Patents

Literature

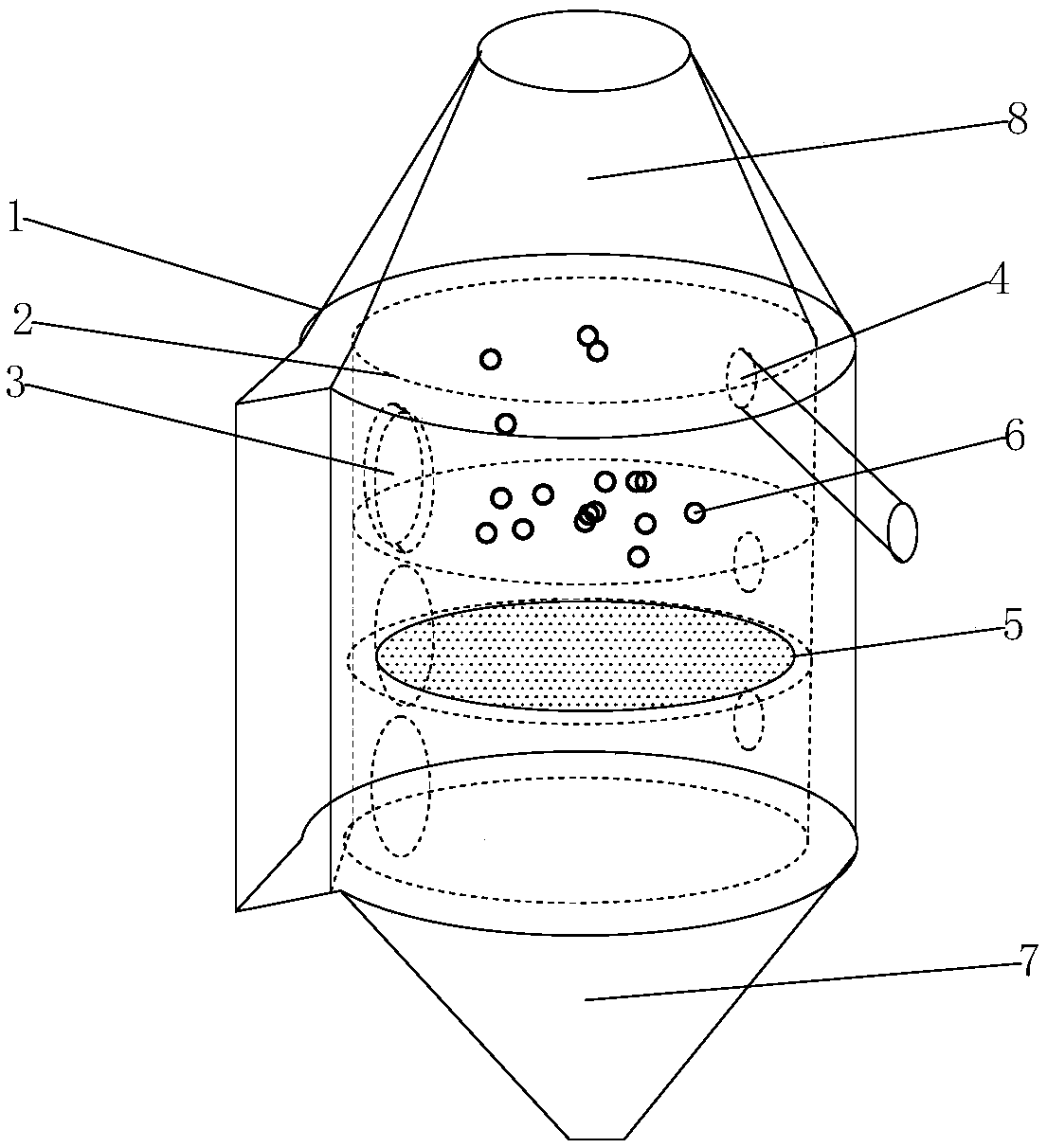

49results about How to "Reduce dust removal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

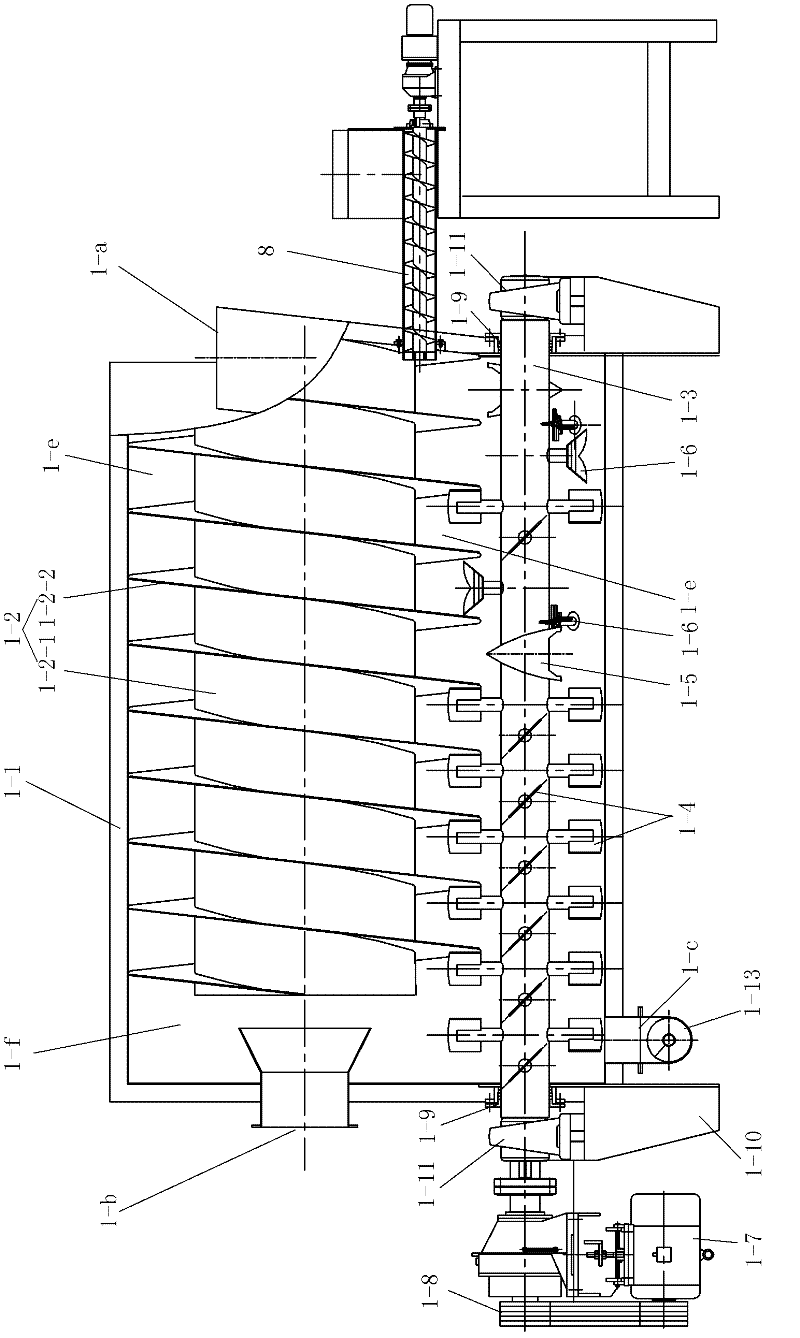

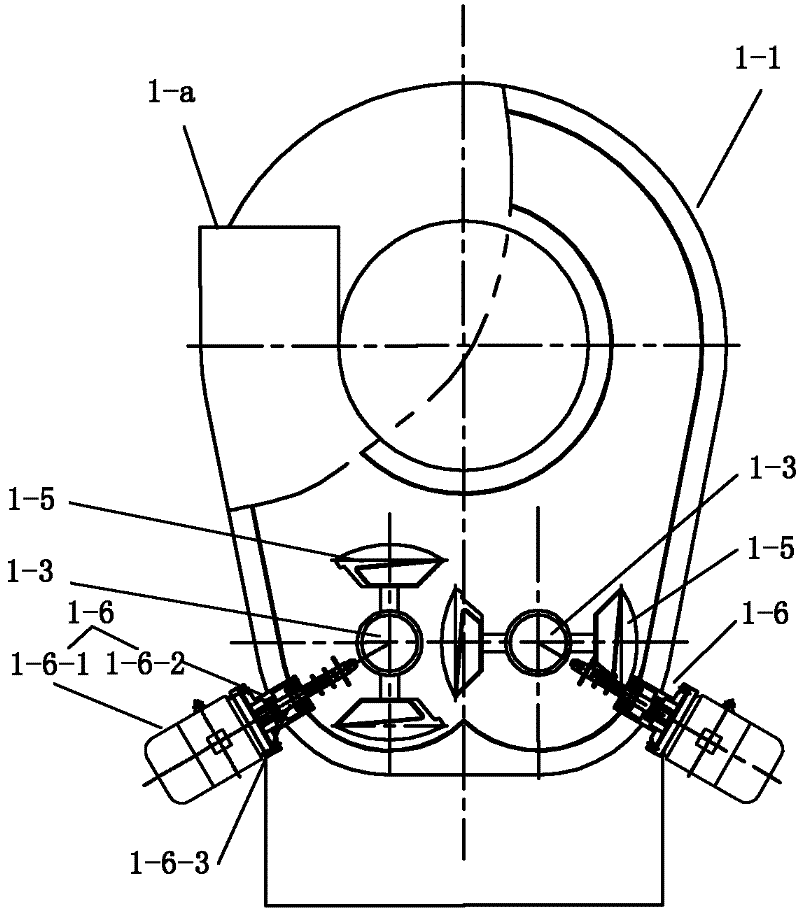

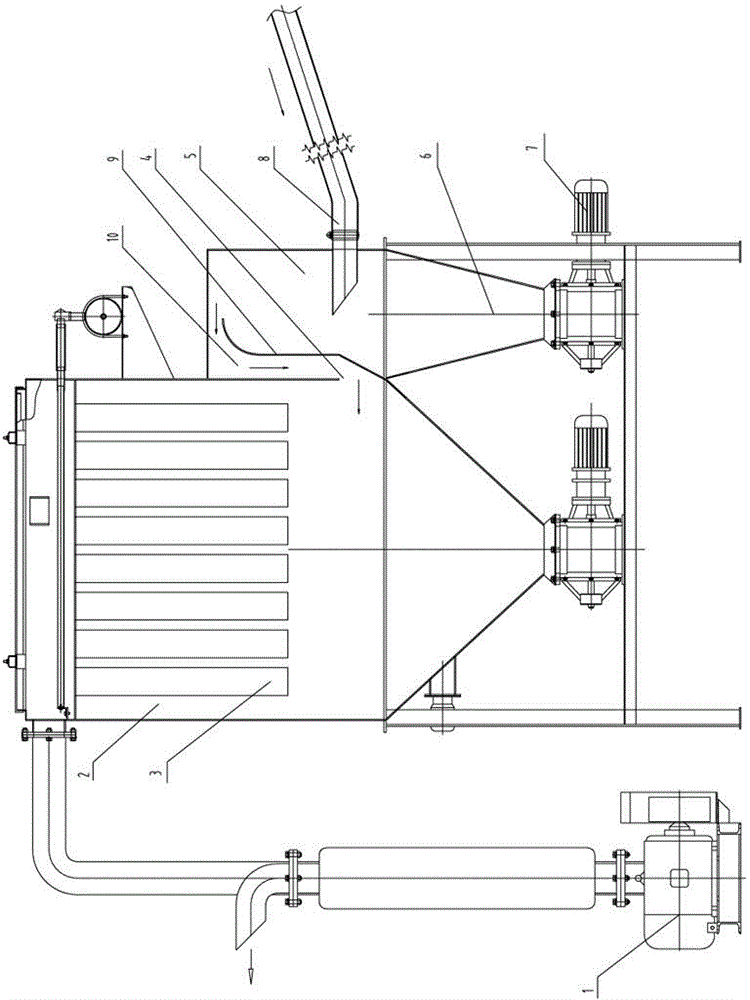

Automatic feeding and dust removing integrating equipment of concrete pump for mine

InactiveCN104265361APrevent proliferationEasy to cleanCleaningMaterial fill-upOrganic glassConcrete pump

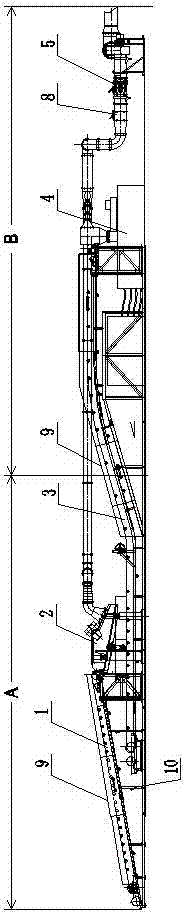

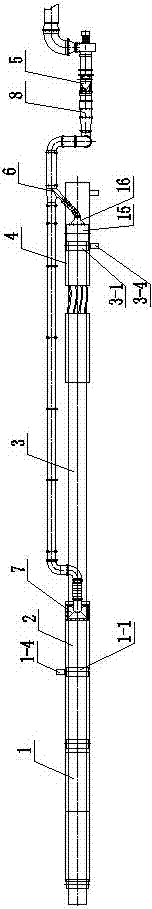

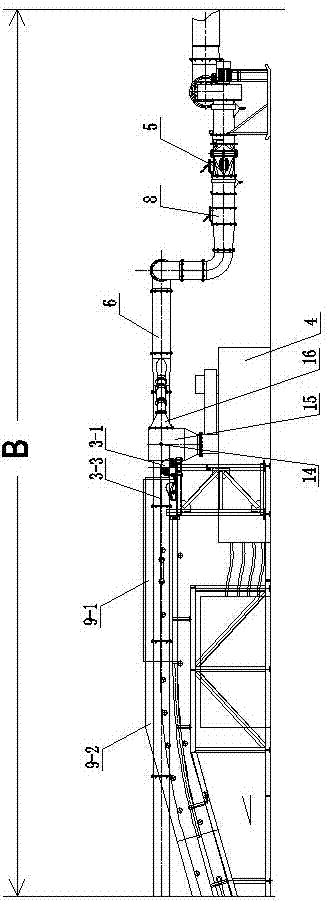

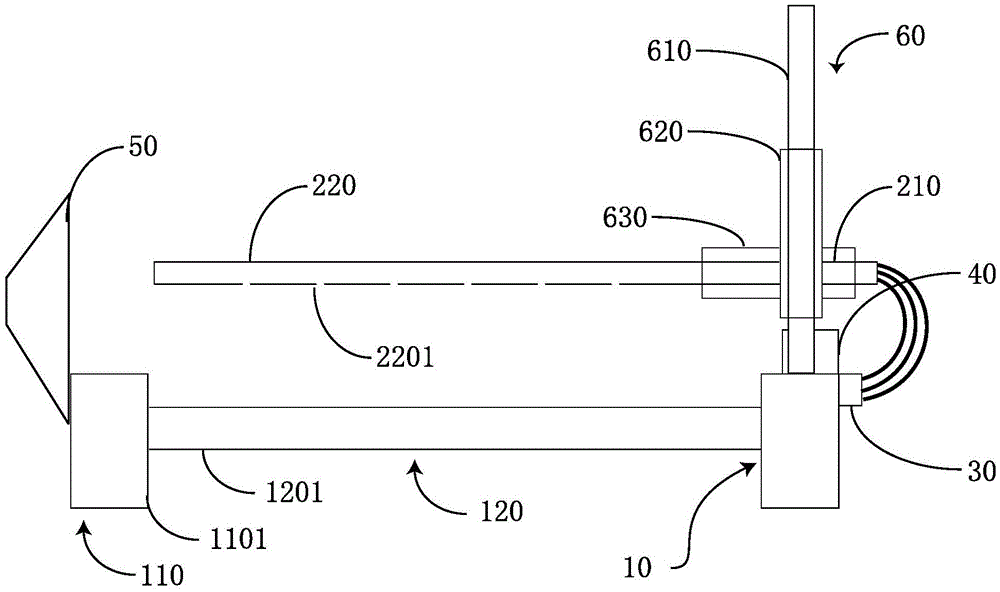

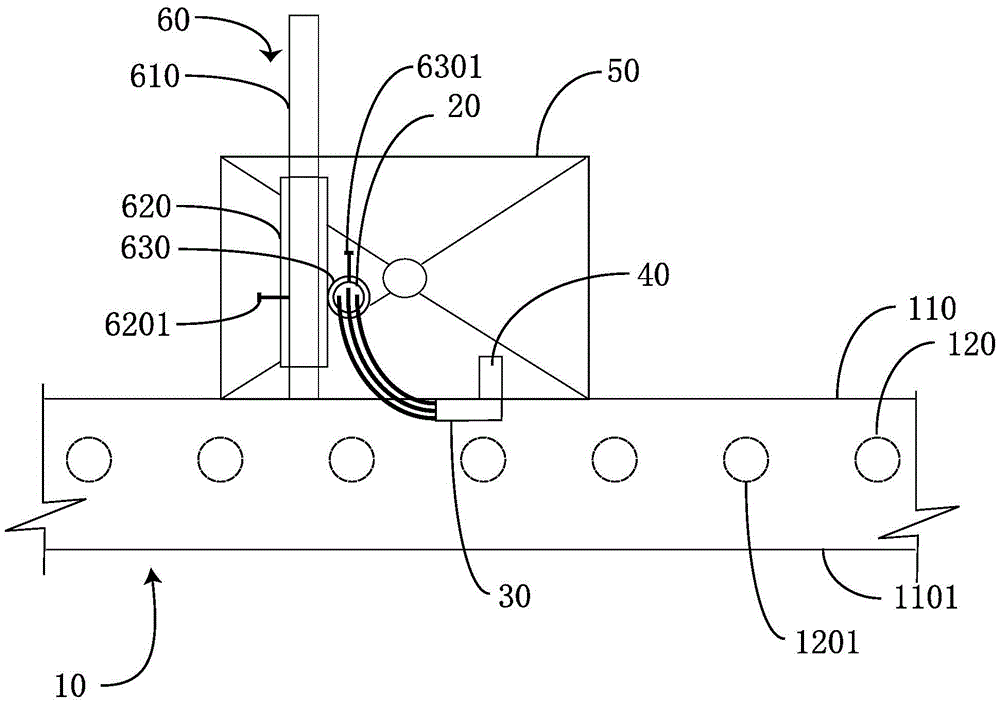

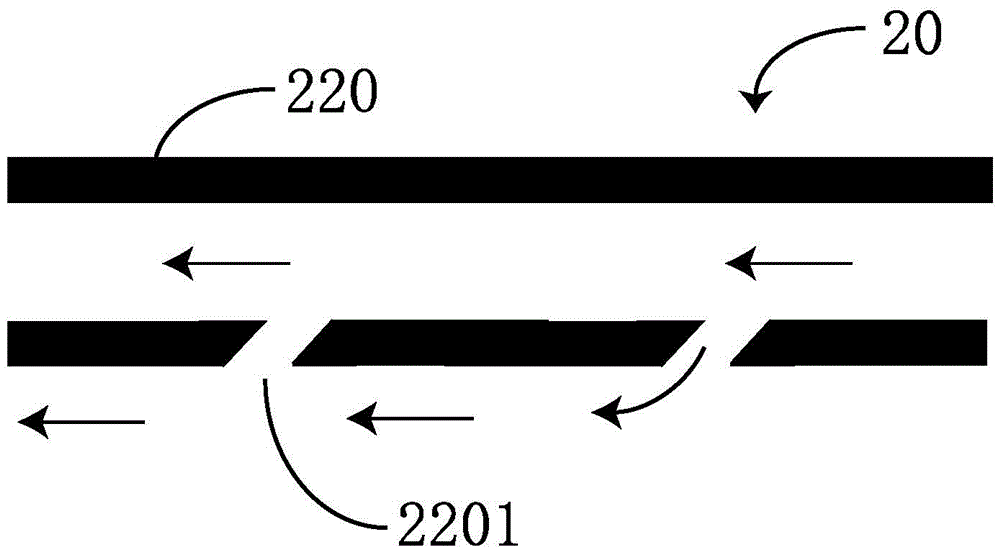

The invention discloses automatic feeding and dust removing integrating equipment of a concrete pump for mine and relates to matched feeding and dust removing integrating equipment for a novel gob-side entry retaining filling technique. The automatic feeding and dust removing integrating equipment of the concrete pump for mine comprises a stand, a primary belt type conveyor, a vibrating sieve, a secondary belt type conveyor, a filling pump and a wet type vibrating string dust remover; a group of dust-proof covers is arranged above each of the primary belt type conveyor and secondary belt type conveyor, each group of dust-proof covers comprises two segments of rectangular sealing dust-proof covers and one segment of organic glass dust-proof cover, the two segments of rectangular sealing dust-proof covers are respectively connected with the stand, the organic glass dust-proof cover is hinged to the stand through a hinge, the organic glass dust-proof cover is arranged between the two segments of rectangular sealing dust-proof covers, a sealing ring is arranged between each segment of rectangular sealing dust-proof cover and the organic glass dust-proof cover, and the organic glass dust-proof cover is connected with a handle. The automatic feeding and dust removing integrating equipment of the concrete pump for mine is capable of preventing dust diffusion, the material bag transportation situation in the belt type conveyors can be observed through the organic glass dust-proof covers, and dust in the belt type conveyors can be cleaned conveniently.

