Energy-saving coke oven door structure

An energy-saving, furnace door technology, used in coke oven doors/closures, coke ovens, and coke oven heating, etc., can solve problems such as limited thermal insulation effect, reduced thermal insulation lining, loss of thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

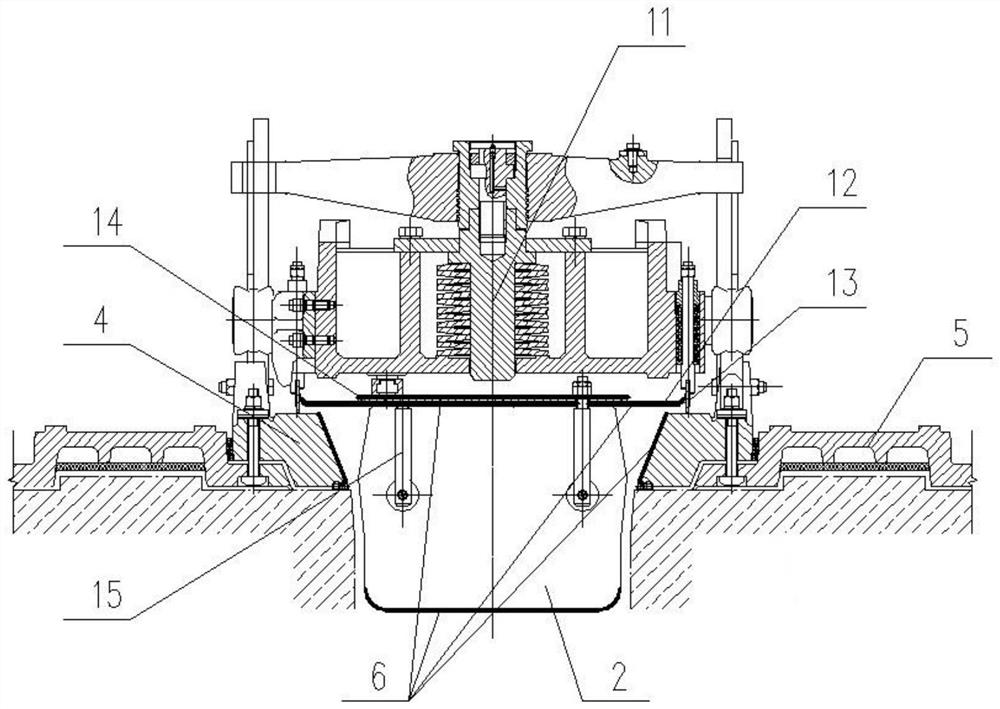

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

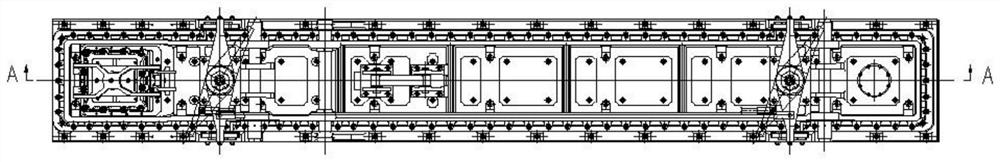

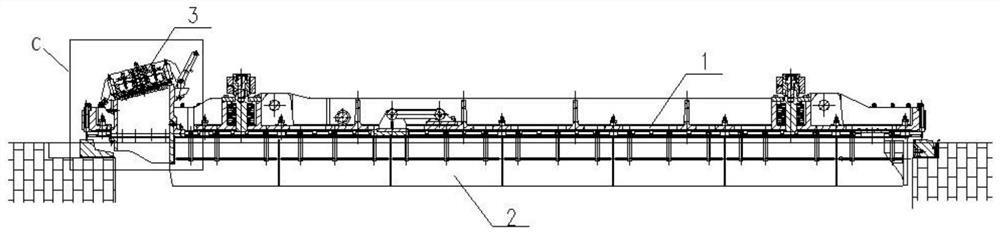

[0026] Such as Figure 1-Figure 3 As shown, an energy-saving coke oven door structure according to the present invention includes a coke oven door composed of furnace door lining bricks 2 and furnace door iron parts 1, and the furnace door iron parts 1 include a furnace door body 11, Furnace door fastener 15, furnace door sliding plate 14, furnace door knife edge 13 and furnace door web 12, the end of furnace door knife edge 13 close to the coke oven body is in contact with the furnace door frame 4 around the furnace door, and the furnace door knife edge The inner side of 13 is in contact with the furnace door belly 12; the surfaces of the furnace door lining brick 2, the furnace door frame 4, the furnace door web 12 and the furnace door sliding plate 14 are coated with a thermal insulation coating 6.

[0027] The furnace door lining brick 2 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com