Composite deduster

A technology of dust collector and shell, which is applied in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high cost and large pressure drop, and achieve the effect of prolonging service life, reducing dust removal pressure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

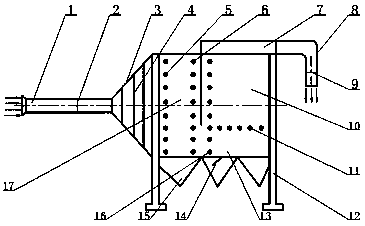

[0013] Examples, see attached figure 1 , a compound dust collector, including inlet pipe 1, left pressure test hole 2, smoke removal box 3, guide installation plate 4, first test surface 5, second test surface 6, clean room 7, outlet pipe 8, right Pressure test hole 9, dust removal area 10, fourth test surface 11, support legs 12, housing 13, baffle plate 14, tapered bucket 15, third test surface 16 and electrostatic dust removal area 17, characterized in that the inlet There is a left pressure test hole 2 on the pipe 1, the inlet pipe 1 is connected with the smoke removal box 3, and the smoke removal box 3 is installed on the left end surface of the shell 13, and a flow guide is installed in the smoke removal box 3 Mounting plate 4, the housing 13 is installed on the support leg 12, the first test surface 5 is arranged near the left end in the housing 13, the second test surface 6 is installed in the housing 13 and is located in the first test On the right side of the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com