Owner:YANGZHOU JIANGLONG MINING EQUIP

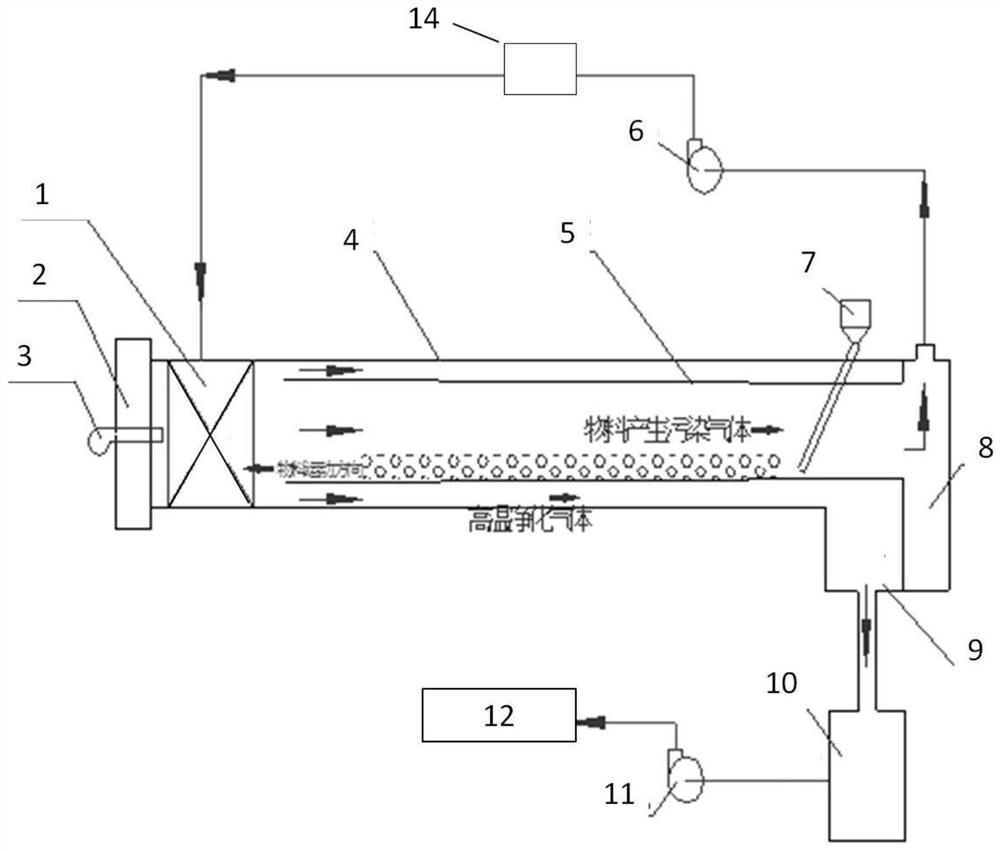

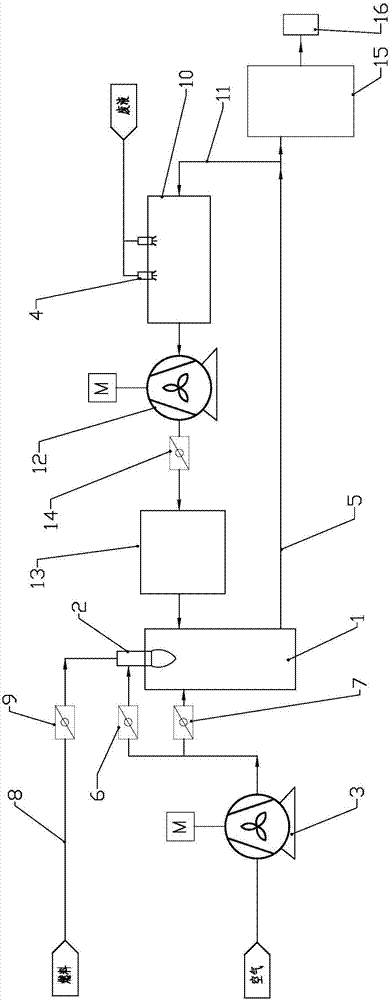

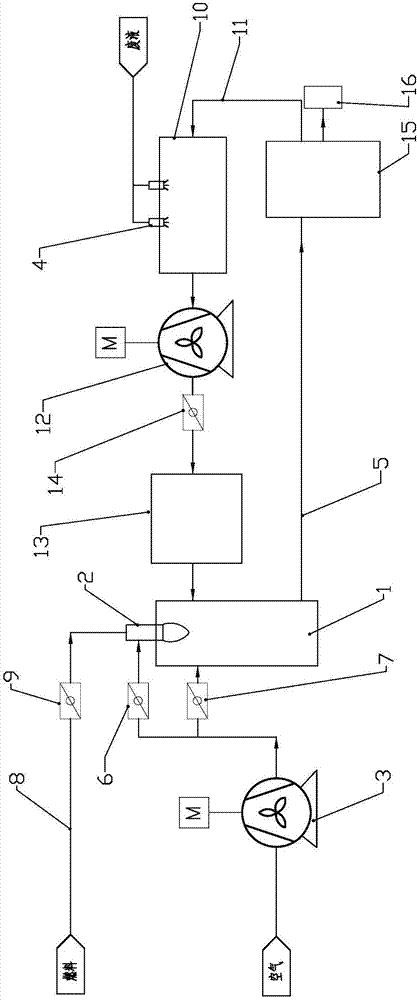

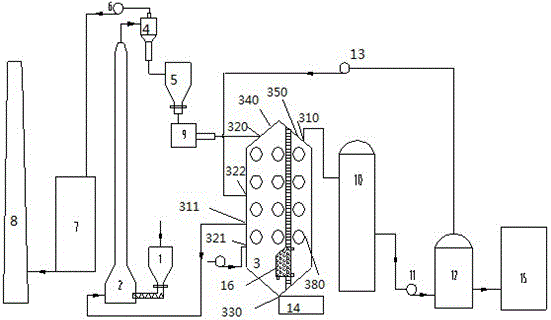

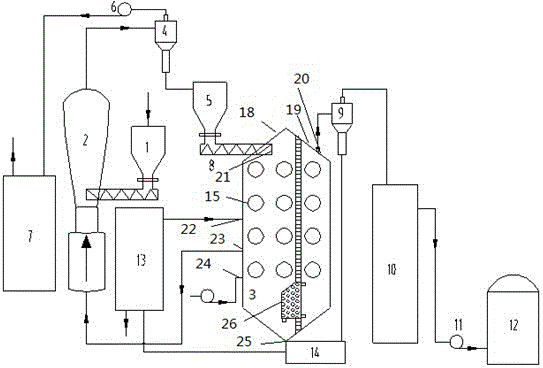

Cyclone drying and solvent recycling system

ActiveCN102230722AOvercome the shortcomings of strict initial moisture requirementsOvercome the disadvantage of not being able to fluidize the filter cakeDrying gas arrangementsDrying solid materialsPulp and paper industrySlurry

