Combustion chamber-carbonization chamber wall structure of coke oven

A carbonization chamber and combustion chamber technology, which is applied in the coking field, can solve the problems of reducing the structural strength of a coke oven body 1 and the air tightness of the combustion chamber and the carbonization chamber, so as to achieve large-scale development, increase coke output, and ensure structural strength and air tightness. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

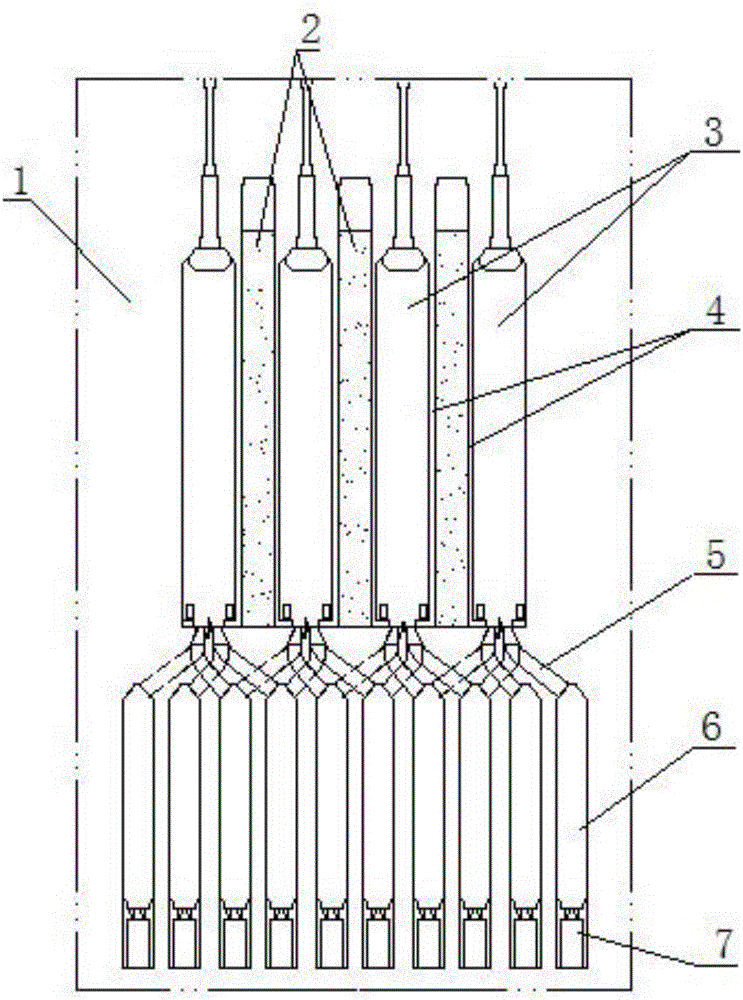

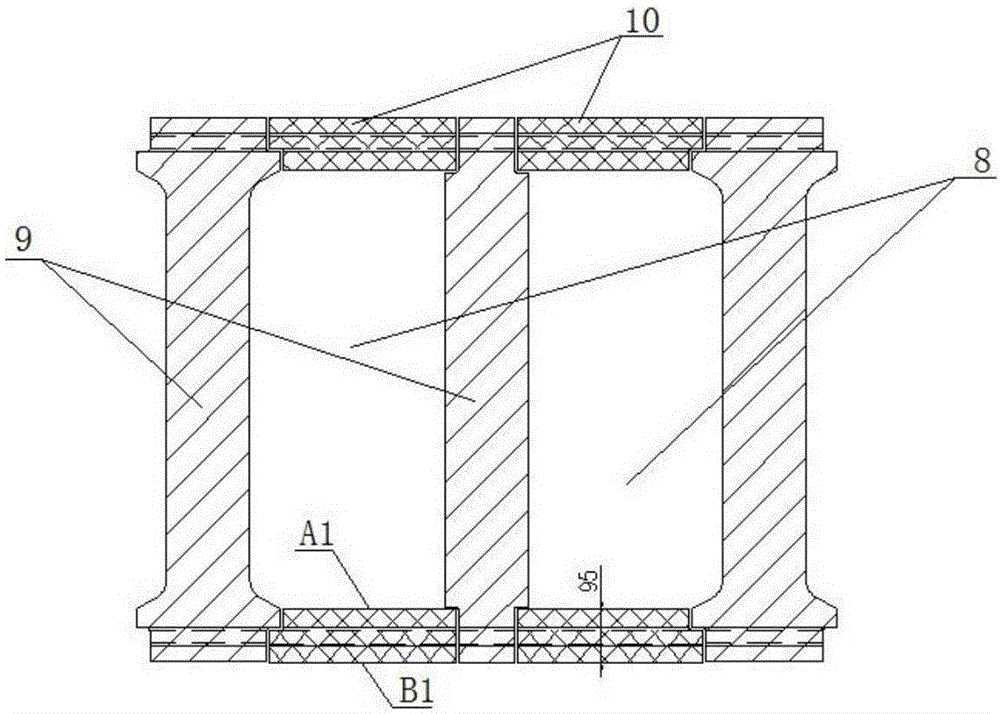

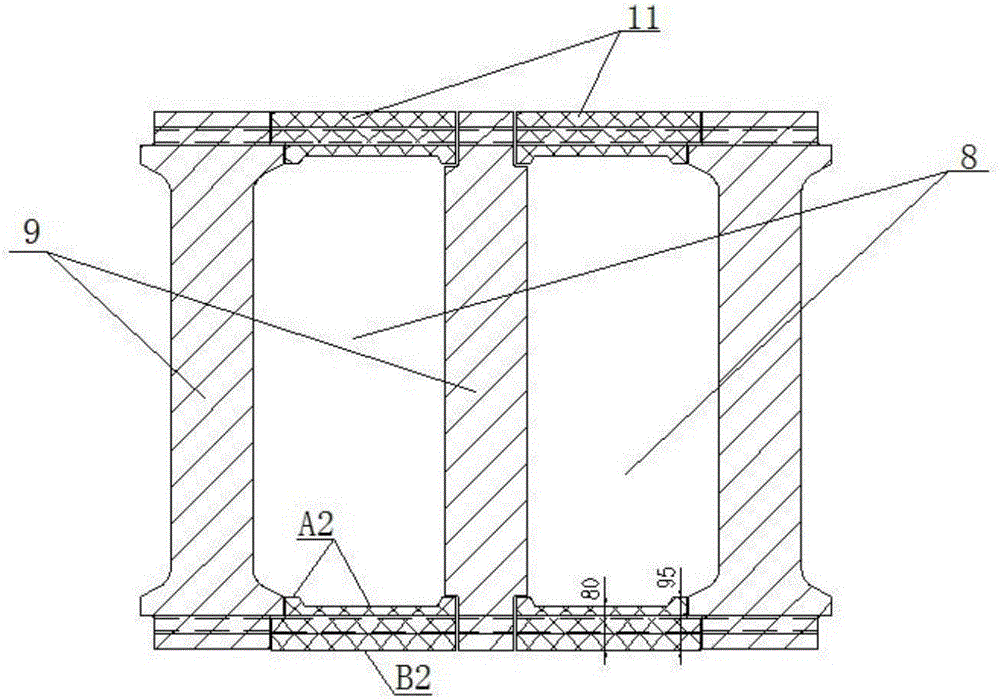

[0019] Such as image 3 As shown, a coke oven combustion chamber-carbonization chamber wall structure described in the present invention, the combustion chamber-carbonization chamber is composed of combustion chambers and carbonization chambers arranged alternately, and the combustion chambers are composed of a plurality of vertical fire channels 8 arranged side by side; A fire passage partition wall 9 is set up between the fire passages 8, a carbonization chamber wall 4 is set between the carbonization chamber and the vertical fire passage, and a concave-convex occlusal structure is set at the connection between the vertical fire passage partition wall 9 in the carbonization chamber and the carbonization chamber wall 11; the carbonization The inner surface of the chamber wall 11 facing the vertical fire channel 8 has a concave structure, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com