Powder metallurgy sintering waste material dust removing device

A powder metallurgy and waste material technology, which is applied in the field of powder metallurgy sintering waste dust removal device, can solve the problems of affecting dust removal efficiency and dust removal effect, health hazards of operators, and large dust of bulk materials, etc., and achieves simple structure, improved dust removal effect, and maintenance The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

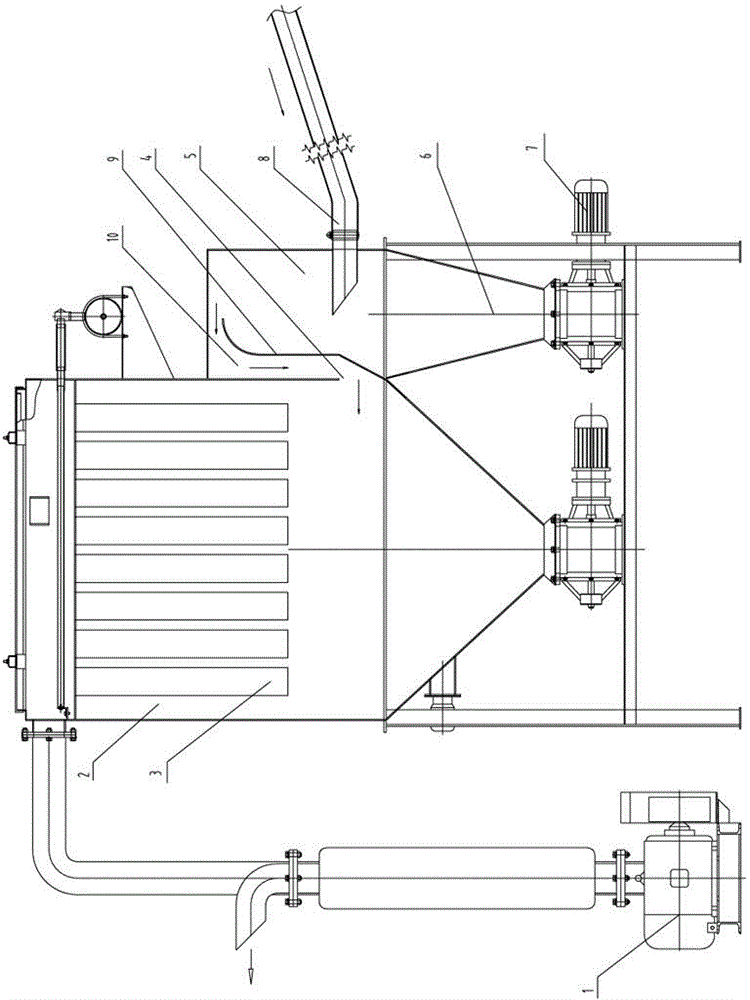

[0013] see figure 1 , the powder metallurgy sintering waste dedusting device of the present invention has a negative pressure dust removal integrated system and a waste material conveying system, the negative pressure dust removal integrated system mainly includes a vacuum pump 1, an integrated separation tower 2, and a filter bag is installed in the upper part of the integrated separation tower 2 3. The integrated separation tower 2 is provided with a waste material inlet 4 on the tower body located at the lower part of the filter bag, and a front small separation tower is installed at the waste material inlet 4, and the separation tower includes an upper separation chamber 5 and a lower collection bucket 6, The bottom of the collecting bucket is equipped with a material gas separator 7; the upper separation chamber is connected with the conveying pipe 8 in the waste material conveying system; a vertical arc-shaped baffle 9 is installed at the waste material inlet in the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com