Metal dedusting device

A technology for metal dust removal and waste, which is used in combination devices, transportation and packaging, dispersed particle filtration, etc., can solve the problems of affecting dust removal efficiency and dust removal effect, health hazards of operators, and large dust from bulk materials. Dust removal effect, low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

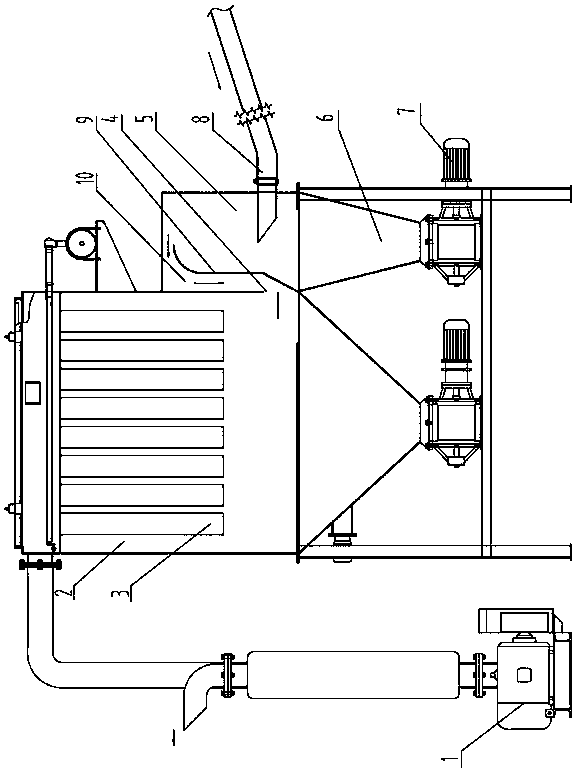

[0016] see figure 1 , the metal dedusting device of the present invention has a negative pressure dust removal integrated system and a waste material conveying system. The negative pressure dust removal integrated system mainly includes a vacuum pump 1, an integrated separation tower 2, and a filter bag 3 is installed in the upper part of the integrated separation tower 2, and the integrated separation A waste material inlet 4 is arranged on the tower body located at the lower part of the filter bag on the tower 2, and a front small separation tower is installed at the waste material inlet 4. The separation tower includes an upper separation chamber 5 and a lower collection bucket 6, and the bottom of the collection bucket is installed There is a material gas separator 7; the upper separation chamber is connected to the conveying pipe 8 in the waste material conveying system; a vertical arc-shaped baffle 9 is installed at the waste material inlet in the upper separation chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com