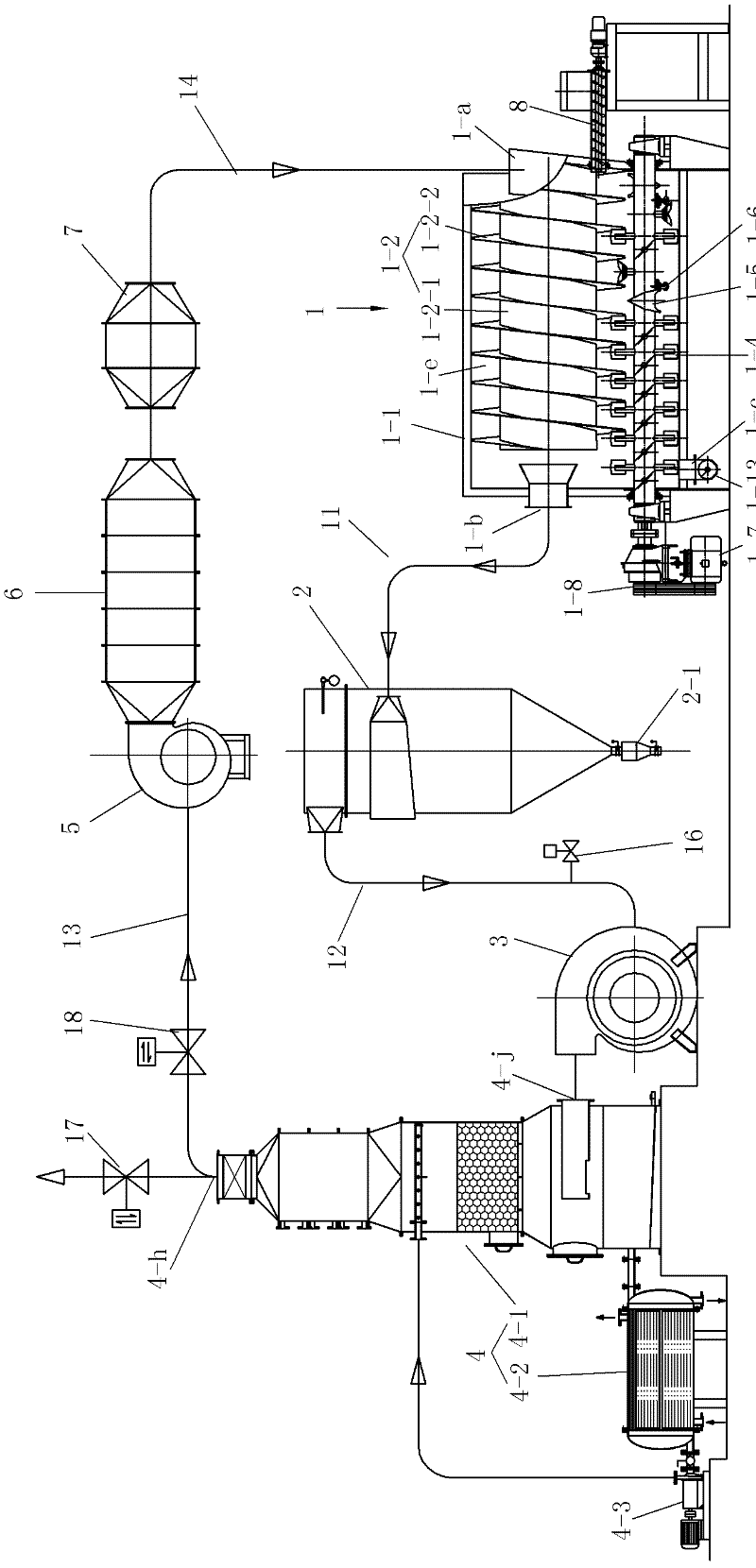

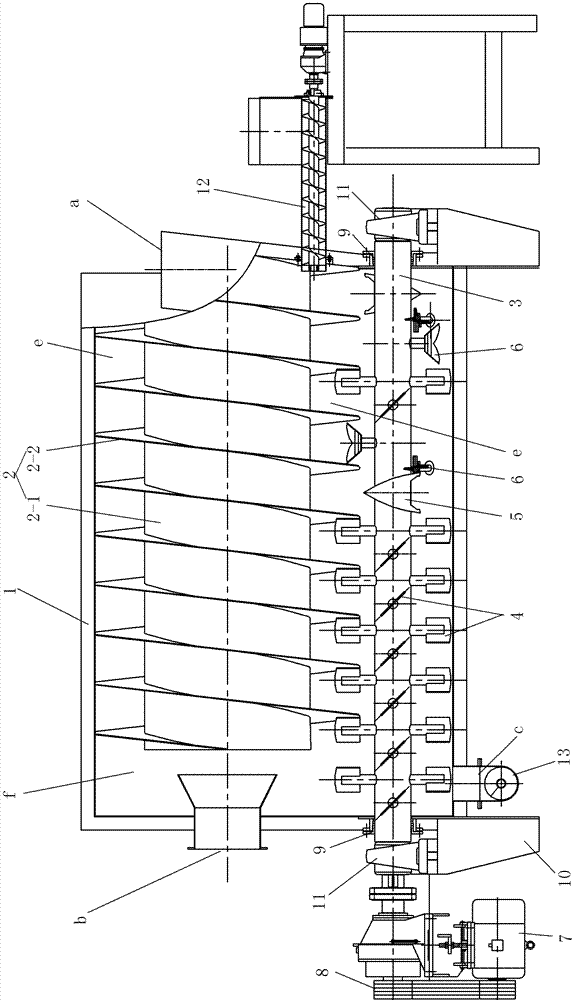

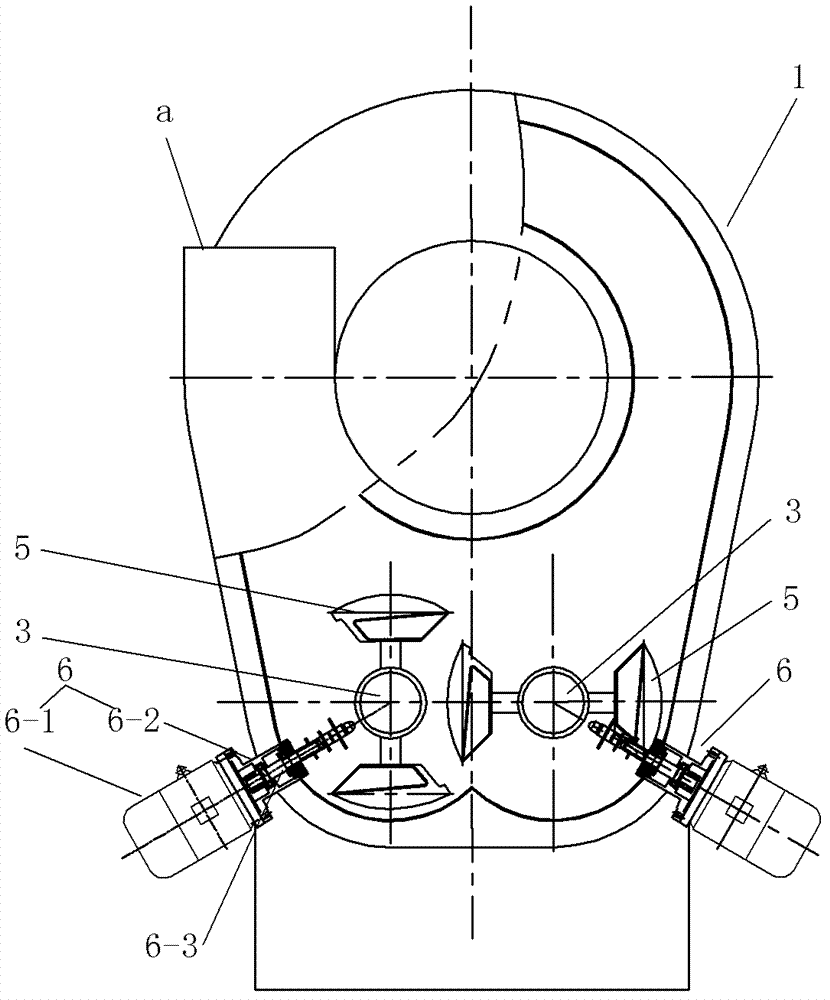

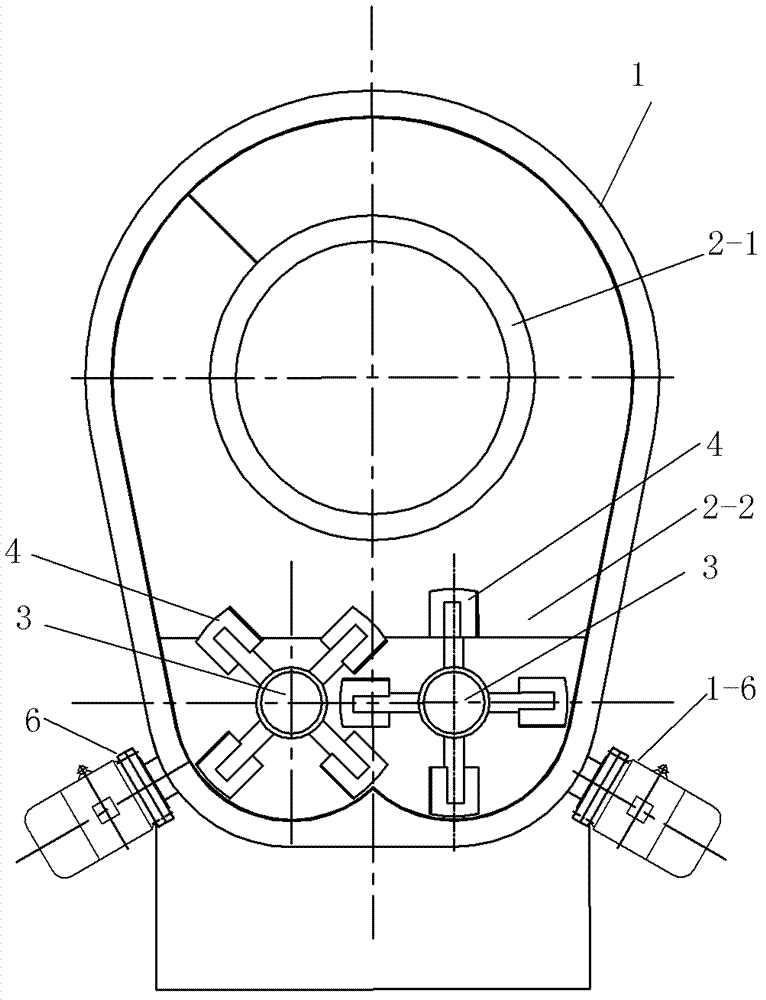

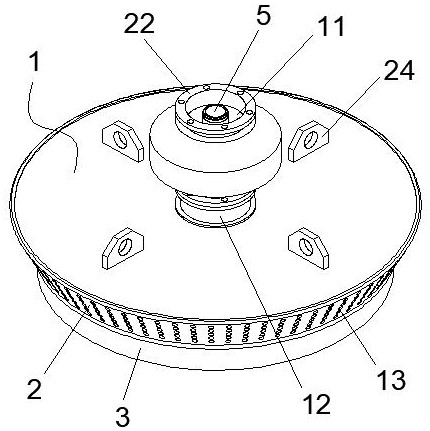

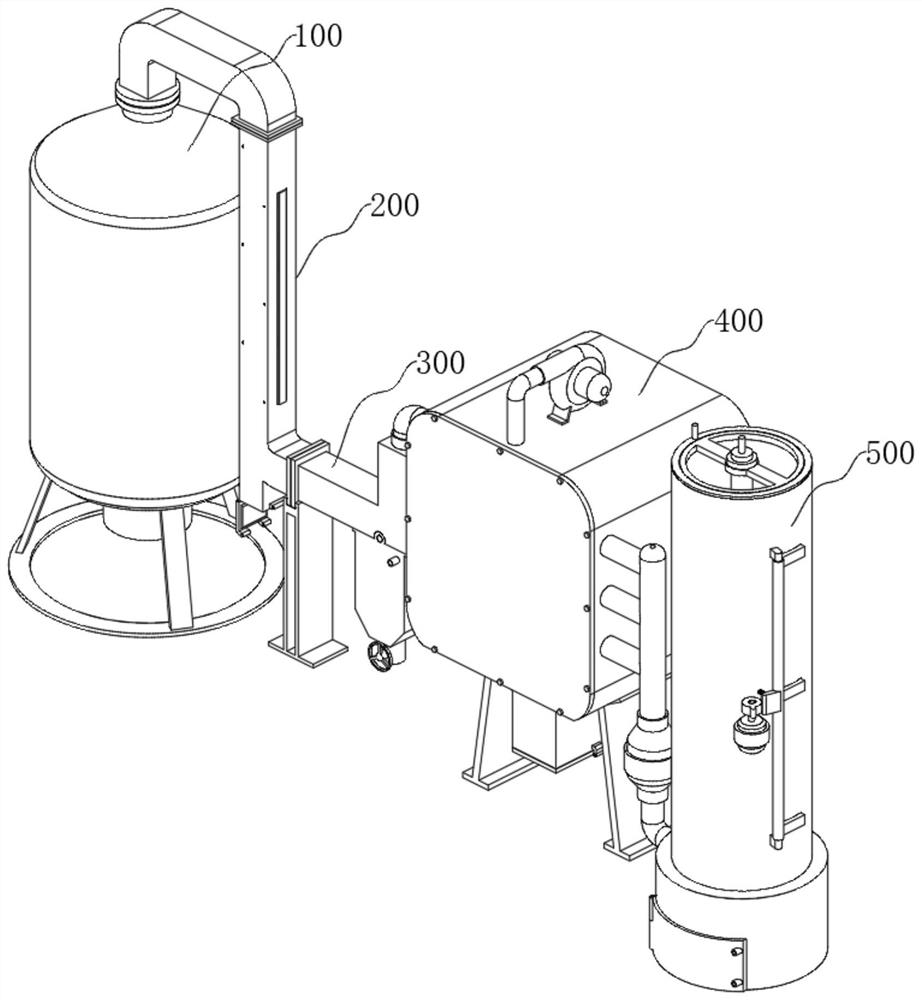

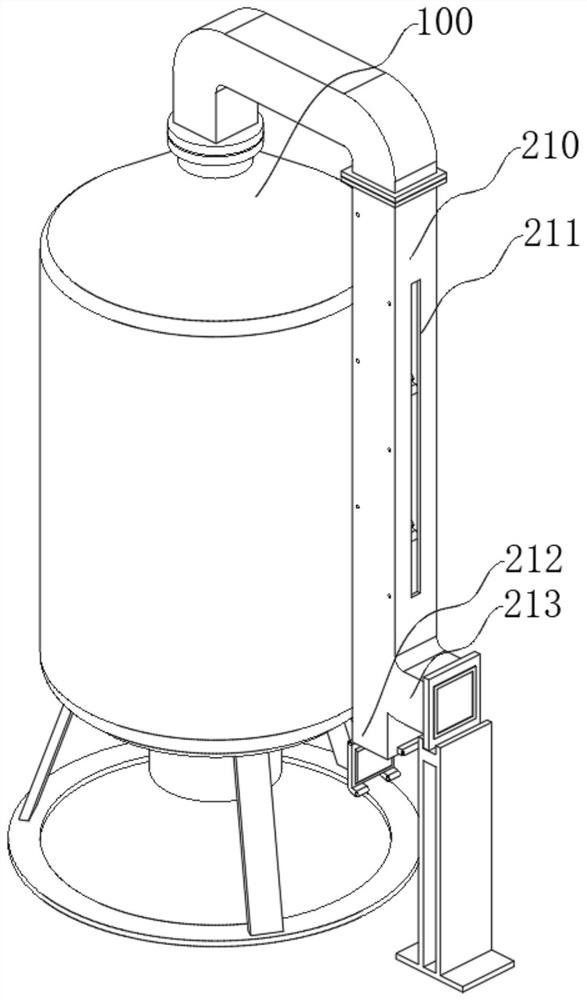

The invention discloses a cyclone drying and solvent recycling system, which is provided with a drying host machine, a bag-type dust removing device, a draught fan, a composite condensing device, a blower, a heater and a filter, wherein the upper part of the machine body cavity of the drying host machine is provided with an air current guide piece; the air current guide piece comprises a core pipe and a spiral band fixed on the core pipe; a spiral groove serves as a spiral air current channel; the back end of the spiral air current channel is communicated with a sedimentation chamber; the edge of the upper half part of the spiral band is fixed on the inner wall of the machine body cavity; the lower part of the machine body cavity is provided with a pair of stirring shafts; and each stirring shaft is provided with multiple pairs of paddle shoveling plates and coulters. By adopting the cyclone drying and solvent recycling system, the application range of fluidization drying is expanded, paste, slurry, particle, powder and filter cake materials can be dried, and crushing and drying are completed in one dryer. The volume drying intensity of the cyclone drying and solvent recycling system is far higher than that of ordinary fluidization drying equipment, the final water content can be lowered to an extremely low value in one drying host machine, and the defect of strict requirement for air current material drying on the initial water content of a material is overcome.

Owner:JIANGSU XIANFENG DRYING ENG

Efficient thermal desorption treatment system and method for restoring mercury contamination

InactiveCN106216380AReduce the amount of fine dustReduce the amount of mercury-containing dustContaminated soil reclamationPre conditioningThermal efficiency

The invention relates to an efficient thermal desorption treatment system and method for restoring mercury contamination. The efficient thermal desorption treatment system comprises a pelletizing pretreatment unit, a feeding unit, a thermal desorption unit, a dust collecting unit, a cooling condensing unit, an exhaust gas washing unit, a gas-liquid separation unit, a water treatment unit, an exhaust gas absorption treatment and emission unit and a cooling discharging unit, wherein the pelletizing pretreatment unit is connected with the feeding unit, the feeding unit, the cooling discharging unit and the dust collecting unit are all connected with the thermal desorption unit, the dust collecting unit is separately connected with the cooling condensing unit and the pelletizing pretreatment unit, the cooling condensing unit is connected with the exhaust gas washing unit, the exhaust gas washing unit is connected with the gas-liquid separation unit, the gas-liquid separation unit is connected with the exhaust gas absorption treatment and emission unit, the cooling condensing unit, the exhaust gas washing unit and the gas-liquid separation unit are separately connected with the water treatment unit, and at the same time, the water treatment unit is connected with the cooling discharging unit. The efficient thermal desorption treatment system has the characteristics of high thermal efficiency, high contaminant removing rate, low exhaust gas dust content and low energy consumption.

Owner:中钢集团天澄环保科技股份有限公司

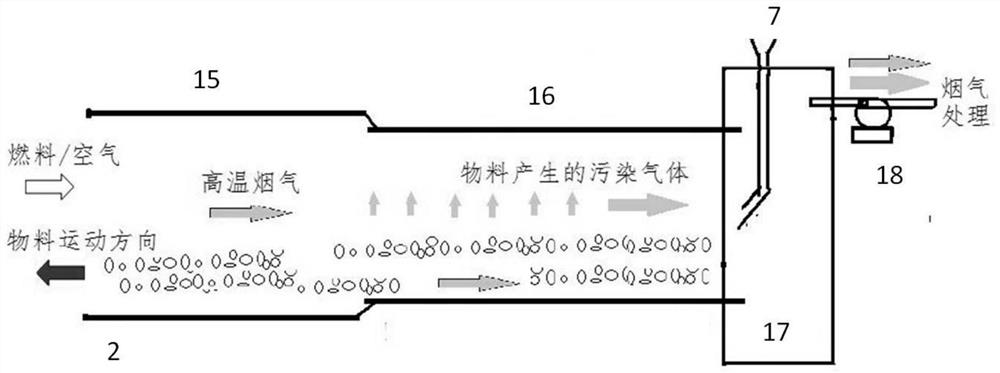

Energy-saving and waste-reducing flue gas recycling jacket rotary kiln and application thereof

PendingCN113357641ANo direct contactAvoid dischargeRotary drum furnacesIncreasing energy efficiencyCombustion chamberThermodynamics

The invention discloses an energy-saving and waste-reducing flue gas recycling jacket rotary kiln and application thereof. The rotary kiln comprises a kiln head, a kiln body, a combustion chamber and dustsettling chambers; the kiln body comprises an outer kiln and an inner kiln located in the outer kiln, and the combustion chamber is arranged at the joint of the kiln head and the outer kiln; the dustsettling chambers comprise the first dust settling chamber and the second dust settling chamber, and the first dust settling chamber and the second dust settling chamber are separated from each other; the first dust settling chamber is connected with the inner kiln and used for collecting and treating flue gas of the inner kiln; the second dust settling chamber is connected with the outer kiln and used for collecting and treating flue gas of the outer kiln; and a flue gas outlet of the first dust settling chamber is connected with the combustion chamber, and the combustion chamber is used for combusting the flue gas flowing out of the first dust settling chamber. According to the energy-saving and waste-reducing flue gas recycling jacket rotary kiln and the application thereof, a conventional treatment path for the flue gas of the rotary kiln in the prior art is broken through for the first time, the quality-divided and flow-divided treatment of the fuel combustion flue gas (namely the flue gas of the outer kiln) and the material pyrolysis waste gas (namely the flue gas of the inner kiln) is realized, and secondary combustion of gaseous pollutants in the flue gas and fuel which is not fully combusted is realized.

Owner:昱源宁海环保科技股份有限公司

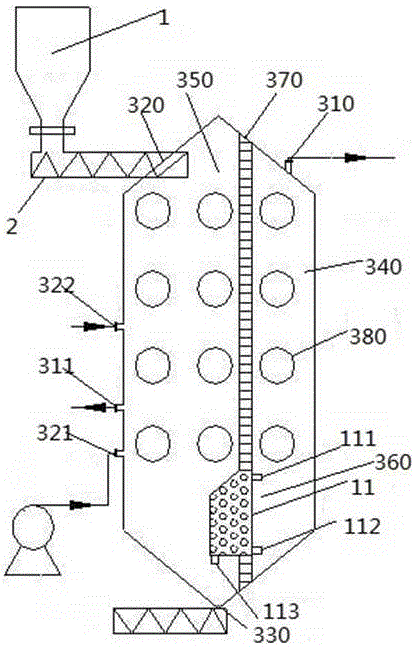

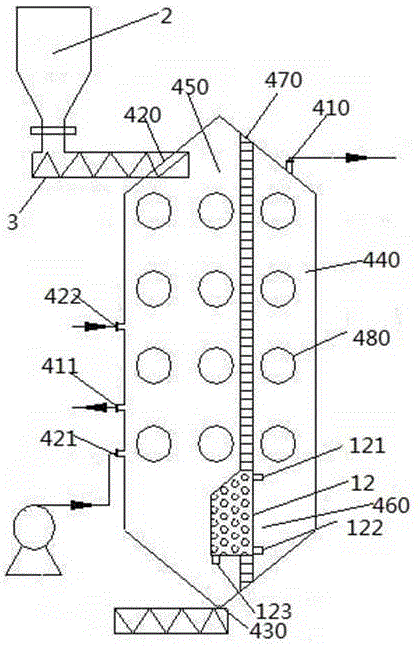

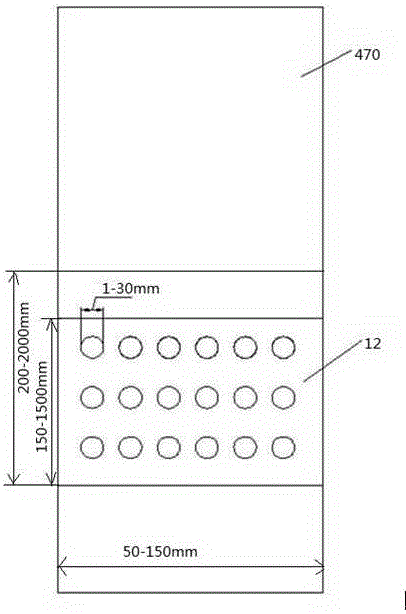

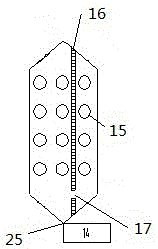

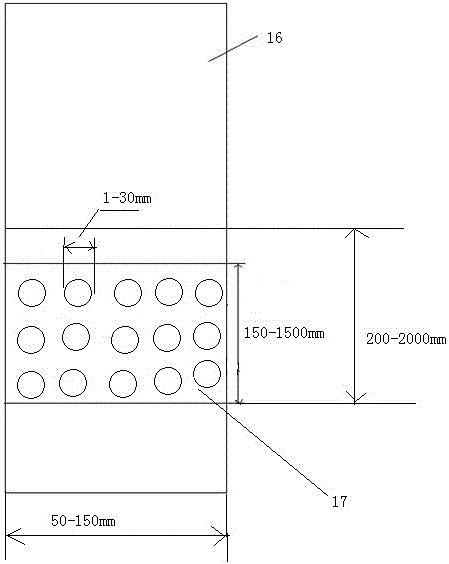

Self-dust-removal type pyrolyzing and cracking system for waste tires

ActiveCN105925293ARealize clean and efficient useReduce dust removal pressureProductsReagentsTarCombustible gas

The invention belongs to the technical field of pyrolysis of waste tires and mainly relates to a self-dust-removal type pyrolyzing and cracking system for the waste tires based on regenerative radiant tube heating. The self-dust-removal type pyrolyzing and cracking system is used for preparing clean combustible gases. Aiming at the defects in the prior art, the invention designs and develops a self-dust-removal type pyrolyzing and cracking reaction system for the waste tires. The reaction system can perform two operations of pyrolyzing and cracking; oil gas generated by pyrolyzing enters into a particle bed dust removing device; after the oil gas is subjected to filtering and dust removal, clean oil gas enters a cracking chamber, so that the dust removing pressure of a subsequent process is reduced, and tar macromolecules are cracked into small molecule gaseous hydrocarbons. According to a reactor, a large amount of cracking gases can be generated, thereby solving the problem that produced pyrolytic tar is difficult to utilize, and really realizing clean and efficient utilization of the waste tires.

Owner:SHENWU TECH GRP CO LTD

Automatic-dust-removal refuse pyrolysis and cracking system

ActiveCN106047382ASimple structureUniform temperature distributionIndirect heating destructive distillationSpecial form destructive distillationCombustible gasTar

The invention belongs to the technical field of refuse pyrolysis, and mainly relates to an automatic-dust-removal refuse pyrolysis and cracking system which is used for preparing clean combustible gas. In order to overcome the defects in the prior art, the invention provides an automatic-dust-removal refuse pyrolysis and cracking system. The reaction system can perform pyrolysis and cracking; oil gas generated by the pyrolysis chamber enters a particle bed for dust removal by a particle bed dust remover, and the clean oil gas enters a cracking chamber for deep cracking, thereby lowering the dust removal pressure at the back end; and the macromolecular tar molecules are cracked into micromolecular gaseous hydrocarbons, so the reactor can generate abundant cracked gas, thereby avoiding the problem of difficulty in utilizing the produced pyrolyzed oil, implementing refuse harmless treatment and dioxin zero discharge in deed, changing wastes into valuable substances, and satisfying the technical requirements for refuse comprehensive treatment in China.

Owner:SHENWU TECH GRP CO LTD

Air filter based on centrifugal principle

ActiveCN110285000AReduce the temperatureTo achieve the purpose of coolingMachines/enginesAir cleaners for fuelAir filterEngineering

The invention discloses an air filter based on the centrifugal principle. The air filter comprises a centrifugal dust removing chamber and a first filtering chamber, wherein the centrifugal dust removing chamber comprises an outer chamber and an inner chamber arranged in the outer chamber, and a first air inlet is formed in the outer chamber; and the bottom of the outer cavity is provided with an air outlet pipe which communicates with the inner cavity, and the air outlet pipe is arranged along the side wall of the inner cavity in the tangential direction. According to the air filter, water in a spraying disc is sprayed on the inner wall of the inner cavity to form a water film and adhere to dust thrown on the inner wall of the inner cavity, so that the purpose of pre-dedusting is achieved; and meanwhile, in the falling process of the water along the inner wall of the inner cavity, the air can play an air-cooling role, and then the water temperature is lowered.

