Sludge treatment chemical adding pipeline mixer

A pipeline mixer and chemical treatment technology, which is applied in the direction of mixers, dehydration/drying/thickened sludge treatment, mixers with rotating stirring devices, etc., can solve the problems of not being able to fully use the effective length of the pipe section, and not being able to mix and react fully , to achieve the effects of increasing bridging and adsorption, ingenious structural design, and increasing the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

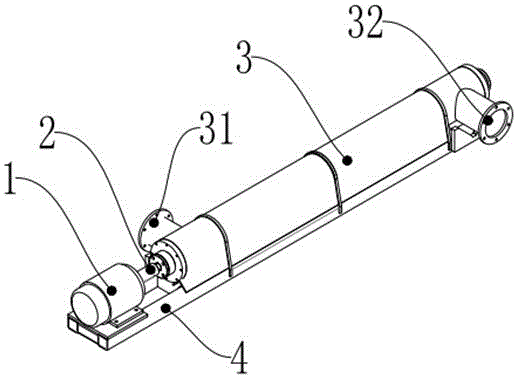

[0021] The structural diagram of a mud treatment agent adding pipeline mixer in this embodiment is as follows figure 1 As shown, including motor 1, spindle 2, mixing tube 3 and mounting frame 4;

[0022] The mixing tube 3 and the motor 1 are arranged on the mounting frame 4, the main shaft 2 is installed in the mixing tube 3, and the two ends of the mixing tube 3 are also provided with flanges, and the flanges are used to fix the main shaft 2; the motor 1 passes through the The coupling is connected with the main shaft 2, the motor 1 is a rotating motor, and the motor 1 drives the main shaft 2 to rotate;

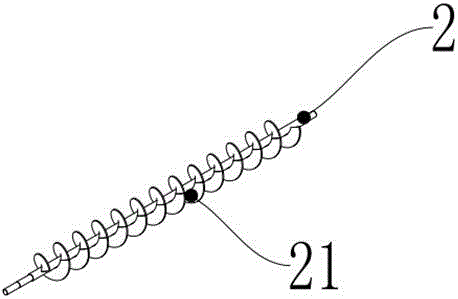

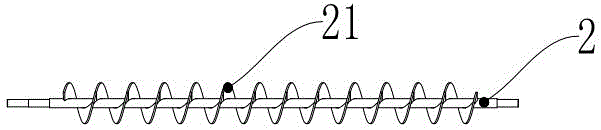

[0023] The main shaft 2 is provided with integrally formed helical blades 21, such as figure 2 and image 3 As shown, the surface of the helical blade 21 is a curved surface; the material of the main sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com