIAOTONG UNIV

Method for realizing mid-consistency grinding in low-consistency device

InactiveCN101654884BConcentrated Refining RealizationHigh strengthPaper/cardboardChemical/chemomechanical pulpMetallurgySlurry

The invention discloses a method for realizing mid-consistency grinding in a low-consistency grinding device. In a slurry preparing stage, a slurry flowage modifier is added so that the slurry flowability is unchanged after increasing the grinding consistency to realize mid-consistency grinding in the low-consistency grinding device. The method comprises the specific steps as follows: placing paper pulp into a pulper for pulping, and adding a slurry flowage modifier inthe pulping process, wherein the use amount of the flowage modifier is 0.005-5 percent of that of oven dry stock; and grindingthe mid-consistency slurry of 6-8 percent after adding the slurry flowage modifier in the low-consistency grinding device for grinding. The method is simple and safe, and realizes mid-consistency grinding in the low-consistency grinding device without equipment investment; in addition, the manufactured slurry can be applied as ordinary slurry for improving the quality of paper.

Owner:GOLD EAST PAPER JIANGSU

Method for improving formed coke consolidation strength

ActiveCN102634398BEnhance carbonization and consolidationLoose structureSolid fuelsMicrometerCarbonization

The invention discloses a method for improving formed coke consolidation strength. Superfine grinding fillers (the superfine grinding fillers are coke powder or anthracite, and the average particle size of the fillers is less than 30.0 micrometers) are mixed with pitch, and then evenly mixed with the coke powder to obtain a mixture, the obtained mixture is added with water for wetting and then fully and evenly mixed again, and is subjected to pressing and forming process as well as volatilization and carbonization treatment at normal temperature to obtain carbonized formed coke, wherein the compression strength can be up to above 19.0 MPa. According to the method disclosed by the invention, the superfine grinding fillers are added into the pitch, enables the superfine grinding fillers to be embedded in a skeleton structure formed by carbonized pitch so as to fill pores created in coal tar pitch heat treatment, enrich the carbonized skeleton and enhance a bridge chain effect among coke powder particles and further improve the formed coke strength. According to the method, only a procedure of superfine grinding filler preparation needs to be added in the method, so that the effect of obvious improvement of the formed coke strength can be reached by performing the process in the conventional formed coke production process.