Owner:高博集团有限公司

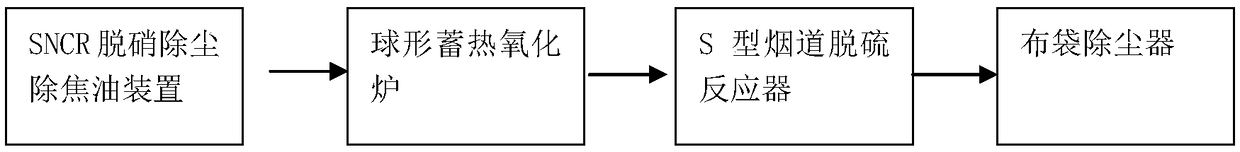

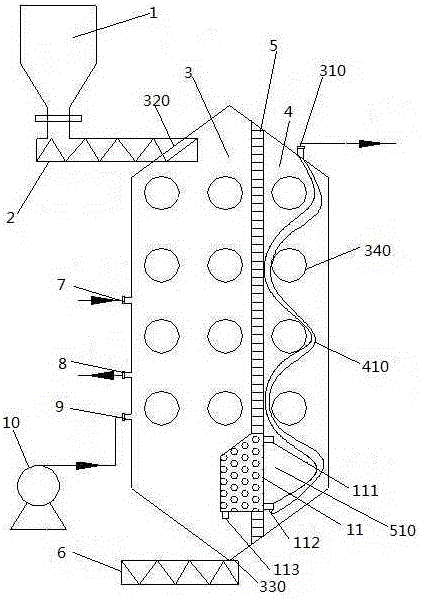

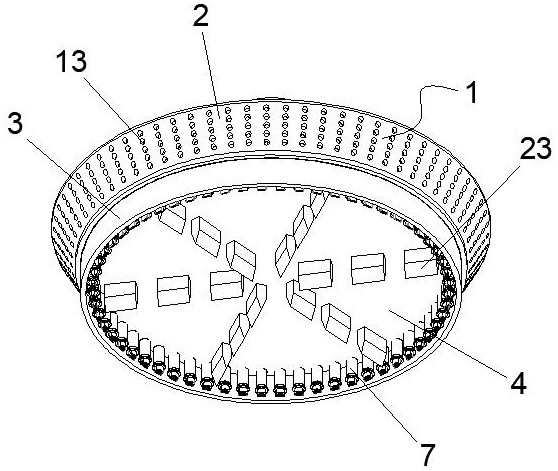

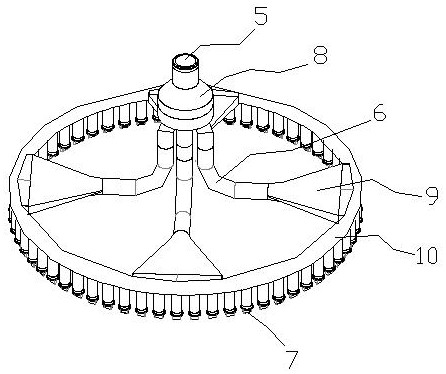

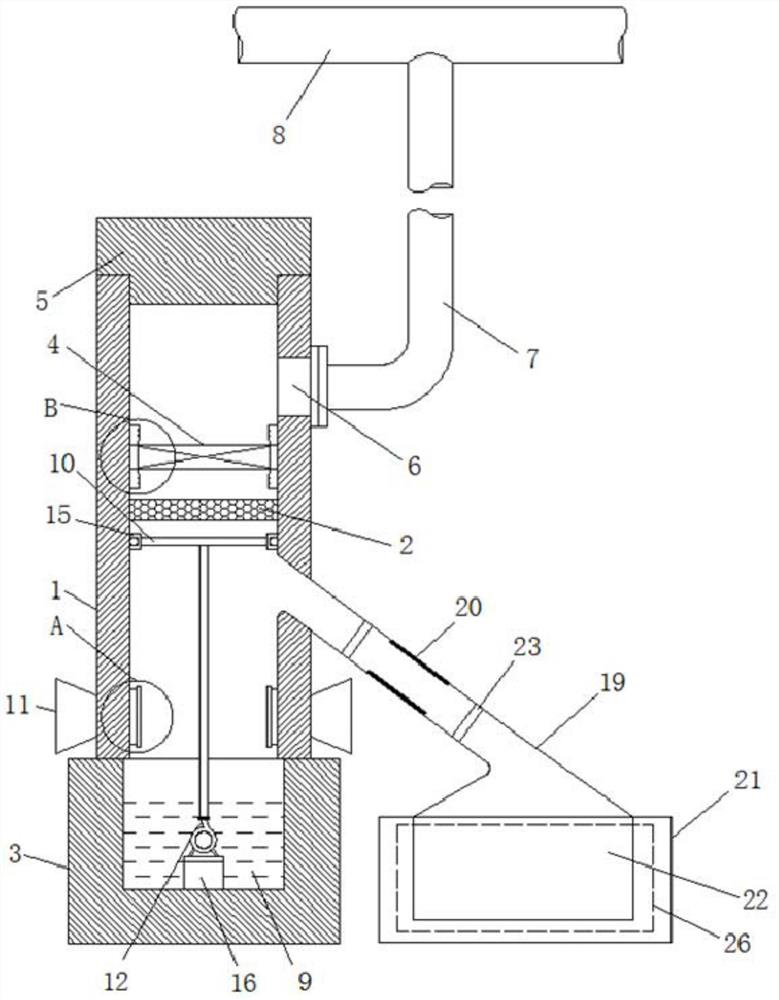

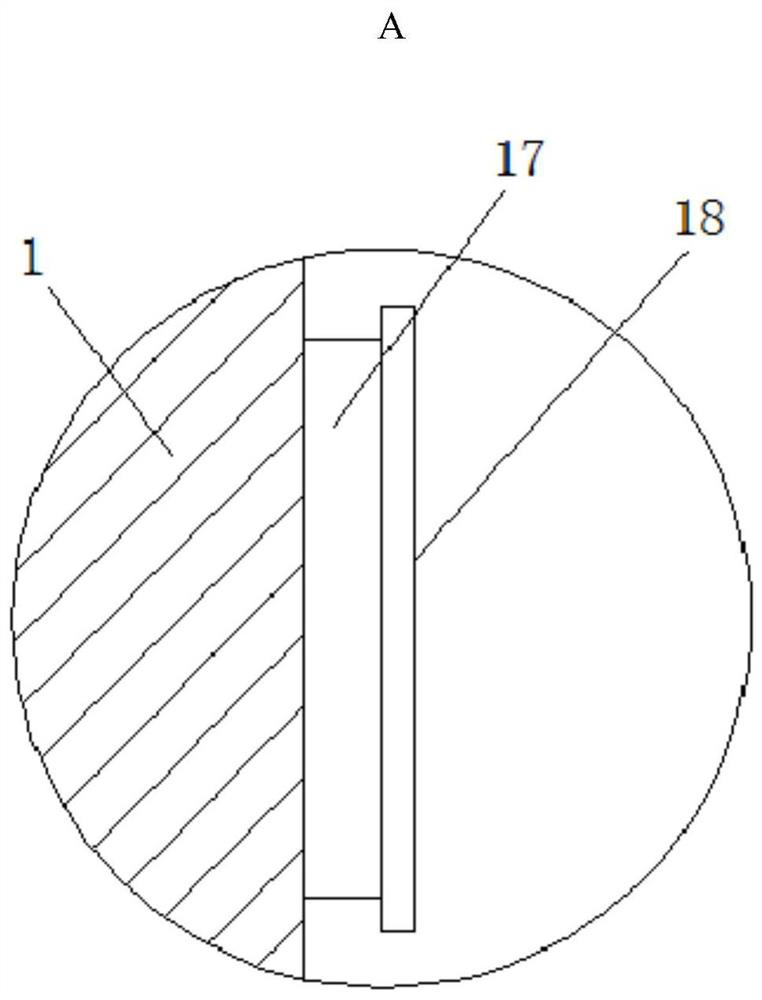

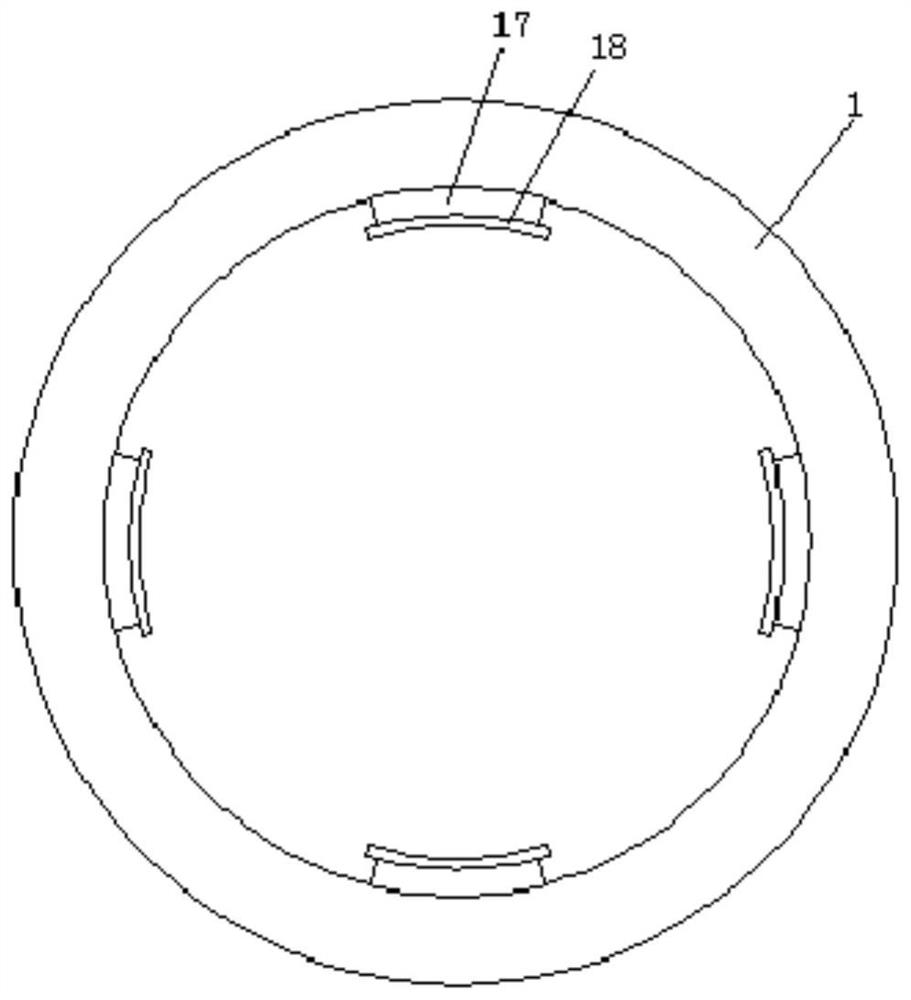

Efficient gas-solid separation and dust removal device

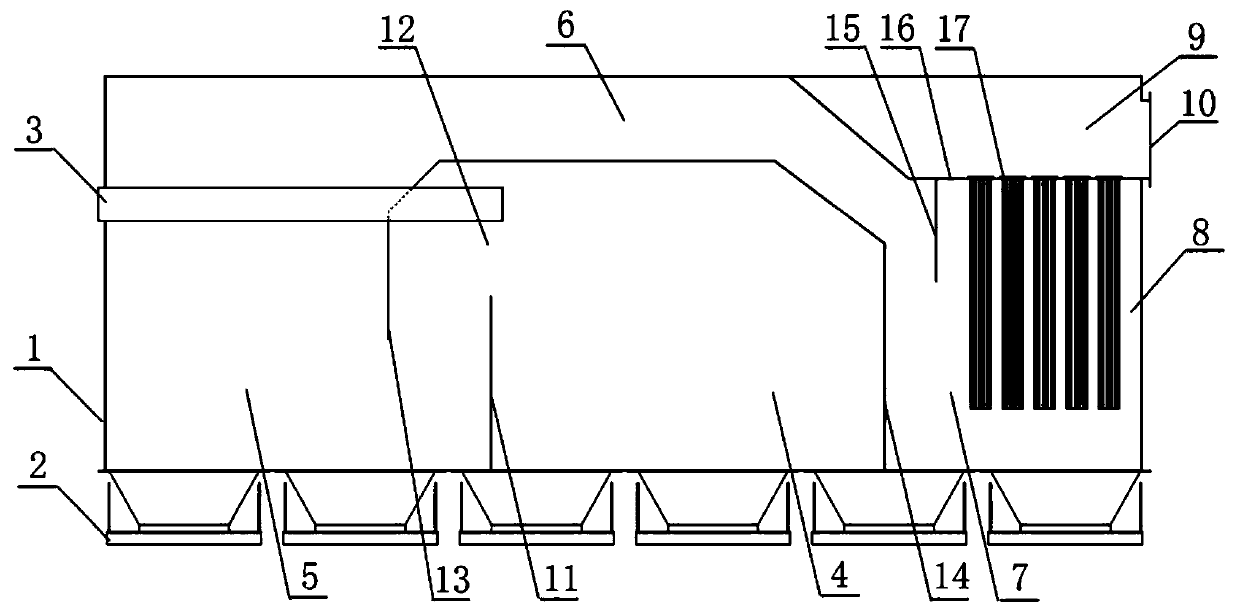

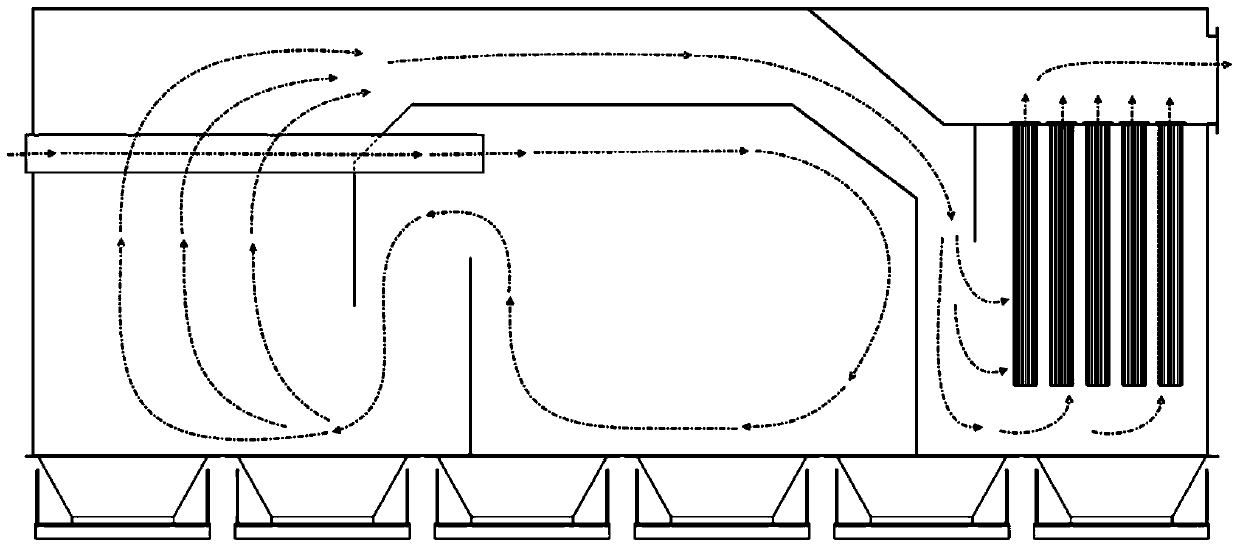

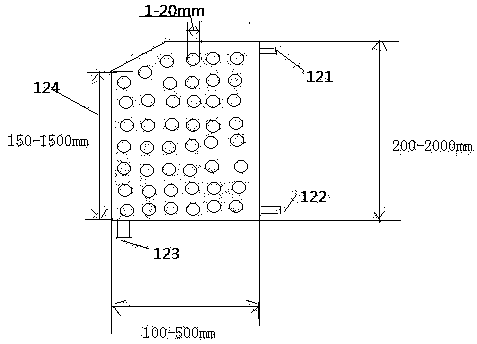

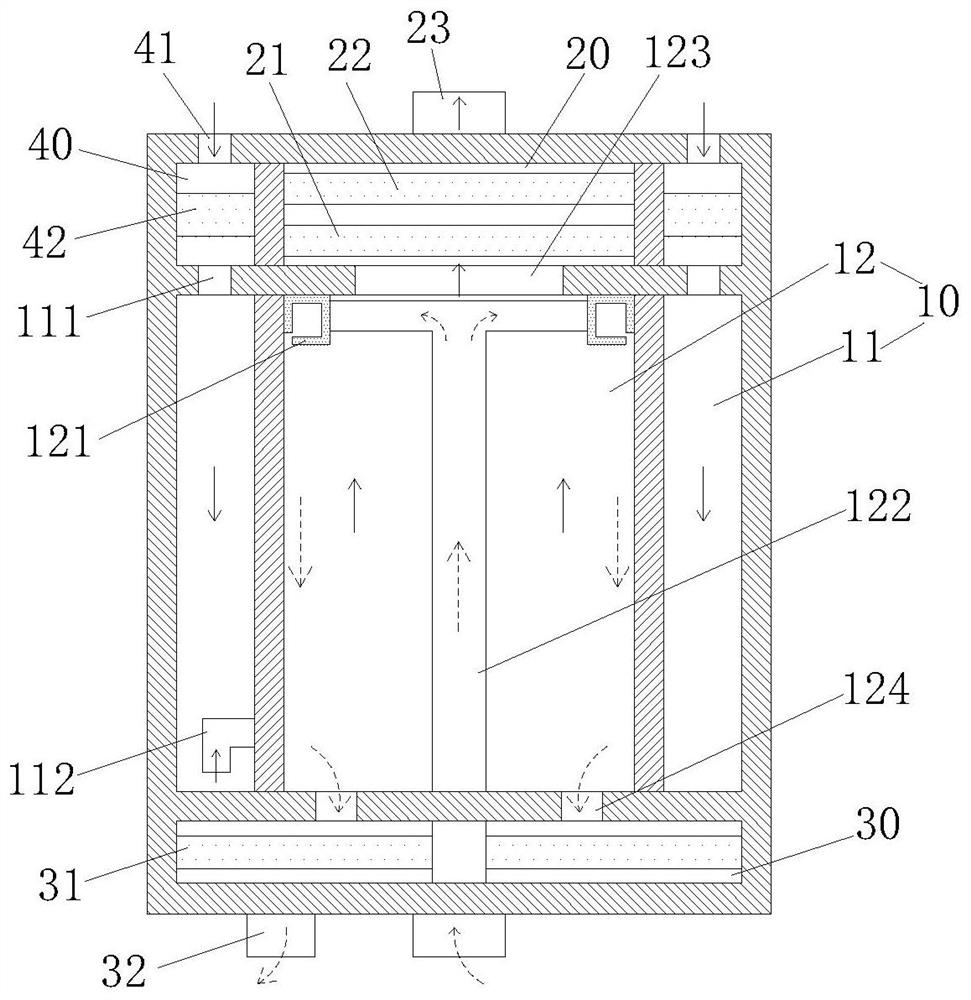

PendingCN111085048AReduce dust removal pressureImprove dust removal effectCombination devicesDispersed particle filtrationGas solidInterior space

The invention relates to an efficient gas-solid separation and dust removal device. The internal space of a device main body (1) is sequentially divided into a 1# gravity settling chamber (4), a 2# gravity settling chamber (5) and a refined filtration chamber (7) through a first partition plate (11) and a second partition plate (14), which are arranged in the device main body (1); materials enterthe 1# gravity settling chamber (4); most of the materials settle for the first time in the 1# gravity settling chamber (4) under the action of self gravity; other fine materials enter the 2# gravitysettling chamber (5), the material settling direction in the 2# gravity settling chamber (5) is opposite to the airflow flowing direction, the fine materials are subjected to secondary settling in the2# gravity settling chamber (5), residual fine particles enter the refined filtration chamber (7) to be subjected to fine filtering treatment, finally, separation of the materials and gas is achieved, and clean air is exhausted. According to the device, materials and air in pneumatic conveying two-phase fluid can be separated, and separated dusty gas is filtered and dedusted, so that the purposesof meeting the emission requirement and protecting gas source machinery are achieved.

