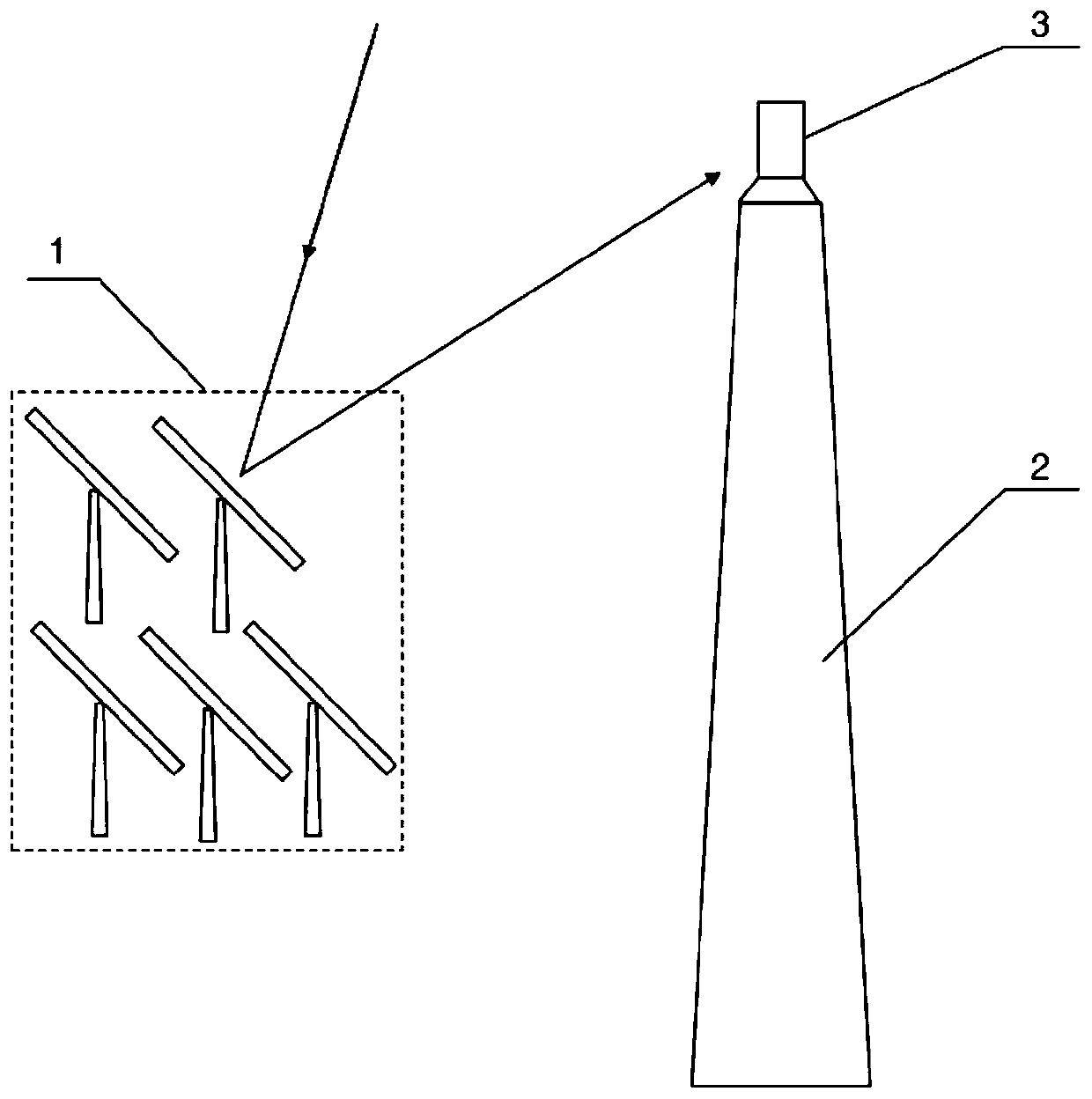

A system and method for catalyzing graphitization of coal using solar energy concentration

A technology of solar concentration and graphitization, which is applied in solar heating systems, solar thermal energy, solar thermal power generation, etc., can solve the problems of high cost, achieve the effects of reducing production costs, realizing clean and efficient utilization, and simple raw material processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