Owner:CENT SOUTH UNIV

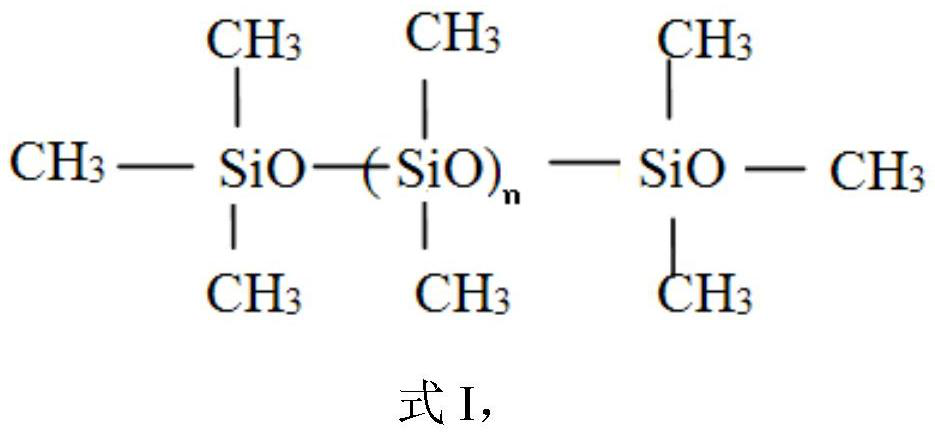

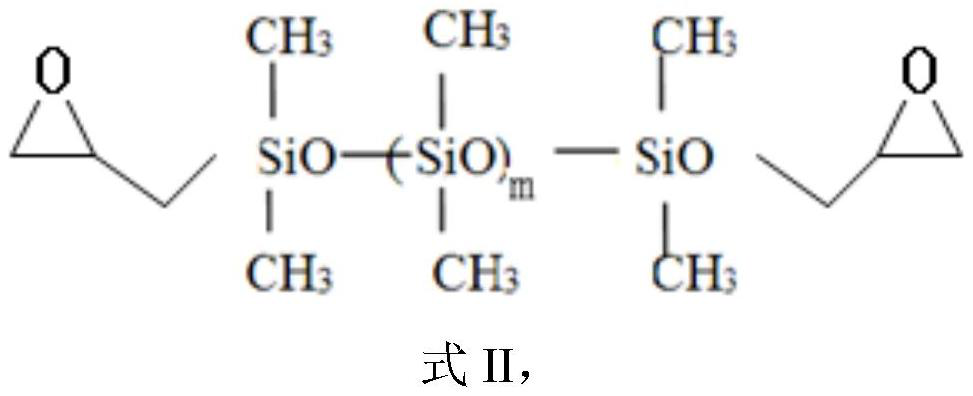

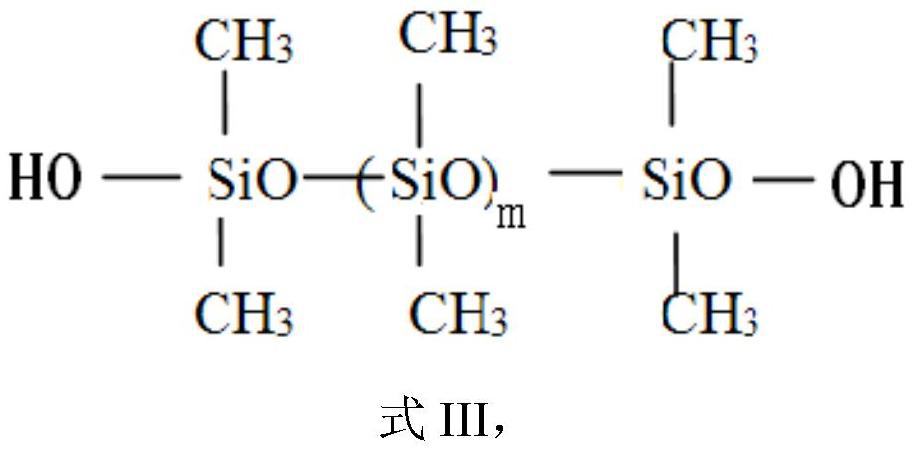

Broad-spectrum high-efficiency defoaming agent for offshore oilfield and preparation method of broad-spectrum high-efficiency defoaming agent

ActiveCN113967372AReduce surface tensionGood spreading and spreadingFoam dispersion/preventionSilicone resinOrganosolv

The invention discloses a broad-spectrum high-efficiency defoaming agent for an offshore oilfield. The broad-spectrum high-efficiency defoaming agent is prepared from the following components in percentage by mass: 8-10wt% of a defoaming main agent, 0.5-1wt% of a defoaming auxiliary agent, 1-2wt% of a synergist and the balance of a dispersing agent, wherein the defoaming main agent is prepared by taking mixed polydimethylsiloxane, epoxy polydimethylsiloxane, polydimethylsiloxane alcohol and hydrogen-containing MQ silicon resin with different molecular weights as raw materials and taking an organic tin compound as a catalyst to react in an organic solvent. The defoaming agent disclosed by the invention can be spread and diffused on the surface of foam more quickly, the interfacial strength of the foam is reduced, the defoaming effect is further enhanced, and the defoaming agent is widely applicable to oil-gas separation treatment of crude oil with different oil properties in offshore oilfields, and is a broad-spectrum and efficient crude oil defoaming agent product.

Owner:中海油(天津)油田化工有限公司 +1

Modified graphite-based functional filler, thermal interface material and preparation method thereof

ActiveCN113788986AIncrease polarityImprove electromagnetic shielding performanceRolling resistance optimizationGraphiteElectromagnetic shielding

The invention discloses a modified graphite-based functional filler, a thermal interface material and preparation methods of the modified graphite-based functional filler and the thermal interface material, the modified graphite-based functional filler comprises vermicular expanded graphite, and the surface of the vermicular expanded graphite is provided with a chemical active coating; the chemical active coating is used for introducing an active group to improve the polarity of the vermicular expanded graphite; the thermal interface material comprises the modified graphite-based functional filler and liquid rubber; and the problem that application of an existing thermal interface material is limited due to the fact that the existing thermal interface material cannot achieve multi-coupling balance of the flexible characteristic, the heat conduction performance and the electromagnetic shielding effectiveness is solved.

