Automatic-dust-removal refuse pyrolysis and cracking system

A self-cleaning dust and garbage technology, applied in the direction of indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems that it is difficult to make a major breakthrough in the comprehensive utilization technology of waste pyrolysis waste, the comprehensive utilization is difficult, and the tar composition is complex. Achieve the effect of saving construction cost and floor area, simple structure and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

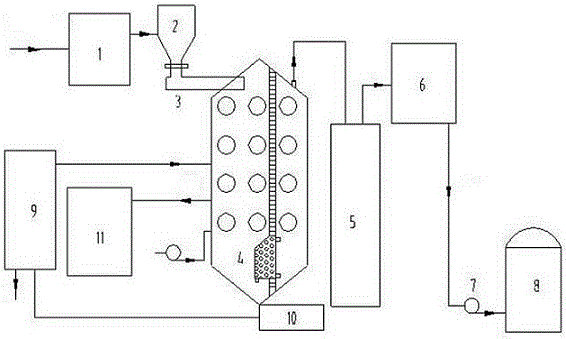

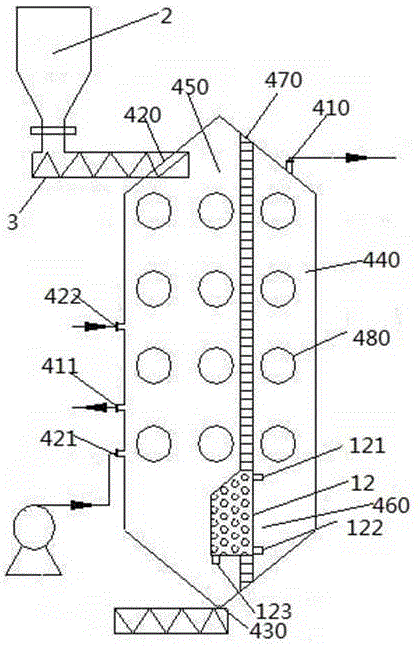

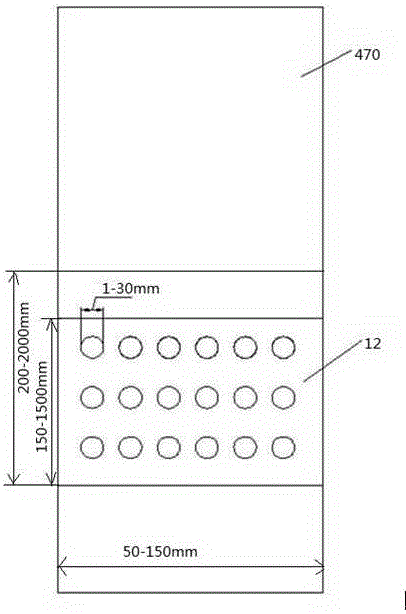

[0079] (1) After removing substances that are not easy to pyrolyze or cannot be pyrolyzed, the garbage that is crushed to a particle size of ≤10mm enters the compression dehydrator 1, and the compressed and dehydrated garbage is sent to the hopper 2 and enters the regenerative downlink through the feeder 3 The bed reactor 4 is divided into a pyrolysis chamber and a cracking chamber by a heat-insulated brick wall.

[0080](2) One-way regenerative radiant tubes are evenly arranged in the pyrolysis chamber, and the temperature of the tube wall is controlled within the range of 500-700°C by a gas regulating valve. The garbage stays in the reactor from top to bottom for 1-30 minutes and is heated. At 500-600°C, the pyrolysis process is completed.

[0081] (3) The oil and gas produced by pyrolysis enters the particle bed dedusting device through the opening of the heat insulating brick wall at the lower part of the reactor. After being dedusted by the particle bed dedusting device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com