High-toughness oxidation-resistant textured high-entropy ceramic as well as preparation method and application thereof

A texturing and oxidation-resistant technology, applied in the field of ceramic materials, can solve the problems of high cost and complicated operation, and achieve the effect of low cost, simple operation, and promotion of directional growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 10μm), TiO 2 (Powder purity 99.9%, particle size 4μm) and Ta 2 o 5 (powder purity 99.9%, particle size 1μm) powder, B 4 C (powder purity 99.9%, particle size 2μm) and graphite powder (purity 99.9%, particle size 1μm), Si 3 N 4 The ball is used as the ball milling medium, and ethanol is used as the solvent, and mixed for 22 hours.

[0034] 2. Graphite powder, B 4 C and HfO 2 or ZrO 2 or TiO 2 The molar ratio of all is 10:8:1, the graphite powder, B 4 C and Ta 2 o 5 The molar ratio is 20:10:10, the graphite powder, B 4 C and Cr 2 o 3 The molar ratio is 10:9:10.

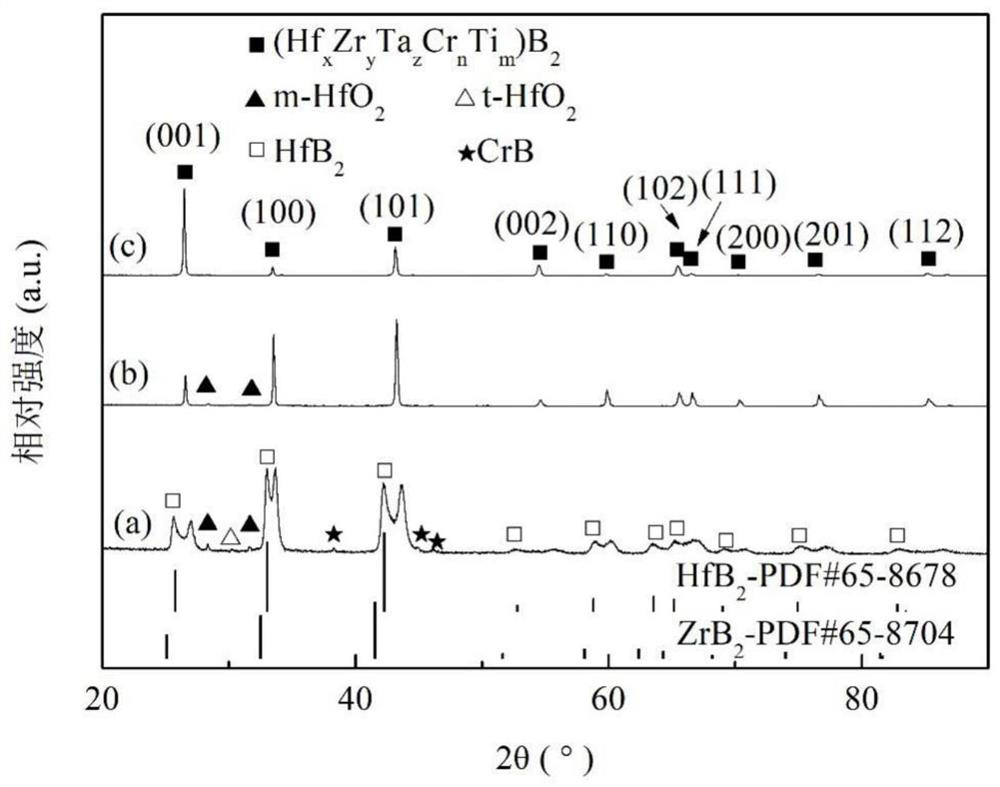

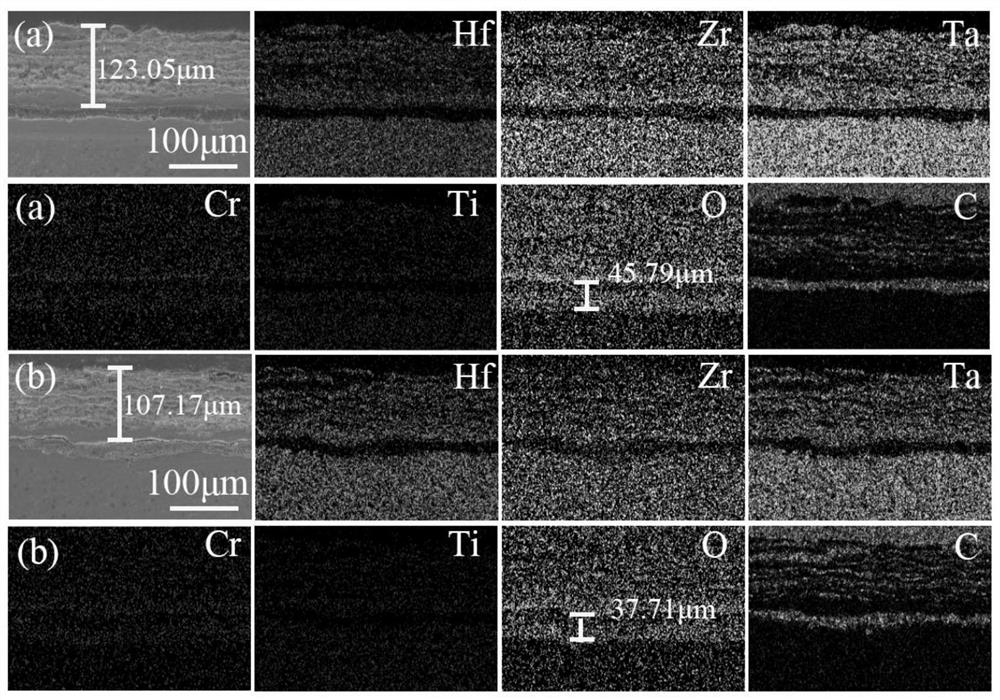

[0035] 3. Mold the mixed powder into a green body, heat-treat it under vacuum, raise the temperature to 1500°C for 2 hours at a heating rate of 15°C / min, and grind and sieve to obtain (Hf 0.2 Zr 0.1 Ta 0.3 Cr 0.1 Ti 0.3 )B 2 Textured high-entr...