Owner:TIANJIN UNIV

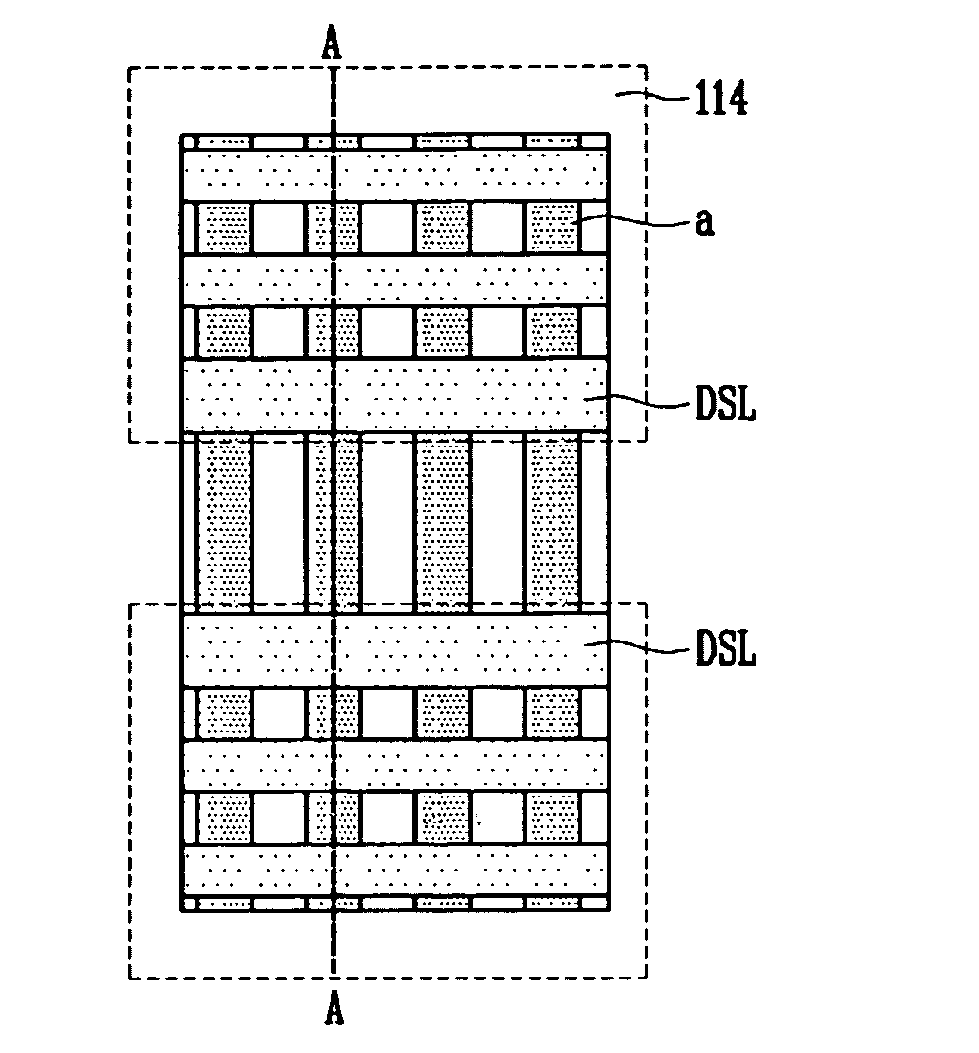

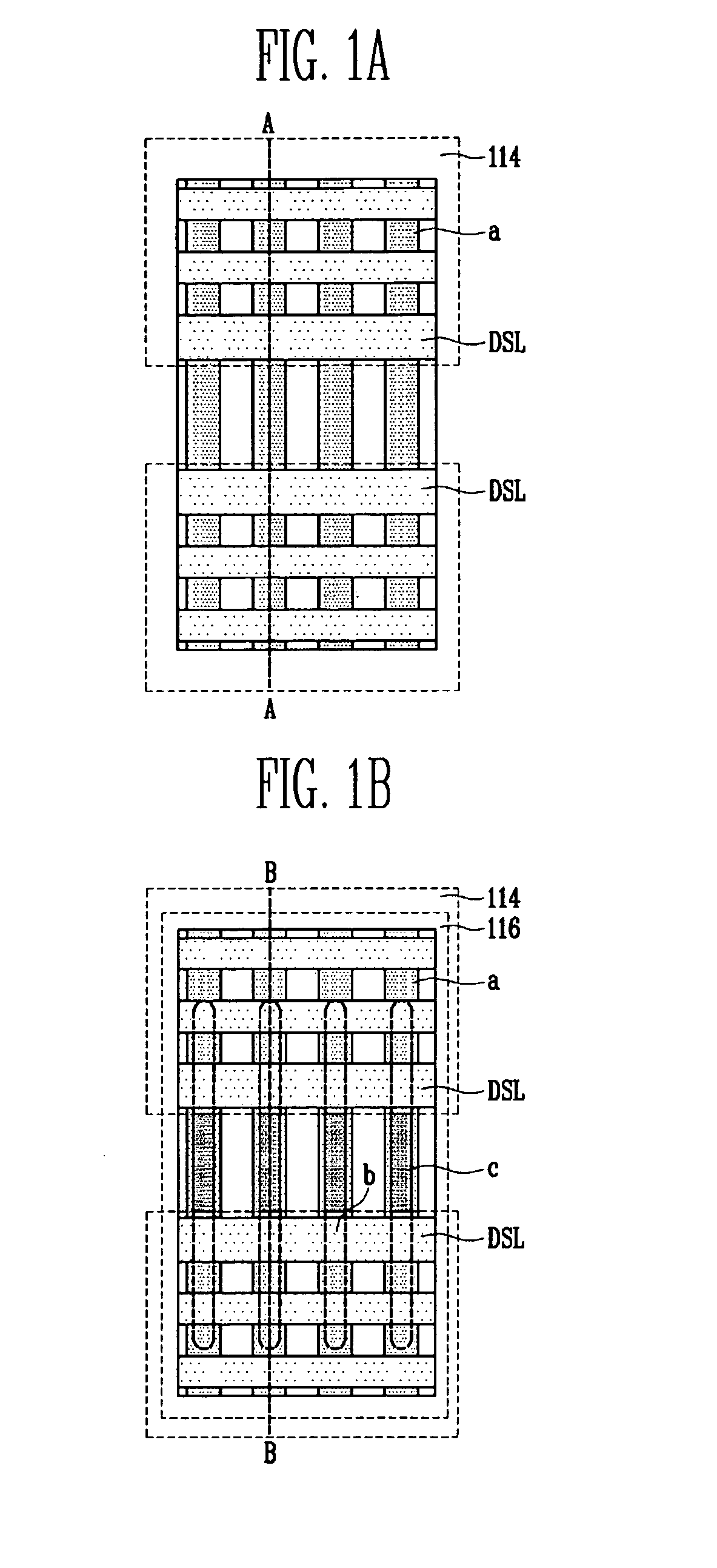

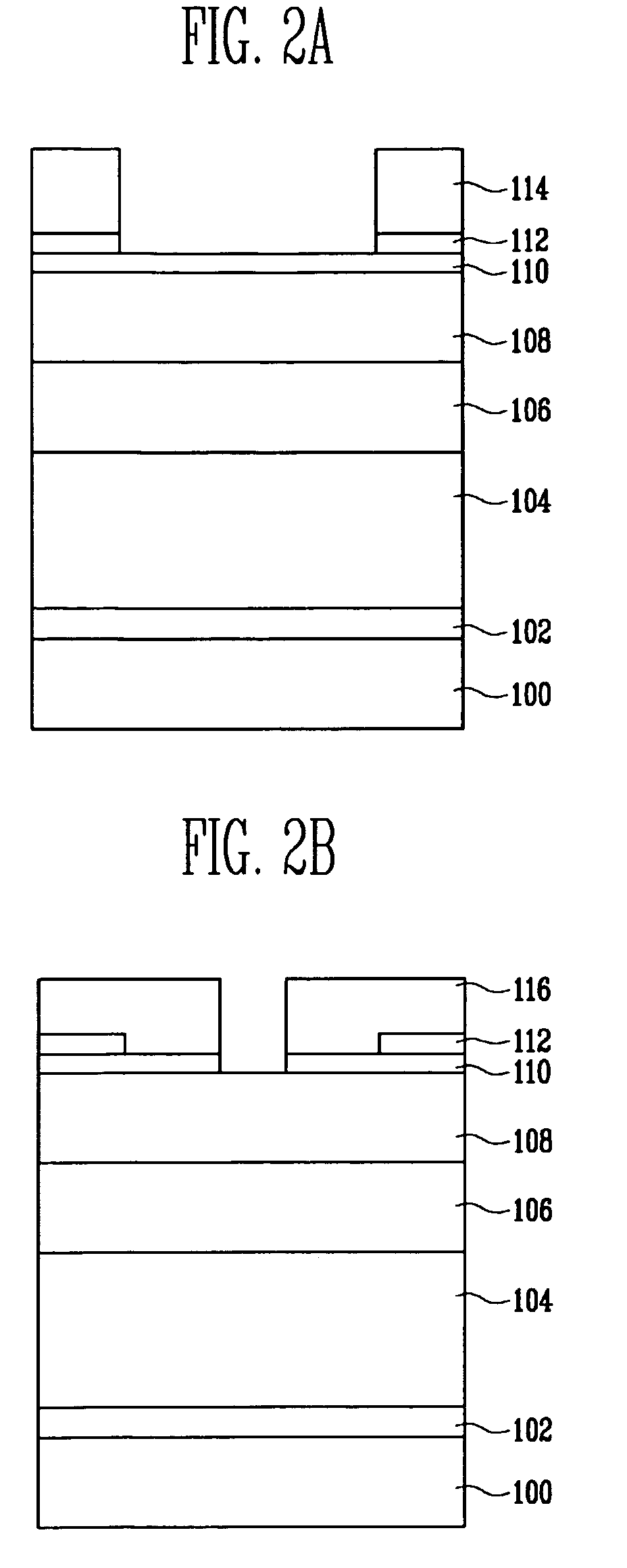

Method of manufacturing flash memory device

InactiveUS20070275559A1Improve bridgingSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor

A method of manufacturing a flash memory device which an etch-prevention layer, first and second interlayer insulating layers, and first, second and third hard mask layers are sequentially formed on a semiconductor substrate. The third hard mask layer is etched to expose a portion of a region on the second hard mask layer. A photoresist pattern of a line shape is formed on the entire surface such that the photoresist pattern is exposed to be narrower than the region through which the second hard mask