Novel energy-saving coke oven door lining brick and manufacturing method thereof

A technology for lining bricks and furnace doors, which is applied in the field of new energy-saving coke oven door lining bricks and its production, and can solve the problems of reduced heat insulation layer and loss of heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

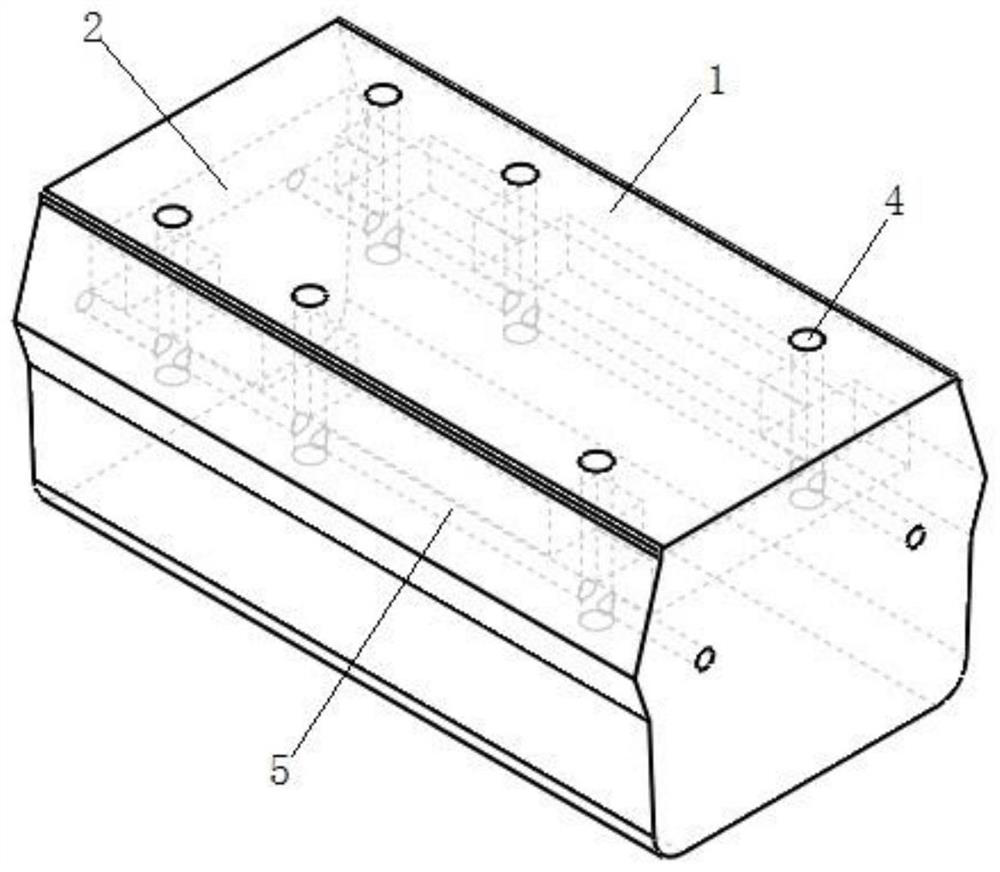

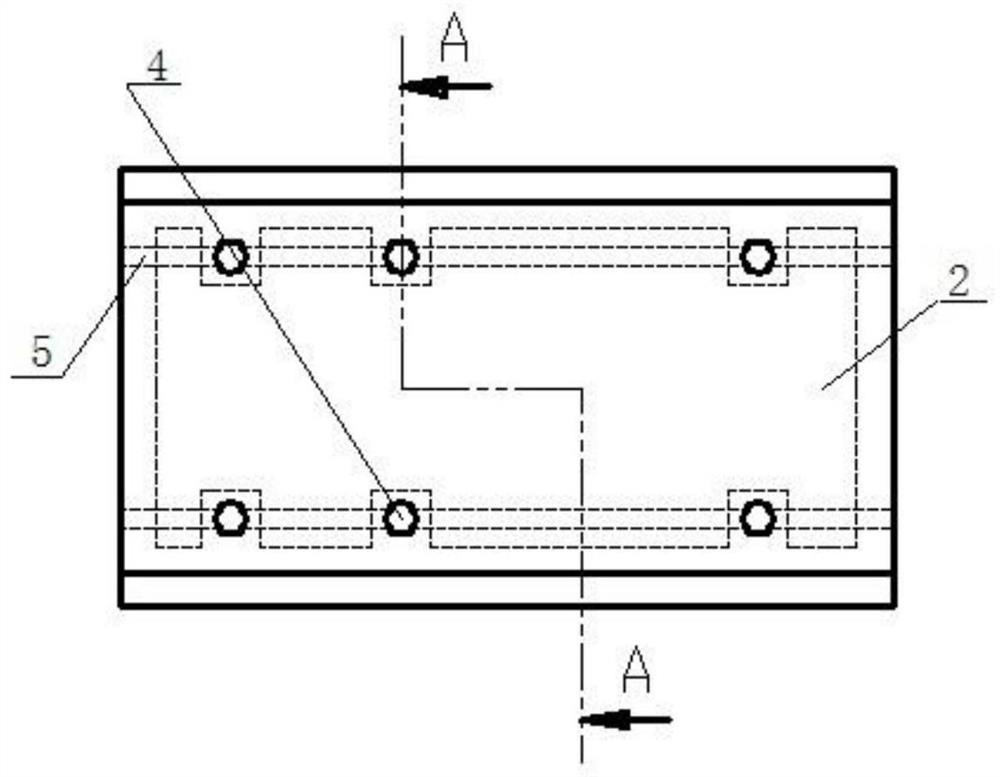

[0063] Such as Figure 1 ~ Figure 3 As shown, in this embodiment, a new type of energy-saving coke oven door lining brick includes a furnace door lining brick body 1, a glaze layer 3, a heat insulation layer 2, a fastener screw hole 4 and a fixing cross bar hole 5.

[0064] The furnace door lining brick body 1 is a castable prefabricated block, and the heat insulation layer 2 is arranged inside the furnace door lining brick body 1 and is completely wrapped. The two sides of the heat insulation layer 2 are parallel to the inner and outer surfaces of the furnace door lining brick body 1 . In order to increase the heat insulation area and reduce the temperature difference at the heat insulation layer 2, the heat insulation layer 2 is arranged on the side close to the iron parts of the furnace door (the outer surface of the furnace door lining brick body 1), where the temperature is relatively low, which can effectively Reduce thermal stress at insulation layer 2.

