Cyclone drying and solvent recycling system

A recycling system and swirling technology, applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems of direct drying of unsuitable filter cake-like or agglomerated materials, improve drying efficiency, reduce dust removal pressure, The effect of not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

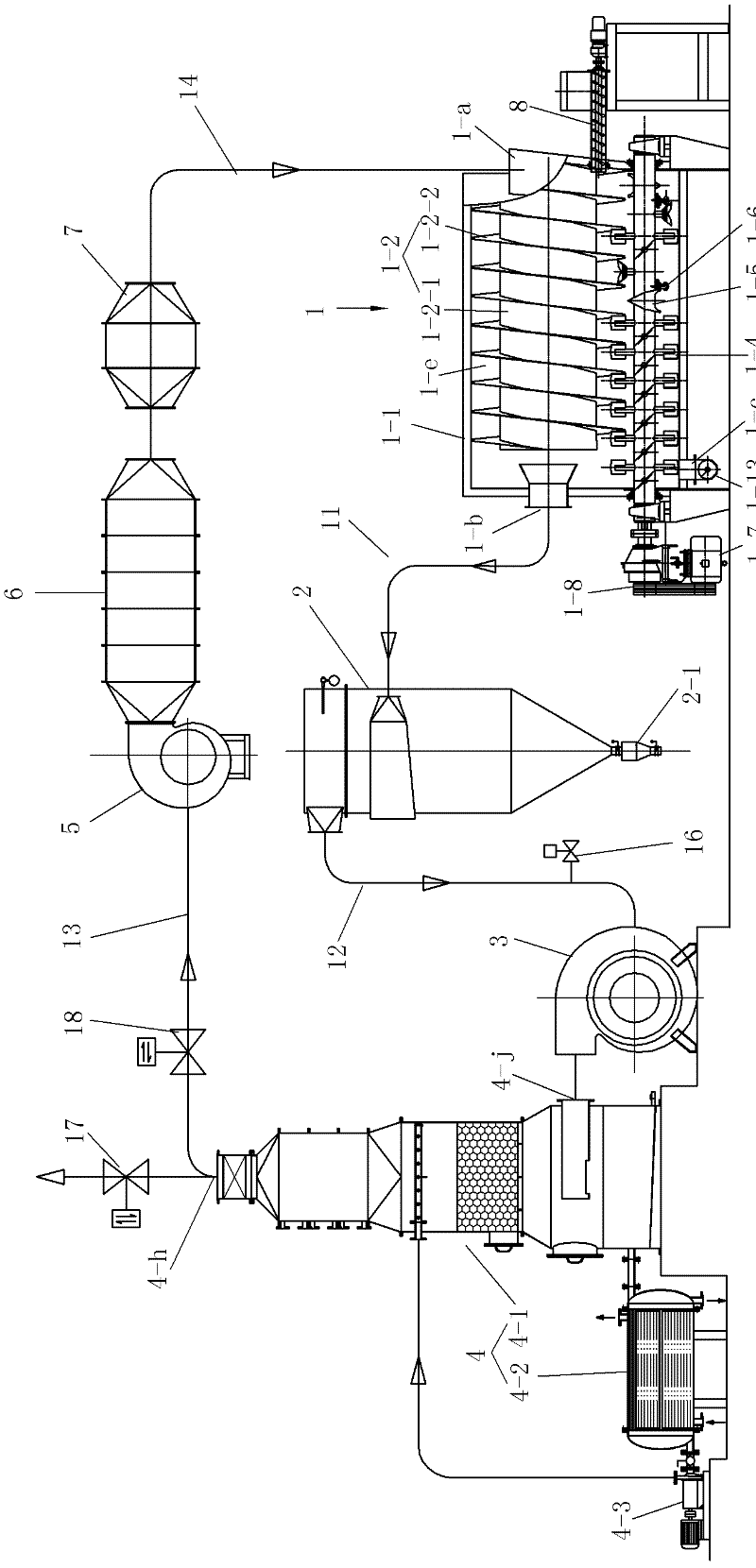

[0021] See Figure 1 to Figure 11 , This embodiment has a drying host 1, a bag dust removal device 2, an induced draft fan 3, a composite condensing device 4, a blower 5, a heater 6, and a filter 7.