layer is exposed. The second hard mask layer is etched using the photoresist pattern as a mask. The first hard mask layer is etched using the photoresist pattern as a mask, and the second and first interlayer insulating layers are then etched using the remaining third and second hard mask layers as masks, thus forming a drain contact hole having a square shape. The etch-prevention layer is etched using the remaining second and first hard mask layers as masks, thereby exposing a predetermined region of the semiconductor substrate and opening the drain contact hole. It is thus possible to improve a bridge occurring between the contacts.

Owner:SK HYNIX INC

Self exciting oscillation pipeline type flocculating device

InactiveCN100430326CImprove mixing conditionsWell mixedWater/sewage treatment by flocculation/precipitationFlocculationIndustrial waste water

The self exciting oscillation pipeline type flocculator is for water supply, industrial waste water and domestic sewage treating engineering and possesses flocculation, deposition, floating and other functions. The flocculator includes water nozzle, mixing cavity, upper nozzle, self exciting cavity and lower nozzle connected successively through pipeline; as well as chemical adding tank, flow rate regulating valve and flocculant conveying pipe with outlet to the mixing cavity connected together. The present invention has raised colloid particle bridging and adsorbing effect and thus raised flocculating efficiency. The flocculator has the pulse flow with pressure amplitude 15-30 % higher than that of inflow.

