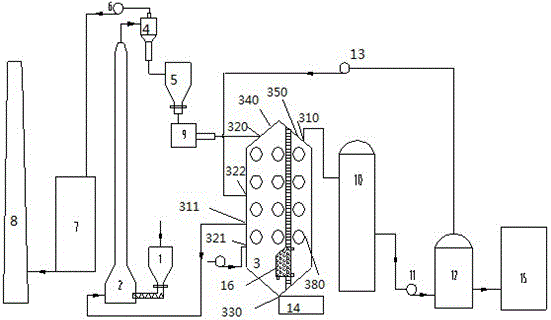

Self dust collection type coal pyrolysis and splitting gas production combined fuel gas power generation system

A technology of coal pyrolysis and self-dedusting, which is applied in gas dust removal, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems of large condensation recovery system, many operating links, and low gas calorific value, so as to save construction costs and floor area, uniform temperature distribution, clean and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) The granular coal crushed to a particle size of ≤10mm enters the riser dryer 2 through the hopper 1. In the riser dryer, 150-250 The flue gas at ℃ dries and lifts the coal, the coal enters the drying cyclone separator 4, and the separated coal powder enters the pyrolysis hopper 5, and the flue gas at about 70-130 °C is sent to the exhaust gas purification through the exhaust fan 6 Device 7, the flue gas that reaches the discharge standard is discharged through the chimney 8.

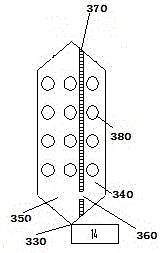

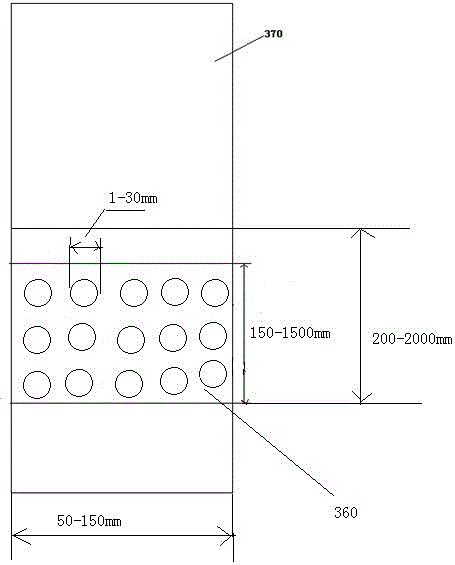

[0062] (2) Coal enters the regenerative moving bed reactor 3 through the star-shaped feeder 9 in the pyrolysis hopper 5, and the moving bed reactor 3 is divided into a pyrolysis chamber and a cracking chamber in a grid pattern.

[0063] (3) One-way regenerative radiant tubes are evenly arranged in the pyrolysis chamber, and the temperature of the tube wall is controlled at 500-700°C by a gas regulating valve. The material stays in the reactor from top to bottom for 1-40 minutes, and is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com