Heat transfer room type heat recovery coke-oven

A technology of heat exchange chamber and heat recovery, applied in coking ovens, petroleum industry, etc., can solve the problems of excess gas, insufficient gas, low production efficiency, etc., and achieve the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

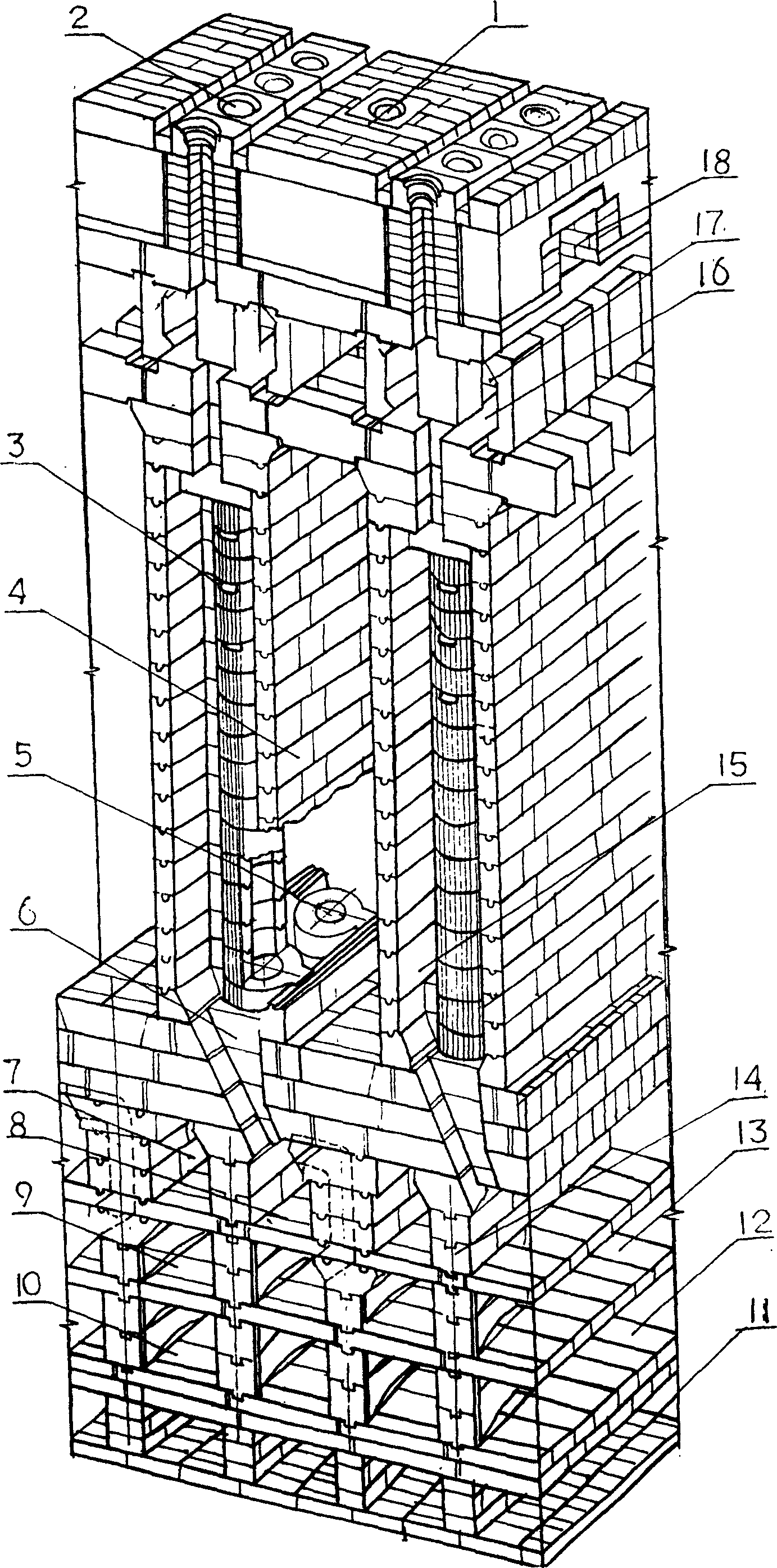

[0009]The top of the coke oven is equipped with a coal charging hole 1 and a fire viewing hole 2. The coal material is sent to the carbonization chamber 4 through the coal charging hole 1. When measuring temperature, the fire viewing hole 2 is opened. The gas channel 16 is evenly distributed to each standing fire channel 15 through the gas distribution hole 17, and the remaining heat gas enters the gas balance channel 18 in the furnace top area, and the gas is supplemented to the vertical fire channel 15 in the combustion chamber at the end of carbonization to balance the interior of each carbonization chamber 4 The gas pressure ensures the gas consumption of each coking chamber 4 in different coking sections. The remaining gas is also introduced from the gas balance channel 18 into the combustion chamber of the peripheral waste heat boiler for combustion. After the exhaust gas is absorbed by the waste heat boiler, the temperature drops to 200-150°C, and then the exhaust gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com