Owner:CHONGQING UNIV

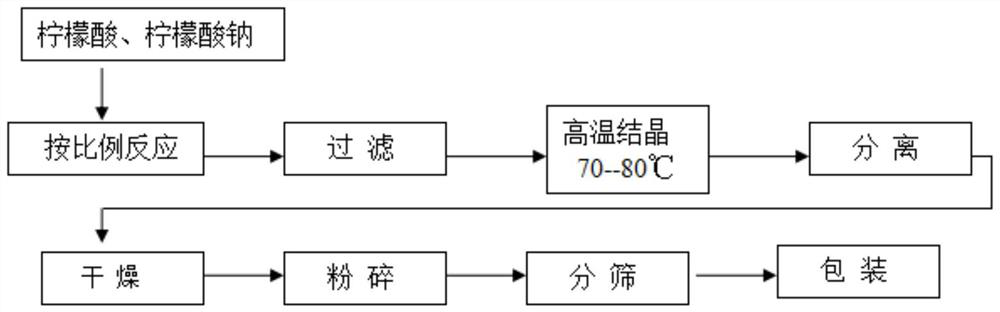

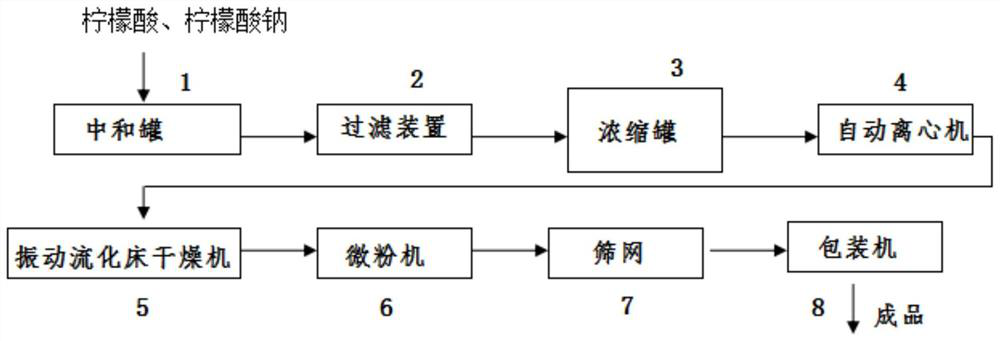

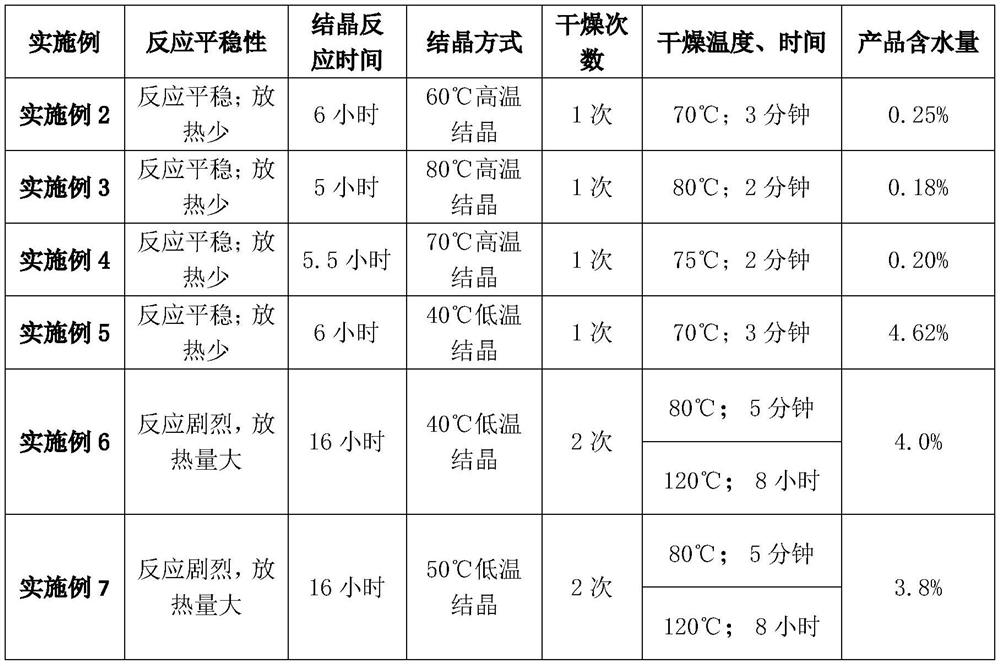

Preparation method and preparation system of monosodium citrate anhydrous

ActiveCN107935838BViolent reactionUnstable responseOrganic compound preparationCarboxylic acid salt preparationFluidized bed dryingPhysical chemistry

Owner:NINGXIANG XINYANG CHEM

A kind of high temperature resistant, thermally conductive nylon composite material and preparation method thereof

ActiveCN106147224BTake advantage of ease of processingTake full advantage of high temperature resistanceGlass fiberElastomer

The invention relates to a high-temperature-resistant and heat-conductive nylon composite material and a preparation method thereof. The high-temperature-resistant and heat-conductive nylon composite comprises the following components in parts by weight: 100 parts of PA66, 40-80 parts of high temperature-resistant nylon, 10-50 parts of a nylon elastomer, 10-30 parts of carbon fibers, 20-50 parts of a heat-conductive filler, 0.2-1.5 parts of a reactive flow modifier, 0.3-1.2 parts of an antioxidant and 0.3-2 parts of a lubricating agent. The preparation method comprises the following steps: uniformly pre-mixing the PA66, the high-temperature-resistant nylon, the nylon elastomer, the heat-conductive filler, the reactive flow modifier, the antioxidant and the lubricating agent, adding from a main feeding port of a double-screw extruder, adding the carbon fibers from a glass fiber mouth, controlling the rotating speed to be 800-1200 revolutions / min and the temperature to be 250-285 DEG C and performing extrusion granulation to obtain the high-temperature-resistant and heat-conductive nylon composite material. The material has excellent high temperature resistance and heat conduction and simultaneously has the characteristics of being good in mechanical property and easy to process.

Owner:上海日之升科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com