Flue gas purification system for roasting furnace of prebaked anode used for aluminum electrolysis

A technology of pre-baked anode and flue gas treatment system is applied in the field of pre-baked anode roaster flue gas treatment system for aluminum electrolysis, and the field of flue gas treatment system can solve the problem that dust, tar cannot be effectively removed, and desulfurization, denitrification, desulfurization and problems such as low denitration efficiency, to achieve the effect of reasonable design, compact system design and easy maintenance

Active Publication Date: 2018-12-18

SUNSTONE DEV

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the problems existing in the existing prebaked anode roasting flue gas treatment process that dust and tar cannot be effectively removed, simultaneous desulfurization and denitrification are impossible, desulfurization and denitrification efficiency is low, and secondary pollution is caused to the environment, the invention provides an aluminum electrolysis Prebaked anode roaster flue gas purification syste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

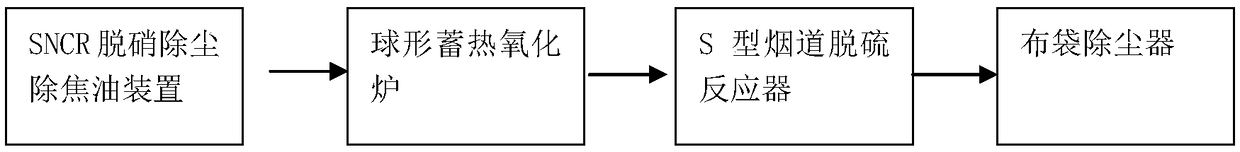

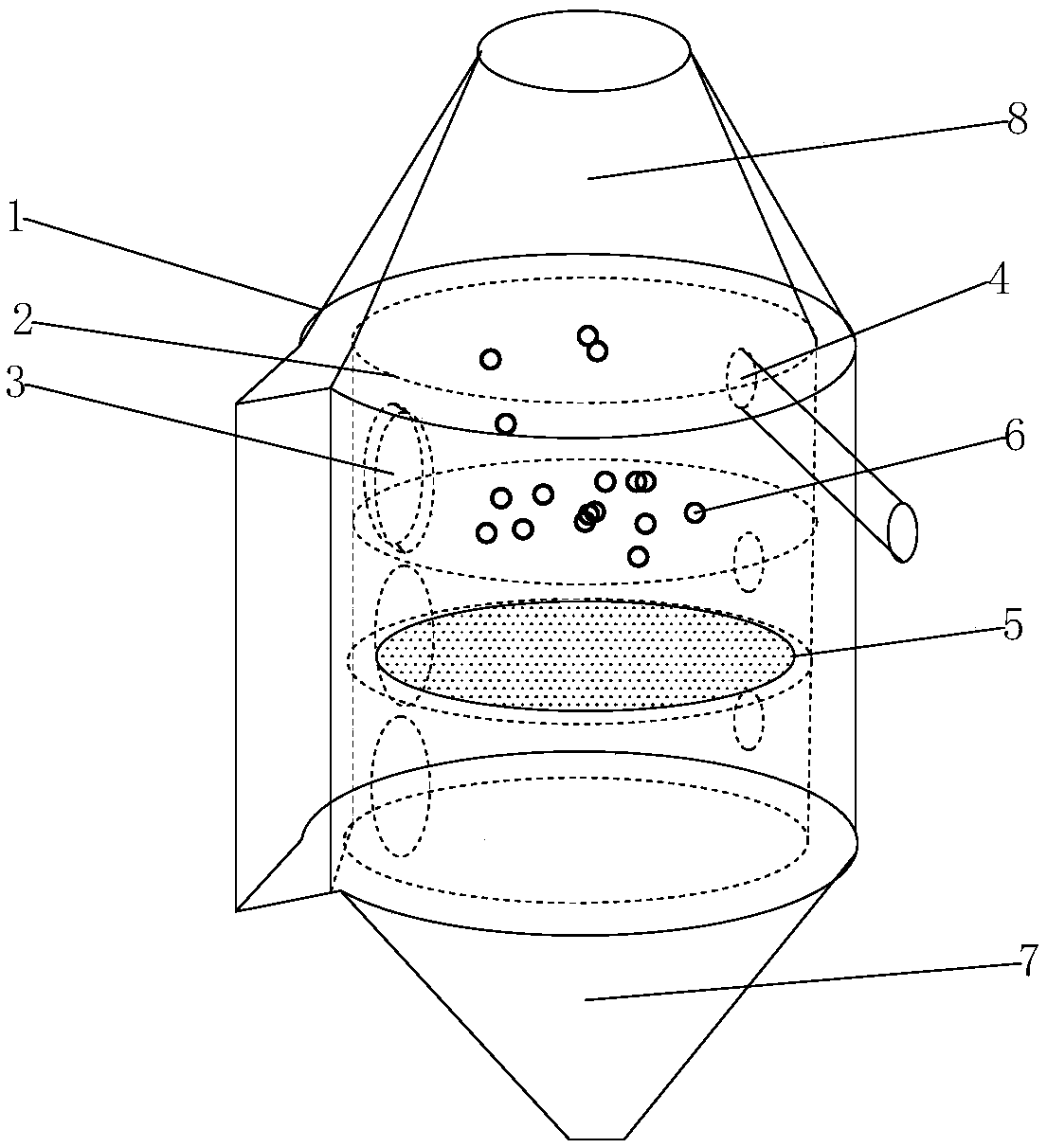

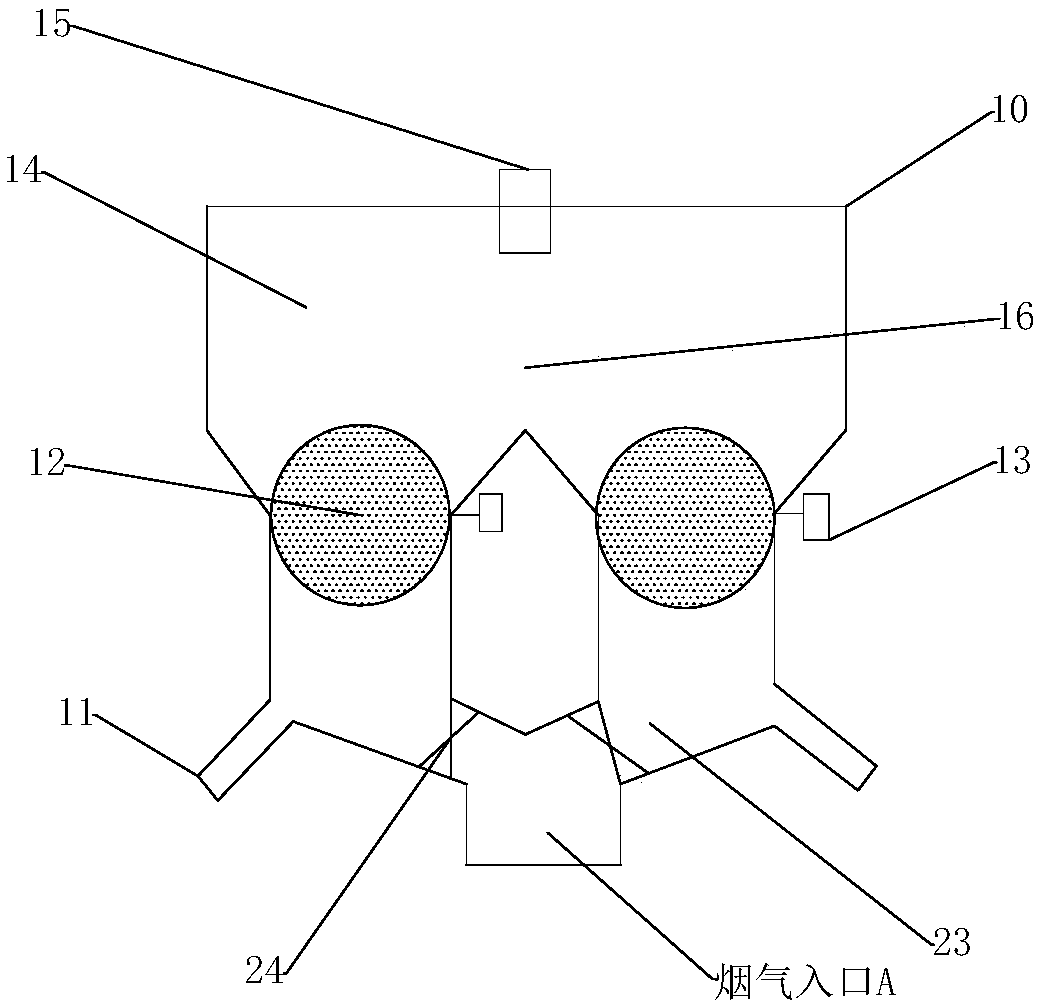

The invention relates to a flue gas purification system for a roasting furnace of a prebaked anode used for aluminum electrolysis. The system mainly includes, in a successively connected manner in series, an SNCR denitration and dust and tar removal apparatus, a sphere heat accumulation oxidizing furnace, an S-shaped flue desulfuration reactor, and a bag-type