Owner:CRCC HIGH TECH EQUIP CORP LTD

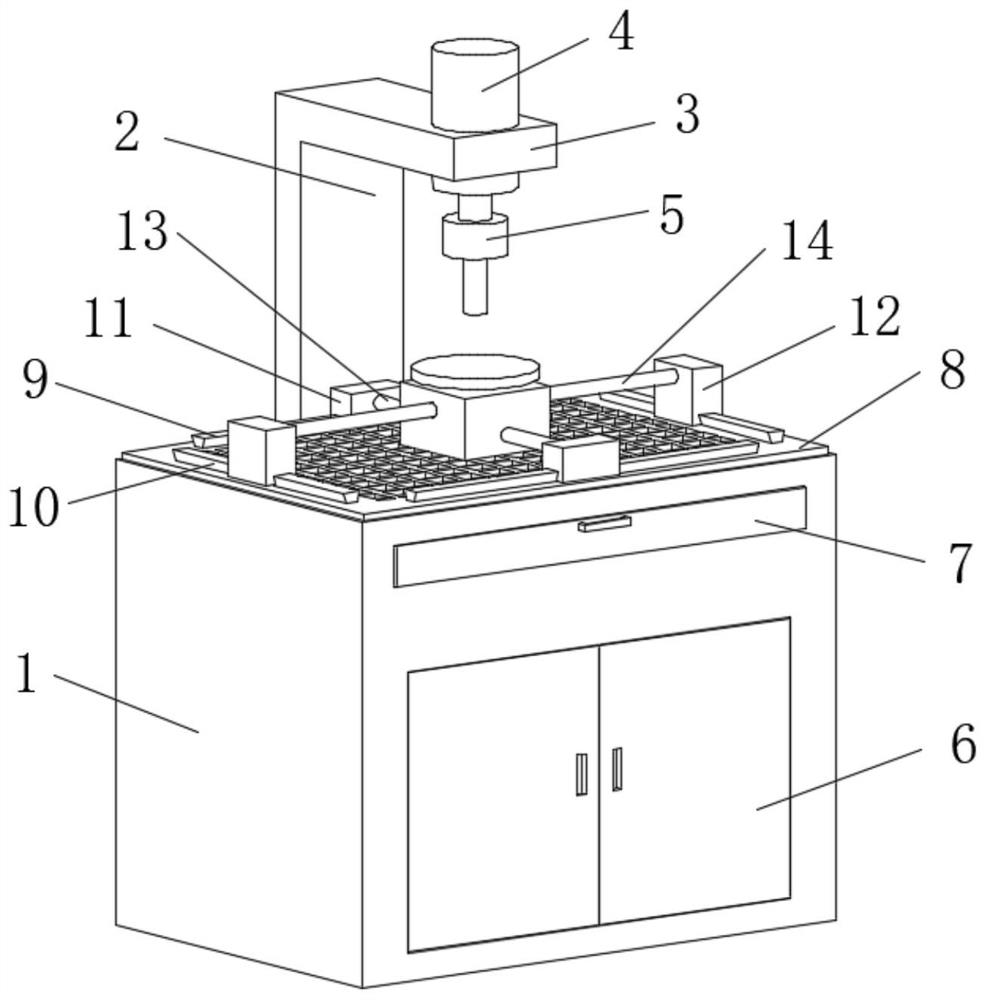

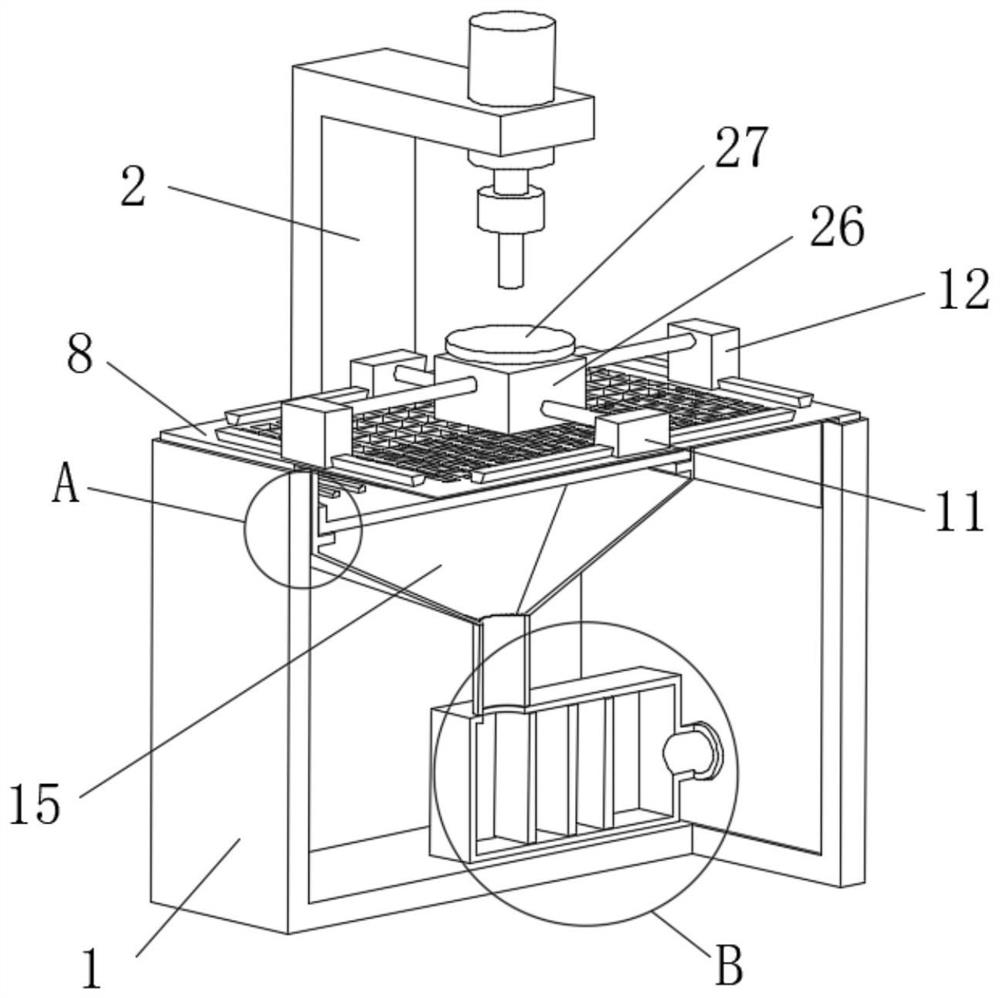

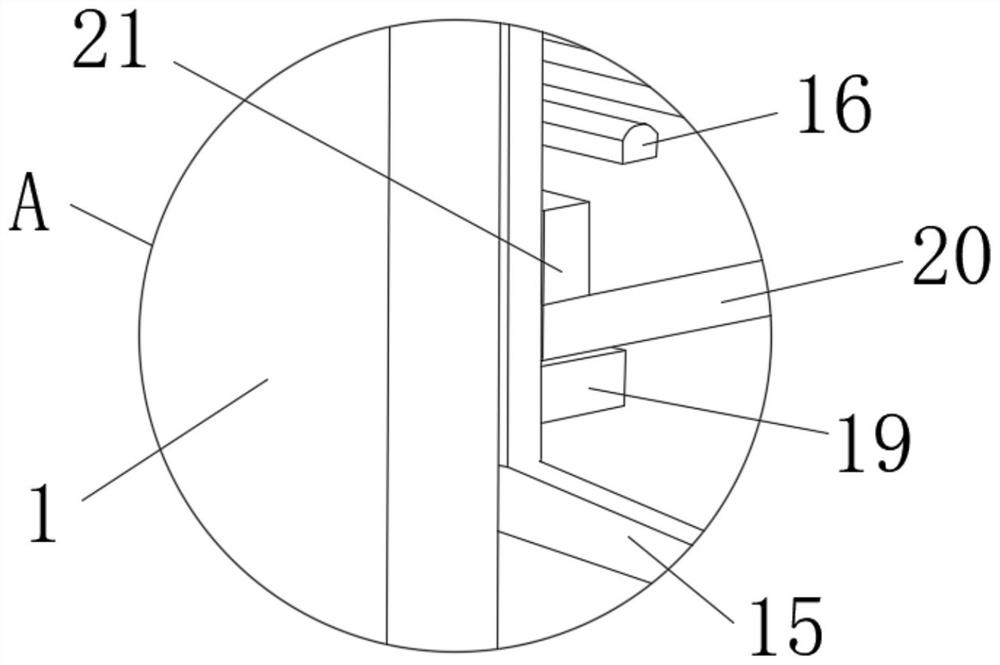

Automobile brake disc drilling center

InactiveCN112518411AAffect healthAffect the effect of dust removalMaintainance and safety accessoriesBoring/drilling machinesAir pumpDust control

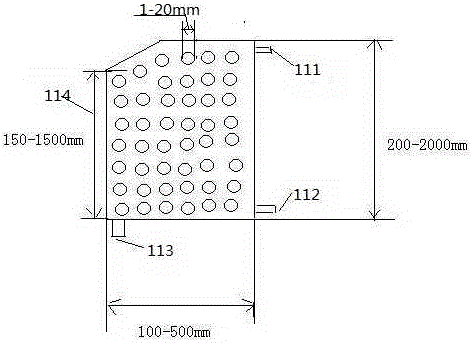

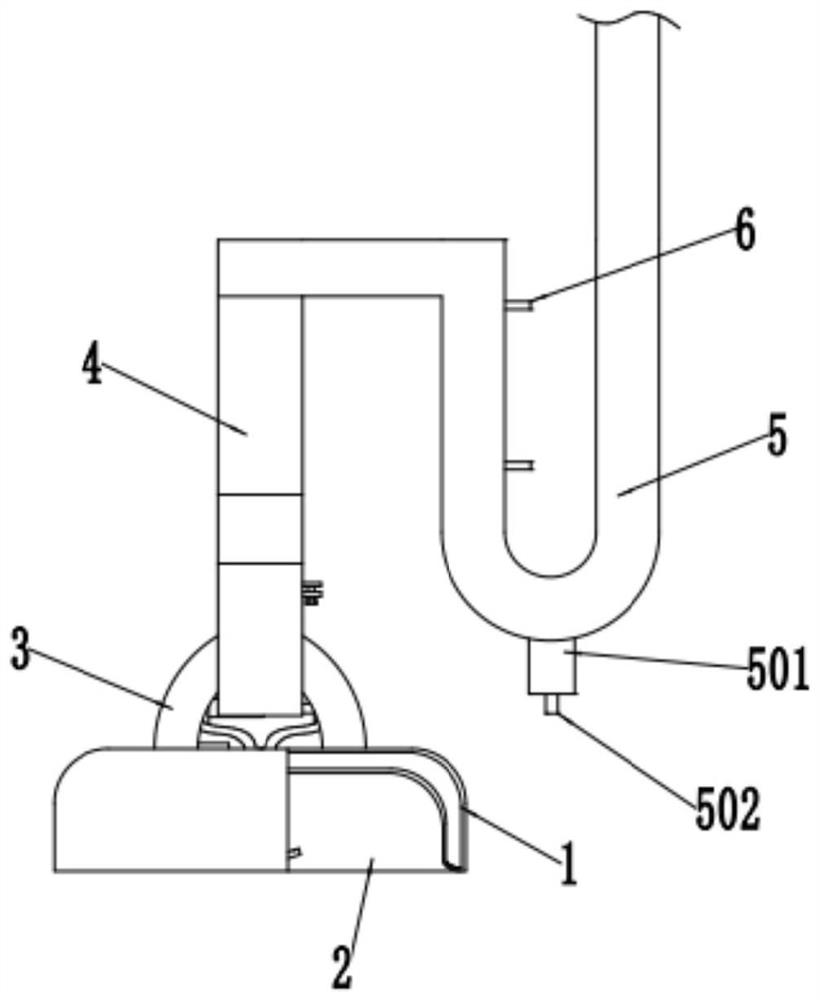

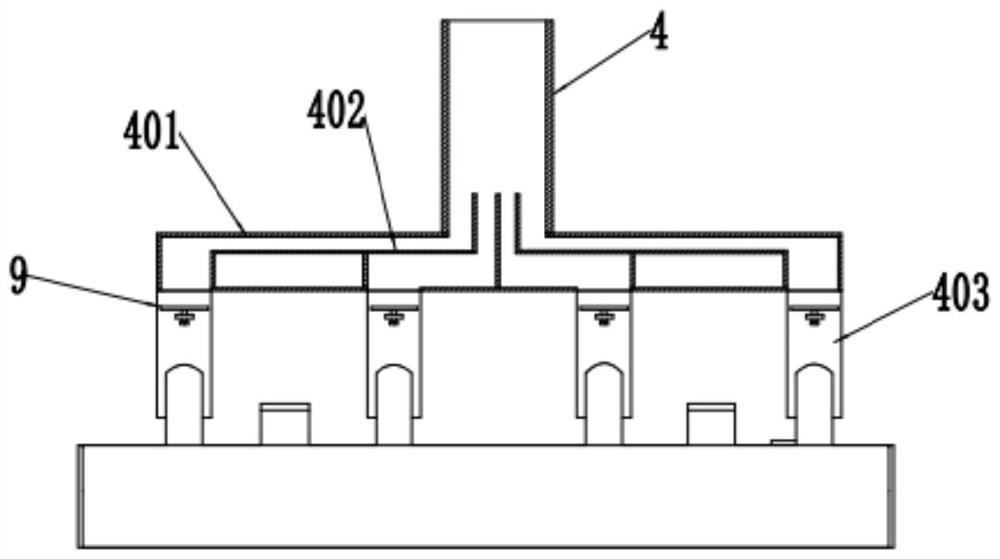

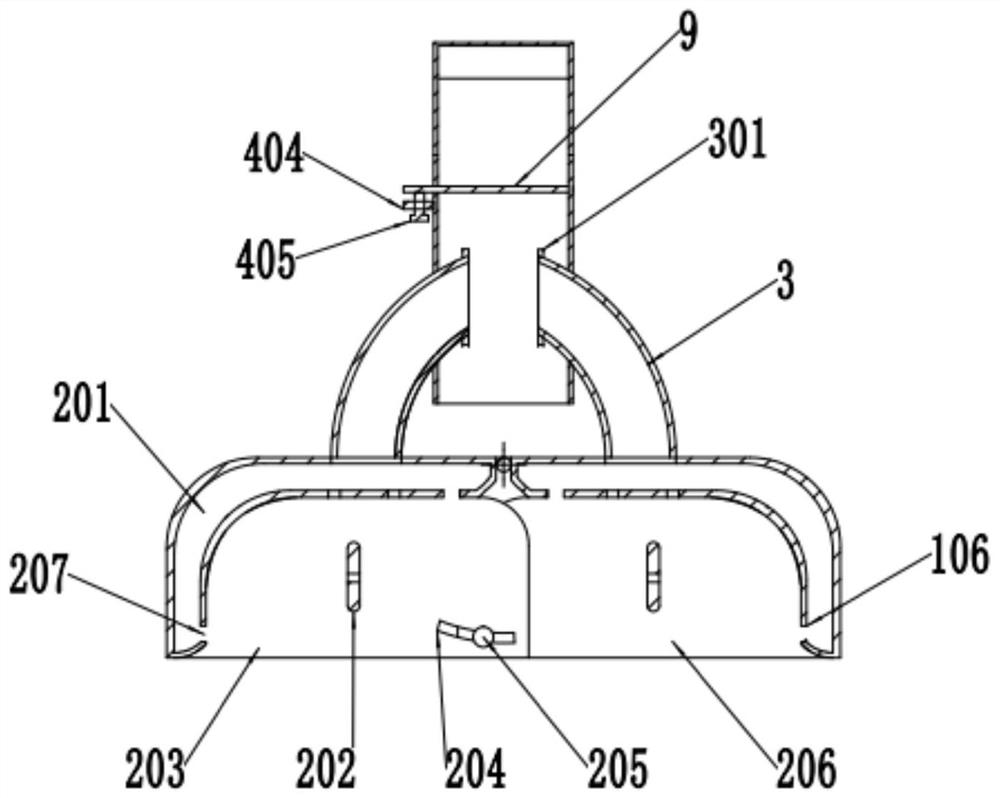

The invention discloses an automobile brake disc drilling center. The automobile brake disc drilling center comprises an operation table and a supporting rod arranged on the back face of the operationtable, wherein the operation table is a rectangular box body; a first notch and a second notch are arranged in the front surface of the box body; a box door is arranged in the first notch through a hinge; a sealing plate is rotatably arranged in the second notch through a hinge; handle structures are arranged on the box door and the sealing plate; the upper surface of the operation table is not closed; a mesh plate is erected on the upper surface of the operation table; and mesh structures are evenly arranged in the center of the mesh plate. The mesh plate is arranged on the upper surface ofthe operation table, a waste hopper is arranged at the lower end of the mesh plate, an outlet in the lower end of the waste hopper is connected to an air inlet of a dust removal box, and an exhaust port of the dust removal box is connected to the air inlet end of an air pump through a second air pipe, so that adsorption force is formed on the upper surface of the operation table through the actionof the air pump, and therefore, the situation that the physical health of workers is affected due to random drifting of dust formed by drilling machining is avoided.

Owner:徐保龙

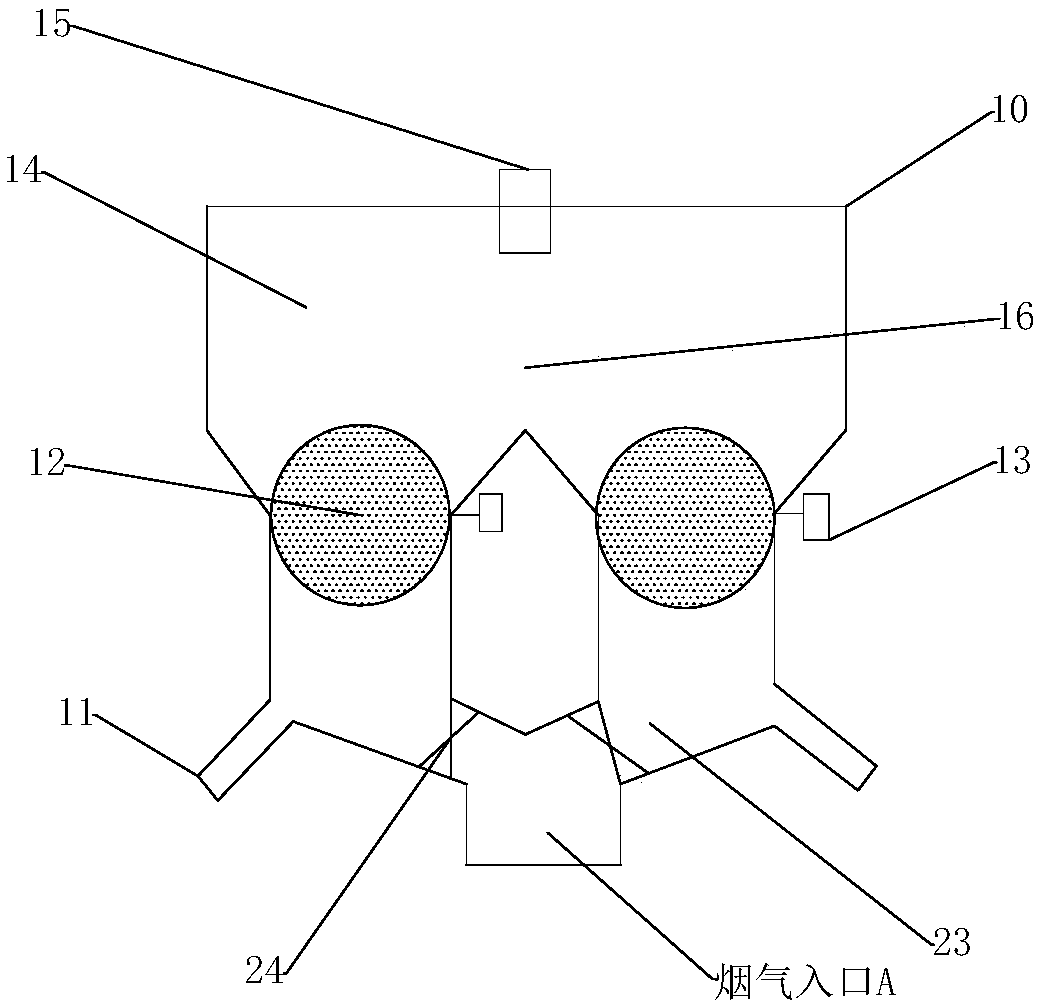

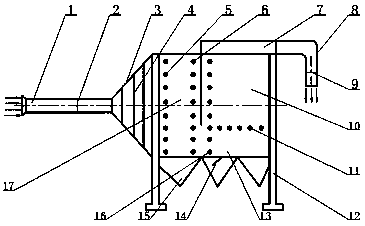

Salt-contained waste liquid incineration device and technology lowering dust harm

InactiveCN107490011AReduce dust removal pressureReduced risk of slaggingIncinerator apparatusParticulatesCombustor

The invention discloses a salt-contained waste liquid incineration device and technology lowering dust harm and belongs to the field of salt-contained waste liquid processing. The salt-contained waste liquid incineration device lowering dust harm structurally comprises an incinerator, a combustor, an air blower and a waste liquid atomizing spray nozzle. The lower portion of the incinerator is provided with an outlet flue. The waste liquid atomizing spray nozzle is arranged on the upper portion of an evaporation chamber. The inlet end of the evaporation chamber is provided with a circulating flue. The outlet end of the evaporating chamber is connected with the inlet end of the circulation draught fan through a pipeline. The outlet end of the circulating draught fan is connected with the inlet end of the dust collector through a pipeline. The outlet end of the dust collector is connected with the incinerator through a pipeline. The salt-contained waste liquid incineration device and technology lowering dust harm have the advantages that evaporation of the salt-contained waste liquid is conducted outside the incinerator, so that the service lives of the waste liquid atomizing nozzle and the incinerator are prolonged, combustible harmful matter in the salt-contained waste liquid can stay for a longer time in the incinerator, so that decomposition of the combustible harmful matter is fuller, solid particles formed in the salt-contained waste liquid can be effectively removed, the generation amount of dioxin is reduced, and the harm of salt to the incinerator is relieved.