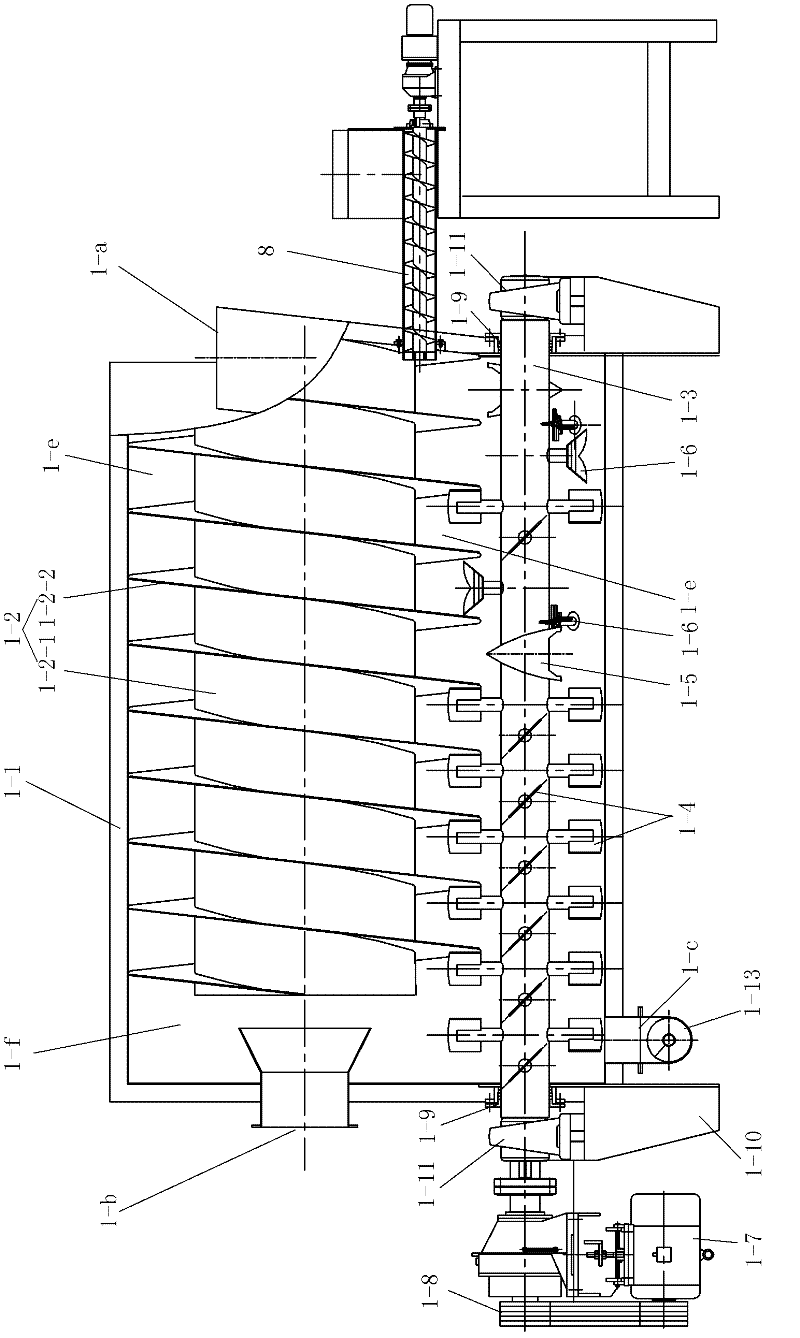

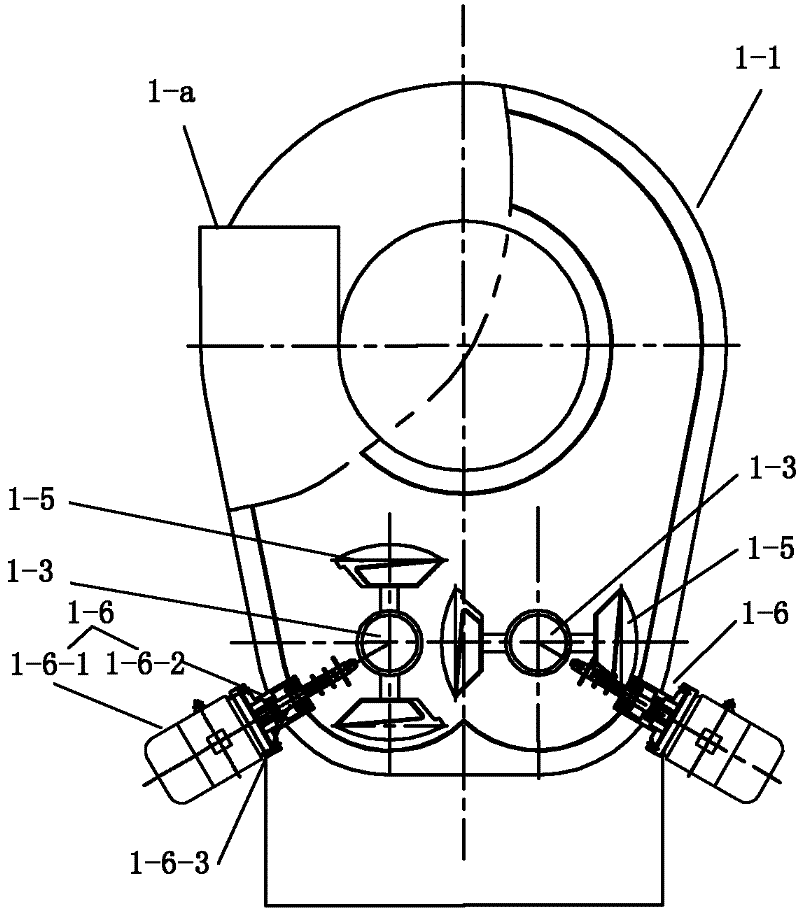

[0022] The main drying machine 1 has a body 1-1 supported by a frame 1-10, the upper part of the main drying machine 1 is arc-shaped, and the bottom is W-shaped. The upper part of the body cavity is provided with an airflow guide 1-2, and the space behind the body cavity behind the airflow guide 1-2 is a swirl chamber 1-f. The airflow guide 1-2 includes a core tube 1-2-1 and a spiral band 1-2-2 fixed on the core tube 1-2-1, and the spiral groove becomes a spiral airflow channel 1-e, and the spiral airflow channel The rear end of 1-e communicates with the settling chamber 1-f, and the airflow guide 1-2 is fixed by fixing the upper half edge of the spiral belt 1-2-2 on the inner wall of the body cavity.

[0023] The lower part of the body cavity is provided with a pair of stirrin...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is that the compound condensation device 4 taken is different, see Figure 12 , compound condensing device 4 with inner finned tube condenser 4-4, gas-liquid separator 4-5 and liquid collection tank 4-6, liquid collection tank 4-6 is equipped with tube and tube cooler 4-7 . The above-mentioned inner finned tube condenser 4-4 and the gas-liquid separator 4-5 are connected to the liquid collecting tank 4-6 and communicate with the liquid collecting tank 4-6, and the hot air inlet 4-j of the composite condensing device 4 It is arranged on the top of the condenser 4-4, and the cold air outlet 4-h of the composite condensing device 4 is arranged on the top of the gas-liquid separator 4-5. The liquid collecting tank 4-6 is provided with a rectifying tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com