dust remover. Flue gas is driven by adraught fan and is fed into the SNCR denitration and dust and tar removal apparatus, then successively passes through the sphere heat accumulation oxidizing furnace, the S-shaped flue desulfuration reactor and the bag-type dust remover, and finally is exhausted via a chimney when the flue gas reaches treatment standard.

Description

technical field [0001] The invention relates to a flue gas treatment system, in particular to a flue gas treatment system of a prebaked anode roaster for aluminum electrolysis, which belongs to the field of flue gas purification. Background technique [0002] my country is the world's largest producer of electrolytic aluminum. Since 2001, its aluminum production capacity has been ranked first in the world. In 2017, my country's prebaked anode production capacity reached 24.48 million tons, and the output reached 19.7 million tons. Prebaked anodes are the main consumption products of electrolytic aluminum production, and about 450kg of anodes are needed per ton of aluminum consumption. Anode roasting is an important process in the production process of carbon products. Under the condition of being isolated from the air, according to the requirements of different types of products, indirect heating is carried out at a certain heating rate to the highest roasting temperature. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/76B01D53/56B01D53/50F23G7/06B01D53/83

CPCB01D53/508B01D53/56B01D53/75B01D53/76F23G7/061F23G2206/20F23G2209/14

Inventor 郎光辉刘瑞吴昆付迎春任涛李军高守磊许秀芹

Owner SUNSTONE DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com