Owner:JINAN TORCH CREATION ENERGY SCI & TECH

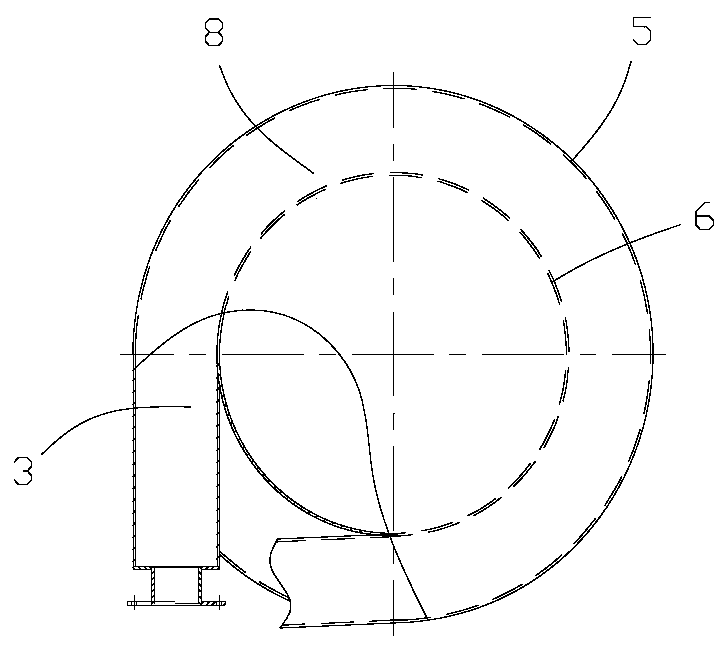

Efficient cyclone dust removal device and dust removal method thereof

The invention discloses an efficient cyclone dust removal device. The efficient cyclone dust removal device comprises an outer shell, an inner shell and a secondary dust removal assembly; the upper part of the inner shell protrudes outside the outer shell and is rotatably connected with the outer shell, the inner shell is driven to rotate by a double-way motor through a driving piece, and the upper edge of the inner shell shrinks upwards and inwards to form an opening of a cone frustum; the secondary dust removal assembly comprises a dust removal net, a net cleaning groove, a dust pipe, an exhaust fan, a dust detector and a controller; the dust removal net is horizontally arranged on the upper part of the inner shell; the net cleaning groove is formed below the dust removal net, and the top of the net cleaning groove is provided with an opening in contact with the dust removal net; the dust pipe is arranged below the net cleaning groove and connected with the bottom of the net cleaninggroove, and an electromagnetic valve is arranged on the lower part of the dust pipe; an air inlet of the exhaust fan is communicated with the dust pipe, located above the electromagnetic valve, through an air inlet pipe; the dust detector is arranged in the inner shell; and the controller is arranged on the outer shell, and electrically connected with the double-way motor, the electromagnetic valve and the exhaust fan. The invention further provides a dust removal method of the efficient cyclone dust removal device. The efficient cyclone dust removal device has the advantages that the effecton removing particles with the small grain sizes is good, and the dust removal efficiency is high.

Owner:施秀英

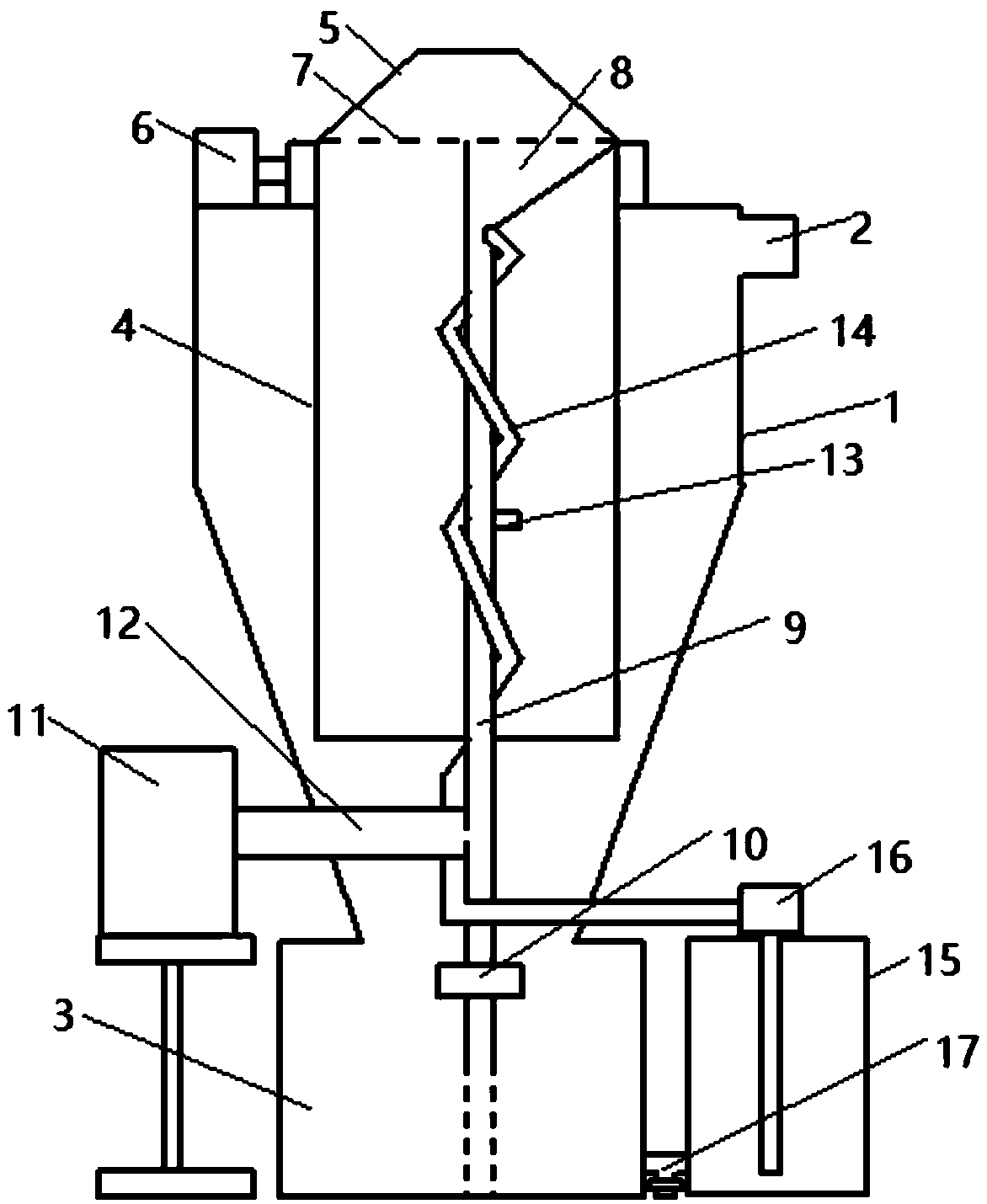

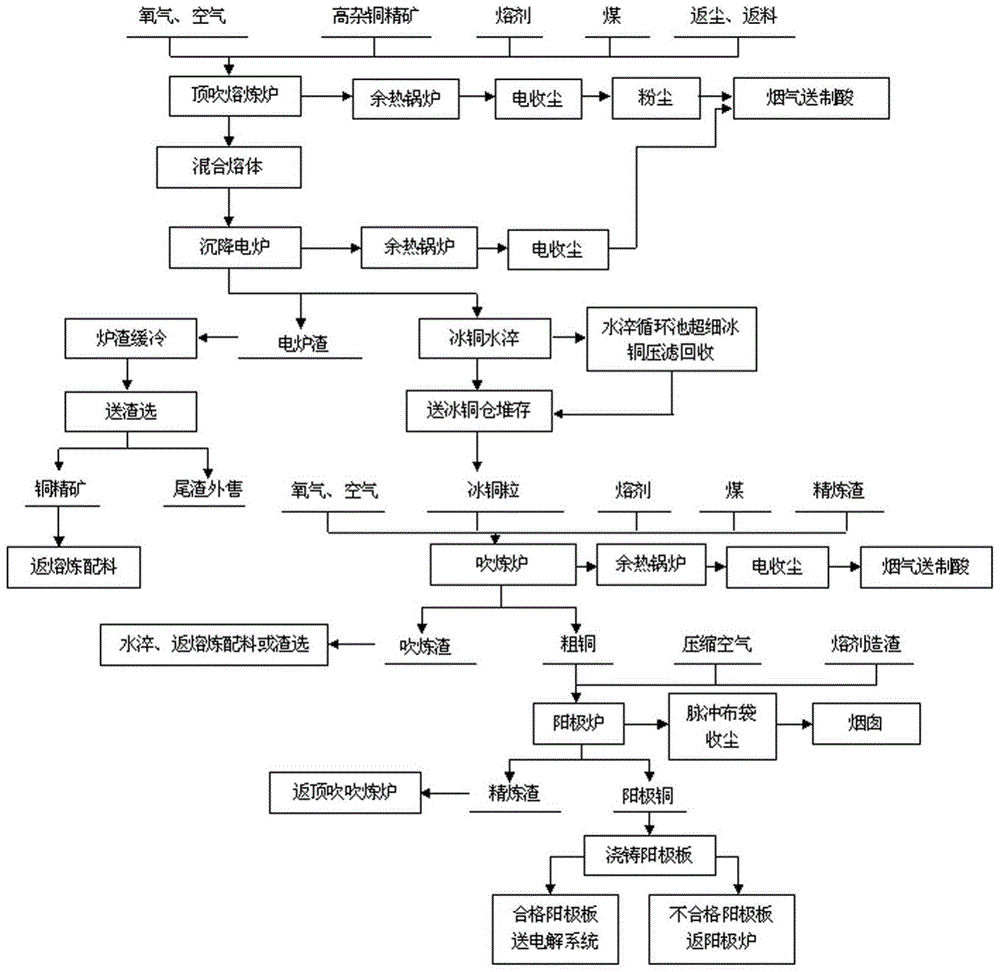

Method for recovering valuable metals by double top-blowing smelting of high-impurity copper-containing materials

The invention discloses a method for recovering valuable metal from high-impurity-content copper-contained materials through double-top-blowing smelting. The method comprises the steps of mixing high-impurity-content copper concentrate with quartz sand flux, coal, returned charge and / or returned dust in a matched mode, directly adding the mixture to a top-blowing smelting furnace, blowing oxygen into the smelting furnace for smelting, and feeding obtained mixed melt into a sedimentation electric furnace to obtain electric furnace slag and high-impurity-content copper matte through sedimentation and separation; conducting water quenching on the high-impurity-content copper matte to obtain copper matte particles; mixing the high-impurity-content copper matte, the quartz sand flux, the coal and refining slag in a matched mode, adding the mixture into a top-blowing converting furnace, and blowing oxygen into the converting furnace for converting to obtain blister copper and converting slag; mixing the electric furnace slag with the converting slag according to the weight ratio of 3:1-5:1, feeding the mixture into a slag mineral separation system to recover copper concentrate; placing the blister copper into an oxygen-rich combustion type anode furnace to be refined, and conducting casting to obtain a copper anode plate. By the adoption of the method, the adaptability of smelting equipment to the copper-contained materials such as the high-impurity-content copper concentrate can be improved, valuable metal in the high-impurity-content copper concentrate or / and the high-impurity-content copper matte can be effectively recovered, valuable metal dust contained in smoke generated during smelting can be effectively recovered, the technology is simple, and environment pollution is light.

Owner:YUNNAN TIN

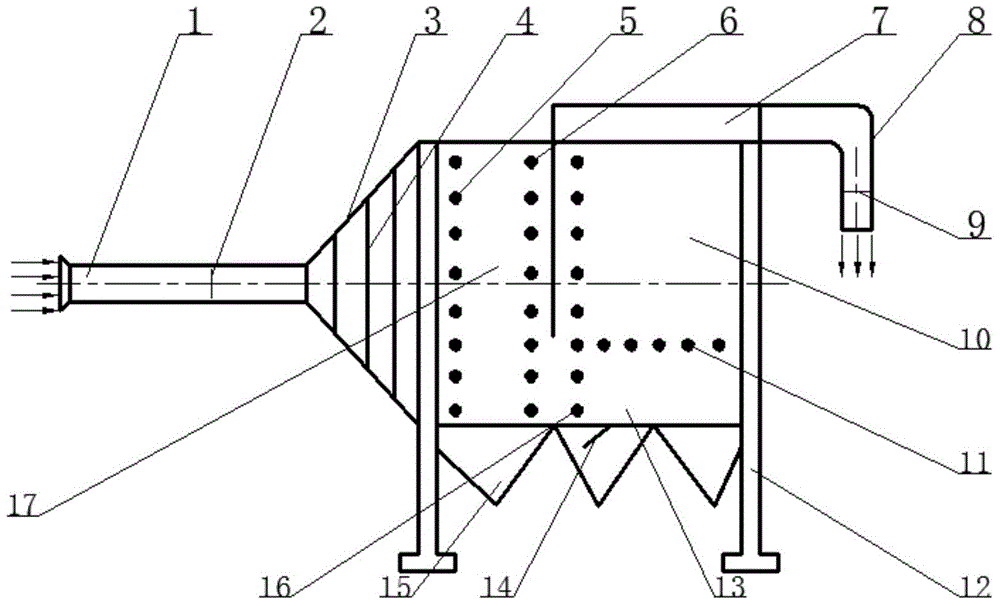

Compound dust collector

InactiveCN104645759AReduce dust removal pressureExtended service lifeCombination devicesEngineeringInlet pressure

The invention relates to a compound dust collector. The compound dust collector is characterized in that a support is fixedly welded on a shell, an inlet pipeline is arranged at the left side of the shell, an inlet pressure measurement hole is formed in the inlet pipeline, an inlet smoke box is connected with the inlet pipeline, an inlet guiding plate is arranged in the inlet smoke box, an electrostatic dust collection region is arranged at the left side of the inside of the shell, a testing fracture surface A and a testing fracture surface B are distributed, a cloth bag dust collection region is arranged at the right side of the inside of the shell, a testing fracture surface C and a testing fracture surface F are distributed, a gas purifying chamber is connected with the cloth bag dust collection region, an outlet pipeline is connected with the gas purifying chamber, an outlet pressure measurement hole is formed in the outlet pipeline, an ash bucket is arranged at the lower end of the shell, and an ash bucket baffle plate is arranged in the ash bucket. The compound dust collector has a simple structure and can be realized easily, the dust collection efficiency is improved, meanwhile, the dust collection pressure of the cloth bag close to the upper part of an air current distributing plate is reduced and the service life of the cloth bag is prolonged.

Owner:XIAN ELITE ELECTRONICS IND

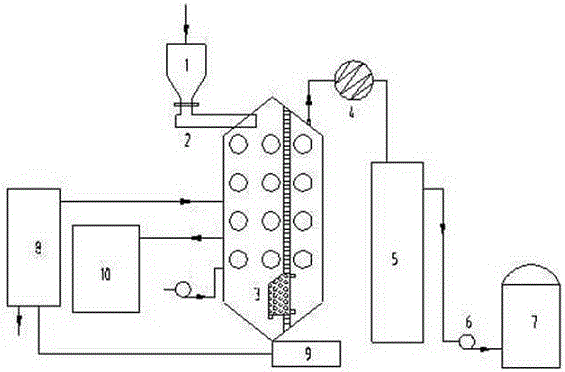

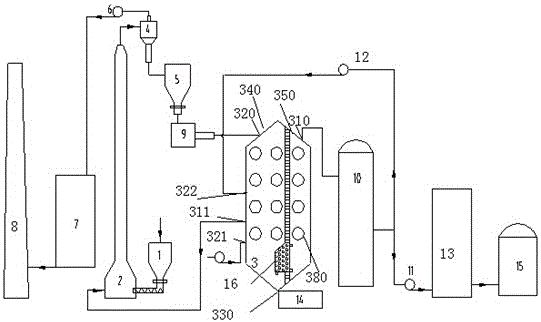

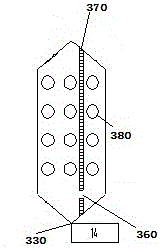

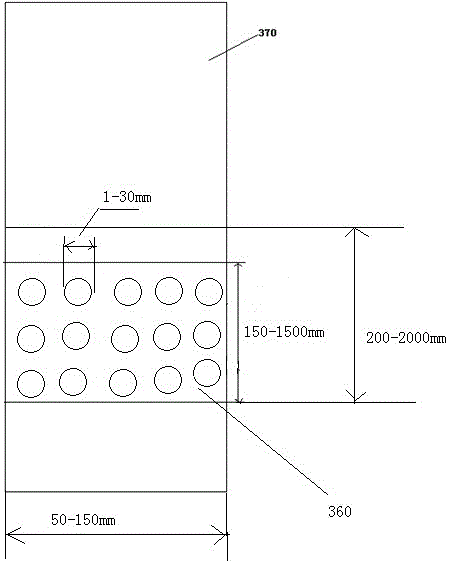

Self dust collection type coal pyrolysis and splitting gas production combined fuel gas power generation system

PendingCN105885899AUniform temperature distributionGood heating effectProductsReagentsBriquetteSpray tower

The invention belongs to the technical field of coal pyrolysis and splitting gas production and fuel gas combustion power generation, and in particular relates to a self dust collection type coal pyrolysis and splitting gas production combined fuel gas power generation system based on a heat accumulation radiation tube heating. The system comprises a pyrolysis hopper, a first feeding device, a pyrolysis and splitting reactor, a heat accumulation type radiation tube, a thermal insulating brick wall, a communicating component, a granule bed dust collection device, a spraying tower, a fuel gas tank and a power generator set, wherein the pyrolysis and splitting reactor comprises a feeding hole, a pyrolysis chamber, a splitting chamber and a splitting gas outlet. The self dust collection type coal pyrolysis and splitting gas production combined fuel gas power generation system provided by the invention is simple in structure, convenient to operate, uniform in temperature distribution and good in heating effect; the granule bed dust collector is arranged at a pyrolysis chamber oily gas outlet; after an oily gas generated from the pyrolysis chamber is subjected to dust collection of a granule bed, a clean oily gas is fed into the splitting chamber for deep splitting, a small part of a splitting gas is fed into the radiation tube for combustion, and the reset fuel gas is fed into the fuel gas power generator set for combustion and power generation, so that the problem that pyrolysis oil contains dust is solved, and the dust collection pressure of a rear end is also alleviated.

