Preparation method and preparation system of monosodium citrate anhydrous

A technology of anhydrous citric acid and sodium citrate is applied in the preparation of carboxylates, carboxylates, organic compounds, etc., and can solve the problems of low production cost and production efficiency, long reaction time and drying time, etc., To achieve the effect of increasing the number of foaming, shortening the time and drying time, and improving the dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

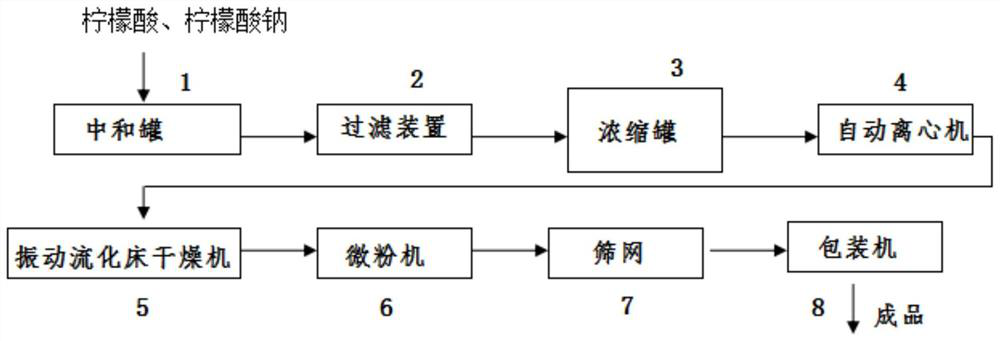

[0054] Such as figure 2 As shown, the present embodiment provides a preparation system of anhydrous monosodium citrate, comprising:

[0055] The neutralization tank 1, filter device 2, concentration tank 3, automatic centrifuge 4, vibrating fluidized bed dryer 5, micronizer 6, screen 7, packaging machine 8 connected in sequence;

[0056] The neutralization tank 1 is provided with a stirring device, a heating device and a feeding device;

[0057]The concentration tank 3 is provided with a stirring device, a heating device and a sampling port.

Embodiment 2

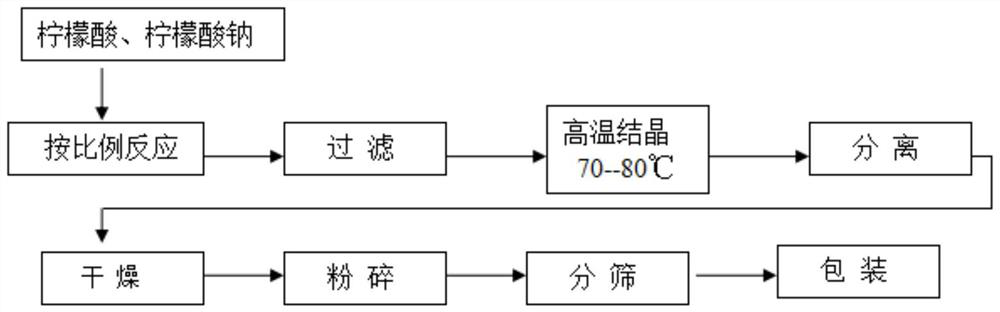

[0059] Such as figure 1 As shown, the present embodiment adopts the preparation system of anhydrous monosodium citrate provided in Example 1, and provides a method for preparing anhydrous monosodium citrate with sodium citrate and citric acid as reaction raw materials. The preparation method specifically comprises the following steps:

[0060] A1, add 25% of the volume of purified water in the neutralization tank 1, and start stirring;

[0061] A2. Add sodium citrate into the neutralization tank 1, then raise the temperature to 70°C to fully dissolve it in purified water;

[0062] A3, then add citric acid in the neutralization tank 1 and make it fully dissolved;

[0063] Citric acid: the molar ratio of sodium citrate is 2:1; the purity of sodium citrate and citric acid is above 99%;

[0064] A4. After the feeding is finished, the materials are fully reacted for 1 hour according to the following reaction equation;

[0065] 2C 6 h 8 o 7 +C 6 h 5 o 7 Na 3 .2H 2 O→3C ...

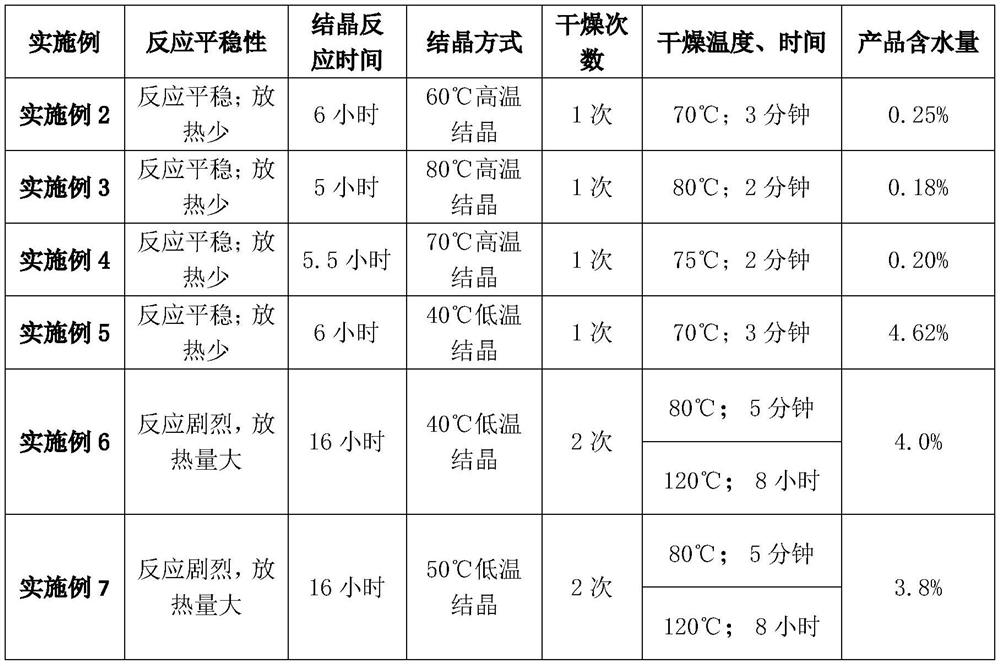

Embodiment 3

[0074] The difference between this embodiment and embodiment 2 is:

[0075] (1) Add 35% volume of purified water in A1, neutralization tank 1;

[0076] (2) A2, heat up to 75°C to fully dissolve the sodium citrate;

[0077] (3) A3, citric acid: the input molar ratio of sodium citrate is 2.5:1;

[0078] (4) A4, after feeding, the material reaction time is 2 hours; the reaction pH value is controlled at 2.8; the mass concentration of the control reaction solution is 1.26g / ml.

[0079] (5) A5, keeping the concentration tank 3 temperature at 80°C for crystallization for 5 hours;

[0080] (6) A7. The crystals are directly put into a vibrating fluidized bed dryer, and dried at 80° C. for 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com