[0065] In or...

Embodiment 2

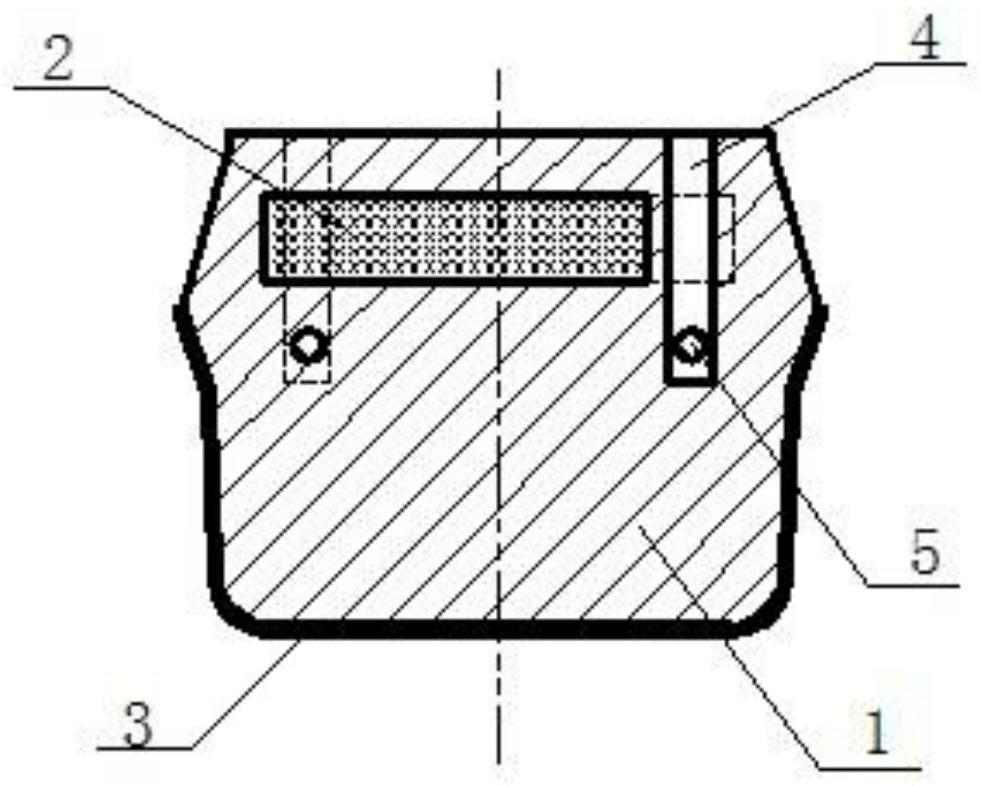

[0077] Such as Figure 4 ~ Figure 6 As shown, in this embodiment, the new energy-saving coke oven door lining brick includes a furnace door lining brick body 1 , a glaze layer 3 , a heat insulation layer 2 , a fastener screw hole 4 and a fixing bar hole 5 .

[0078] The furnace door lining brick body 1 is a castable prefabricated block, and the heat insulation layer 2 is arranged inside the furnace door lining brick body 1 and is completely wrapped by the furnace door lining brick body 1 . The two sides of the heat insulation layer 2 are parallel to the inner and outer surfaces of the furnace door lining brick body 1 . In this embodiment, the heat insulation layer 2 is a cuboid structure, and is arranged on the side of the furnace door lining brick body 1 close to the carbonization chamber, where the temperature is relatively high. The four corners of layer 2 are provided with chamfering structure, and the chamfering radius is 10mm.

[0079] In order to ensure the strength o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com