Vertical cylidndrical coke oven and submerging coke quenching method

A coke oven and vertical technology, applied in cylindrical vertical coke oven and water immersion coke quenching, international patent classification C10B33/00 "coke guide device field, can solve the problems of polluting the surrounding environment, consuming water resources, and excessive steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

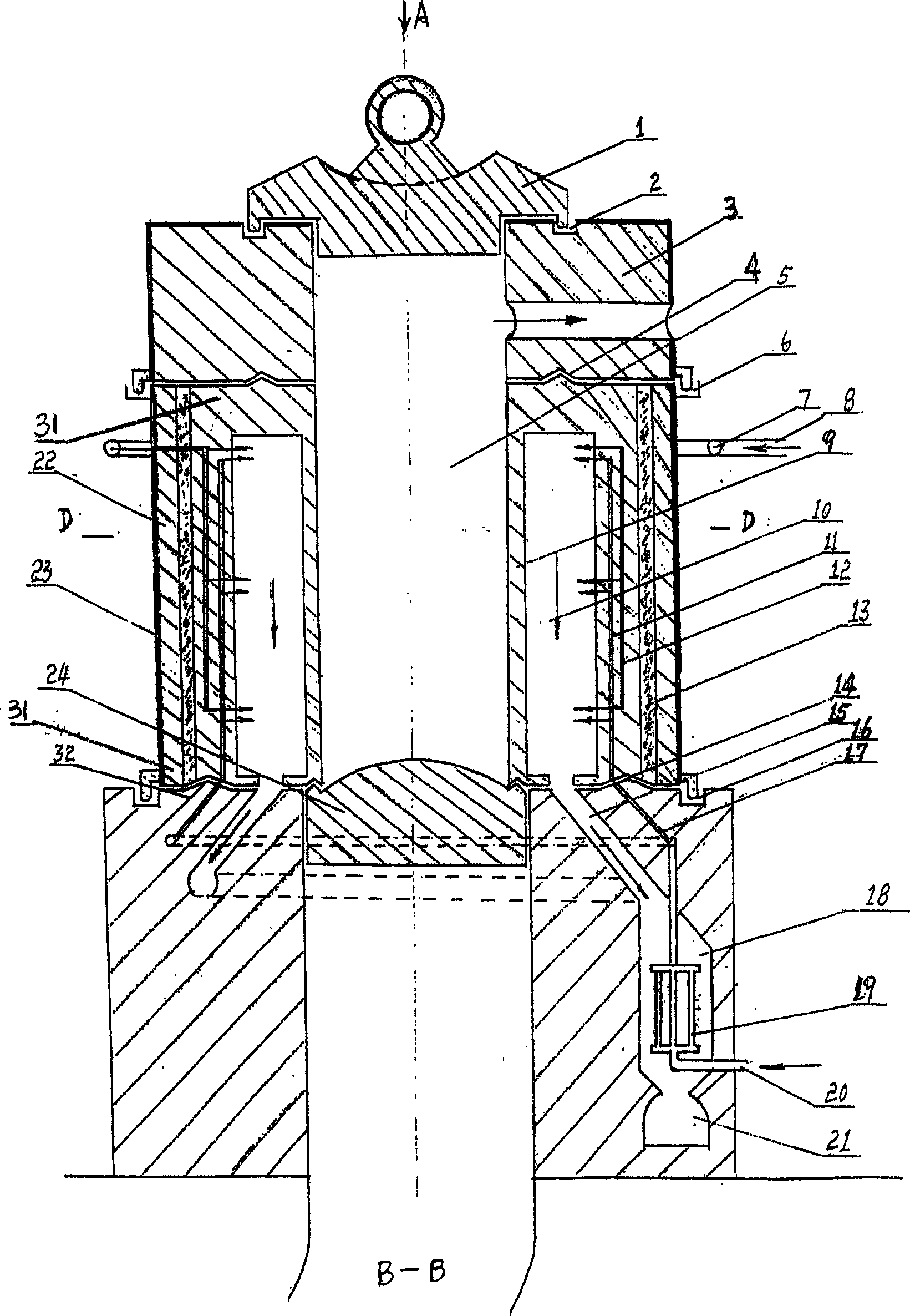

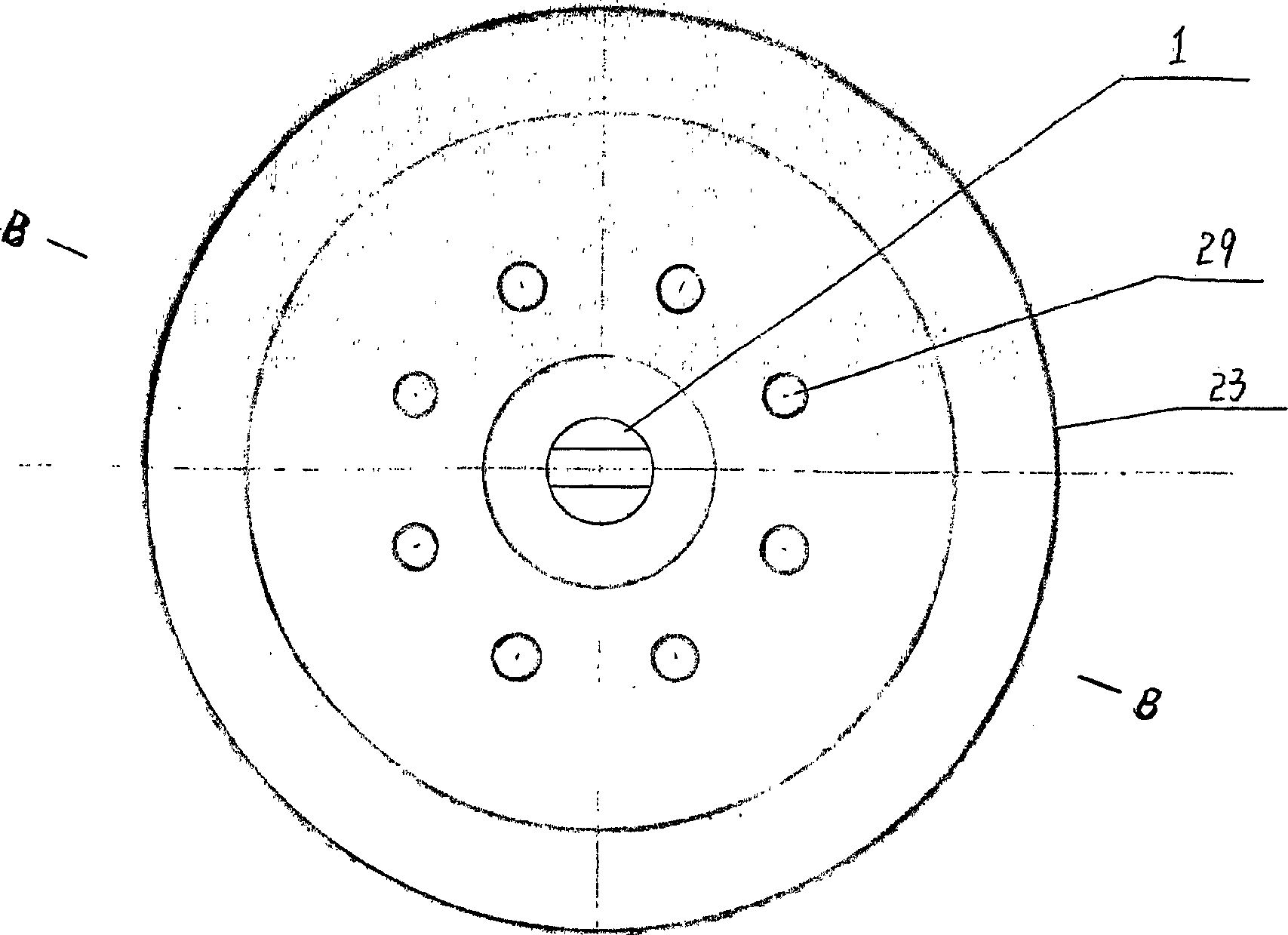

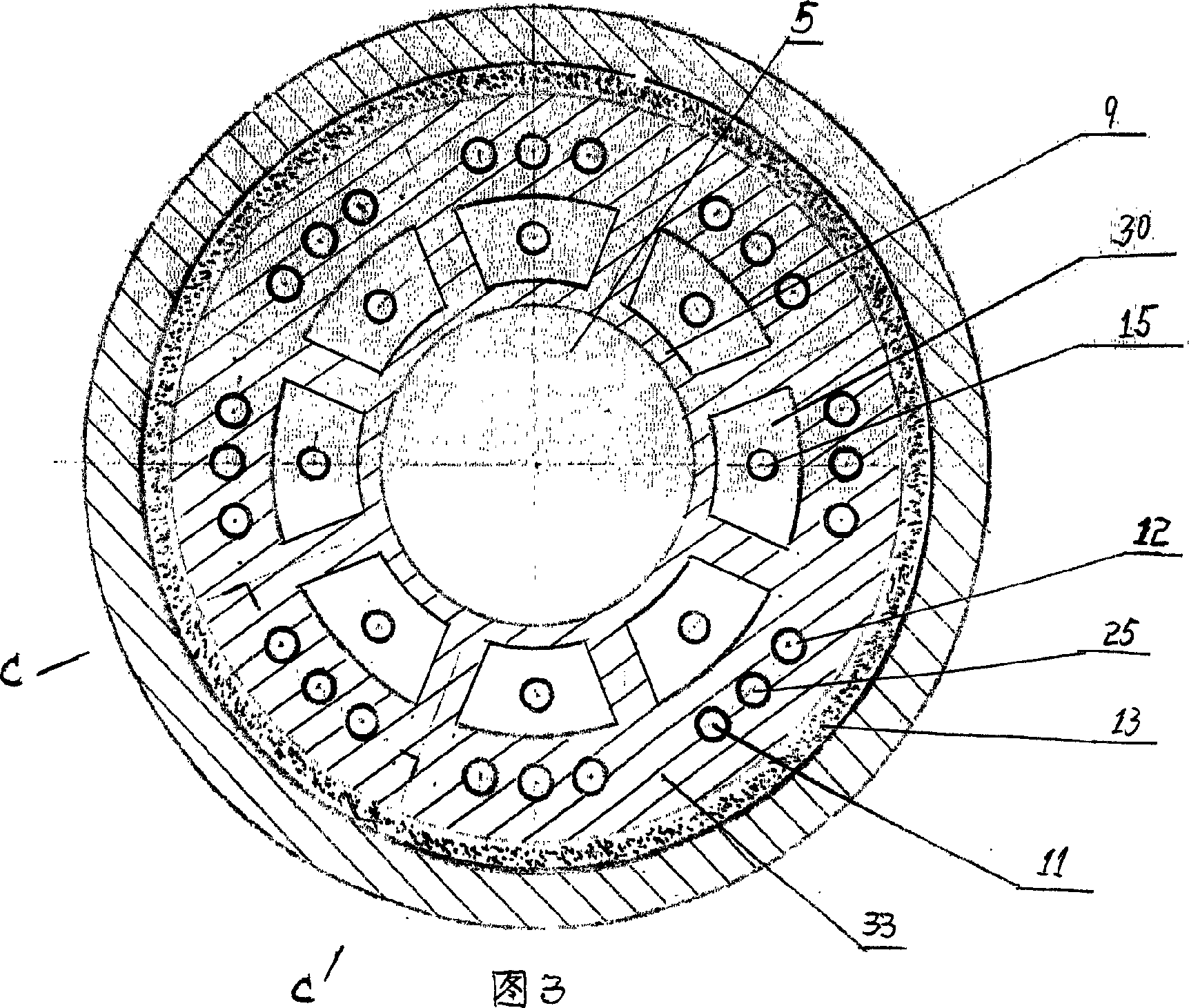

[0016] Such as figure 1 As shown in -4, the present invention adopts a cylindrical carbonization chamber 5 and an annular combustion chamber 10, including a cylindrical carbonization chamber 5 and an annular combustion chamber 10; an elliptical cylindrical carbonization chamber 5 and an elliptical annular combustion chamber 10; a polygonal prismatic carbonization Chamber 5 and combustion chamber 10 are polygonal rings. The coke oven is composed of a furnace body 31, a furnace roof 3, a coal charging hole cover 1, a furnace base 32 and a coke oven door 24. A temperature measuring hole 29 is arranged on the top of the furnace, and the furnace body 31 includes a carbonization chamber 5, a heat conduction wall 9, a combustion chamber 10, an outer wall 33 of the vertical fire passage, a heat insulation layer 13, a supporting wall 22, and iron parts 23 for protecting the furnace. Combustion chamber 10 is divided into several independent vertical fire passages 30, and air preheating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com