Owner:SHENWU TECH GRP CO LTD

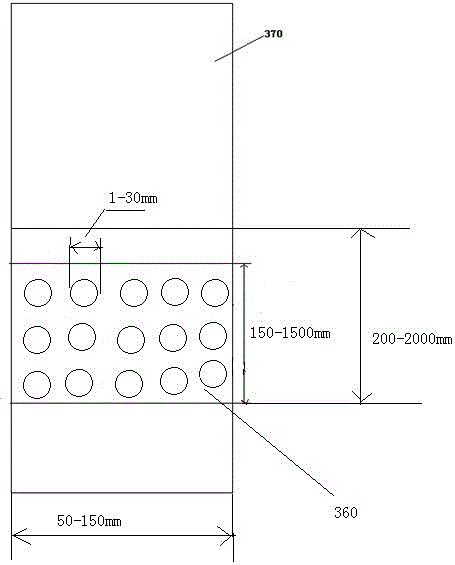

Flue gas purification system for roasting furnace of prebaked anode used for aluminum electrolysis

ActiveCN109012107AReasonable designSimple processDispersed particle separationIncinerator apparatusTarFlue

Owner:SUNSTONE DEV

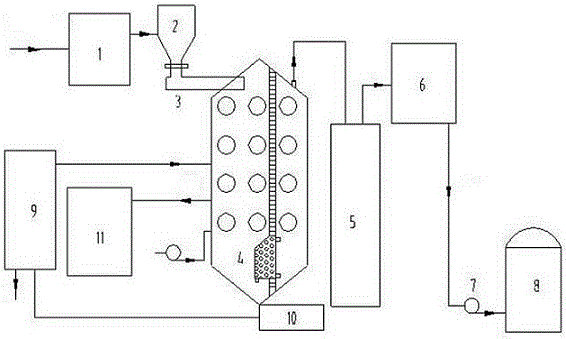

Self-dedusting type system for producing synthetic gas through pyrolysis and cracking of coal

The invention relates to the technical field of gas production through pyrolysis and cracking of coal, in particular to a self-dedusting type system for producing a synthetic gas through pyrolysis and cracking of coal based on heating of a regenerative radiant tube. The system comprises a pyrolysis hopper, a first feeding device, a pyrolysis and cracking reactor, a spray tower, a transform furnace and a fuel gas tank, wherein the pyrolysis and cracking reactor comprises a feeding port, a pyrolysis chamber, a cracked gas outlet, the regenerative radiant tube, a heat insulating brick wall, a communicating member and a granular bed dedusting device. The self-dedusting type system for producing the synthetic gas provided by the invention is simple in structure, convenient to operate, uniform in temperature distribution and excellent in heating effect; the reactor comprises the pyrolysis chamber and a cracking chamber; the granular bed dedusting device is arranged at an oil gas outlet of the pyrolysis chamber; after an oil gas produced by the pyrolysis chamber is dedusted by a granular bed, the clean oil gas enters the cracking chamber and is subjected to deep cracking, so as to reduce the dedusting pressure of a rear end, avoid a problem that a pyrolysis oil contains dust, and truly realize the clean and efficient utilization of fossil fuels.

Owner:SHENWU TECH GRP CO LTD

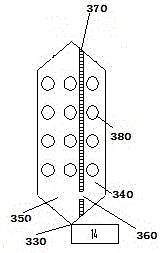

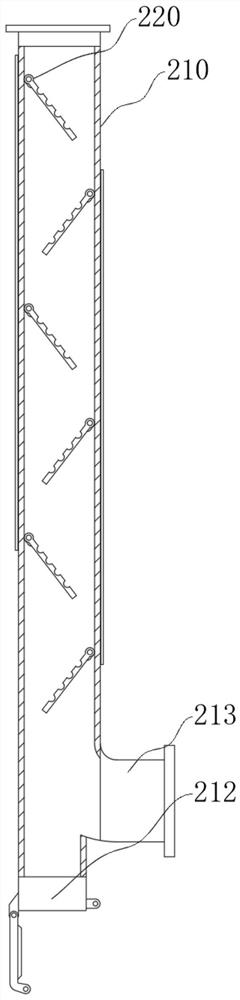

Powder metallurgy sintering waste material dust removing device

InactiveCN105645140AReduce dust removal pressureImprove operational efficiencyLoading/unloadingTowerWaste material

Disclosed is a powder metallurgy sintering waste material dust removing device. The powder metallurgy sintering waste material dust removing device comprises a negative pressure dust removal integrated system and a waste material conveying system. A small front-mounted separation tower is disposed at a waste material inlet of the negative pressure dust removal integrated system. The separation tower comprises an upper separation chamber and lower collecting buckets. Material-air separators are disposed at the bottoms of the collecting buckets. The upper separation chamber is connected with a conveying pipe in the waste material conveying system. A vertical arc-shaped baffle is disposed at a waste material inlet and in the upper separation chamber. The curved surface of the baffle faces an outlet of the conveying pipe. A channel capable of allowing waste materials to enter the waste material inlet is reserved between the top of the baffle and the upper separation chamber. By means of the powder metallurgy sintering waste material dust removing device, as primary separation is conducted before the waste materials enter the negative pressure dust removal integrated system, the dust removal pressure of the system is greatly relieved, and the operation efficiency and dust removal effect of equipment are improved; the additionally arranged small front-mounted separation tower is simple in structure and convenient to mount and maintain; the dust removal efficiency is further improved by means of the arc-shaped baffle; and the powder metallurgy sintering waste material dust removing device is convenient to manufacture and low in maintaining cost.

Owner:黄冈市劲马窑炉机械有限公司

Self-dust-removal type pyrolyzing and cracking system for biomass

PendingCN105925283AHigh thermal efficiencyReduce back-end dust removal pressureBiofuelsIndirect heating destructive distillationCycloneBrick

The invention belongs to the technical field of biomass pyrolysis and mainly relates to a self-dust-removal type pyrolyzing and cracking system for biomass based on regenerative radiant tube heating. The system comprises a pyrolysis hopper, a pyrolyzing and cracking reactor, regenerative radiant tubes, a heat insulation brick wall, a communicating member, a particle bed dust removing device, a cracking gas cyclone separator, a spraying tower and a gas tank, wherein the pyrolyzing and cracking reactor comprises a feed opening, a pyrolysis chamber, a cracking chamber and a cracking gas outlet; the cracking gas cyclone separator is connected with the cracking gas outlet, a semicoke conveying device and the spraying tower. The reaction system disclosed by the invention has the advantages of simple structure, convenience in operation, uniform temperature distribution, good heating effect, high utilization rate of raw materials and suitability for popularization; the biomass with the size of 20mm or less can be treated.

Owner:SHENWU TECH GRP CO LTD

Metal dedusting device

InactiveCN108014585AReduce dust removal pressureImprove operational efficiencyCombination devicesGas treatmentScrapIntegrated systems

The invention relates to a metal dedusting device. The metal dedusting device has a negative pressure dedusting integrated system and a waste conveying system, a waste inlet of the negative pressure dedusting integrated system is equipped with a preposed small separation tower, the separation tower includes an upper separation chamber and a lower collecting hopper, and the bottom of the collectinghopper is equipped with a material gas separator; the upper separation chamber is connected to a conveying pipe in the waste conveying system, a vertical arc-shaped baffle plate is mounted at a wasteinlet in the upper separation chamber, the curved surface of the baffle plate faces the outlet of the conveying pipe, and a channel for waste to enter the waste inlet is left between the baffle platetop and the upper separation chamber. According to the invention, as primary separation is carried out before waste enters the negative pressure dedusting integrated system, the dedusting pressure ofthe system is greatly alleviated, and the equipment operation efficiency and dedusting effect are improved. The added preposed small separation tower has a simple structure, is convenient for installation and maintenance, the arc-shaped baffle plate further improves the dedusting efficiency, also the making is convenient, and the maintenance cost is low.

Owner:湖北骏马环保科技有限公司

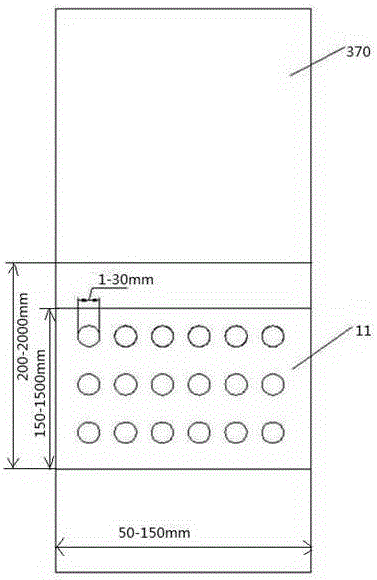

Self-dust-removal type pyrolyzing and cracking tube cracking reactor

PendingCN105925291AHigh yieldRealize comprehensive utilizationSpecial form destructive distillationTarCombustible gas

The invention belongs to the technical field of pyrolyzing and cracking of fossil fuel and in particular relates to a self-dust-removal type pyrolyzing and cracking tube cracking reactor for resources such as oil shale and coal. The self-dust-removal type pyrolyzing and cracking tube cracking reactor is used for preparing combustible gases and semicoke products. Aiming at the defects in the prior art, the invention designs and develops the self-dust-removal type pyrolyzing and cracking tube cracking reactor; a pyrolysis chamber and a cracking chamber are integrally designed in the reactor; oil gas generated by the pyrolysis chamber enters into a particle bed dust removing device; after the oil gas is subjected to dust removal by the particle bed dust removing device, clean oil gas enters the cracking chamber for deep cracking, so that the dust removing pressure at the rear end is reduced; cracking tubes are spirally distributed in the cracking chamber and are distributed around radiant tubes in a zigzag manner; the stay time of the oil gases in the cracking tubes is long, and tar macromolecules are cracked into small molecule gaseous hydrocarbons. According to the reactor, a large amount of cracking gases can be generated, so that the problem that produced pyrolytic tar contains dust is solved, and clean and efficient utilization of the fossil fuel is really realized.

Owner:SHENWU TECH GRP CO LTD

Reciprocating type section mill smoke dust collecting device

PendingCN114534411AImprove dust collection effectImprove efficiencyUsing liquid separation agentDirt cleaningThermodynamicsAir volume

The invention discloses a reciprocating type section mill smoke and dust collecting device which comprises a dust suction hood and a dust suction pipe, the dust suction hood is formed by hinging two hood bodies, each hood body comprises an outer hood and an inner hood, the outer hood is connected with the periphery of the inner hood, a cavity is formed between the outer hood and the inner hood, dust suction holes are evenly formed in the inner hood, and the dust suction pipe is arranged in the cavity. The interior of the inner cover is divided into a plurality of dust suction chambers through a plurality of partition plates, the lower end of the dust suction pipe is connected with a uniform distribution pipe, the uniform distribution pipe is connected with pull pipes with the number corresponding to that of the dust suction chambers, the upper end of the outer cover is provided with an air outlet hole, the air outlet hole is connected with an arc-shaped suction pipe in sliding connection with the pull pipes, and each dust suction chamber corresponds to a suction pipe. And the side wall of the pull pipe is provided with an insertion plate for adjusting the air volume. The size of the opening of the dust hood can be adjusted according to requirements, generated water vapor and dust can be comprehensively absorbed, and the dust collection effect and efficiency of the dust hood are improved.

Owner:SHANDONG IRON & STEEL CO LTD

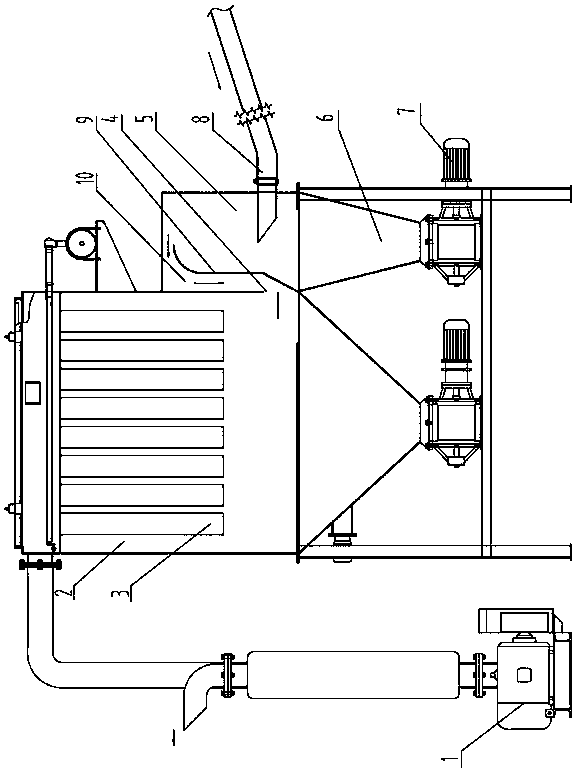

Spiral-flow dryer

ActiveCN102230719BOvercome the shortcomings of strict initial moisture requirementsOvercome the disadvantage of not being able to fluidize the filter cakeDrying solid materials with heatDrying gas arrangementsSlurryEngineering

The invention provides a spiral-flow dryer. An air flow guide-component is configured at the upper part of a dryer cavity. The air flow guide-component comprises a core tube and a spiral band fixed on the core tube. A spiral groove serves as a spiral air flow passage, and the rear end of the spiral air flow passage communicates with a rotational flow chamber. The edge of the upper half of the spiral band is fixed on the inner wall of the dryer cavity. A couple of mixer shafts are configured at the under part of the dryer cavity, and couples of paddle copy boards and coulters are configured on each of the mixer shafts. The invention expands the application scope of fluidized drying and is capable of breaking up and drying materials of shapes such as paste, slurry, granule, powder and filter cake inside the dryer. The invention is far superior to the common fluidized dryers in terms of volumetric drying intensity and can reduce the final moisture to an extremely low value, thereby overcoming the shortcoming that the materials for air flow drying set strict requirements for the original moisture in the materials.

Owner:JIANGSU XIANFENG DRYING ENG

Argon blowing protection ladle cover for metal smelting

PendingCN114749613AAchieve dust removal effectReduce the temperatureMelt-holding vesselsGas supplyMaterials science

The upper layer of a cover body of the ladle cover is a dust removal wall, the lower layer of the cover body of the ladle cover is a protective ring, and a heat preservation protective cover is arranged in the protective ring; the argon conveying mechanism sequentially comprises an argon conveying opening, connecting pipes, argon blowing cavities and nozzles, the argon conveying opening is formed in the upper portion of the cover body, the gas inlet ends of the multiple sets of connecting pipes are connected with the argon conveying opening through branch cavities, the argon blowing cavities are formed in the cover body and comprise fan-shaped argon blowing cavities and annular argon blowing cavities, the gas supply ends of the connecting pipes are communicated with small openings of the fan-shaped argon blowing cavities, and the annular argon blowing cavities are communicated with small openings of the annular argon blowing cavities. A large opening of the fan-shaped argon-blowing cavity is communicated with the side wall of the annular argon-blowing cavity; a plurality of nozzles are arranged at the bottom of the annular argon-blowing cavity; the bottom end of the dedusting connecting pipe of the dedusting mechanism penetrates into the cover body, the main dedusting opening is communicated with the interior of the cover body through the dedusting connecting pipe, and a plurality of dedusting holes are formed in the dedusting wall. The heat preservation protection cover protects the interior of the ladle cover, a negative pressure cavity is formed in the ladle cover through the main dust removal opening and the external dust suction device, and gas and smoke dust generated by the steel ladle are sucked into the dust removal holes when meeting the dust removal wall and are treated for dust removal.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

A self-dusting pyrolysis and catalytic cracking reactor

ActiveCN105885898BHigh yieldRealize comprehensive utilizationSpecial form destructive distillationHydrogenTar

The invention belongs to the technical field of pyrolysis and cracking of fossil fuel and in particular relates to a self-dust-removal type pyrolysis and catalytic cracking reactor which is mainly specific to resources such as oil shale and coal and used for preparing flammable gas and semicoke products. The invention, aiming at overcoming the defects of the prior art, designs and develops a self-dust-removal-type pyrolysis and catalytic cracking reactor. In the reactor, a pyrolysis chamber and a cracking chamber are designed in an integrated manner, oil gas produced in the pyrolysis chamber enters a particle bed dust removal device, after dust removal is carried out by the particle bed dust removal device, clean oil gas enters the cracking chamber to be deeply cracked, rear-end dust removal pressure is reduced, macromolecular tar molecular is cracked into micromolecular gaseous hydrocarbon, and a large amount of hydrogen is produced in a catalytic cracking manner, so that the problem that pyrolyzed oil contains dust is avoided and clean and efficient utilization of the fossil fuel is really realized.

Owner:SHENWU TECH GRP CO LTD

Composite deduster

InactiveCN107774073AReduce dust removal pressureExtended service lifeCombination devicesEngineeringSmoke

The invention discloses a compound dust remover, the main content is: the inlet pipe is provided with a left pressure test hole, the inlet pipe is connected with a smoke removal box, the smoke removal box is installed on the left end surface of the shell, and the smoke removal box A deflector mounting plate is installed, the shell is installed on the supporting legs, the first test surface is arranged near the left end of the shell, the second test surface is installed in the shell and is located on the right side of the first test surface, and the clean room is installed on the shell The upper end communicates with the shell, the outlet pipe is connected with the clean room, the right end of the shell is the dust removal area, the left end of the shell is the electrostatic dust removal area, the fourth test surface is set on the bottom surface of the shell and is located in the dust removal area, and the inside of the shell is located in the dust removal area. There is a third test surface at the left end of the area, a cone-shaped bucket is installed on the bottom surface of the shell, and a baffle is installed inside the cone-shaped bucket.

