High-salt-tolerance super absorbent resin and preparation process thereof

A super absorbent resin and a technology for its preparation process, applied in the field of resins, can solve the problems of high synthetic industrial cost, non-natural degradation, poor salt resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

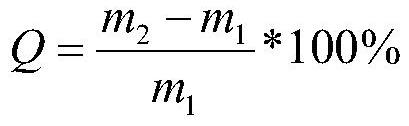

Method used

Image

Examples

Embodiment 1

[0032] A highly salt-tolerant superabsorbent resin, comprising the following raw materials: 5 parts of sodium alginate, 80 parts of acrylic acid, 50 parts of acrylamide, 20 parts of chitosan, 10 parts of diatomaceous earth, and 10 parts of humic acid , 0.05 parts of an initiator, 0.3 parts of a crosslinking agent, and 0.05 parts of an antioxidant.

[0033] The crosslinking agent is one or more of N, N-methylenebisacrylamide, polyethylene glycol diacrylate, glycerol, pentaerythritol, trimethylolmethane triacrylate, sodium citrate complex.

[0034] The initiator is benzoyl peroxide or azobisisobutyronitrile or dilauroyl peroxide or di-tert-butyl peroxide.

[0035] The antioxidant is any one of 2,6-di-tert-butyl-4-methylphenol, 4-hydroxydodecanoic acid anilide, antioxidant 1076, and antioxidant 264.

[0036] The above-mentioned high salt-tolerant superabsorbent resin is prepared by the following preparation process, including the following steps:

[0037] Step 1, dissolving ch...

Embodiment 2

[0042] A high salt-tolerant superabsorbent resin, comprising the following raw materials: 10 parts of sodium alginate, 100 parts of acrylic acid, 60 parts of acrylamide, 30 parts of chitosan, 20 parts of diatomaceous earth, and 15 parts of humic acid , 2.5 parts of initiator, 5 parts of crosslinking agent, 3 parts of antioxidant.

[0043] The crosslinking agent is one or more of N, N-methylenebisacrylamide, polyethylene glycol diacrylate, glycerol, pentaerythritol, trimethylolmethane triacrylate, sodium citrate complex.

[0044] The initiator is benzoyl peroxide or azobisisobutyronitrile or dilauroyl peroxide or di-tert-butyl peroxide.

[0045] The antioxidant is any one of 2,6-di-tert-butyl-4-methylphenol, 4-hydroxydodecanoic acid anilide, antioxidant 1076, and antioxidant 264.

[0046] The above-mentioned high salt-tolerant superabsorbent resin is prepared by the following preparation process, including the following steps:

[0047] Step 1, dissolving chitosan directly in...

Embodiment 3

[0055] A high salt-tolerant superabsorbent resin, comprising the following raw materials: 8 parts of sodium alginate, 90 parts of acrylic acid, 55 parts of acrylamide, 25 parts of chitosan, 15 parts of diatomaceous earth, and 20 parts of humic acid , 0.1 part of initiator, 0.6 part of crosslinking agent, 0.5 part of antioxidant.

[0056] The crosslinking agent is one or more of N, N-methylenebisacrylamide, polyethylene glycol diacrylate, glycerol, pentaerythritol, trimethylolmethane triacrylate, sodium citrate complex.

[0057] The initiator is benzoyl peroxide or azobisisobutyronitrile or dilauroyl peroxide or di-tert-butyl peroxide.

[0058] The antioxidant is any one of 2,6-di-tert-butyl-4-methylphenol, 4-hydroxydodecanoic acid anilide, antioxidant 1076, and antioxidant 264.

[0059] The above-mentioned high salt-tolerant superabsorbent resin is prepared by the following preparation process, including the following steps:

[0060] Step 1, dissolving chitosan directly in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com