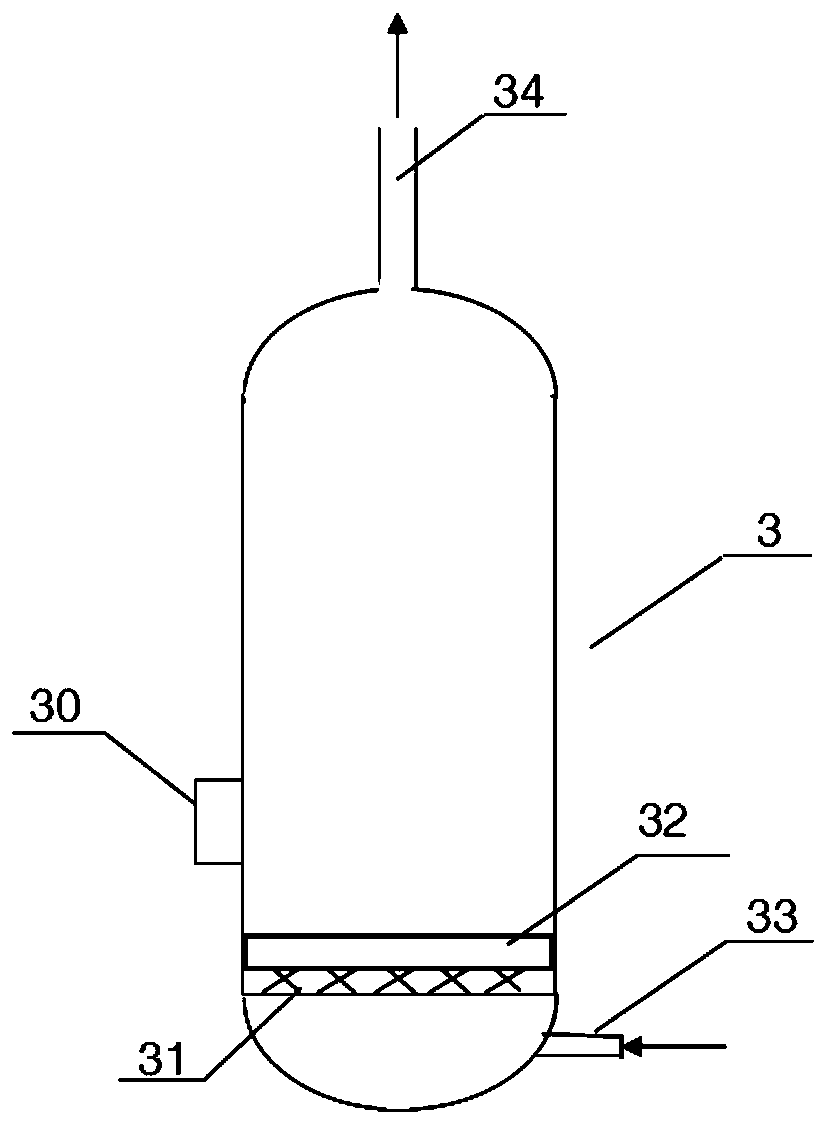

[0045] A method for utilizing solar energy concentration to catalyze the graphitization of coal, comprising the steps of:

[0046] S1. Take a certain amount of anthracite (Shanxi Jincheng coal) and grind it by a coal mill, use a 20-mesh and 40-mesh sieve to sieve a coal sample with a particle size of 20-40 mesh, and take it out after drying in an oven at 105°C for 12 hours; take a certain amount 20-40 mesh dried coal sample 2g, add 10% Fe by mass 3 o 4 Mix well and place in graphitization reactor, pass N 2 , the flow rate is set to 0.5L / min;

[0047] S2. Adjust the concentration so that the reaction temperature rises to 900°C, control the reaction temperature at 900-1200°C, react for 3 hours, take it out after cooling down.

[0048] Taking the product taken out after cooling down as a sample, it is detected and analyzed by XRD (X-ray diffraction), and its degree of graphitization is calculated. The degree of graphitization of the treated graphite-type carbon in this implem...

Embodiment 2

[0050] A method for utilizing solar energy concentration to catalyze the graphitization of coal, comprising the steps of:

[0051] S1. Take a certain amount of anthracite (Shanxi Jincheng coal) and grind it by a coal mill, use a 20-mesh and 40-mesh sieve to sieve a coal sample with a particle size of 20-40 mesh, and take it out after drying in an oven at 105°C for 12 hours; take a certain amount 20-40 mesh dried coal sample 2g, add 10% Fe by mass 2 o 3 Mix well and place in graphitization reactor, pass N 2 , the flow rate is set to 0.5L / min.

[0052] S2. Adjust the light concentration so that the reaction temperature rises to 1200°C, control the reaction temperature at 1200-1500°C, react for 2 hours, and take it out after cooling down.

[0053] Taking the product taken out after cooling down as a sample, it is detected and analyzed by XRD (X-ray diffraction), and its degree of graphitization is calculated. The degree of graphitization of the treated graphite-type carbon in...

Embodiment 3

[0055] A method for utilizing solar energy concentration to catalyze the graphitization of coal, comprising the steps of:

[0056] S1. Take a certain amount of anthracite (Shanxi Jincheng coal) and grind it by a coal mill, use a 20-mesh and 40-mesh sieve to sieve a coal sample with a particle size of 20-40 mesh, and take it out after drying in an oven at 105°C for 12 hours; take a certain amount 20-40 mesh dried coal sample 2g, add 10% iron powder by mass and mix well, then put it in the reactor, pass N 2 , the flow rate is set to 0.5L / min;

[0057] S2. Adjust the degree of concentration so that the reaction temperature rises to 1500°C, control the reaction temperature at 1500-1600°C, react for 1 hour, and take out the product after cooling down; if purification is required, further purification by acid washing can be considered.

[0058] Taking the product taken out after cooling down as a sample, it is detected and analyzed by XRD (X-ray diffraction), and its degree of grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com