Self-dust-removal type pyrolyzing and cracking system for oil shale

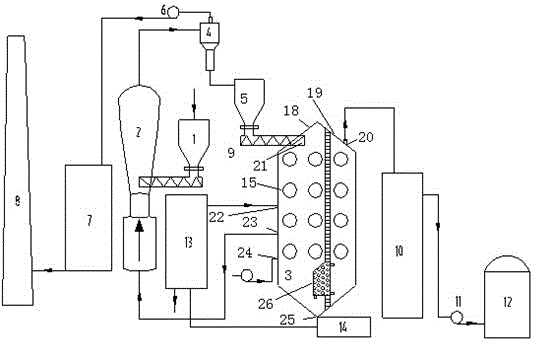

A cracking system and oil shale technology, which is applied in the field of self-dusting granular oil shale pyrolysis and cracking system, can solve the problems that pyrolysis oil is difficult to be effectively used, and the value of pyrolysis oil is not high, so as to avoid pyrolysis oil containing dust, saving construction cost and floor space, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

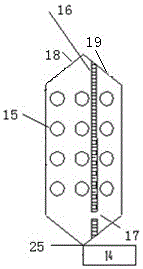

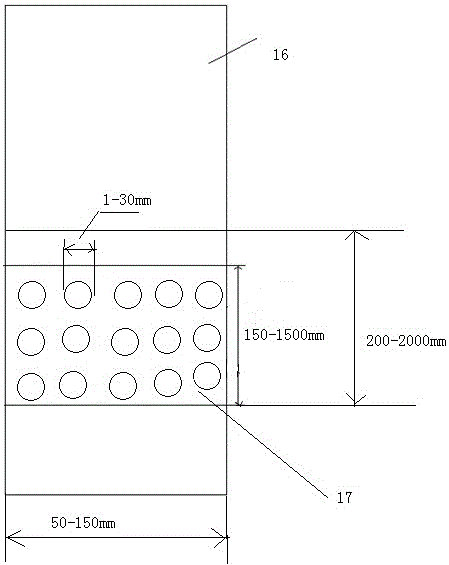

Method used

Image

Examples

specific Embodiment

[0065] Longkou oil shale was processed by self-cleaning oil shale pyrolysis and cracking system. The basic data of raw materials are shown in Table 1.

[0066] Table 1: Basic data of Longkou oil shale

[0067]

[0068] Using this reactor to treat Longkou oil shale, the yield of gas products obtained is 15%, which is much higher than that obtained by pyrolysis of aluminum retort in the laboratory. The pyrolysis tar is almost completely cracked into gaseous products, and the gas yield is high. . The heat value of pyrolysis gas is as high as 5000kcal / m 3 , high quality, the dust content in the pyrolysis gas produced by the system is less than 1%, and the gas is relatively clean.

[0069] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com