Small constant pressure coking device and constant pressure coking method

A small, hydraulic pump technology, applied in the field of coking in the laboratory, can solve problems such as the inability to carry out constant pressure coking, and achieve the effects of avoiding coke pushing failure accidents, shortening coking time, and improving coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

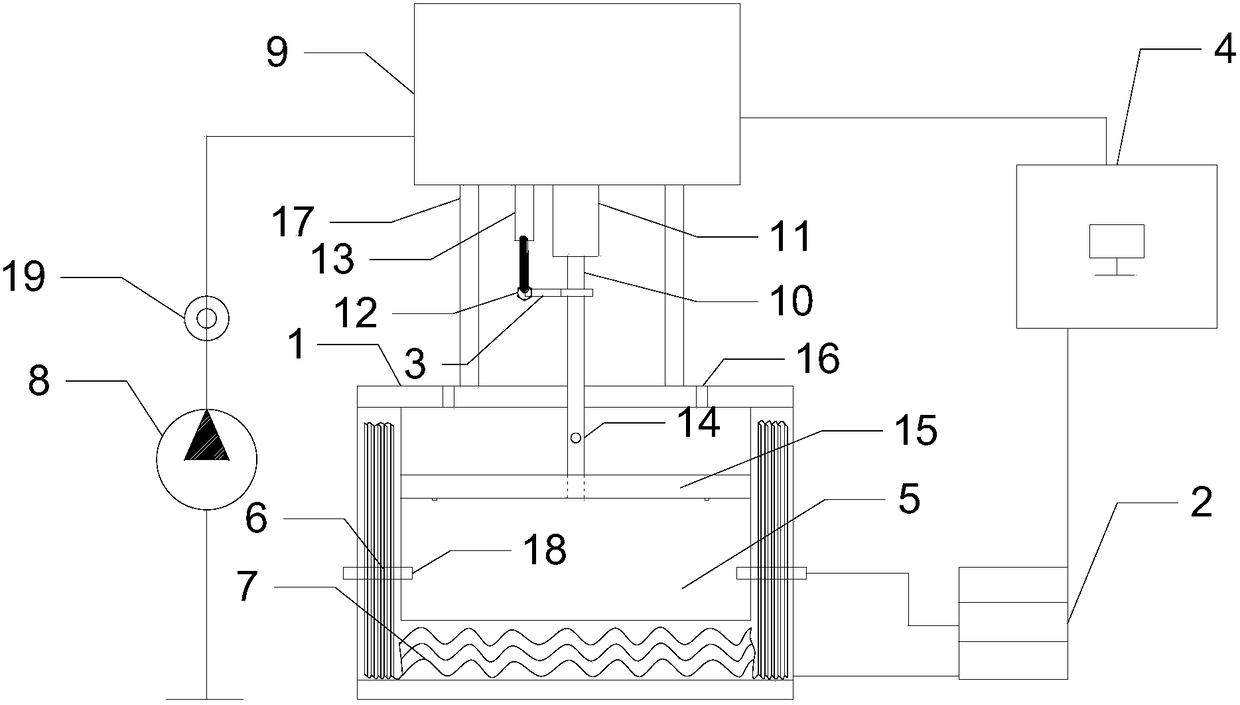

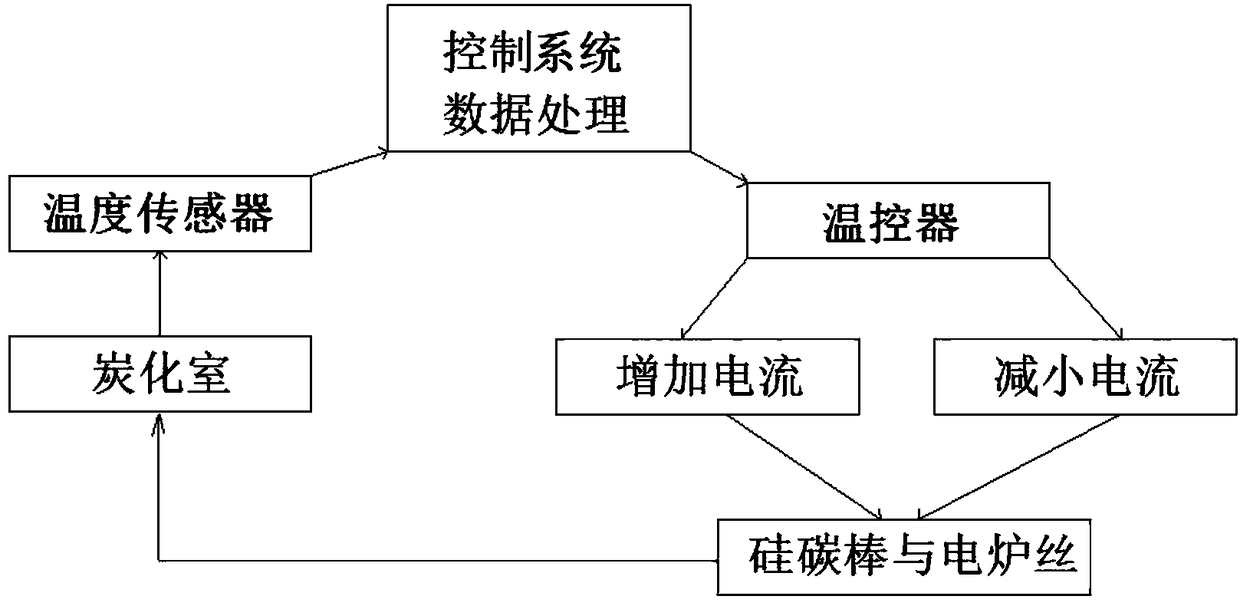

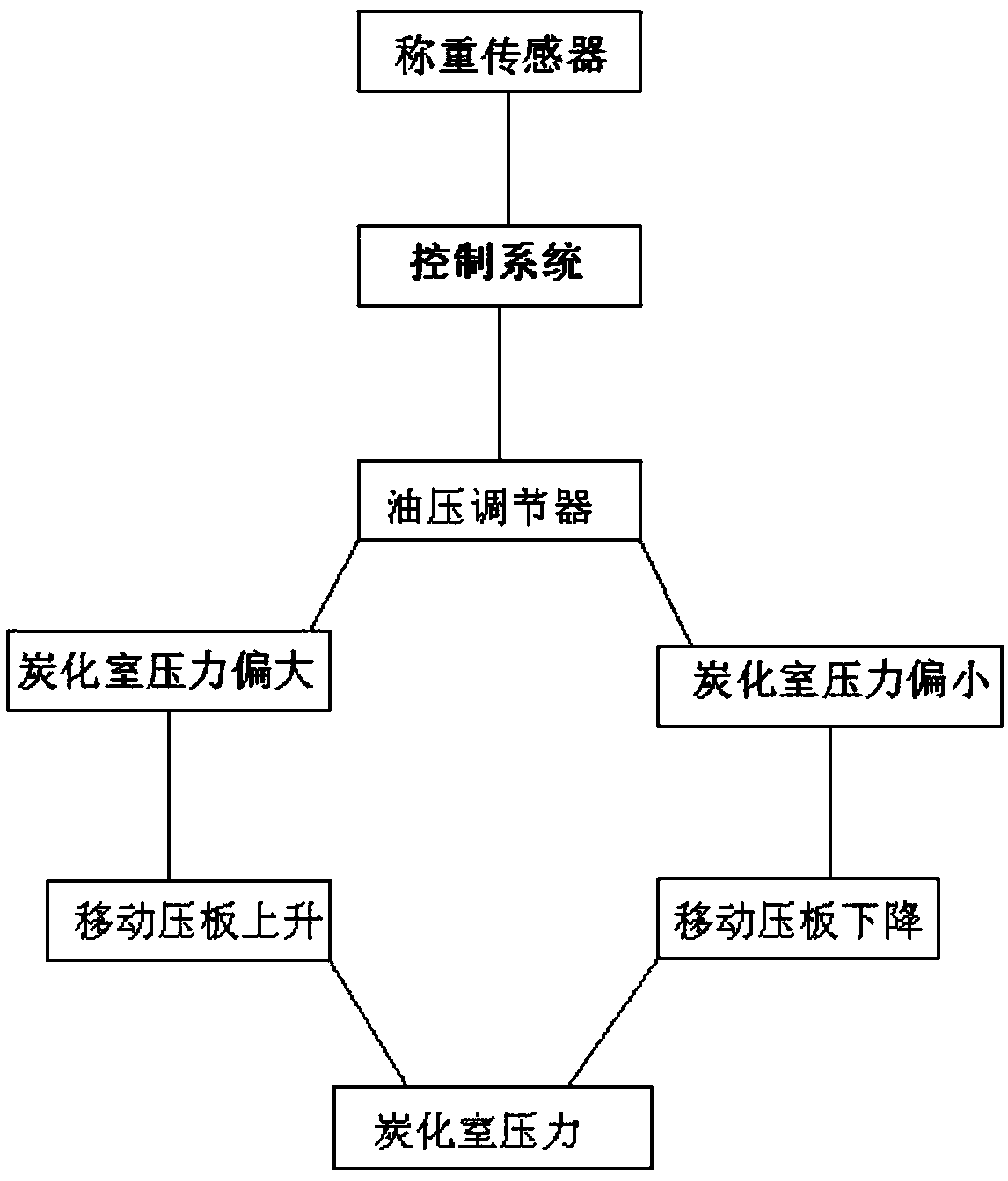

[0027] Such as figure 1 As shown, the small-scale constant pressure coking device of the present invention includes an experimental coke oven 1, a temperature controller 2, a constant pressure system and a control system; Silicon carbon rod 6, the resistance wire 7 is set at the bottom of the experimental coke oven 1, the silicon carbon rod 6 and the resistance wire 7 are controlled by the temperature controller 2, and the carbonization chamber 5 is set in the experimental coke oven 1; the constant pressure system is composed of a hydraulic pump 8, a buffer Cylinder 9 and moving platen 15 are composed, hydraulic pump 8 provides power for buffer cylinder 9, the push rod of buffer cylinder 9 is connected to moving platen 15 through first hollow tube 10 and can drive it to move up and down in carbonization chamber 5; the lower part of buffer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com