Spiral-flow dryer

A dryer and swirling technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of limited drying capacity, heat transfer area, complex structure, etc., and overcome the strict requirements of initial moisture content , intense heat and mass transfer, and low dust removal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

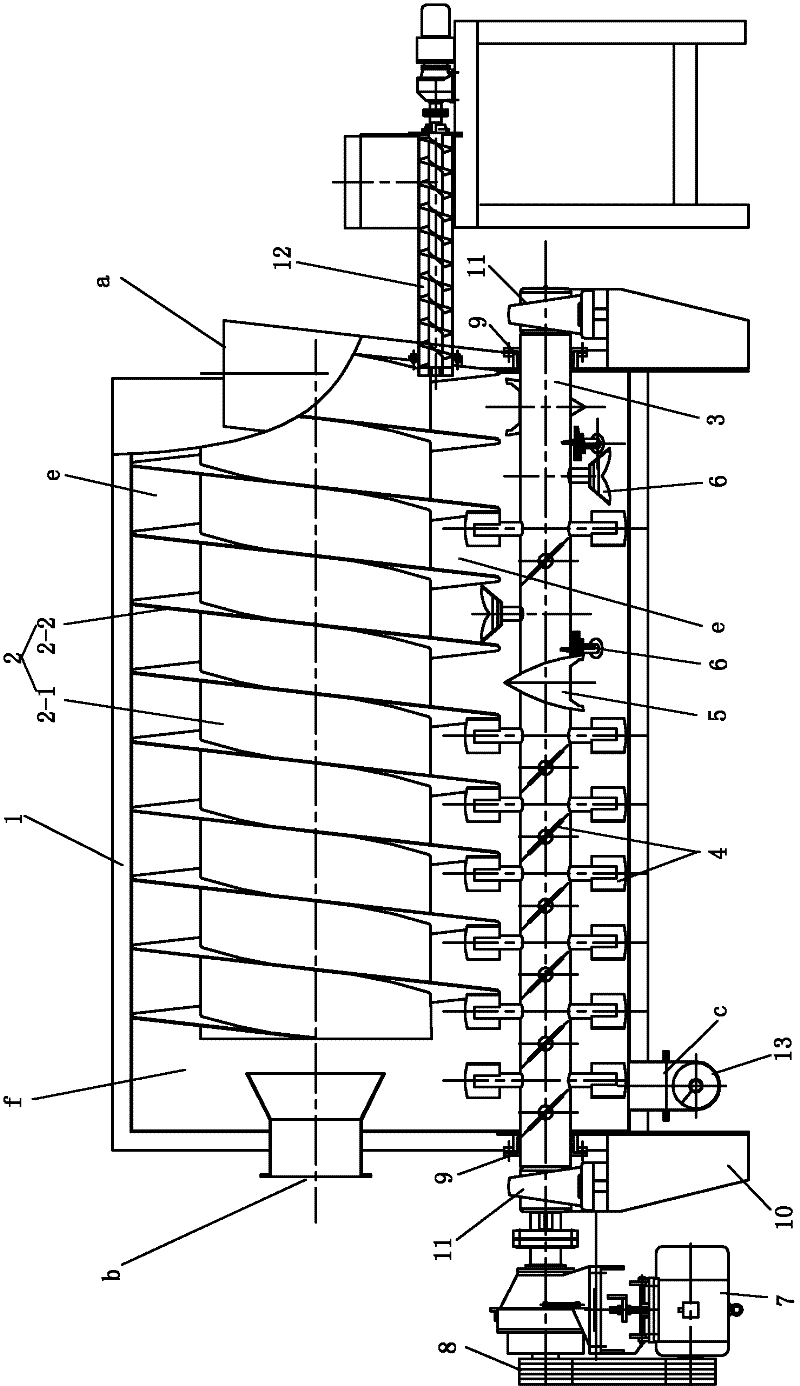

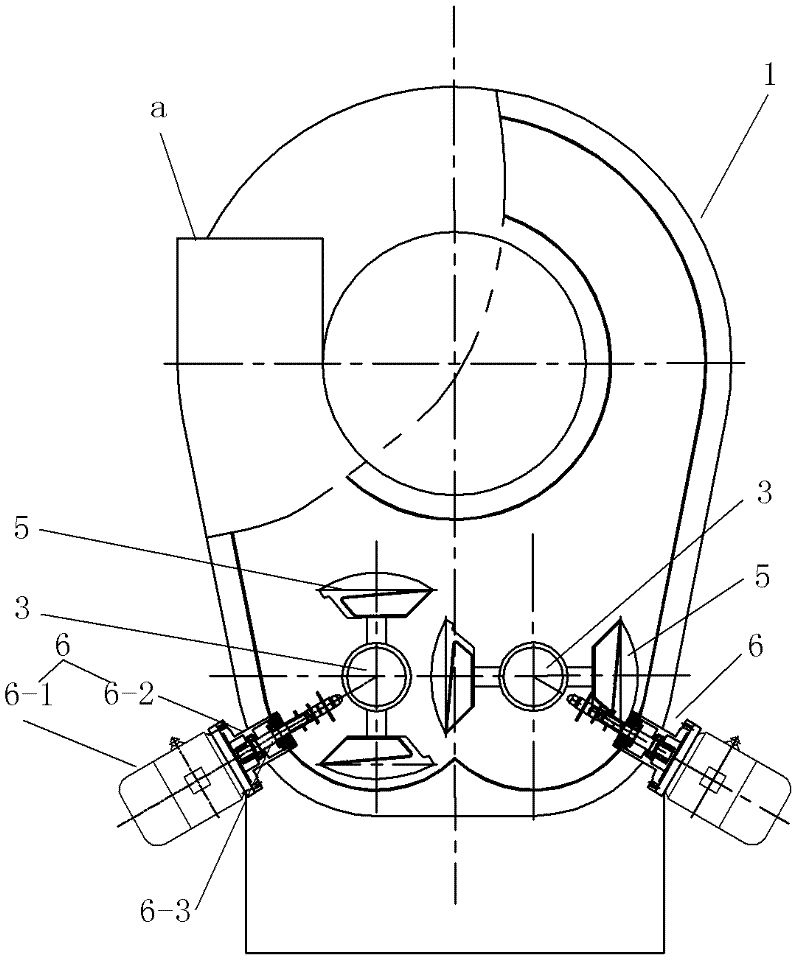

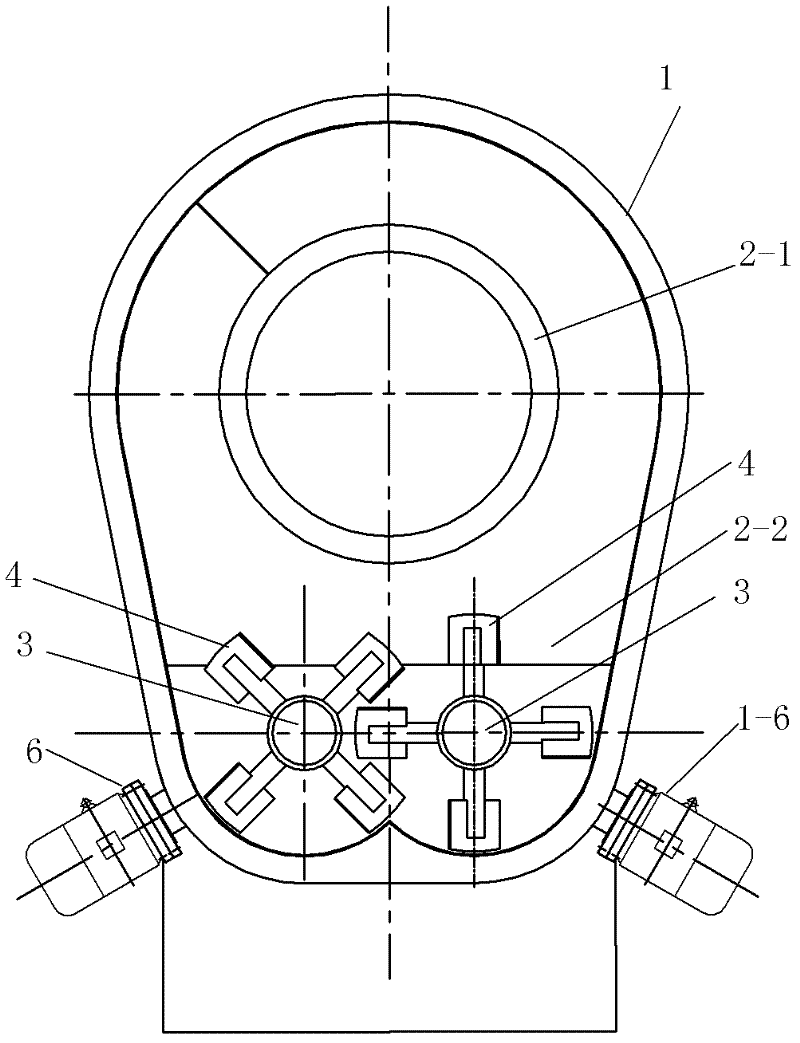

[0015] See Figure 1 to Figure 6 , the present embodiment has a body 1 supported by a frame 10, the upper part of the body 1 is arc-shaped, and the bottom is W-shaped. The upper part of the body cavity is provided with an air flow guide 2, and the space behind the body cavity and the air flow guide 2 is a swirl chamber f. The airflow guide 2 includes a core tube 2-1 and a spiral band 2-2 fixed on the core tube 2-1, and the spiral groove becomes a helical airflow channel e, and the rear end of the helical airflow channel e communicates with the settling chamber f, The airflow guide 2 is fixed by fixing the upper half edge of the spiral belt 2-2 on the inner wall of the body cavity.

[0016] The lower part of the body cavity is provided with a pair of stirring shafts 3, and the two stirring shafts 3 are respectively set corresponding to the two grooves at the bottom of the W shape. 9. The stirring shaft 3 is supported by a pair of bearing housings 11 fixed on the frame 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com