Self-dust-removal type pyrolyzing and cracking system for waste tires

A waste tire, self-dusting technology, applied in the direction of indirect heating dry distillation, special form dry distillation, educts, etc., can solve the problems of high viscosity, high oxygen content, difficult industrial application, etc., to save construction cost and floor space, Uniform temperature distribution to avoid hard-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

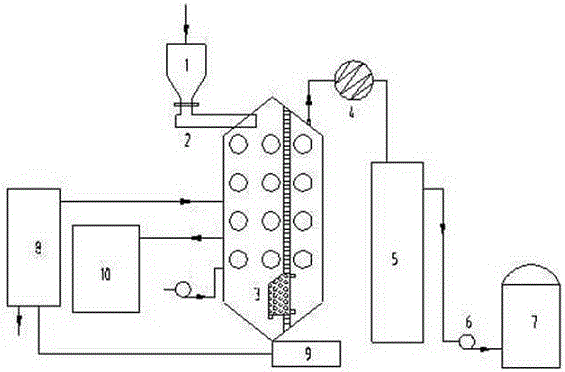

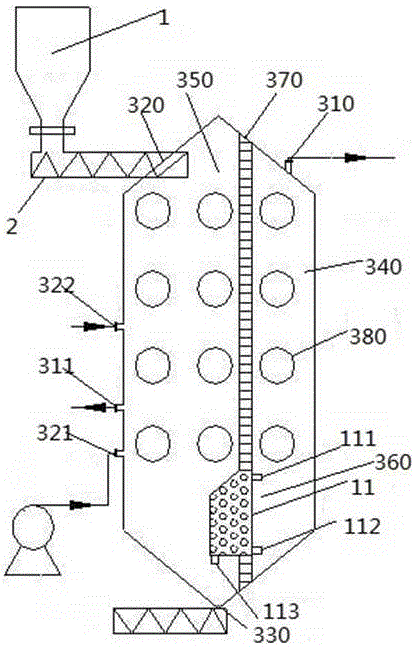

[0066] (1) Waste tires crushed to a particle size of ≤20mm enter the regenerative moving bed reactor 3 through the feeder 2 in the hopper 1, and the moving bed reactor 3 is divided into a pyrolysis chamber and a cracking chamber by a heat-insulating brick wall.

[0067] (2) One-way regenerative radiant tubes are evenly arranged in the pyrolysis chamber. The temperature of the tube wall is controlled in the range of 500-700°C by a gas regulating valve. The waste tires stay in the reactor from top to bottom for 1-50 minutes, and Heat to 500-600°C to complete the pyrolysis process.

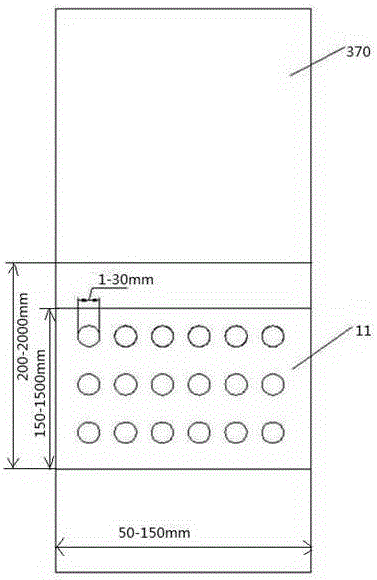

[0068] (3) The oil and gas produced by pyrolysis enters the particle bed dedusting device through the opening of the heat insulation brick wall at the lower part of the reactor. After being dedusted by the particle bed dedusting device, the clean oil and gas enter the cracking chamber of the reactor, Unidirectional regenerative radiant tubes are evenly arranged in the center, and the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com