Owner:CHANGZHOU FEISHENG PLASTIC MACHINERY

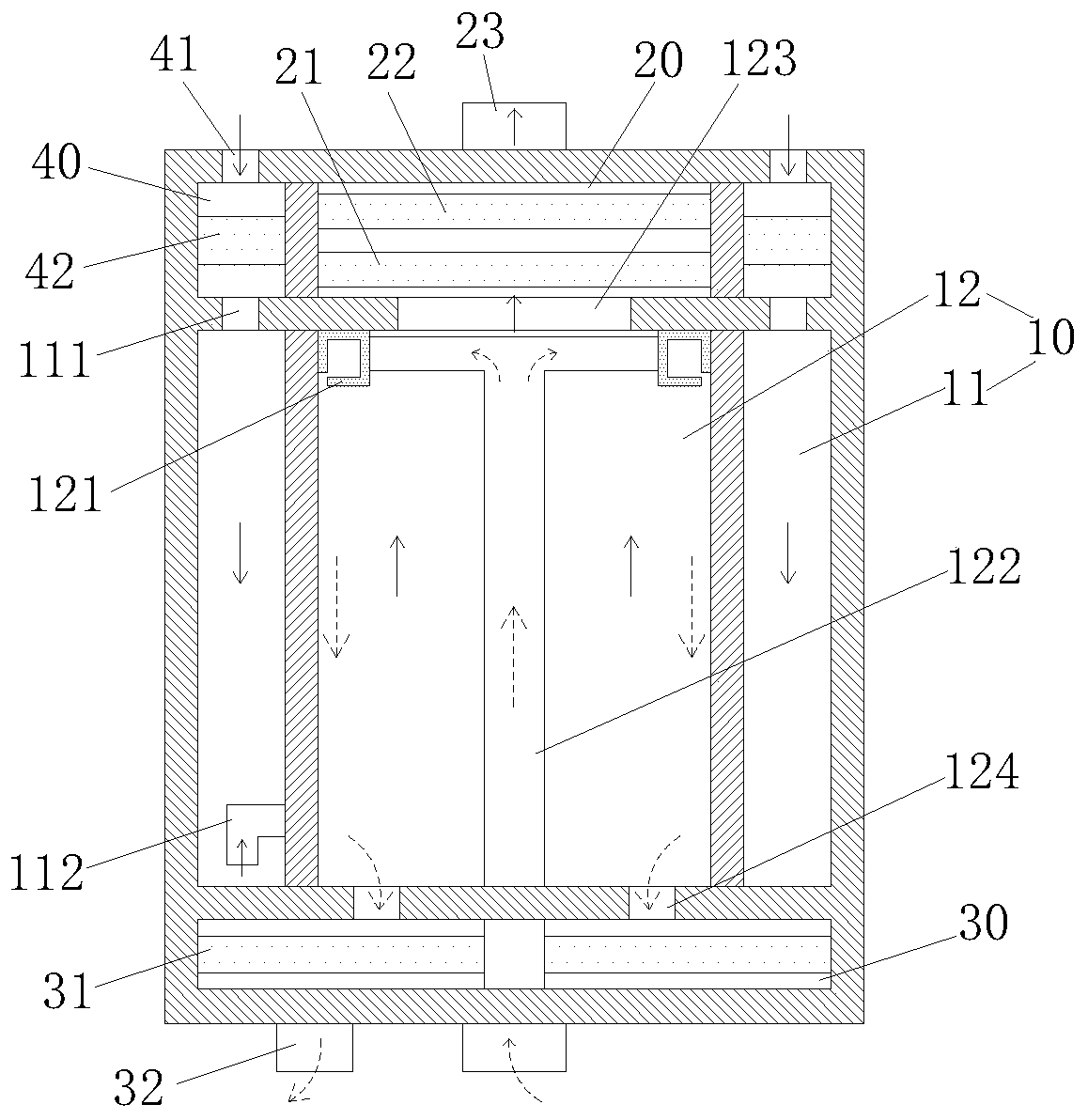

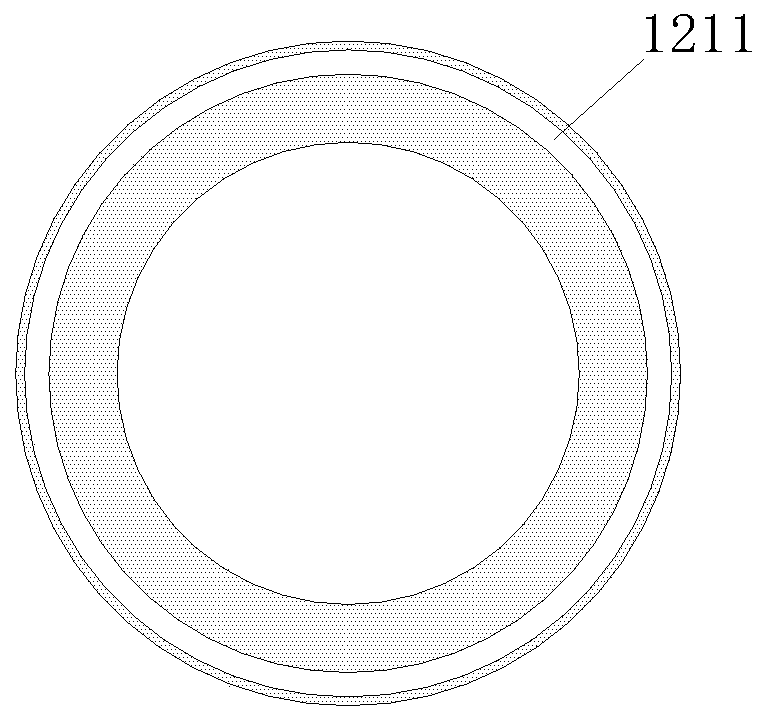

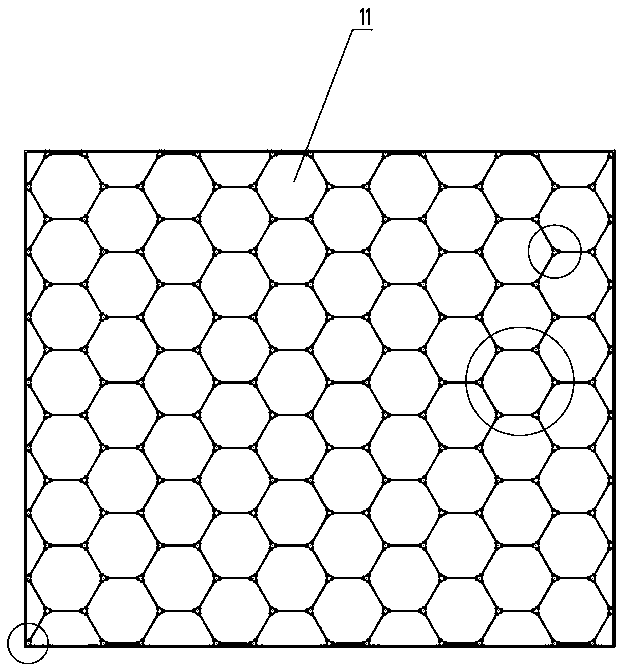

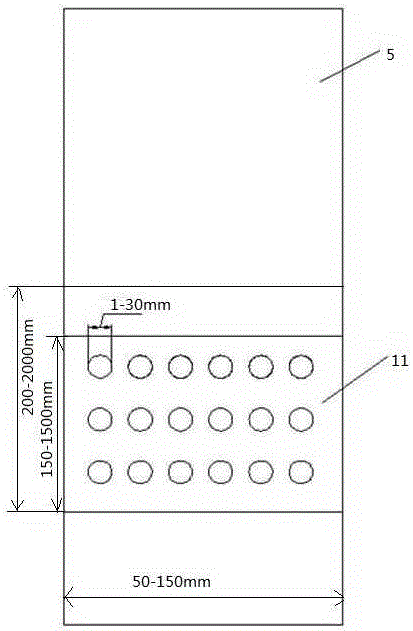

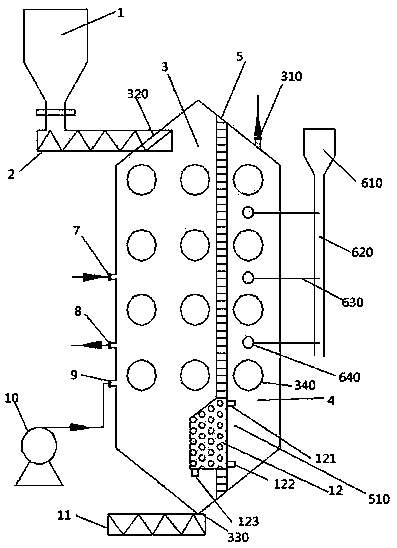

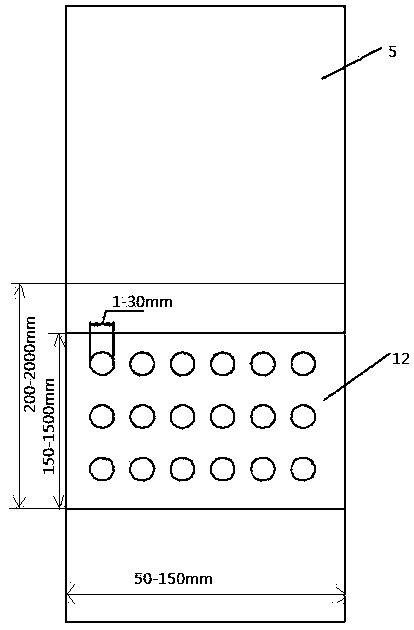

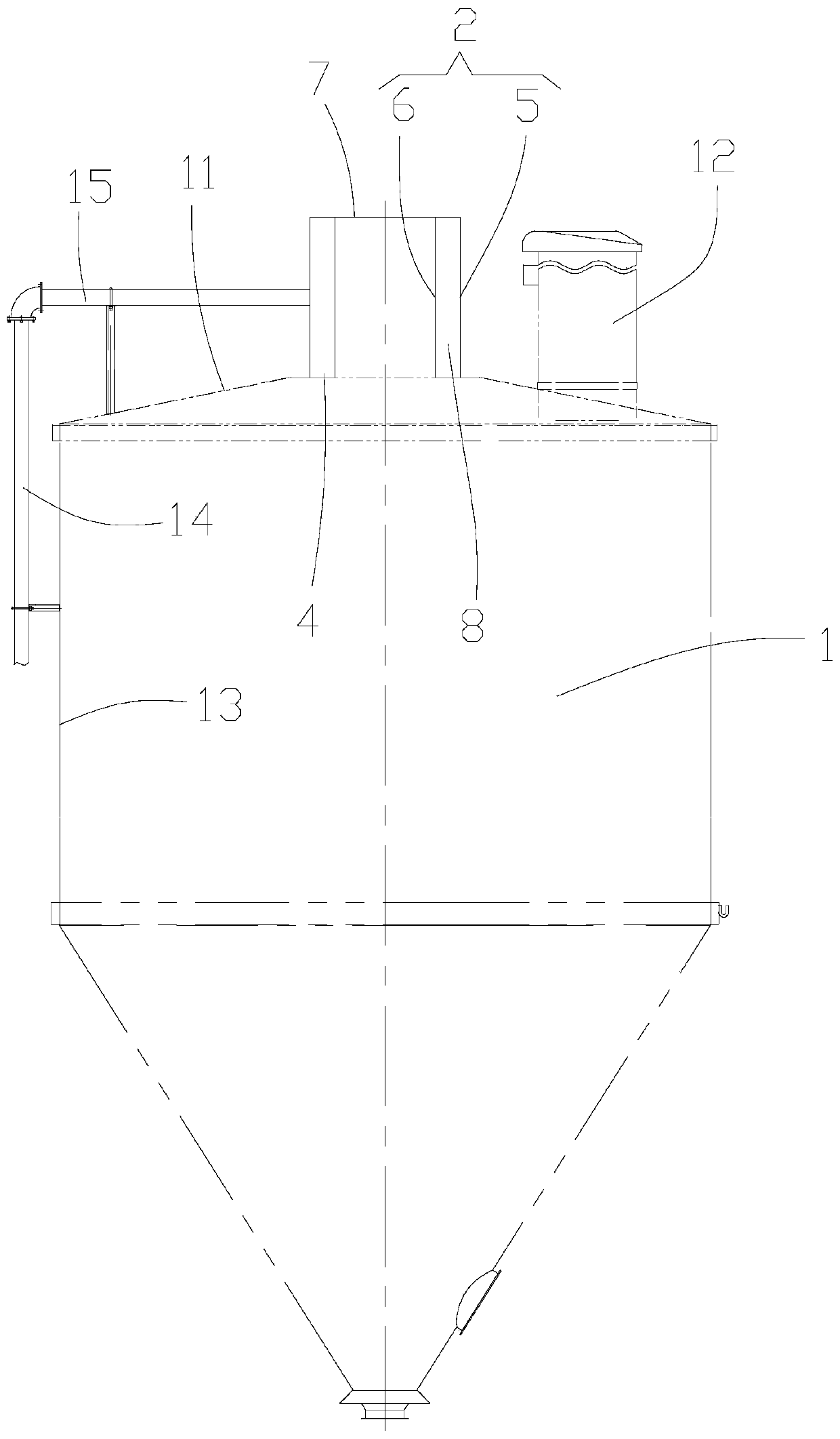

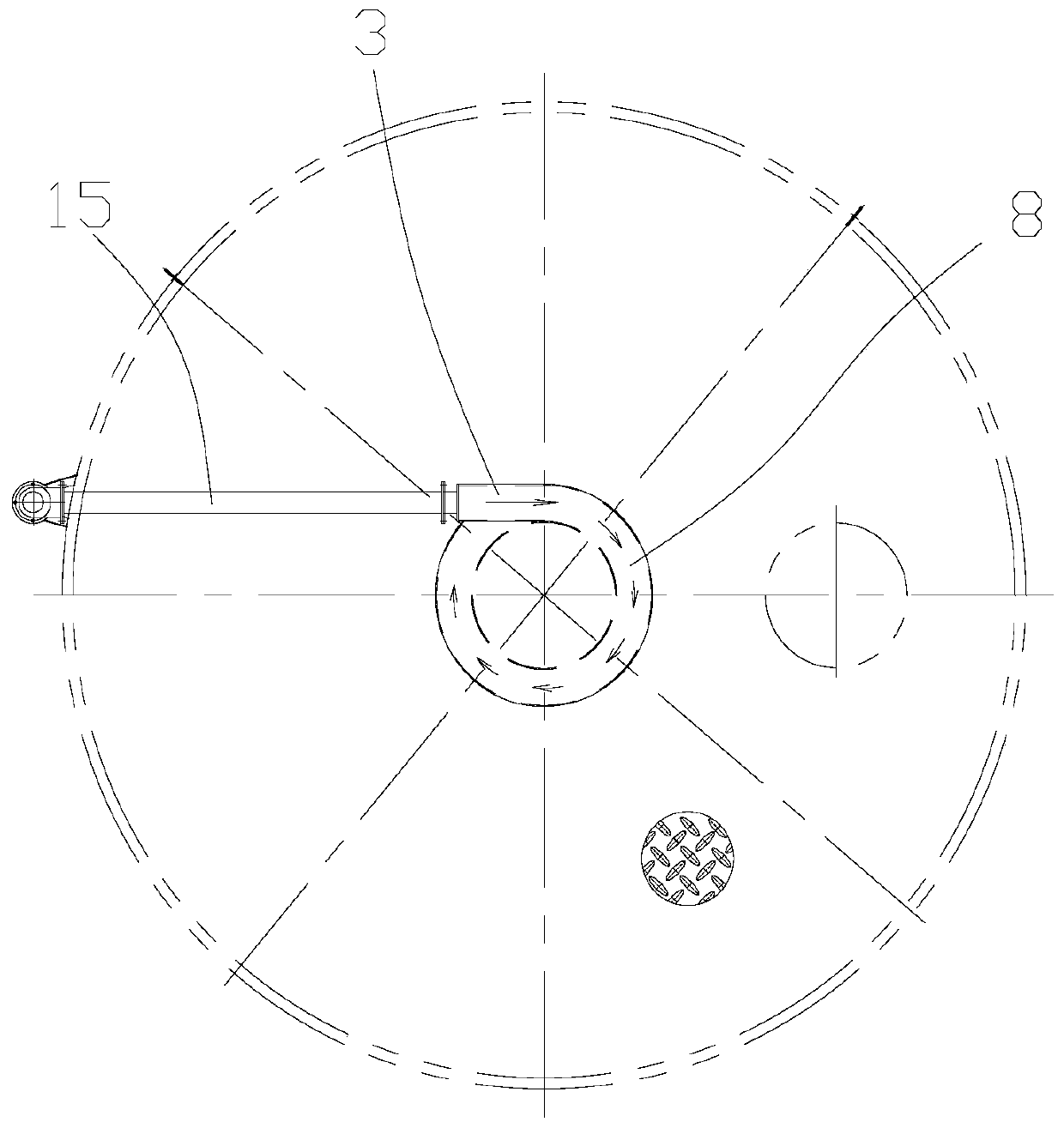

Silo, silo feeding method and concrete mixing plant

ActiveCN109531810BReduce dust removal pressureReduce generationDischarging apparatusMixing operation control apparatusDust controlStructural engineering

The invention relates to the technical field of silo feeding, and discloses a silo and a silo feeding method. The silo comprises a material containing cavity defined by the silo wall, wherein a cyclone feeding cylinder is arranged on the silo wall, the cyclone feeding cylinder comprises a feeding channel, a feeding inlet at one end of the feeding channel communicates with the outside of the silo,a feeding outlet at the other end of the feeding channel communicates with the material containing cavity, and the structure of the feeding channel is set to achieve the effect that a material conveyed by the wind power moves downwards in the circumferential direction of the feeding channel and enters the material containing cavity in the circumferential direction from the feeding outlet. Due to the fact that the powder material moves downwards in the circumferential direction of the feeding channel, the initial speed of the powder material when the powder material enters the silo is reduced,then the amount of dust generated in the powder material falling process is reduced, and then the dust removal pressure of the silo is further reduced, such as the dust removal pressure of a dust remover arranged on the silo.

Owner:湖南中联重科混凝土机械站类设备有限公司 +1

A simple air purifier for sandblasting room

ActiveCN109331596BImprove dust removal efficiencyReduce dust removal pressureCombination devicesAir purifiersSand blasting

The invention relates to a simple air purifier for a sand blasting room, which comprises a purification barrel, wherein the purification barrel is internally equipped with a filter component; the bottom of the purification barrel is mounted on a base; air inlets are formed in a side wall at the bottom of the purification barrel; an exhaust fan is further mounted in the purification barrel; a plugis arranged at the top of the purification barrel; an air outlet is formed in the purification barrel and located at the rear of the exhaust fan; and the purification barrel is further internally provided with a water spray mechanism. The air purifier can pretreat air in the sand blasting room, reduces the dust content in the air, completely treat dust in the sand blasting room and improve dust removal efficiency of a deduster after the air purifier is matched with the deduster. Since an inner wall of the purification barrel is provided with running water, after the air containing the dust enters the purification barrel from the air inlets, the dust in the air close to the inner wall of the purification barrel is absorbed due to tension of the water and brought away by the water; the burden of the filter component is reduced; and a service life of the filter component is prolonged.

Owner:张子欣

Air filter based on centrifugal principle

ActiveCN110285000BReduce the temperatureTo achieve the purpose of coolingMachines/enginesAir cleaners for fuelAir filterCentrifugation

Owner:高博集团有限公司

A chip removal device

ActiveCN104708665BLabor savingImprove dust removal efficiencyMetal working apparatusLight sensingImpurity

The invention discloses a scrap removing device which is applicable to plate machining. The scrap removing device comprises a conveying track, an air blow pipe, an air supply device and a light sensing device. The conveying track is used for conveying plates. The side, facing the conveying track, of the air blow pipe is provided with a plurality of air outlet holes. The air supply device is connected to the air blow pipe and used for supplying air to the air blow pipe. The light sensing device is used for projecting light rays along a short side. When the plates shield the projected light rays, the light sensing device senses corresponding reflected light rays and drives the air supply device to supply the air to the air blow pipe according to the sensing result so that the air can be blown to the surfaces of the plates through the air outlet holes and can blow away impurities on the surfaces of the plates. By the adoption of the scrap removing device, the problem that when a traditional manual scrap removing method is adopted, the operating efficiency is low, and the method can not adapt to streamlined production in processing workshops, labor is saved, the dedusting efficiency is improved, and the dedusting pressure of big environments of the processing workshops is lowered.

Owner:DUOWEI UNION GRP

Efficient dust removal process for dust gas

InactiveCN111991976APass smoothlyReduce dust removal pressureHuman health protectionCombination devicesEnvironmental engineeringDust particles

The invention discloses an efficient dust removal process for dust gas. The process comprises the following steps that: firstly, exhaust gas of a processing furnace passes through a dust blocking device and a filtering device, a large amount of dust in the gas is preliminarily intercepted; then the gas is purified again through a dust removal bag in a dust removal device; and finally the gas is thoroughly purified through an electrostatic dust remover with an electrostatic dust removal effect and then discharged into the atmosphere. Through the arrangement of the dust blocking device and the filtering device, a large number of dense dust particles are blocked, so that the subsequent dust removal pressure is reduced; the dust blocking device and the filtering device are both of mechanical structures, so that the cost input is low; the dust blocking device and the filtering device are installed in a pipeline, so that occupied space is not needed, public resources are saved, and popularization is facilitated; and a large amount of dust is gathered and filtered through the arranged dust removal device, so that the gas is more transparent and cleaner, and atmosphere pollution is avoided.

Owner:沈高金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com