Double-beam laser TIG composite welding process for thin plate butt welding net forming

A hybrid welding, double beam technology, applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problems of bulge, inability to meet the flow channel morphology of active thermal protection components, and spatter on the back of the weld. It can achieve the effect of good formation of the front of the weld, suppressing defects such as back spatter and bulge, and realizing the net shape of the back of the weld.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

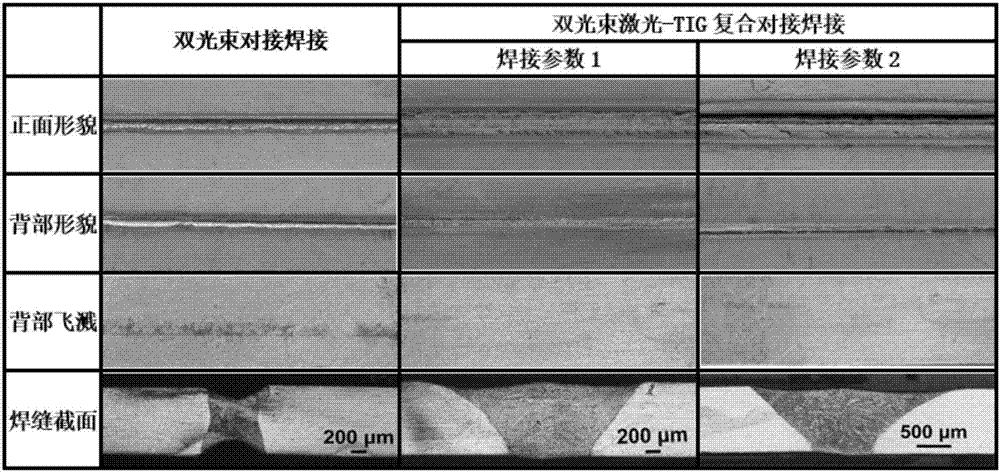

[0016] Embodiment 1 welding process parameter is as shown in the table below:

[0017]

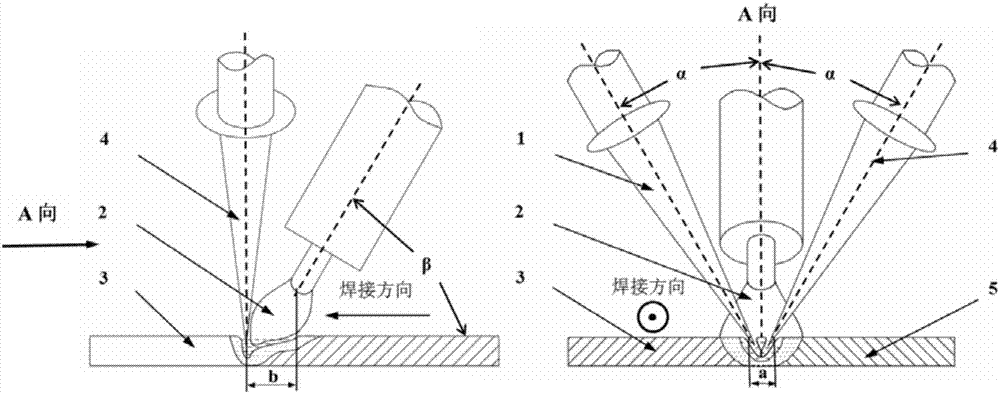

[0018] Among them, P is the laser power, V is the welding speed, I is the arc current, α is the incident angle of the laser beam, β is the inclination angle of the arc, and a is the distance between the focal points of the laser beam; the butt gap is set to 0.2 mm, and the laser beam defocus The distance between the center line of the laser beam 4 and the arc 2 on the workpiece 6 is b=2mm, the shielding gas is Ar gas, and the gas flow rate is 15L / min; during welding, a spatter receiving plate is set at 2 mm from the lower surface of the workpiece, and the surface state after welding is used to represent the degree of back spatter during welding. The material used in this embodiment is a GH3128 thin plate with a thickness of 1 mm. Before welding, use acetone to remove the oil stains on the surface of the workpiece to be welded and the butt surface.

[0019] From the weld surface and cr...

Embodiment 2

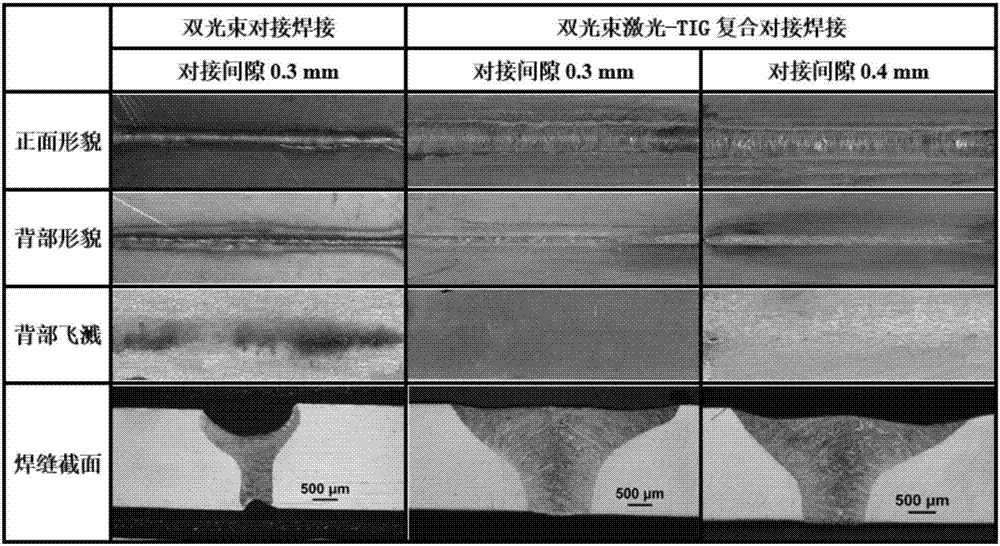

[0021] Embodiment 2 Welding process parameters are as shown in the table below:

[0022]

[0023] Among them, P is the laser power, V is the welding speed, I is the arc current, △t is the butt gap; the distance between the laser beam focus is a=1.5mm, the laser beam incident angle α=10°, and the arc inclination β=60° , the defocusing amount of the laser beam is 0mm, the height of the tungsten electrode is H=1.5mm, the extension length of the tungsten electrode is L=5mm; the distance between the center line of the laser beam 4 and the arc 2 on the workpiece 6 is b=2mm, and the protective gas is Ar gas , the gas flow rate is 15L / min; when welding, a spatter receiving plate is set at 2 mm from the lower surface of the workpiece, and the surface state after welding is used to represent the degree of back spatter during welding. The material used in this embodiment is a GH3128 thin plate with a thickness of 2mm. Before welding, use acetone to remove the oil stains on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com