A kind of production method of environment-friendly composite sludge conditioner

A technology for sludge conditioning and production methods, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high water content in sludge and inability to improve sludge dehydration, and achieve The preparation process is simple, the adsorption performance is reduced, and the conditioning is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The invention provides a technical solution: a production method of an environmentally friendly composite sludge conditioner, comprising the following steps:

[0019] (1) Preparation of reagent A: Dissolve polydimethyldiallyl ammonium chloride and polydichloroethyl ether tetramethylethylenediamine in pure water at 60°C, stir for 1 hour, and cool to obtain A Reagents, wherein by mass percentage, polydimethyldiallylammonium chloride accounts for 15%, polydichloroethyl ether tetramethylethylenediamine accounts for 50%, and the rest is pure water;

[0020] (2) Preparation of B reagent: A certain amount of sodium alginate and chitosan are respectively added into 1% acetic acid solution by mass percentage of acetic acid, configured into 2g / L sodium alginate solution and chitosan solution, and then equal volumes Pour the sodium alginate solution into the chitosan solution, stir continuously for 4 hours, ultrasonically disperse for 15-30 minutes, and then add acetone. After pre...

Embodiment 2

[0023] The sludge conditioner provided by this embodiment has the same preparation process as in Example 1, only adjusting the mass ratio of the following preparation raw materials:

[0024] (1) Prepare A reagent: by mass percentage, polydimethyldiallylammonium chloride accounts for 10%, polydichloroethyl ether tetramethylethylenediamine accounts for 30%, epichlorohydrin-dimethylamine 30% copolymer, the rest is pure water;

[0025] (2) Preparation of reagent B: sodium alginate-chitosan polymer accounts for 70%, and fly ash accounts for 30%;

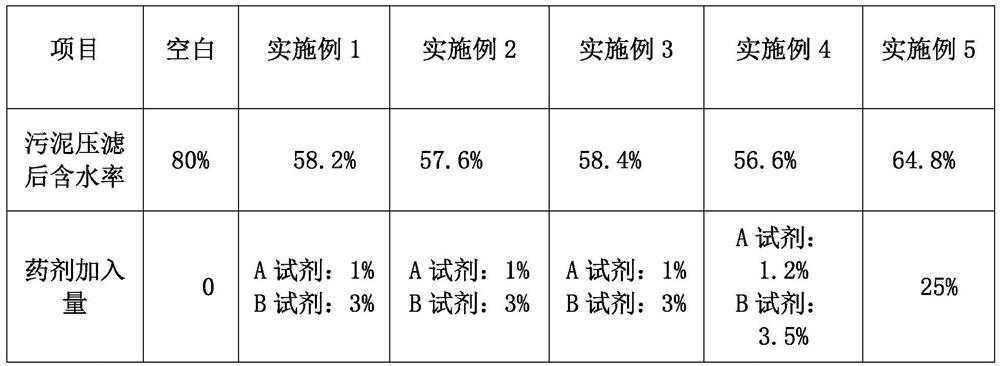

[0026] After the sludge conditioner provided in this example is used for sludge concentration and before deep dehydration treatment, the water content of the sludge to be treated is first detected. The results show that the water content of the sludge to be treated is 97.5%. Based on the amount of absolute dry sludge, first sprinkle the sludge conditioner A reagent, the effective dosage of A reagent is 1% of the sludge mass, after mixing...

Embodiment 3

[0028] The sludge conditioner provided by this embodiment has the same preparation process as in Example 1, only adjusting the mass ratio of the following preparation raw materials:

[0029] (1) Preparation of reagent A: by mass percentage, polydimethyldiallylammonium chloride accounts for 15%, epichlorohydrin-dimethylamine copolymer 50%, and the rest is pure water;

[0030] (2) Preparation of reagent B: sodium alginate-chitosan polymer accounts for 60%, and fly ash accounts for 40%;

[0031] After the sludge conditioner provided in this example is used for sludge concentration and before deep dehydration treatment, the water content of the sludge to be treated is first detected. The results show that the water content of the sludge to be treated is 97.5%. Based on the amount of absolute dry sludge, first sprinkle the sludge conditioner A reagent, the effective dosage of A reagent is 1% of the sludge mass, after mixing evenly, keep stirring for 10 minutes, then add into B reag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com