Preparation method of nano polyaluminum iron silicate-graft modified starch hybrid flocculant

A polyaluminum ferric silicate, graft modification technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of poor removal of dissolved organic matter, weak coagulation ability of high-salt wastewater, and flocculation of cationic modified starch. The problem of low molecular weight of the agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

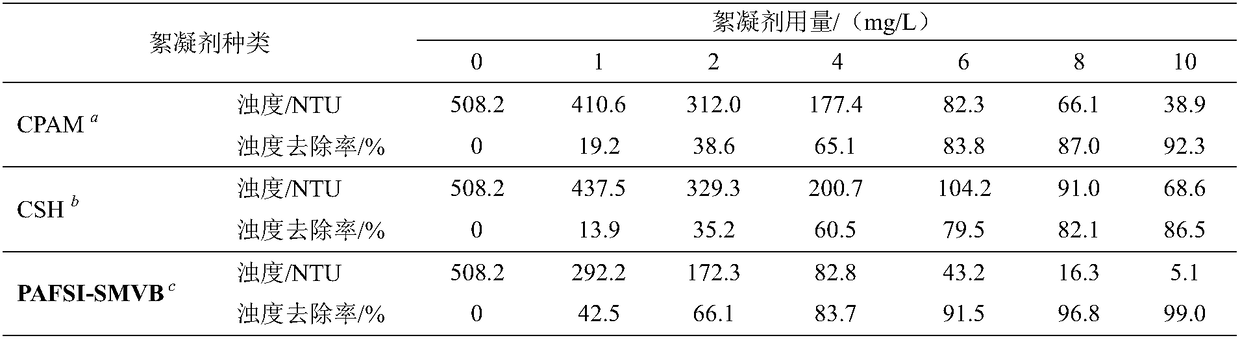

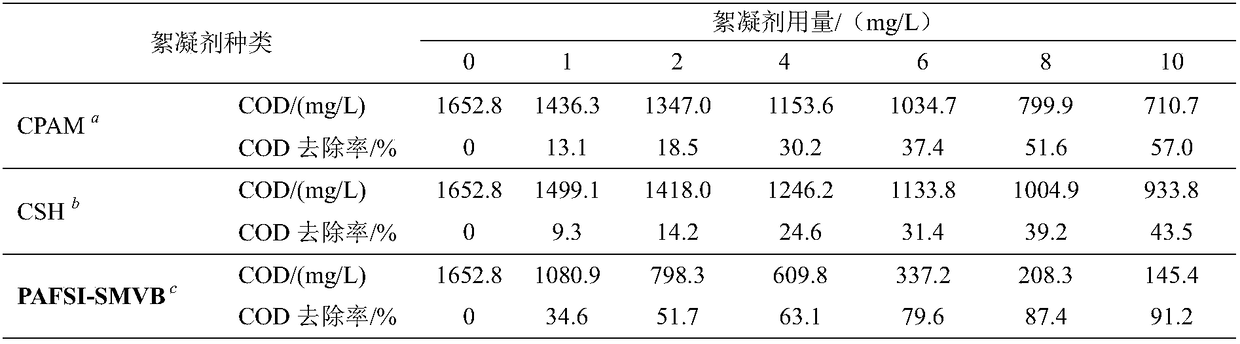

Examples

Embodiment 1

[0020] 20 g Na 2 SiO 3 Add 350 grams of deionized water into a three-necked reaction flask, stir to form a solution, adjust the pH value of the solution to 3 with sulfuric acid, and react at 30°C for 3 hours to obtain activated silicic acid; in 20 grams of activated silicic acid in Slowly add AlCl with stirring 3 120mL of ethylene glycol solution with a mass concentration of 100g / L, then slowly add FeCl 3 145mL of ethylene glycol solution with a mass concentration of 100g / L was stirred and reacted at 30°C for 3 hours, the pH was controlled to be 2, and then cooled to room temperature, then 1.330g of trimethylhexadecyl ammonium chloride was added and stirred. Standing and aging for 24 hours, nano-polyaluminum iron silicate PAFSI was prepared. Add 20 grams of starch and 29 grams of deionized water into the three-necked reaction flask, stir to make the starch fully mixed, pass N 2 , gelatinize the starch at 65°C for 1 hour, then cool to 30°C, then add 0.815 grams of trimethyl...

Embodiment 2

[0022] 20 g Na 2 SiO 3 Add 350 grams of deionized water into a three-necked reaction flask, stir to form a solution, adjust the pH value of the solution to 3 with sulfuric acid, and react at 25°C for 3 hours to obtain activated silicic acid; in 20 grams of activated silicic acid, Slowly add AlCl with stirring 3 258mL of ethylene glycol solution with a mass concentration of 100g / L, then slowly add FeCl 3 176mL of ethylene glycol solution with a mass concentration of 100g / L was stirred and reacted at 40°C for 2.5 hours, the pH was controlled to be 3, then cooled to room temperature, and 2.106g of trimethylhexadecyl ammonium chloride was added and stirred. Standing and aging for 24 hours, nano-polyaluminum iron silicate PAFSI was prepared. Add 20 grams of starch and 91 grams of deionized water into the three-necked reaction flask, stir to make the starch fully mixed, pass N 2 , gelatinize the starch at 70°C for 1 hour, then cool to 30°C, then add 2.160 grams of trimethylhexad...

Embodiment 3

[0024] 20 g Na 2 SiO 3 Add 350 grams of deionized water into a three-necked reaction flask, stir to form a solution, adjust the pH value of the solution to 2 with sulfuric acid, and react at 20°C for 3 hours to obtain activated silicic acid; in 20 grams of activated silicic acid, Slowly add AlCl with stirring 3 440mL of ethylene glycol solution with a mass concentration of 100g / L, then slowly add FeCl 3 215mL of ethylene glycol solution with a mass concentration of 100g / L was stirred and reacted at 50°C for 3 hours, the pH value was controlled to 4, and then cooled to room temperature, then 2.725g of trimethylhexadecyl ammonium chloride was added and stirred, Standing and aging for 24 hours, nano-polyaluminum iron silicate PAFSI was prepared. Add 20 grams of starch and 145 grams of deionized water into the three-necked reaction flask, stir to make the starch fully mixed, and turn on N 2 , gelatinize the starch at 80°C for 1 hour and cool to 30°C, then add 3.047 grams of tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com