Embodiment 2

[0039] 1. With HfO 2 (powder purity 99.9%, particle size 1μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 1μm), TiO 2 (powder purity 99.9%, particle size 1μm) and Ta 2 o 5 (powder purity 99.9%, particle size 1μm) powder, B 4 C (powder purity 99.9%, particle size 2μm) and graphite powder (purity 99.9%, particle size 1μm), Si 3 N 4 The ball is used as the ball milling medium, and ethanol is used as the solvent, and mixed for 24 hours.

[0040] 2. Graphite powder, B 4 C and HfO 2 or ZrO 2 or TiO 2 The molar ratio of all is 10:6:3, the graphite powder, B 4 C and Ta 2 o 5 The molar ratio is 20:7:10, the graphite powder, B 4 C and Cr 2 o 3 The molar ratio is 10:9:7.

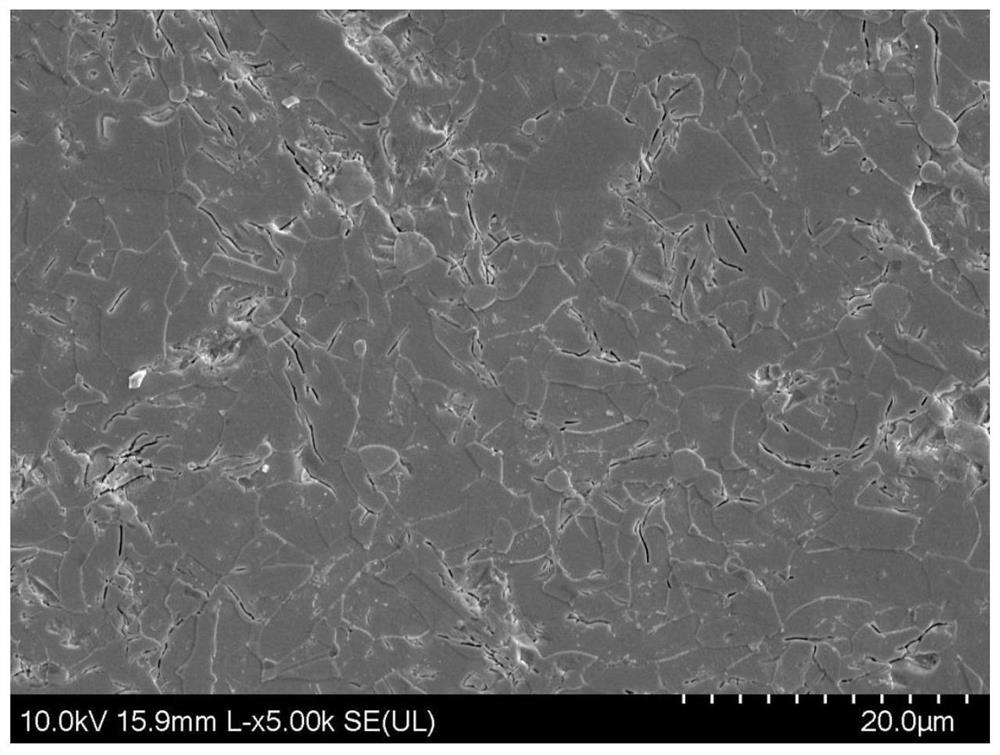

[0041] 3. Mold the mixed powder into a green body, heat treatment under vacuum condition, raise the temperature to 1600°C for 2 hours at a heating rate of 10°C / min, grind and sieve to obtain (Hf 0.2 Zr 0.2 Ta 0.2 Cr 0.2 Ti 0.2 )B 2 Textured high-...

Embodiment 3

[0047] 1. With HfO 2 (powder purity 99.9%, particle size 1μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 4μm), TiO 2 (powder purity 99.9%, particle size 8μm) and Ta 2 o 5 (powder purity 99.9%, particle size 1μm) powder, B 4 C (powder purity 99.9%, particle size 2μm) and graphite powder (purity 99.9%, particle size 5μm), with Si 3 N 4 The ball is used as the ball milling medium, and ethanol is used as the solvent, and mixed for 20 hours.

[0048] 2. Graphite powder, B 4 C and HfO 2 or ZrO 2 or TiO 2 The molar ratio is 8:6:3, the graphite powder, B 4 C and Ta 2 o 5 The molar ratio of all is 17:7:10, the graphite powder, B 4 C and Cr 2 o 3 The molar ratio is 7:9:7.

[0049] 3. Mold the mixed powder into a green body, heat treatment under vacuum conditions, raise the temperature to 1600°C for 1.5h at a heating rate of 15°C / min, and grind and sieve to obtain (Hf 0.2 Zr 0.2 Ta 0.1 Cr 0.3 Ti 0.2 )B 2 Textured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com